Category and field of Solution

TDC’s technology is used in various industries, requiring ultra-precise quality.

Our technology is used in many fields for more than 3000 customers such as research institution, universities and Enterprises.

As an example of fields, there are Nanotechnology, MEMS, Micro machine, semiconductor processing equipment, medical equipment, Optical devices, pharmaceutical industry, Printing industry, Electronics industry and others.

Nano & Micro technology, MEMS, NEMS

Precision polishing of Nano imprinting mold. Any kinds of material and any kinds of shape such as flat, curved, Roll surface and inside of tube, etc.

TDC guarantee severe specs of any geometric aspects, such as roughness, flatness, cylindricity,

Metrological Inspection Equipment

Our precise Dimensional control technology is used for Measurement equipment and machine tools. Stone/Granite surface plate does not have high wear resistance so it has to be reworked periodically.

TDC reworks on your used surface plate, or we can also produce a new surface plate.

Solutions for precision machining in measuring instruments and machine tools

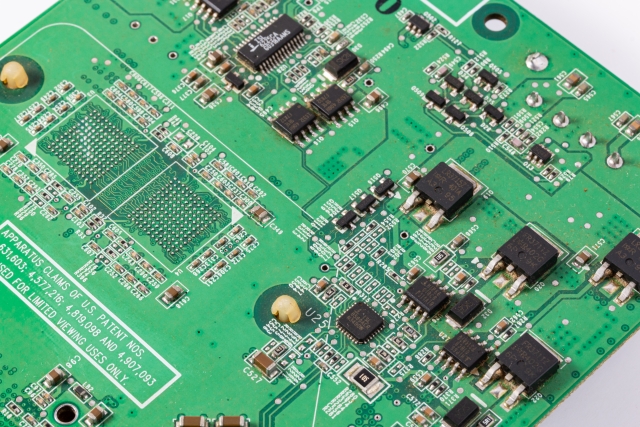

Semiconductor Manufacturing Equipment

We contributed to cost down and Improvement of the device by manufacturing in high quality. Use our precise mirror polishing technology to improve the quality for stages.

We will aim for an extreme preciseness in tolerance, roughness, flatness, parallelism, angle with any material such as metal, ceramics, resin, glass and so on.

Solutions for precision machining in semiconductor manufacturing equipments

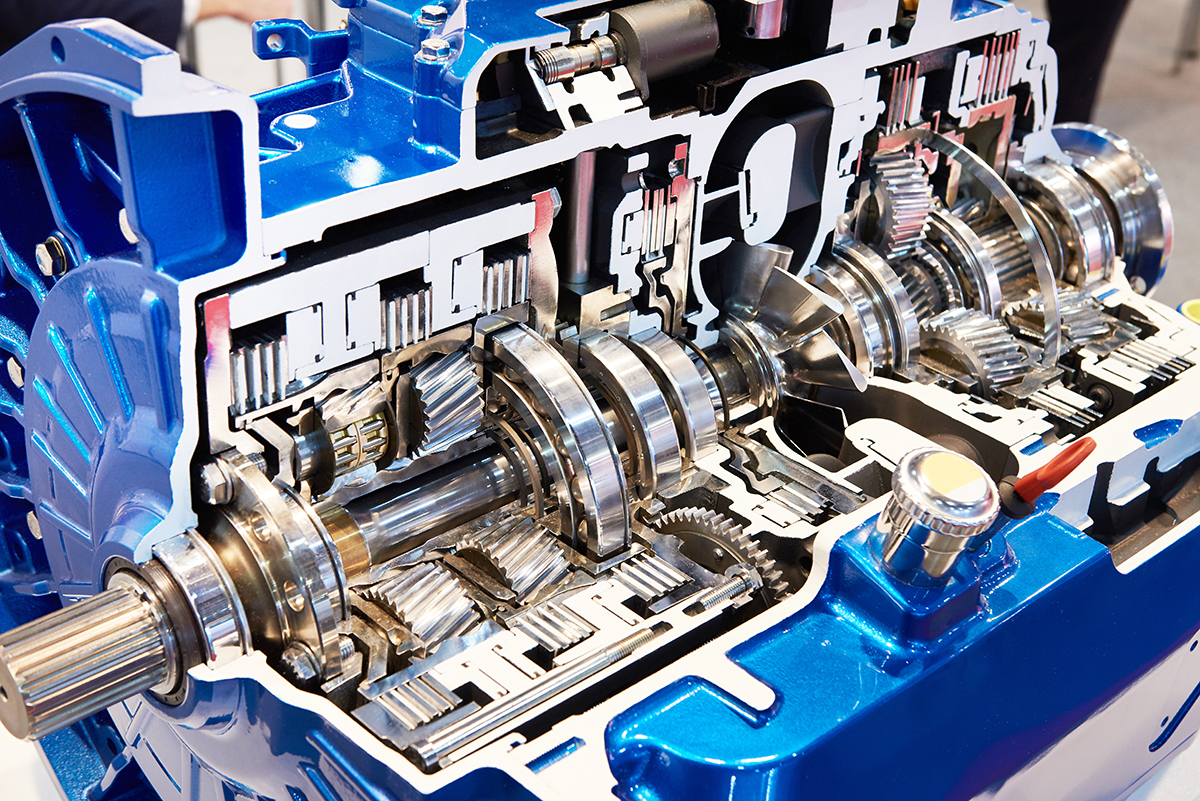

Automotive industry

Corresponds to the needs of automotive industry by manufacturing test pieces for R&D, Production of tool and jig.

Electronics /Engineering

Useful for electronics fields by polishing crystal materials and wafers. TDC’s lapping technology not only finishes the surface in high quality roughness, but also can achieve precise flatness and parallelism.

TDC is also offer the precision polishing for injection molds for electronics parts.

Aerospace industry

Aerospace field. We are capable of manufacturing metal/crystal Reflecting mirrors, and improve the surface condition.

Related page