In-house developed technology

We make full use of our unique technology, such as the sophistication of conventional technology and the development of new equipment, in response to customers’ requests and concerns such as “I want you to do this more” and “Is it possible to do this?” We have responded. Here, we would like to introduce the in-house developed technology that was created in this way.

Spacer/Shim(Feeler Gauge)

TDC’s super precision shims, spacers, washers without dispersion in thickness lead to high assembly precision and realize the reproducibility and reliability of assembly.They reduce looseness even after long-term use.

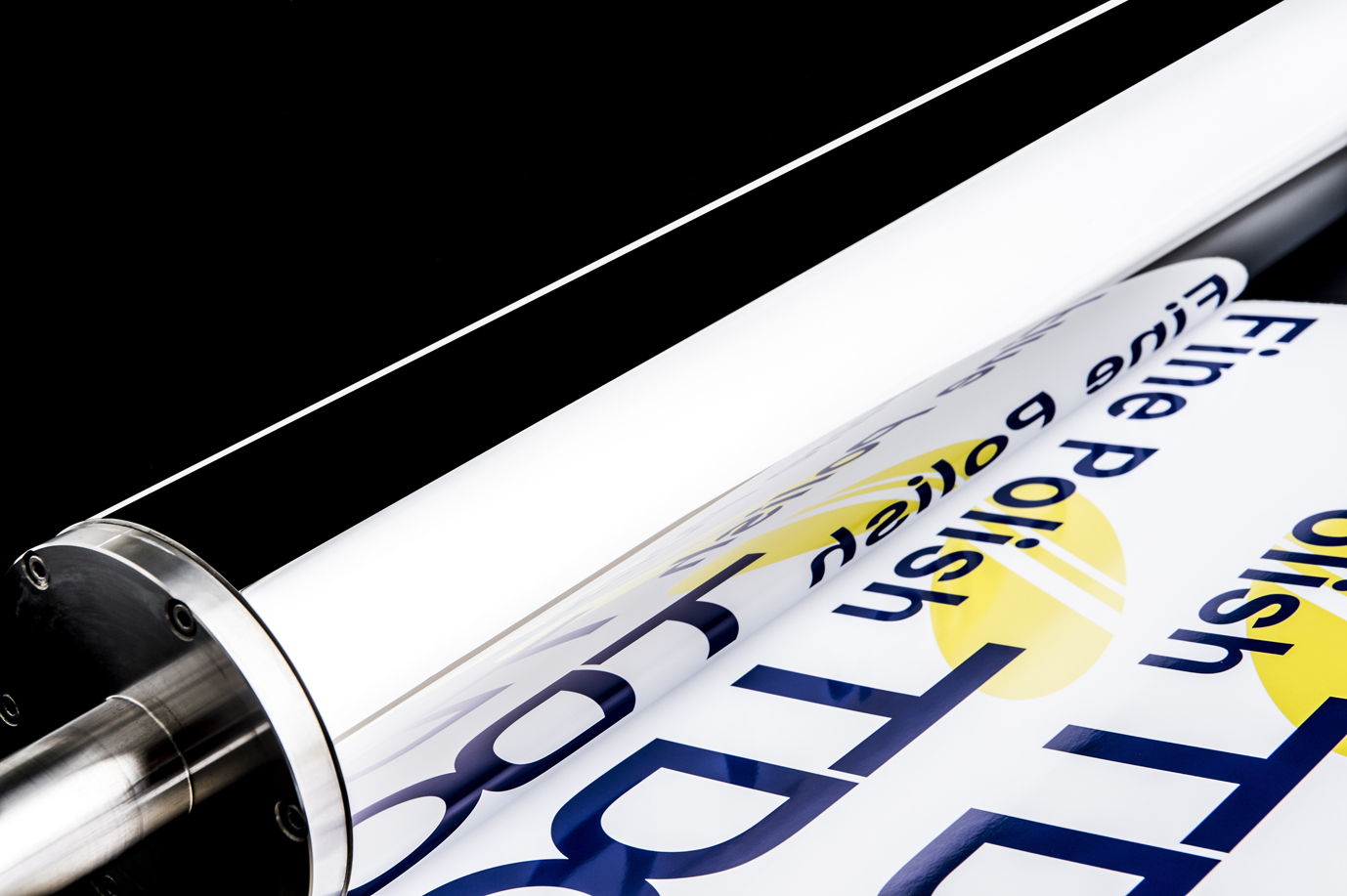

Super Mirror-Polished Roll/ Shaft

TDC technology achieves nano-level surface roughness while maintaining dimensional and shape accuracy. Achieves high precision of molds for manufacturing high-performance films. In addition to stainless steel, nickel, glass, etc., titanium and pure aluminum can also be processed.

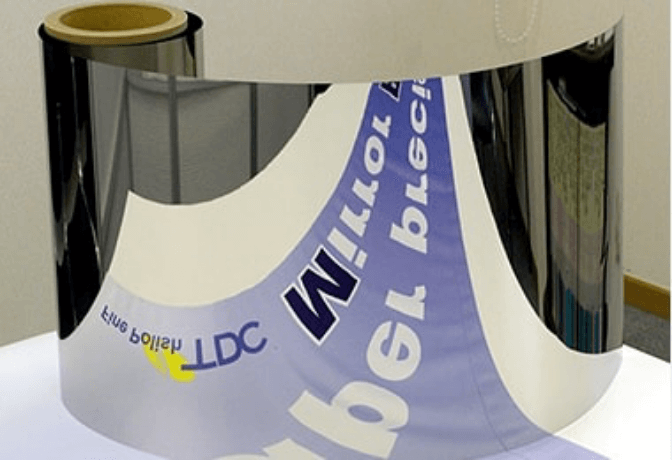

Super Precision Long Foil Polishing

We have developed in-house a dedicated device that can realize nano-order surface roughness, which was previously only possible with a small size, even with a length exceeding 100 meters. It is possible to manufacture metal foil with a surface roughness of single nanometer as long as 100 meters. (The width is 300 mm or less and the thickness is about 20 to 200 μm.)

We are here to help you!

“TDC is able to respond to short delivery times according to the desired delivery date, and has accumulated unique technological development and know-how in processing, making it possible to respond to any shape.

If you have any technical issues, please take advantage of these technologies developed by TDC.

Please feel free to contact us if you have questions or inquiry”

Related page