Symbol used for polishing

This page explains the symbols used for polishing.

Please also refer to the “What is Polishing” page for the polishing process performed by TDC.

Contents

What is surface roughness?

The surface of the work piece has complex undulations with continuous peaks and valleys of different heights, depths, and intervals.

Those with large undulations are called “waviness”, and those with small undulations are called “surface roughness / surface roughness”.

Surface roughness and surface roughness affect not only the precision of processed products, but also the gloss and texture of the surface, so they are one of the factors that influence the product image and product brand.

>>Click here for a list of TDC surface roughness and surface roughness results.

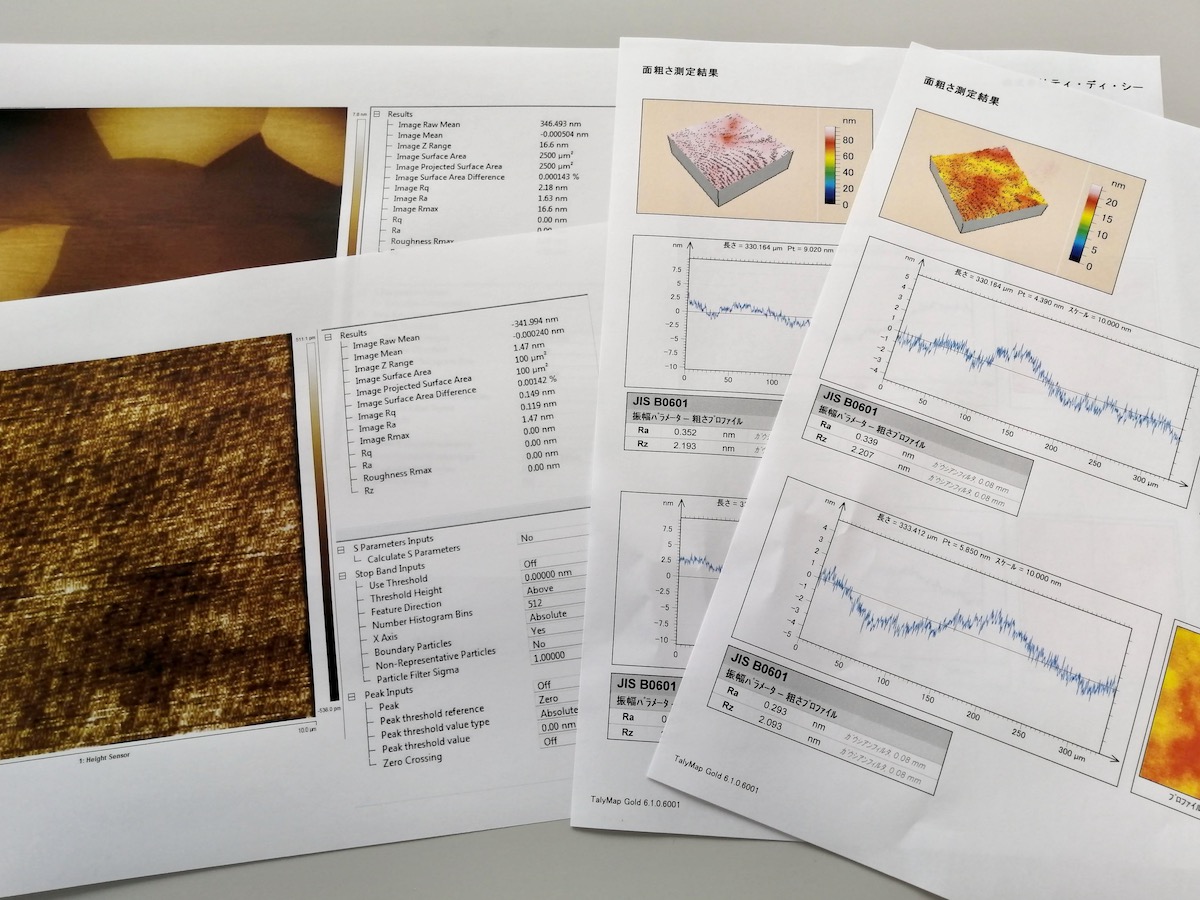

Measurement of surface roughness

Measurement of surface roughness and surface roughness is important not only for controlling the finished state and appearance quality of processing, but also for controlling product life and mechanical efficiency.

Especially in the field of ultra-precision machining, not only machining accuracy but also high surface treatment ability is required, so this surface roughness and surface roughness are important.

Surface roughness measurement method

When cut in a plane perpendicular to the surface to be measured, a curve that outlines the surface appears at the cut end. This is called a “cross-section curve”.

In general measurement, the surface is traced with a stylus, etc., and the record of the vertical movement of the stylus is taken as a “cross-sectional curve”, and a certain length (reference length) is extracted from this curve to obtain the surface roughness.

“Contact type” and “Non-contact type”

There are roughly two methods for measuring surface roughness: “contact type” and “non-contact type”.

In the “contact type”, a pointed diamond needle called a stylus directly traces the sample to measure the unevenness of the surface. This method is widely used for measuring surface roughness.

On the other hand, the “non-contact type” is a method of measuring surface roughness using light. There are laser microscopes that use the confocal method and white interferometers that use the white interferometry, which have the advantage of being able to measure surface roughness without damaging the sample.

TDC owns both “contact type” and “non-contact type” measuring machines, but we use non-contact type surface roughness measuring machines for mirror-finished products.

>>Click here for details on the measuring equipment handled by TDC

Triangular symbol (JIS-1982)

In JIS up to 1994, the surface roughness was indicated by the following triangular symbols.

| Triangular symbol | Finished surface |

| ▽ | Rough finish |

| ▽▽ | Normal finish |

| ▽▽▽ | Mirror finish |

| ▽▽▽▽ | Polish finish |

| ~ | Not specified |

Currently, due to advances in measuring equipment and mechanical technology, it is recommended to quantitatively indicate the roughness using numerical values instead of conceptual displays such as triangular symbols.

Surface Roughness Symbol-New JIS (JIS-2001) and Old JIS (JIS-1994)

After two revisions from the triangle symbol, the surface roughness is now revised so that it can be specified numerically from the triangle symbol.

“Triangle symbols” and “old JIS symbols” are sometimes used in the current drawings, so let’s understand the difference.

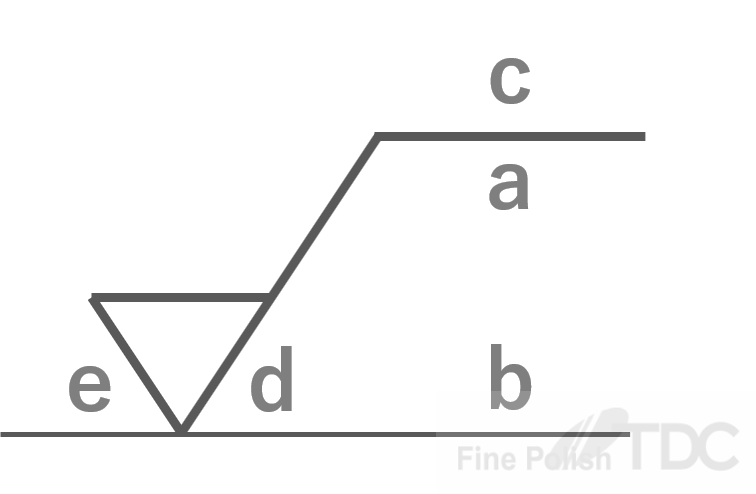

Symbols and instruction methods for indicating the target surface (JIS-2001)

a: Passband or reference length, surface texture parameter symbol and its value

b: Second and subsequent parameter instructions when multiple parameters are requested

c: Processing method

d: Streaks and their directions

e: In ISO1302, enter the shaving allowance

Example of surface roughness symbol

- Parameter tolerance: Upper limit U or lower limit L

- 2. Filter shape X: Phase compensation, or 2RC

- Passband: λs-λc (mm)

- Parameters: Curve

- Parameters: Type

- Evaluation length ℓn Medium standard length n: Standard 5

- Pass / Fail Judgment: 16% or max

- Tolerance limit value (μm)

Symbol used for “processing method”

| Processing method | Symbol |

| Turning outside | L |

| Surface cutting | LFC |

| Boring machine | B |

| Flat cutting | P |

| Milling | M |

| Flat milling | MP |

| Reamer finish | DR |

| Drilling (drilling) | D |

| Shape cutting | SH |

| Broach shaving | BR |

| Reamer finish | FR |

| Grinding | G |

| Belt sanding | GB |

| Honing board | GH |

| Liquid honing finish | SPL |

| Barrel polishing | SPBR |

| Buff finish | FB |

| Blast finish | SB |

| Lapping finish | FL |

| File finish | FF |

| Scraping | FS |

| paper finish | FCA |

| casting | C |

Symbols used for “streaks and their directions”

| Symbol | Meaning |

| = | The direction of the streaks of the blade by processing is parallel to the projection plane in the figure with the symbol. Example) Shaped surface, turning surface, ground surface |

| ┴ | The direction of the streaks of the blade by processing is perpendicular to the projection surface of the figure with the symbol written on it. Example) Shaped surface, turning surface, ground surface |

| × | The direction of the streaks of the blade by processing intersects the projection surface of the figure with the symbol diagonally in two directions. Example) Honing finished surface |

| M | The streaks of the blade due to processing intersect in multiple directions or are non-directional Example) Wrap finished surface, super finished surface, front milling surface with lateral feed or end mill machined surface |

| C | The streaks of the processed blade are almost concentric with respect to the center of the surface on which the symbol is written. Example) Surface cut surface |

| R | The streaks of the processed blade are almost radial to the center of the surface on which the symbol is written. |

| P | Particle-like depressions, non-directional or particulate protrusions Example) EDM surface, super-raised surface, plasticing surface |

Contact TDC for consultation on surface roughness and surface roughness

TDC Co., Ltd. has accumulated unique technological development and know-how in various processing, and can handle and consult with processing of all surface roughness.

We can handle all precision machining required by our customers, so please feel free to contact us.

The following page introduces an example of the actual surface roughness and surface roughness of TDC.

>>Click here for a list of TDC surface roughness and surface roughness results.

- Precision lapping service / ultra precision lapping service

- Polishing service

- What is Grinding

- What is cutting

- What is a chuck table? | Basic information and description of types, Processing accuracy at TDC

- Copper polishing

- Polishing after thermal spraying

- Sapphire polishing

- Polishing of plastic/acrylic resin

- Polishing after surface treatment/coating

- Symbol used for polishing

- Polishing of SiC

- Polishing of titanium

- Cylindrical grinding/cylindrical polishing

- Type of polishing process

- What is the accuracy that can be achieved by polishing?

- Principle of polishing process

- Polishing process for Resin

- Metal polishing process

- ステンレスの研磨加工

- What is CMP

- What is polishing?

- About Lapping and Polishing