Niobium

On this page, we will explain the characteristics and properties of Tantalum, which is one of the processing materials, its applications, and the processing of niobium in TDC.

Contents

What is Niobium?

Niobium is a rare metal classified as a transition metal that is damp and crystalline, and is full of superconducting elements.

Niobium is a rare metal classified as a transition metal that is soft, gray and crystalline, and is one of the superconducting elements.

Due to its very similar physical and chemical properties to tantalum, it was named after the daughter of Tantalus in Greek mythology, “Niobe”, which is the origin of the word tantalum.

Production of niobium in nature

Elementary substance niobium has not been found in nature and is contained in minerals (niobium ore) combined with other elements.

Niobium ore is mainly the following rocks

- Columbite – Granite A special rock called pegmatite

- Columbite – Granite A special rock called pegmatite Pyrochlore ore Carbonatite, a special rock formed by the cooling and solidification of carbonated magma

Most of the reserves and production are dependent on Brazil, and because they have more reserves and are cheaper than tantalum, they are often used as a substitute for tantalum.

Niobium’s Features, Characteristics, and Properties

Niobium is a glossy gray metal that is soft and has excellent malleability and ductility, so it is easy to process.

In addition, niobium becomes superconducting at extremely low temperatures, and at atmospheric pressure it becomes superconducting at 9.2 kelvin, which is the highest critical temperature for elemental superconductors.

一The general and physical characteristics are as follows.

| General characteristics | |

| name |

niobium |

|

Chemical formula |

Nb/41 |

|

Classification |

Transition metal |

|

Tribe / Cycle / Block |

5/5/d |

|

Atomic weight |

92.90638 |

|

Electronic configuration |

[Kr] 4d4 5s1 |

|

electronic shell |

2、8、18、12、1 |

|

Physical characteristics |

|

|

Density (near room temperature) |

8.57 g/cm3 |

|

Liquid density at melting point |

7.83(fusion、liquid) g/cm3 |

|

melting point |

2741 K, 2468 °C |

|

boiling point |

5015 K, 4742 °C |

|

Heat of fusion |

30 kJ/mol |

|

Heat of vaporization |

689.9 kJ/mol |

|

Heat capacity |

(25 °C) 24.60 J/(mol·K) |

Niobium applications

金Adding niobium to metal materials increases toughness and heat resistance. Therefore, niobium is mainly used as an alloy that requires strength, and includes applications such as high-strength steel, tool steel, stainless steel, and heat-resistant alloys for electronic parts and chemical equipment.

It is also used as an additive element for capacitors, magnets, and metals, and niobium alloys are planned to be used for superconducting magnets in linear motor cars.

It is also used as a high-refractive index material that replaces titanium oxide, especially in scenes where a multilayer film is required and as a material for optical thin films.

Niobium processing in TDC

| Roughness | <Ra0.001 |

| Flatness | <0.001mm |

| Parallelism | <0.001mm |

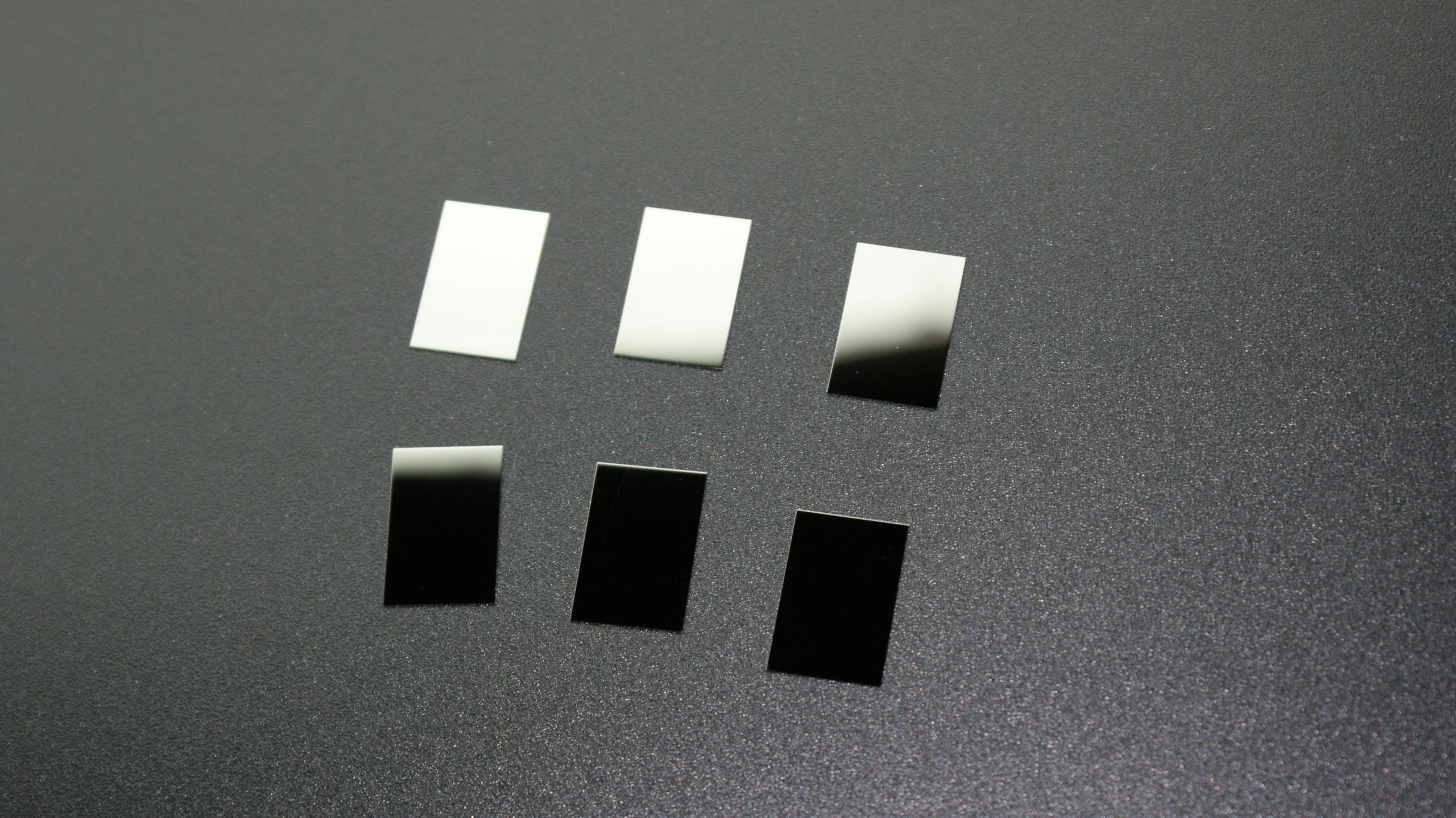

Niobium processing examples

TDC accepts the production of niobium mirror test. Surface roughness can be guaranteed at Ra 1 nm or less. Quantity from 1 piece.

Of course, we can also manufacture parts in various shapes other than test pieces.

Please contact TDC for Niobium processing

At TDC, we are able to handle mirror polishing of all materials and accuracy by using the processing know-how according to the material and the polishing processing technology accumulated so far.

If you have a Nolibium processing project that was rejected by another company, please feel free to contact TDC.

- インコネルとは?| 基礎情報・特徴の解説と加工事例

- 難削材とは? | 基礎知識と種類についての解説

- What is gallium nitride (GaN)? | Basic information/explanation of features and processing examples

- What is Vespel? | Vespel features and processing examples

- What is Tungsten? | Tungsten characteristics and processing examples

- Nickel

- Tantalum

- Glassy carbon (glassy carbon)

- Plate thickness and material of stainless steel plate (SUS)

- Coefficient of linear expansion

- Invar/Super Invar

- Niobium

- Hastelloy

- Engineering Plastic