Coefficient of linear expansion

In this page we will explain the coefficient of linear expansion.

Contents

What is linear expansion coefficient?

The coefficient of linear expansion is the rate at which an object changes or expands in length due to an increase in temperature.

Therefore, it can be said that materials with large coefficients of linear expansion tend to change in length due to temperature rise.

What is the difference from the coefficient of thermal expansion?

In some cases, the coefficient of linear expansion is called the coefficient of thermal expansion, and they are almost synonymous.

In the case of the coefficient of thermal expansion, it is sometimes expressed as the “volumetric expansion coefficient,” which is the rate at which the volume of an object expands.

Formula for coefficient of linear expansion

The coefficient of linear expansion can be obtained from the ratio of the amount of deformation ΔL due to a temperature change of 1°C and the length L before deformation.

The calculation formula is as follows.

- Coefficient of linear expansion α=(ΔL/L)×(1/ΔT)

Unit of coefficient of linear expansion

The unit of coefficient of linear expansion is expressed as one of the following.

- 1/℃

- 1/K

“℃” is the unit of Celsius temperature, and “K” is the unit of absolute temperature, read as “Kelvin”.

Even if the unit of coefficient of linear expansion is converted from “1/°C” to “1/K”, the value will be the same.

Coefficient of linear expansion of main materials

The linear expansion coefficients of commonly used materials are as follows.

Coefficient of linear expansion of metal

| Material | Coefficient of linear expansion(10-6/℃) | |

| aluminum | A2017 | 23.6 |

| A5052 | 23.8 | |

| A5056 | 24.3 | |

| A7075 | 23.6 | |

| structureal steel | SS400 | 11.7 |

| carbon steel | S45C | 12.1 |

| S50C | 11.7 | |

| S55C | 11.7 | |

| tool steel | SKS3 | 12.2 |

| SKD11 | 12.0 | |

| stainless steel | SUS303 | 17.3 |

| SUS304 | 17.3 | |

| SUS430 | 10.4 | |

| coppere | C1100 | 17.7 |

| C1020 | 17.7 | |

| brass | C2801 | 20.8 |

| C3604 | 20.5 | |

| C2700 | 20.3 | |

| titanium | 6.3~8.4 | |

| magnesium | AZ31 | 26.8 |

| AZ91 | 27.2 | |

| molybden | 5.2 | |

| tungsten | 4.4 | |

| inconel | 11.5~13.3 | |

| potassium | 85 | |

| gold | 14.2 | |

| silver | 18.9 | |

| lron | 11.8 | |

| lead | 28.9 | |

| nickel | 13.4 | |

| platinum | 8.8 | |

| magnesium | 24.8 | |

| prehardened steel | 11.5 | |

| nichrome | 18 | |

| duralumin | 23 | |

| platinum | 8.9 | |

Linear expansion coefficient of resin

| Material | Coefficient of linear expansion(10-6/℃) | |

| MC nylon | MC801 | 80 |

| 6 nylon | 6N | 72 |

| Duracon, Polyacetal | POM | 81~85 |

| polypropylene | PP | 58~100 |

| polyethylene | PE | 120~140 |

| Polycarbonate | PC | 66 |

| polyethylene terephthalateート | PET | 65 |

| acrylic | PMMA | 50~90 |

| vinyl chloride | PVC | 50~100 |

| Acrylonitrile・Butadiene・Styrene | ABS | 65~95 |

| Teflon | PTFE | 70~100 |

| polybutylene terephthalate | PBT | 25~95 |

| polyether ether ketone | PEEK | 25~50 |

| Polyphenylene sulfide | PPS | 49 |

| polyamide imide | PAI | 30.6 |

| polyvinylidene fluoride | PVDF | 160 |

| paper bake | cloth bake | |

| paper bake | 160 | |

| Epoxy Glass | 60~60.5 | |

| Polystyrene | 34-210 | |

| Polymethyl Methacrylate | 80 | |

Linear expansion coefficient of other materials

| Material | Linear expansion coefficient(10-6/℃) |

| silicon | 2.6 |

| diamond | 1.0 |

| zirconia | 5.4 |

| graphite | 3.1 |

| boron | 4.7 |

| granite | 4-10 |

| marble | 3〜15 |

| common grass | 8-10 |

| pyrex glass | 2.8 |

If you have any questions about precision machining, please contact TDC

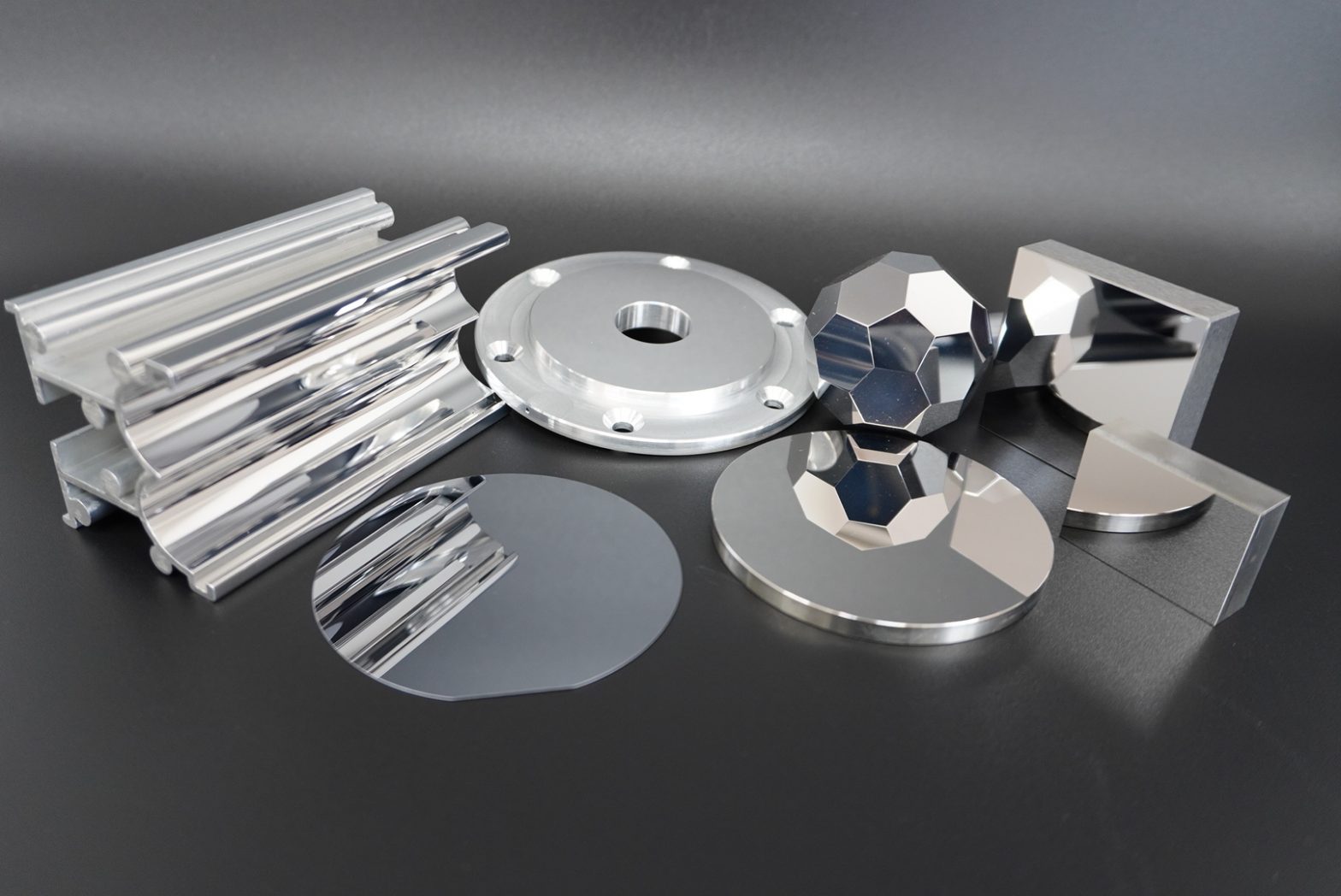

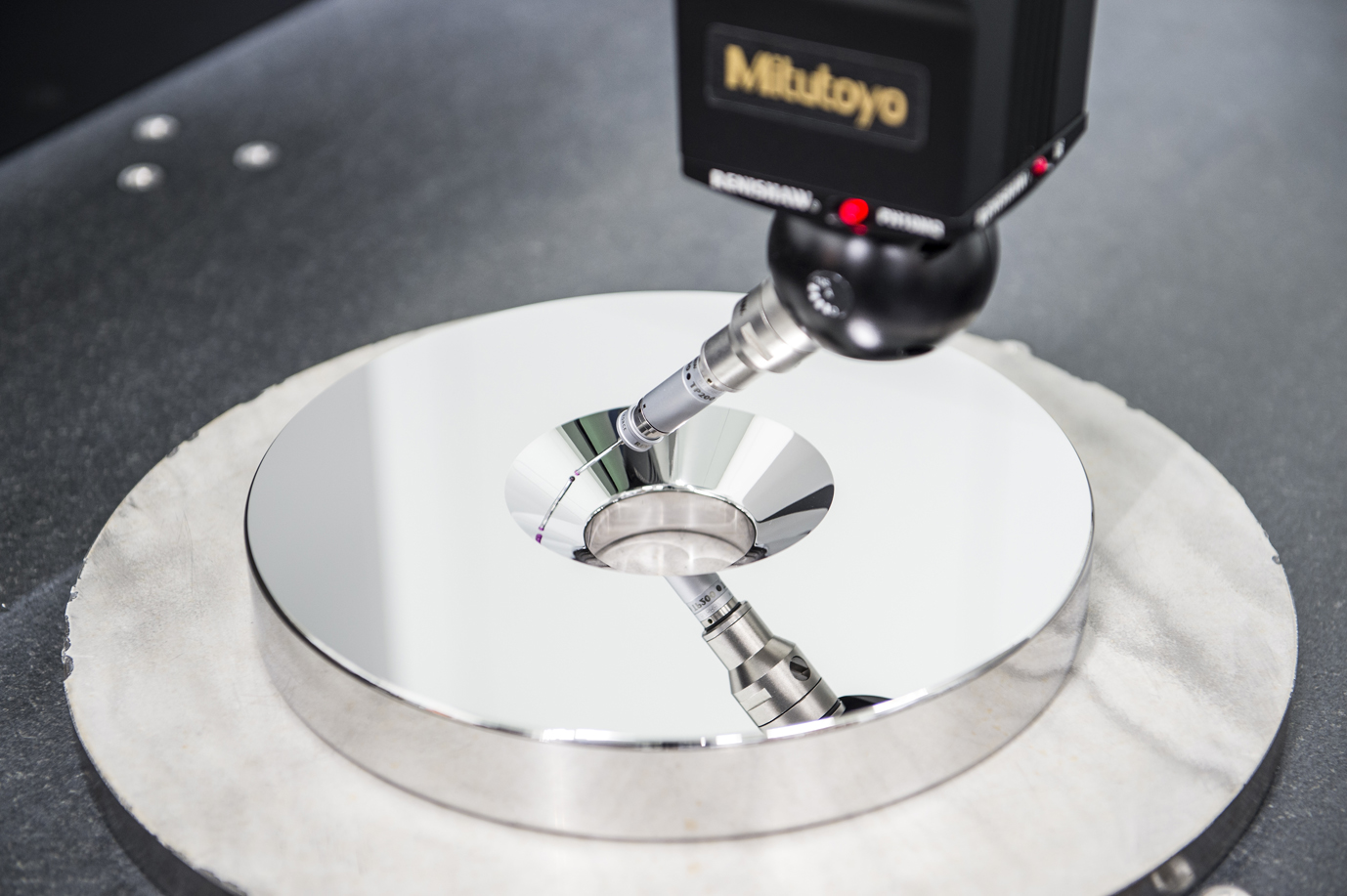

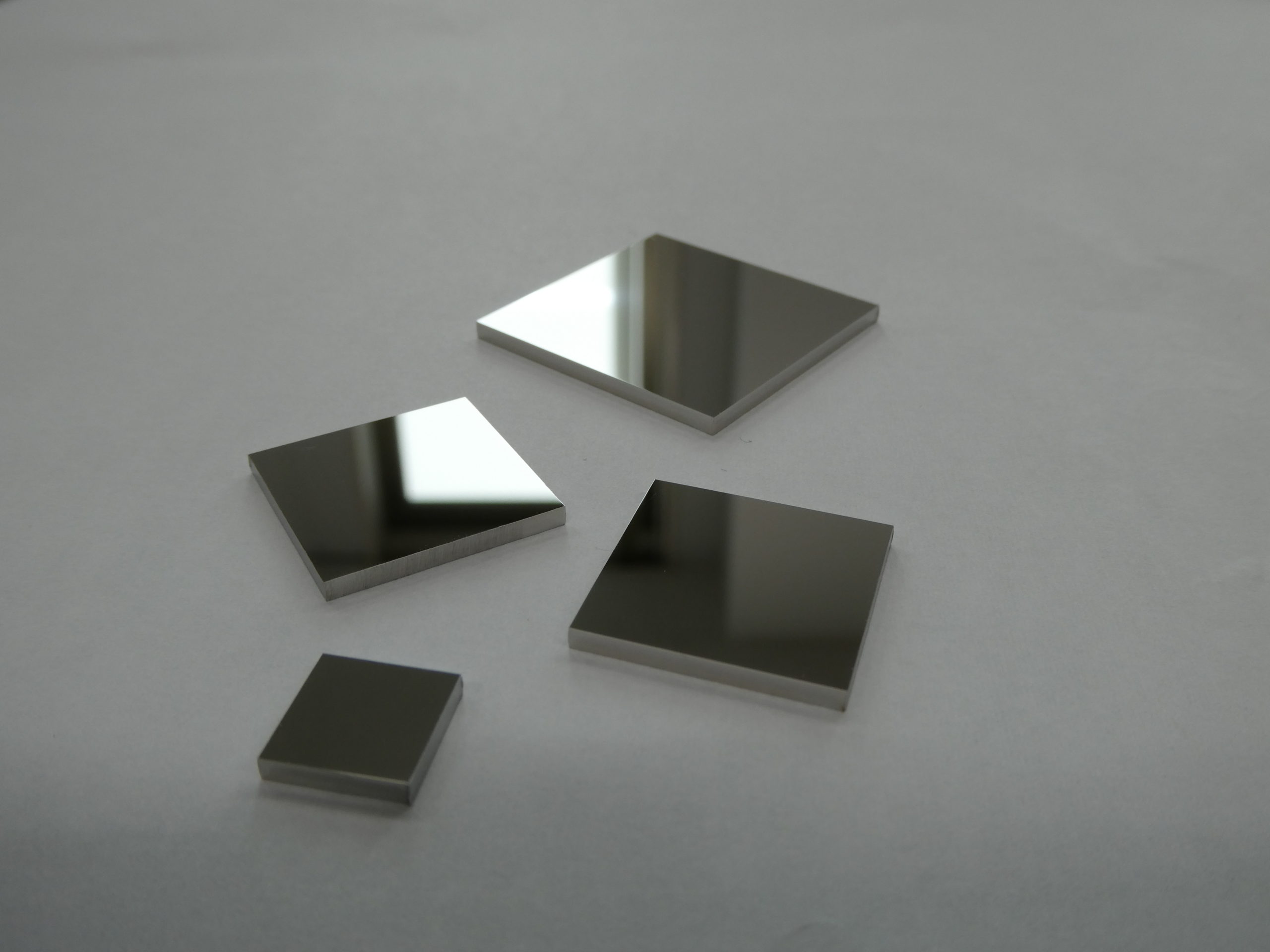

At our company, in order to suppress thermal expansion, we polish so as not to generate frictional heat as much as possible. In addition, we take measures to prevent the measurement results from being affected by temperature acclimatization before measurement.

Precise polishing is possible not only for the above materials, but also for various materials such as metals, resins, ceramics, and crystal materials. If you have any questions regarding the selection of materials, please feel free to contact us.

Related page

- インコネルとは?| 基礎情報・特徴の解説と加工事例

- 難削材とは? | 基礎知識と種類についての解説

- What is gallium nitride (GaN)? | Basic information/explanation of features and processing examples

- What is Vespel? | Vespel features and processing examples

- What is Tungsten? | Tungsten characteristics and processing examples

- Nickel

- Tantalum

- Glassy carbon (glassy carbon)

- Plate thickness and material of stainless steel plate (SUS)

- Coefficient of linear expansion

- Invar/Super Invar

- Niobium

- Hastelloy

- Engineering Plastic