ステンレスの研磨加工

このページでは、TDC(ティ・ディ・シー)で行っているステンレスの研磨加工をご紹介します。

TDCで行っている研磨加工については、『研磨加工』ページも合わせてご参照ください。

Contents

TDCのステンレス研磨加工

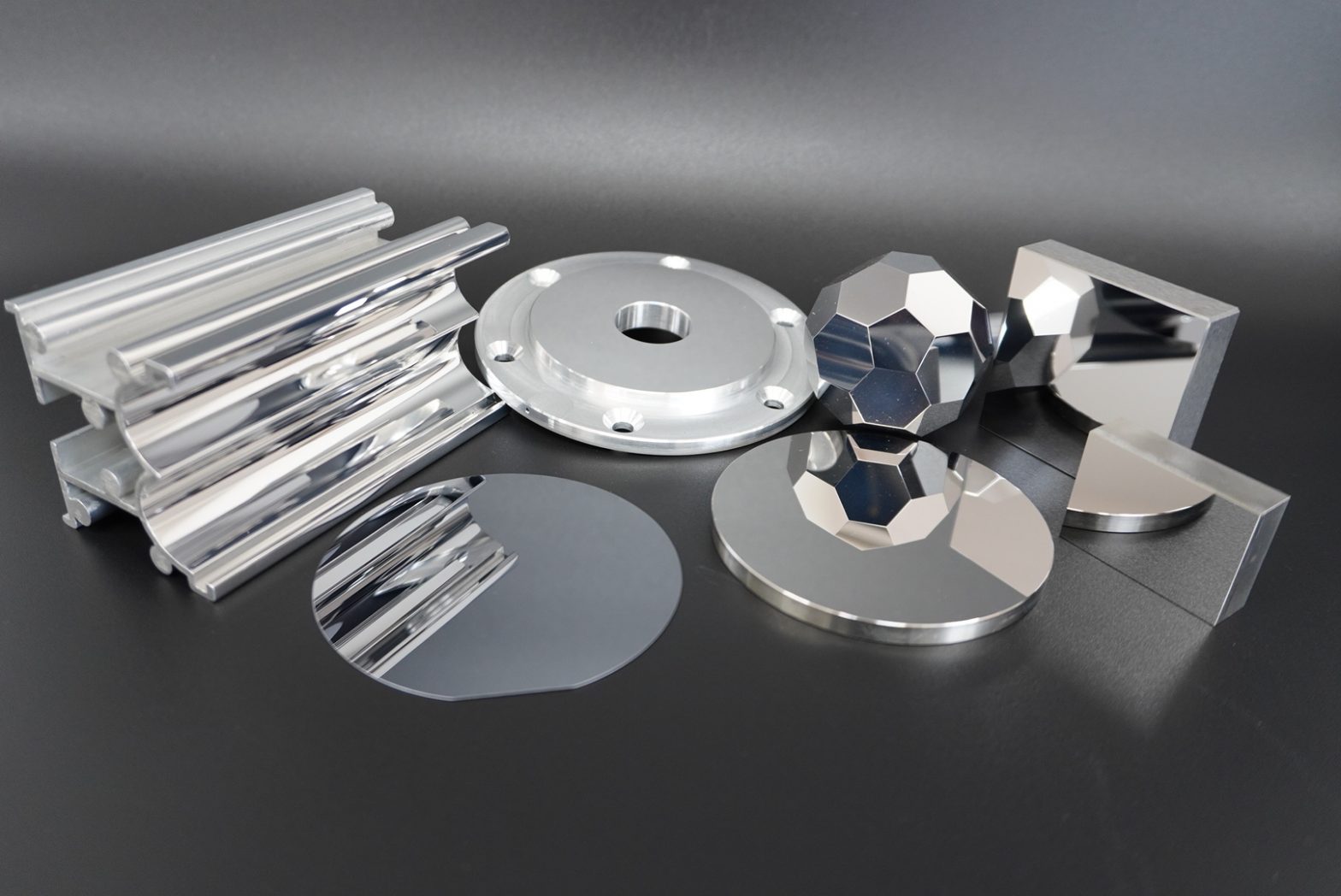

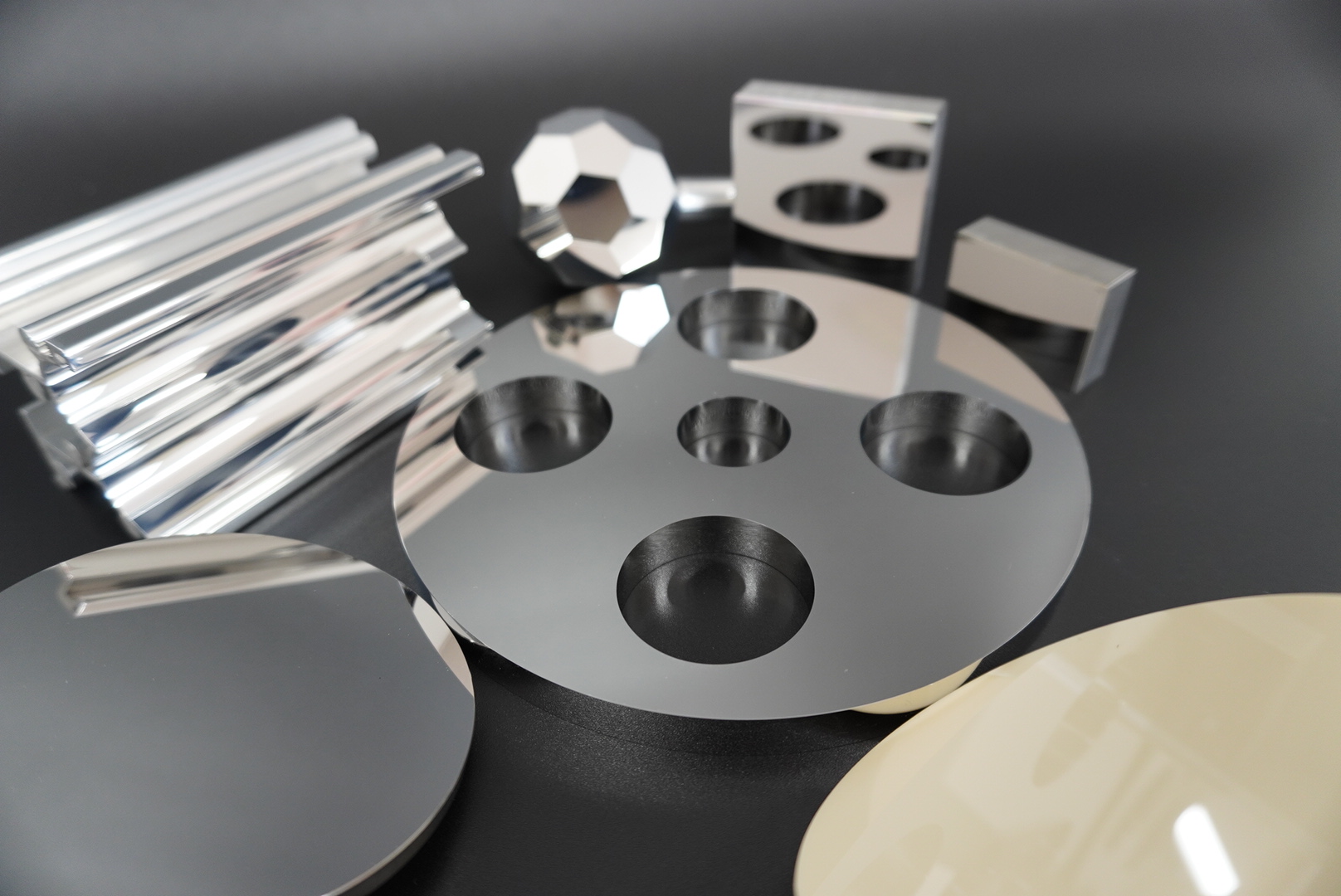

独自の技術開発やこれまでに培ってきた研磨技術によって、TDCはステンレスをはじめとするあらゆる金属の研磨加工を得意としております。

高い精度が求められる精密部品や金型用の研磨加工、ステンレス表面の鏡面研磨加工まで、幅広いステンレス研磨加工に対応することができます。

TDCの研磨加工に関する詳しい解説は、『研磨加工』ページをご確認ください。

クロム合金ステンレス工具鋼の一種であるSTAVAX材金型のご紹介は、以下動画をぜひご参照ください。

TDCのステンレス研磨加工の特徴

TDCのステンレス研磨加工には、以下のような強み・特徴があります。

- 高精度な研磨技術

TDCが誇る精密研磨技術により、除去量を制御することでミクロン単位・ナノレベルでの超高精度金属精密加工を実現しています。

切削や研削などの加工方法と比較しても、対象物に負荷をかけることなく、あらゆる形状への対応が可能です。 - 短納期・特急対応が可能

100台以上の研磨装置を所有することにより、大量ロットや複雑な加工であっても短納期を実現。

お急ぎの場合には、「特急対応」でのご相談にも対応させて頂きます。 - 小ロットからでもお気軽にご相談ください

1個からの小ロットでのご依頼、試作品の製作もお任せください。 - 100台を超える豊富な加工機械を所有

TDCでは、ラップ研磨機や平面研削盤などの研磨装置を100台以上所有。

マシニングセンター、フライス盤などの各種加工機も揃えているため、あらゆる加工にも対応が可能です。 - 研磨装置の約半数が自社製

100台以上ある研磨装置のうち約半数は自社製となり、「低コスト」で「高品質」なモノづくりを実現しています。

TDCのステンレス研磨加工例

TDCにおける代表的なステンレス研磨加工例を3つご紹介します。

その他材質についての加工実績は、下記ページよりご覧いただけます。

>>TDCの表面粗さ・面粗度実績

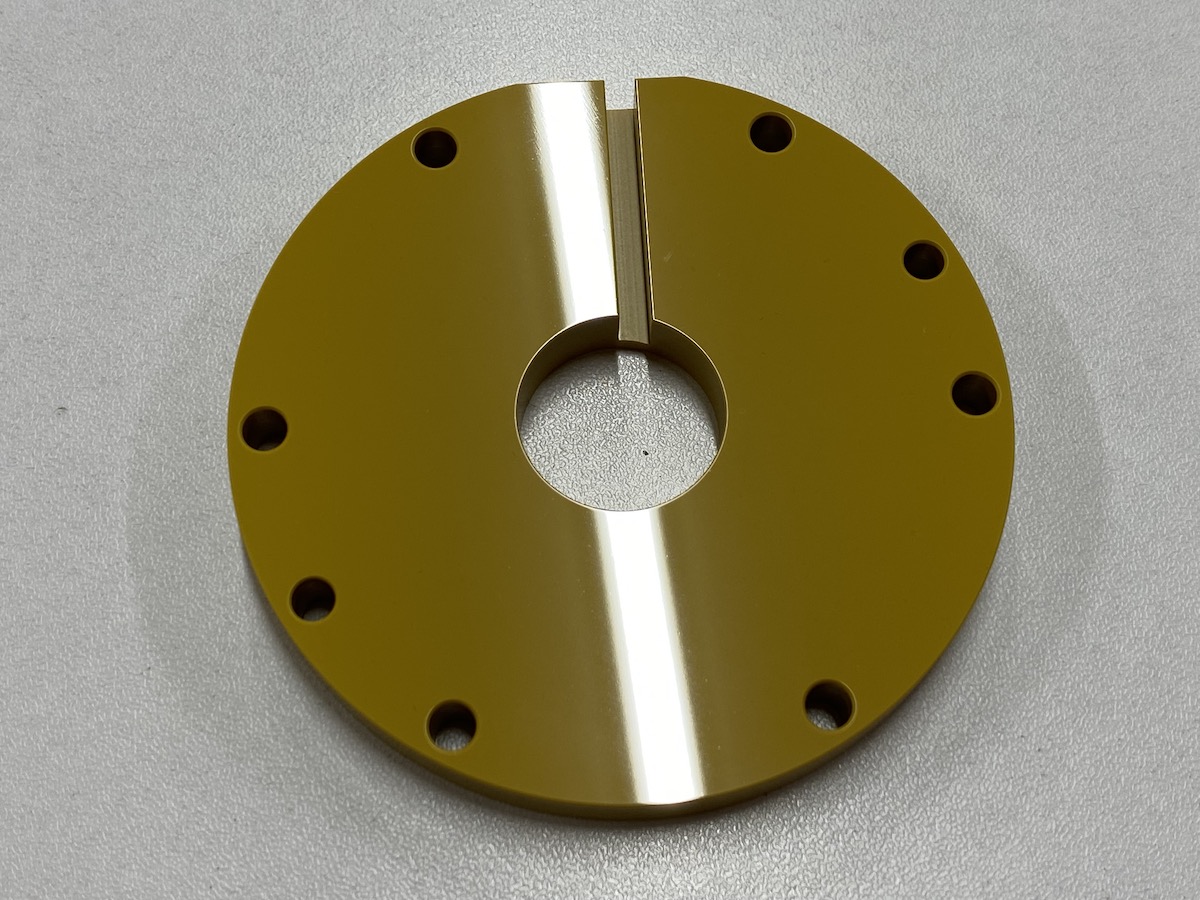

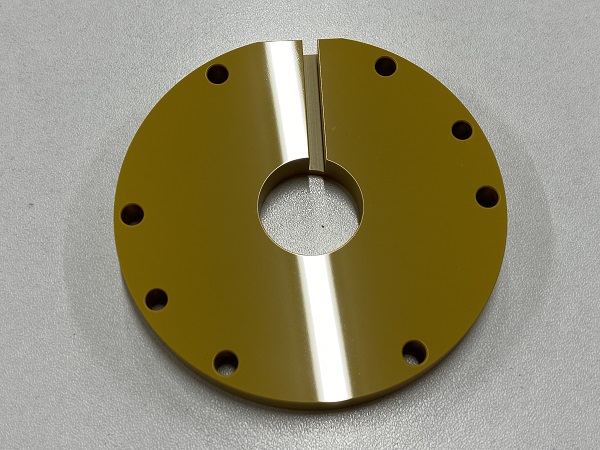

ステンレス研磨加工例①:SUS303 吸着テープル

- 材質:SUS303

- サイズ:φ145x5t

- 加工内容:平面研削にて面出しをした後、ラッピング研磨にて仕上げ加工。

- 精度:平面度 0.001mm (1um) 以下、面粗さ Ra1nm以下

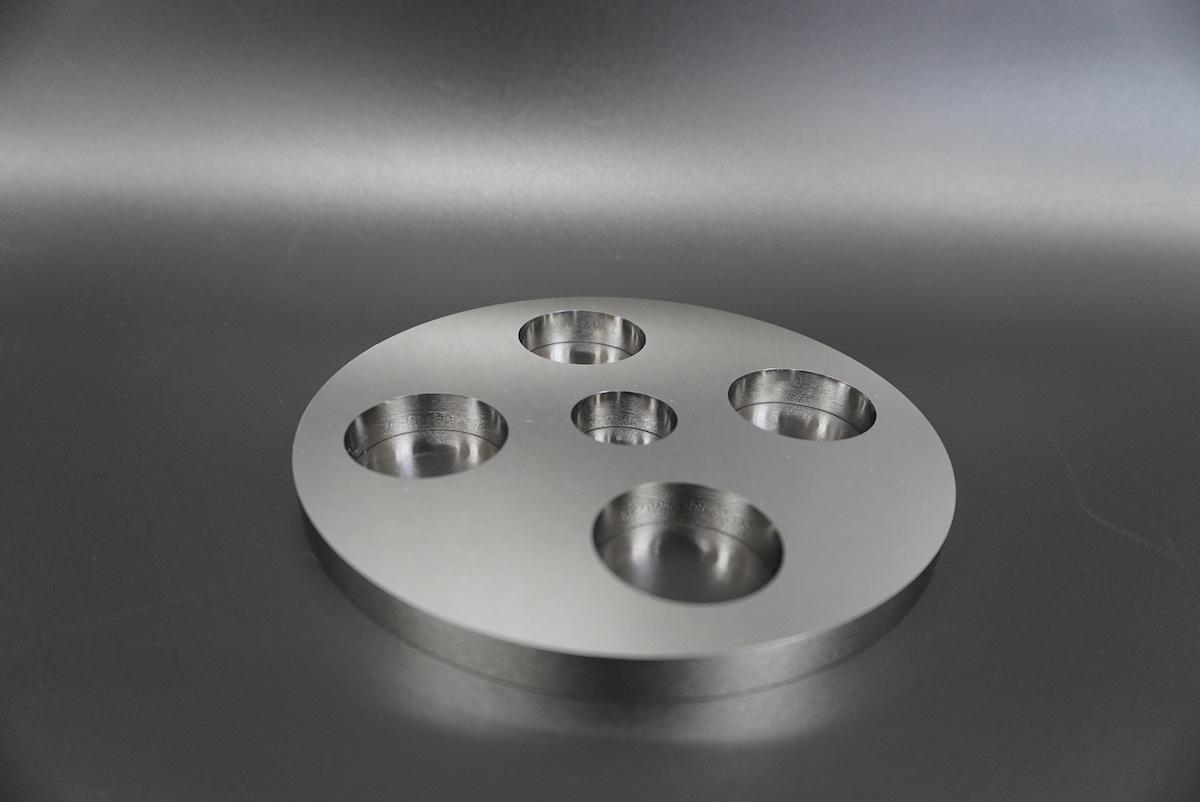

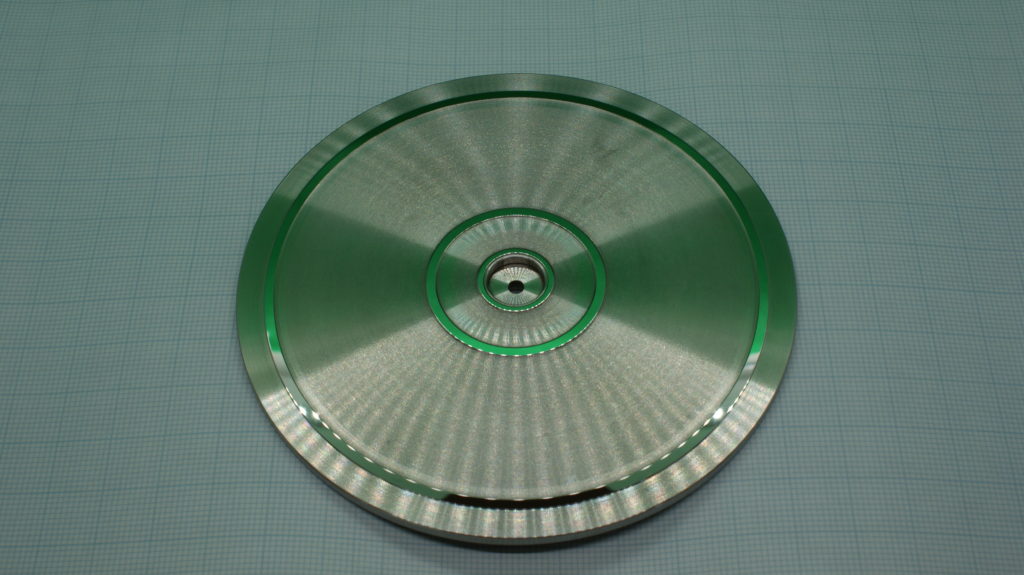

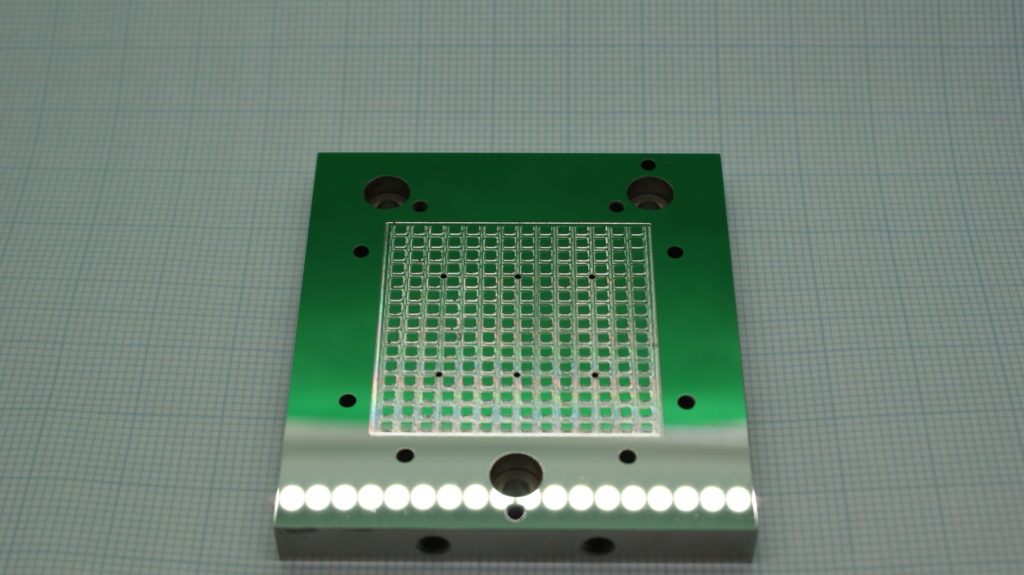

ステンレス研磨加工例②:SUS430 吸着ステージ

- 材質:SUS430

- サイズ:70x70x9t

- 加工内容:平面研削にて面出しをした後、ラッピング研磨にて仕上げ加工。

- 精度:平面度 0.0005mm (0.5um) 以下、面粗さ Ra1nm以下

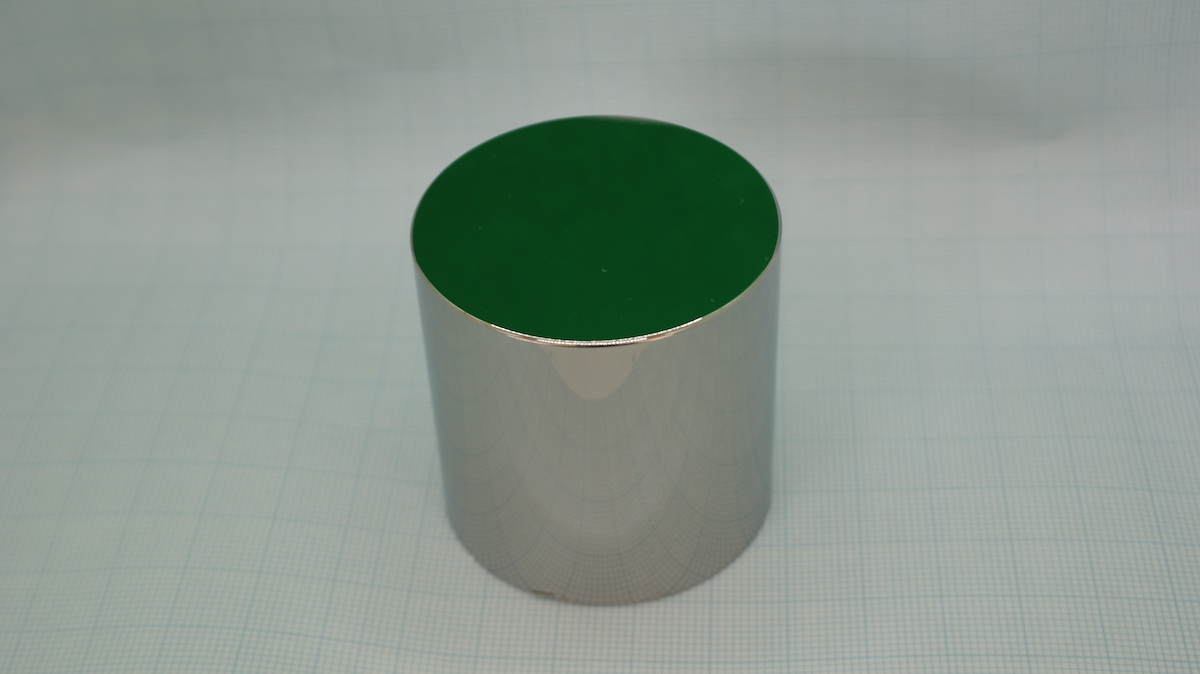

ステンレス研磨加工例③:SUS304 吸着ノズル

- 材質:SUS304

- サイズ:φ30x15t

- 加工内容:平面研削にて面出しをした後、ラッピング研磨にて仕上げ加工。

- 精度:平面度 0.0002mm (0.2um) 以下、面粗さ Ra1nm以下

ステンレスとは?

ステンレスとは、鉄を主成分・50%以上とし、クロムを10.5%以上含んだ錆びにくい合金で、日本での正式名称を「ステンレス鋼」と呼びます。

ステンレスは耐食性以外にも耐熱性や加工性、強度、意匠性などに優れた特徴をもっており、メンテナンスが容易であることも大きな特徴となっています。

環境に対する社会の関心が高まるなか、100%リサイクル可能な材料として高く評価され、あらゆる製造業種においても注目されている金属材質のひとつとなっています。

ステンレスの種類

ステンレスは、ニッケルやクロームの含有量や、モリブデン含有の有無などによって種類が細かく分別されます。ステンレスは、「Steel Use Stainless」の頭文字を取った「SUS」という材質記号で表され、このSUSの後につく数字・記号で種類を区別しています。

一般的なステンレスの比重は7.7~8.0前後となっていますが、ステンレスの中でも良く選ばれる「SUS304」は比重7.93で、鉄の重さとほぼ同等となります。

また、素材の組成によってはマグネットに付く物も存在しますが、ほとんどのステンレスには磁性がありません。一般的な加工機械はマグネットで素材を固定するものが多いため、ステンレスは一般的に加工がしづらい材質となります。

ステンレスの研磨

ステンレス材というと、美しい光沢を放つ鏡面仕上げがイメージされますが、実はステンレス自体は元々光沢をもった素材ではありません。

求める仕上がりやステンレスの種類によって、加工工程や研磨方法、使用する研磨剤などが変わってきます。

ステンレス研磨の種類

ステンレスの研磨と一言でいっても、さまざまな種類が存在します。

- ヘアライン仕上げ・ヘアライン研磨

ストレートヘアのように、一方向にまっすぐな直線が入った意匠仕上げとなります。ヘアライン仕上げを応用し、交差することによる「クロスヘアライン」、円形状に加工をおこなうレコード盤のようなライン研磨も可能です。 - バイブレーション仕上げ・バイブレーション研磨

別名、ランダム研磨、パーマネントヘアラインとも呼ばれ、不規則な研磨ラインが特徴です。見る角度によって輝きが変わる加工方法となり、その落ち着いた外観やエレガントな雰囲気からも、建築物などに多く利用される仕上げとなります。 - ブラスト仕上げ・ブラスト研磨

ガラスや砂、鉱物、金属などの「投射材」を噴射して研磨する方法となります。上品に煌めく仕上がりが特徴で、ハイエンドなデザイン分野で幅広く利用される仕上げ方法のひとつです。 - 鏡面仕上げ・鏡面研磨

金属の表面を鏡のように仕上げる加工方法で、ステンレス材の仕上げ・研磨においてスタンダードな方法となります。

ステンレス鏡面仕上げの代表的な方法「ラッピング研磨」と「バフ研磨」

「ラッピング研磨」

ラッピング研磨とは、ラップ盤と呼ばれる平坦な円盤状の台に、製品を載せて上下から圧力をかけることで研磨していく加工方法のことを指します。

砥粒の選定と加工条件の調整により高精度な研磨が可能となるため、あらゆる鏡面仕上げにも対応が可能な方法のひとつとなります。

「バフ研磨」

バフ研磨は、麺、ウール、スポンジといった柔らかい素材で作られた円盤状のバフに、研磨剤やワックスを付けながら研磨を行う方法です。バフを当てるときの力加減や角度が仕上がりに大きく影響するため、高い精度を出すためには熟練した技術が必要となる高度な研磨加工方法だといえます。

TDCではラッピング研磨をはじめ、さまざまな研磨技術を用いることでご要望のステンレス研磨をおこなうことが可能となっています。

ステンレス研磨とステンレス研削の違いは?

一般的な「研磨」と「研削」の違いと同様に、ステンレス研磨は「ステンレス表面を磨くこと」で、「ステンレス研削」は文字通り「ステンレス表面を削る」という点で違いあります。

簡単にいえば、ステンレスの形状を変えずに表面だけ磨き上げることで精度や仕上げを行う作業は研磨となります。

一方で、ステンレスの部材自体を削って形を変えたり薄くする作業は研削となります。

加工が難しいとされるステンレス研磨加工・研削加工もTDCにご相談ください

一般的に加工がしづらいとされるステンレス材ですが、TDCでは、ラップ研磨機や平面研削盤などの研磨装置を100台以上所有しています。

また、これまでに蓄積された研磨加工技術により、あらゆる材質・精度の研磨加工にも対応が可能となっています。

他社で断られたステンレス研磨加工や切削加工も、ぜひ一度TDCにご相談ください。

Related page