Precision parts processing

On this page, we will explain about precision parts processing and introduce some of TDC’s precision parts processing results.

Contents

What is precision parts processing?

Precision parts processing refers to processing that meets requirements at the level of several nanometers to several microns in the fields of parts manufacturing and parts processing.

In general, precision parts are manufactured and processed by one of the following methods.

- Manufacturing and processing parts one by one from one material

Using high-precision machine tools and tools, our engineers process parts one by one. It is suitable for manufacturing and creating parts in small lots. - Make a mold and start mass production

We prepare a “mold” for mass production in advance, and manufacture and process the parts. Mold making costs are required, but parts can be produced in large quantities.

For TDC’s precision processing services, please refer to “Precision lapping service / ultra precision lapping service“.

Main processing methods used in precision parts processing

The following processing methods are generally used in precision parts processing.

- milling

- lathe manufacturing

- keyway machining

- EDM

- Machining

- milling

- wire cut processing

- lapping process

- Polishing process

- surface grinding

- Demand for precision parts processing

Industries and needs requiring precision parts processing

Precision parts processing is required in various industries that require high-precision quality, such as semiconductors and optical equipment.

- mechanical parts

- Equipment with limited production volume

- semiconductor

- car

- aircraft

- Industrial machinery, high-precision machine tools, tools

- optical equipment

- electrical equipment

- Telecommunications

- FA equipment

- Medical equipment

- robot

Precision parts machining at TDC

TDC’s precision parts processing results

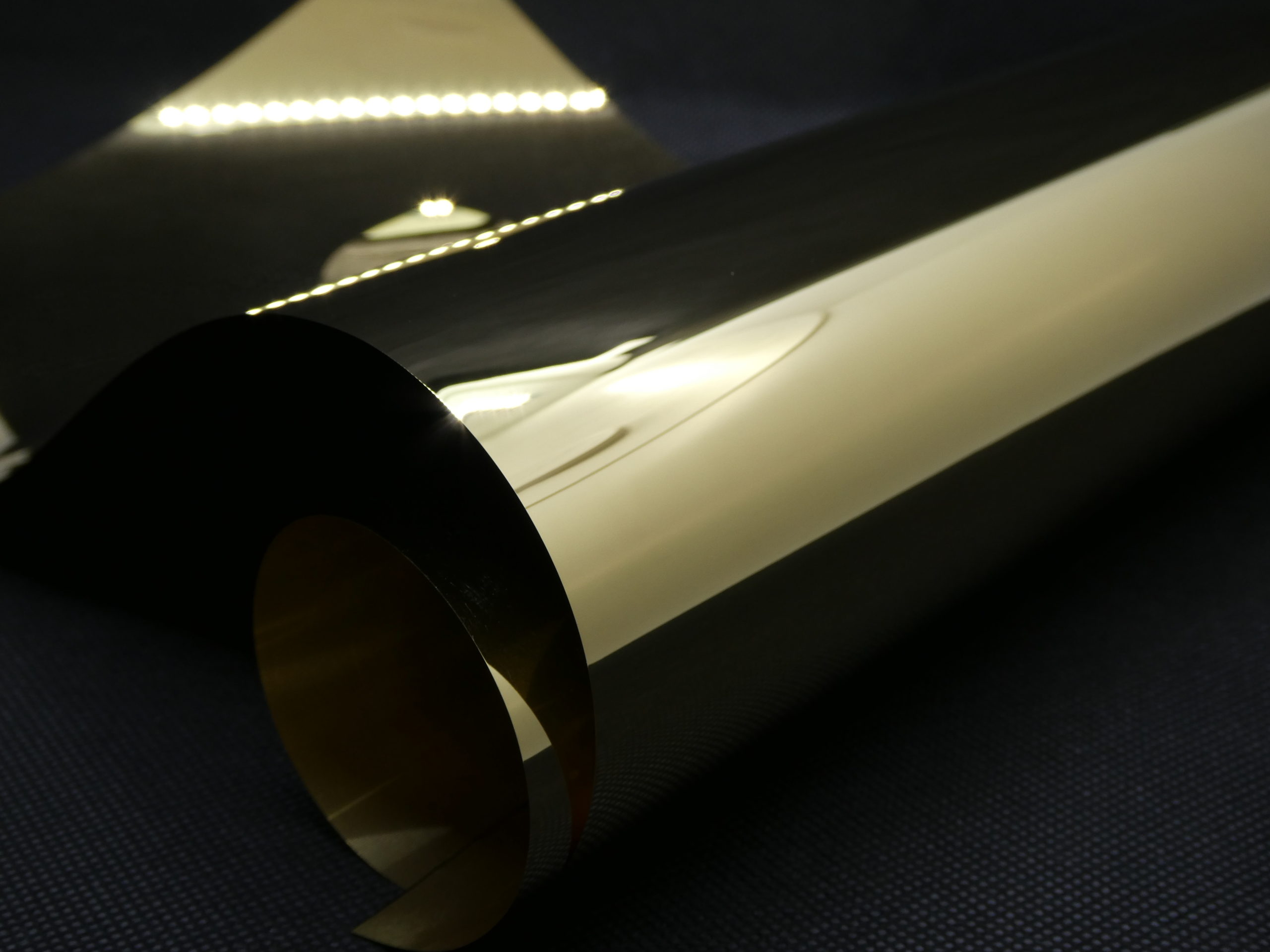

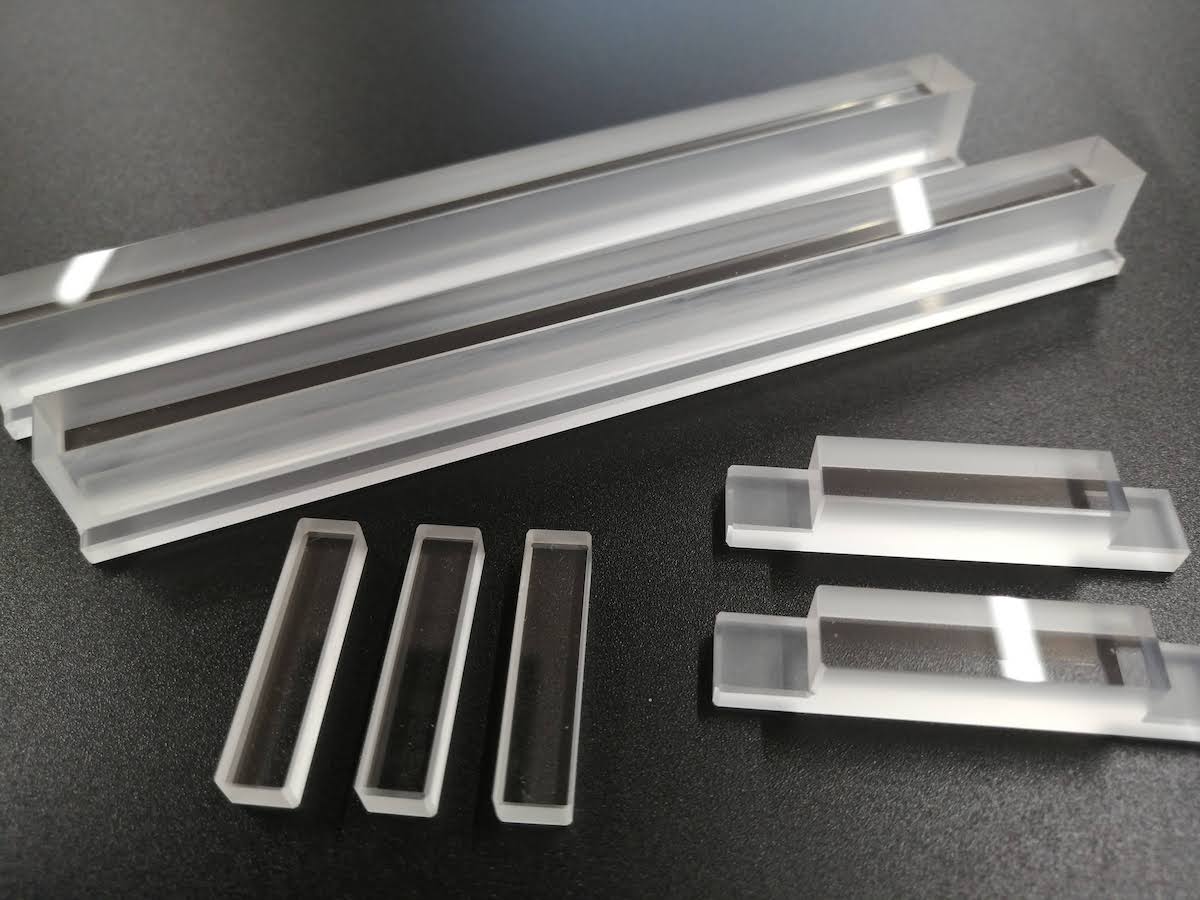

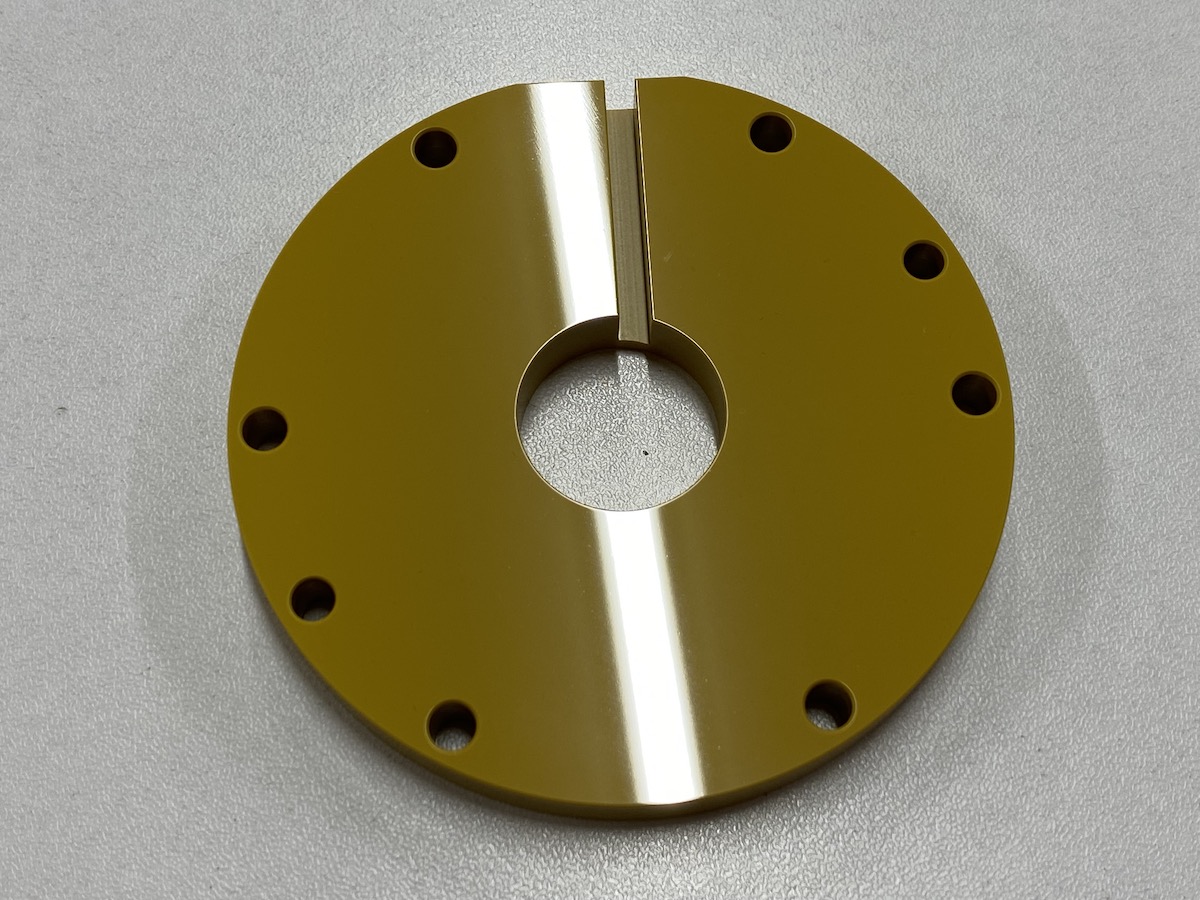

- Ultra-precision polishing processing

- Available materials: metals, resins, ceramics, glass, semiconductor crystals, optical crystals, etc.

- Available lots: 1 piece or more

- Available sizes: up to 700 square (depending on specifications, please contact us for details)

- Accuracy: flatness 0.001 or less, parallelism 0.001 or less, surface roughness Ra 0.001 or less, dimensional tolerance ±0.001 or less

TDC’s precision parts processing equipment

TDC owns various equipment used for precision parts processing.

Please refer to the following pages for detailed explanations of the facilities.

COntact TDC for precision polishing parts processing

At TDC, we can process precision parts of any material within the following range.

- Number of lots that can be handled: From 1 piece to mass production

- Available sizes: up to 700 square (depending on specifications, please contact us for details)

- Available shapes: plates, inner and outer diameters of rolls and shafts, 3D shapes, etc.

At TDC, we specialize in high-precision and high-precision micron-level parts processing using the polishing technology know-how we have cultivated over the years.

We also have a large number of machine tools that are indispensable for precision parts processing, and we can realize one-stop from design to processing, quality assurance, and delivery.

From mass production to prototype development products, we can handle small lot production from 1 unit, and mass production, so if you have any concerns about parts processing, please contact TDC.

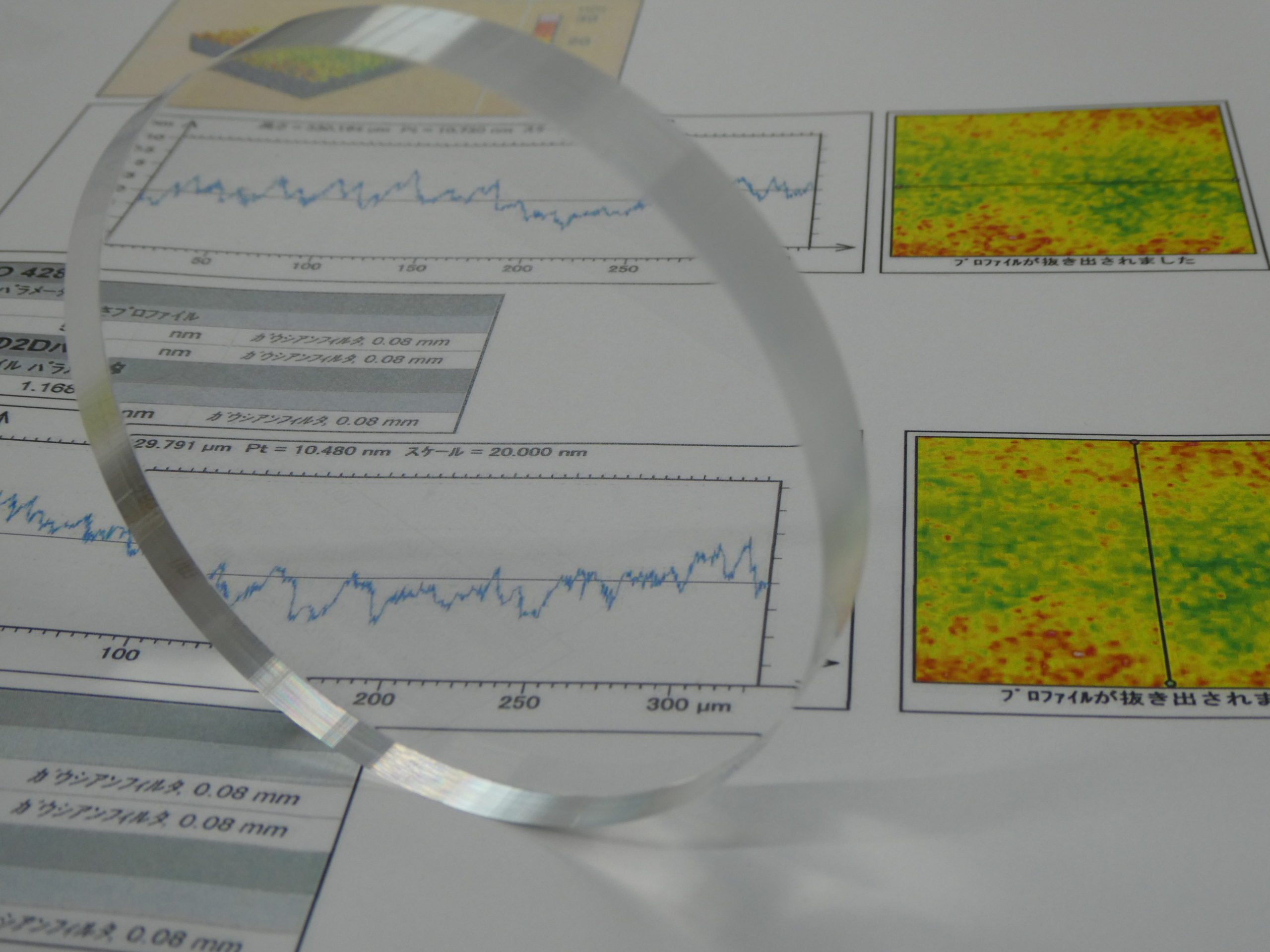

Using precision polishing processing technology and know-how that has been cultivated over many years to stably realize high-precision manufacturing and cutting-edge measuring equipment, we process not only dimensional tolerances but also various geometrical tolerances to the nano-order.

Quality control and quality assurance for precision parts

At TDC, we use the world’s highest standard measurement environment and evaluation technology to ensure the quality of ultra-precision manufacturing.

The precision parts to be manufactured and processed are manufactured while measuring the surface roughness, flatness, parallelism, dimensional tolerance, dimensions, etc., and the quality is guaranteed by our precision measuring equipment.

We will provide quality assurance data at the time of shipment.

For TDC’s quality assurance, please also refer to the “Quality Assurance” page.

Flow of request for precision parts processing

- specification meeting

- supplied materials or material arrangements

- precision polishing

- wash/clean

- measurment

- shipping

Related page

- What is a chuck table? | Basic information and description of types, Processing accuracy at TDC

- Copper polishing

- Precision processing of crystal materials and glasses

- Polishing after thermal spraying

- Mirror Finishing/Mirror Polishing

- Sapphire polishing

- Polishing of plastic/acrylic resin

- Polishing after surface treatment/coating

- Precision parts processing

- KEYENCE measuring instruments used at TDC

- Precision Cleaning Service

- Symbol used for polishing

- SUS (stainless steel) material test piece/specimen

- Polishing of SiC

- Polishing of titanium

- Cylindrical grinding/cylindrical polishing

- Mold Processing

- Precision machining of ceramics

- ガラスエポキシ(ガラエポ)の精密加工

- Type of polishing process

- 真鍮の精密加工・研磨加工

- What is the accuracy that can be achieved by polishing?

- Principle of polishing process

- Semiconductor Wafer Cleaning

- Ultrapure Water Cleaning

- Bruker “Dimension Icon”

- Talysurf

- Talyrond

- Dial gauge

- Precision processing of resin and plastic

- Polishing process for Resin

- Precision Measurement

- Mirror-finishing for aluminum

- Mirror-finishing for plastic/acrylic resin

- Wafer Cleaning Equipment

- Mirror Polishing for Stainless Steel/SUS304

- Metal polishing process

- Mitutoyo measuring instrument used in TDC

- Polishing of Aluminum

- Optical Nano Gauge

- ステンレスの研磨加工

- TDC’s precision machining

- 微細加工とは? | 基礎知識と加工方法の解説

- Precision polishing technology of Diamond wafers

- What is CMP

- What is polishing?

- About Lapping and Polishing