Solutions for precision machining in MEMS

We will introduce precision machining solutions in the field of MEMS by TDC

What is MEMS?

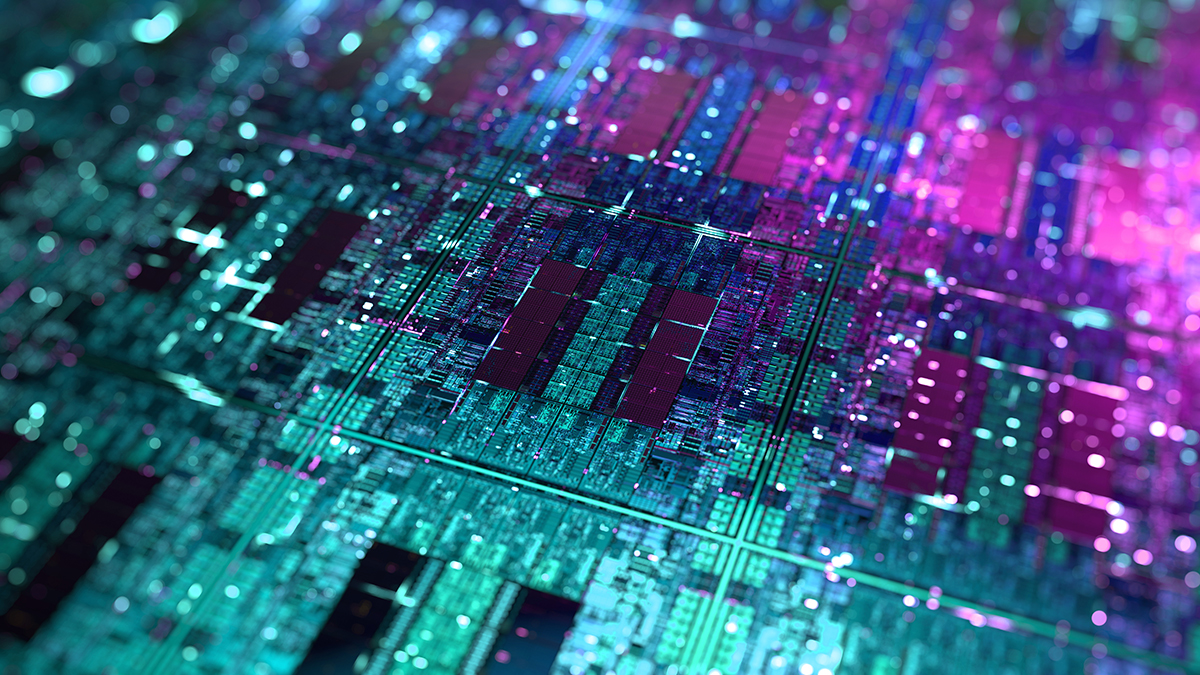

MEMS stands for “Micro Electro Mechanical Systems. “MEMS is a general term for forming a micron-level three-dimensional structure on a support substrate such as a silicon wafer and integrating functions such as electronic circuits, sensors, and actuators.

Similar to semiconductors, this technology is applied to various products such as automobiles, smartphones, inkjet printer heads, and optical scanners.

Since it is applied in a wide variety of fields, it is in high demand both in Japan and overseas, and is one of the technologies that is attracting attention as a technology that will lead the next generation of the Japanese manufacturing industry.

Definition and features of MEMS

MEMS stands for “Micro Electro Mechanical Systems. “MEMS is a general term for forming a micron-level three-dimensional structure on a support substrate such as a silicon wafer and integrating functions such as electronic circuits, sensors, and actuators.

Similar to semiconductors, this technology is applied to various products such as automobiles, smartphones, inkjet printer heads, and optical scanners.

Since it is applied in a wide variety of fields, it is in high demand both in Japan and overseas, and is one of the technologies that is attracting attention as a technology that will lead the next generation of the Japanese manufacturing industry.

Definition and features of MEMS

The definition of MEMS is sometimes ambiguous, and DNA chips that do not have a movable structure are sometimes called MEMS. However, the general definition is “micromachine”, which is a micromachine with the mechanical structure of moving parts and electronic circuits. As for the size, the total length is mm (millimeter) or less, and most of the parts used are ordered in um (micrometer). Because of its characteristics, it is sometimes called “moving semiconductor” as a popular name. In this way, MEMS is a very fine, complex, and advanced technology, but the power consumption required for it is extremely small. Therefore, it will be a next-generation technology that contributes to the miniaturization and weight reduction of digital devices such as digital cameras and smartphones, and the extension of operating time.

Application in MEMS

Products to which MEMS is applied can be seen in our daily lives.

For example, smartphones that everyone owns these days. MEMS is also applied to microphones, BAW filters, accelerometers, gyro sensors, and pressure sensors.

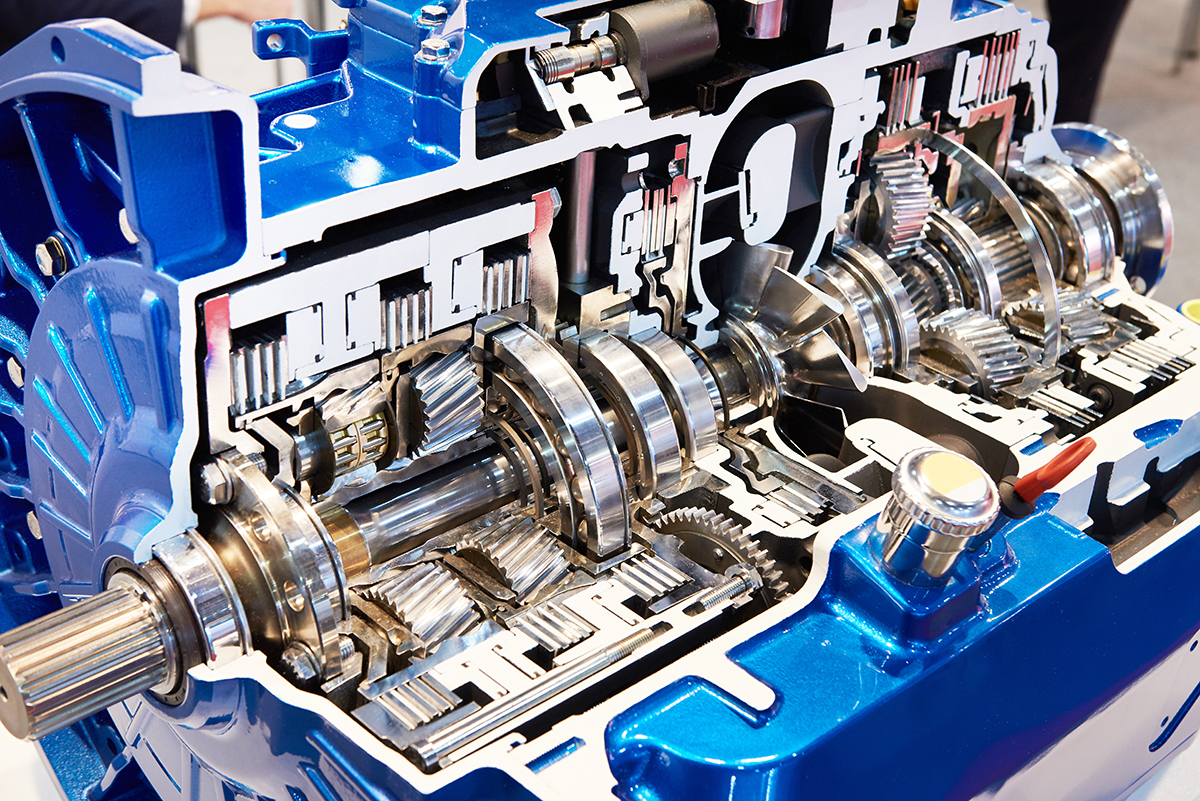

Speaking of automobiles, MEMS technology includes gyro sensor parts such as navigation and vehicle motion control, airbags and engine electronic suspensions, acceleration sensor parts that control the optical axis of headlights, and brake oil sensors and wipers. It has been applied.

In addition to the above, it is one of the technologies that are very widely applied, such as automatic blood pressure monitors and weight scales used at home, high-performance inkjet printers, and digital cameras with image stabilization functions.

TDC’s solution in MEMS

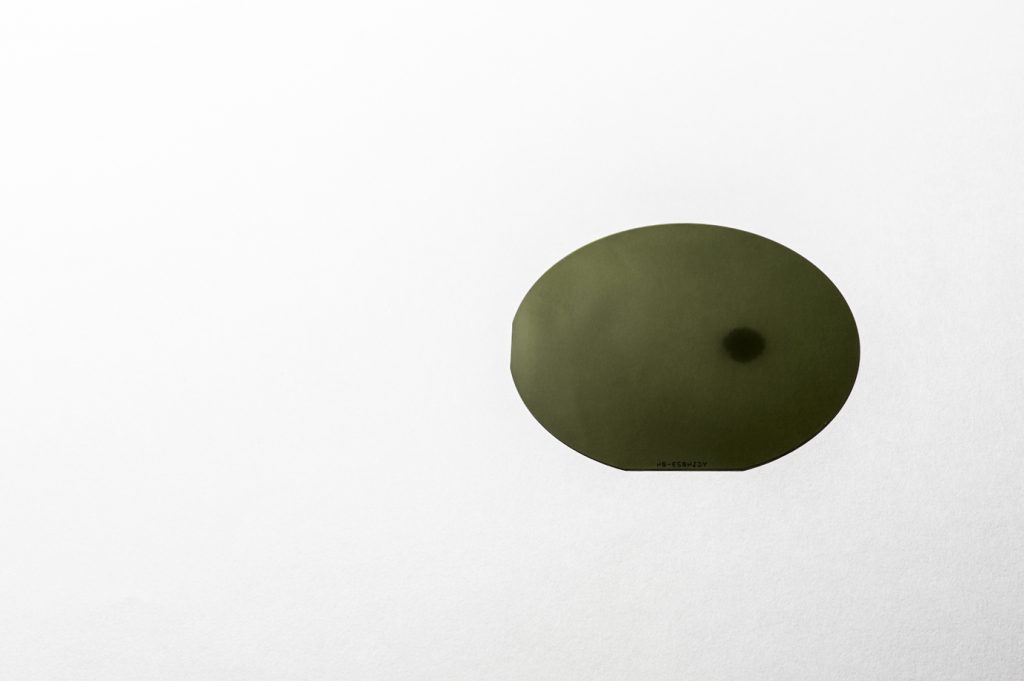

TDC can solve problems in the MEMS field by improving and cleaning the surface roughness of bonding substrates, thinning and improving TTV of bonded wafers, and controlling the thickness by polishing the back surface of microfabricated substrates.

In addition, we provide polishing to various materials using CMP technology, surface roughness improvement, thinning technology, and cleaning technology.

Commitment to MEMS solutions

TDC can always provide a stable surface roughness of Ra1nm (nanometer) or less, and can process thin wafers without variation in thickness.

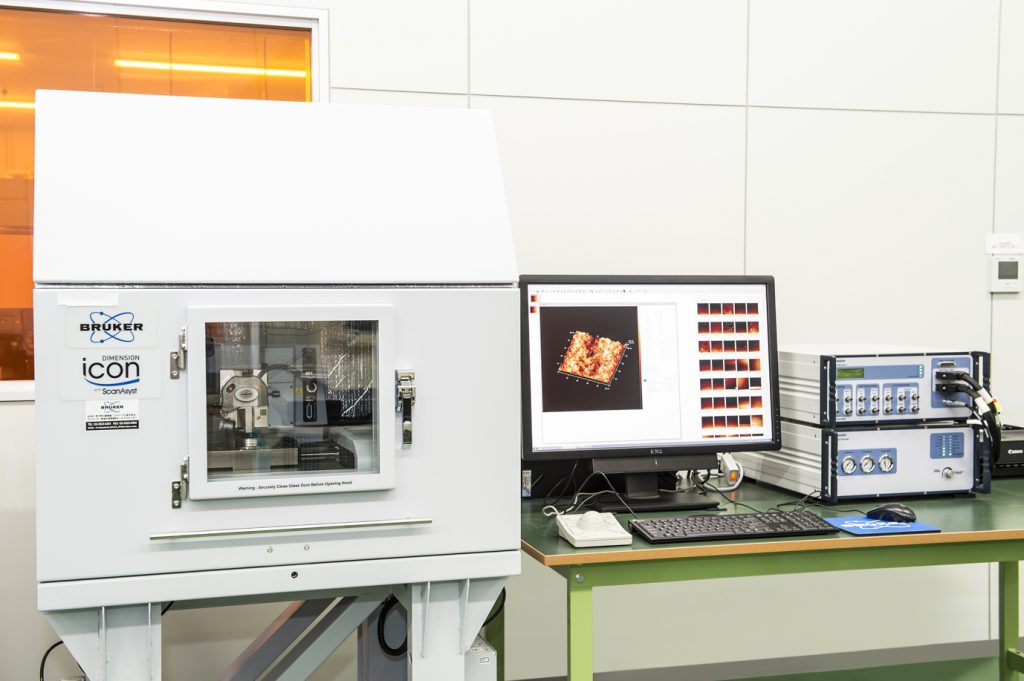

High-precision TTV management is possible, and it is possible to provide both precision measurement and precision machining axes using highly reliable measuring machines such as AFM and film thickness measuring instruments.

Please contact TDC for precision machining issues in the MEMS field.

Related page