.jpg)

Precision Cleaning Service

This page provides basic knowledge about precision cleaning performed at TDC. For information on TDC’s processing facilities, please also refer to “Processing Equipment” and for more information on wafer cleaning, please refer to “Wafer Cleaning Equipment“.

Contents

What is Precision Cleaning?

Precision cleaning refers to the process of removing adhesive substances from the surfaces of parts, products, semiconductors, etc., and finishing cleaning with ultrapure water and ultrasonic waves. This cleaning also removes invisible dirt and residue, and removes particulates and ionic matter to levels that are not problematic. For example, in semiconductor manufacturing, vaporized materials and reaction products adhere to and accumulate in the manufacturing process. Precision cleaning is an indispensable process, because a certain amount of adhering matter or deposits can cause product defects or production problems.

Features of precision cleaning

Precision cleaning has the following features:

- No unwanted substances such as chemicals remain.

- Even complex shapes can be cleaned

- No secondary waste generated

- Virtually no morphological or dimensional changes on the base material surface

Precision cleaning applications

Precision cleaning is mainly used for the following purposes.

- Cleaning of parts for semiconductor, liquid crystal, and organic EL manufacturing equipment

- Cleaning of HDD parts, semiconductors, liquid crystal manufacturing equipment parts, etc.

- Cleaning electronics that cannot be cleaned with water or chemicals

- Complex mold cleaning

- Cleaning of parts that require cleanliness such as medical equipment

TDC’s Precision cleaning Service

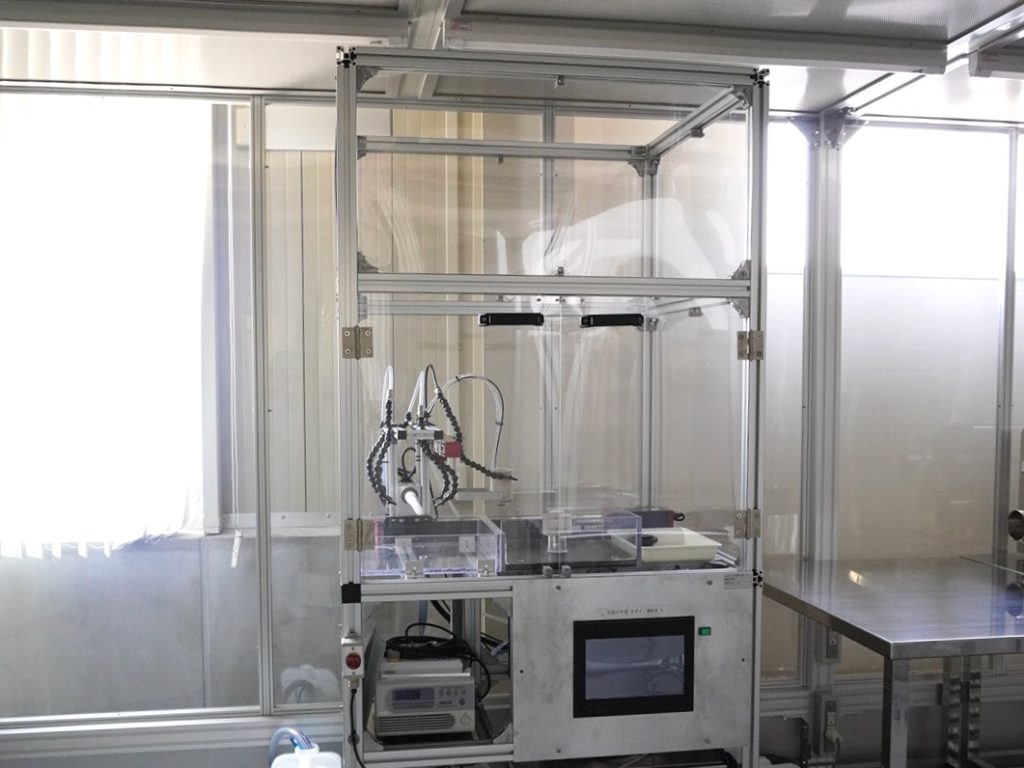

In April 2021, TDC set up precision cleaning equipment, enabling us to handle from precision polishing to precision cleaning in house. Please feel free to contact us.

with nano-level precision polishing.

and production from single units to mass production.

Materials to be cleaned

Single wafer cleaning type

- Compatible size:

2~8 inches (single side) - Achievement:

4-inch LT/LN/Si/crystal wafer, 2-inch GaN/Si/sapphire wafer

Batch type

- Compatible size:

~6 inches - Achievement:

4 inch transparent ceramic substrate, 10mm squre sapphire substrate, 4mm squre diamond substrate, SUS304 parts

Flow of TDC’s precision cleaning

We have two types of wafer cleaning equipment: a “single wafer cleaning type” that cleans one wafer at a time and a “batch type” that cleans several wafers at once. Although it may vary depending on the material and shape, the basic cleaning process for each is as follows.

Single wafer cleaning

- wafer setting

- ultrasonic spot shower

- scrub cleaning

- ultrasonic spot shower

- spin drying

- case packaging

- degassing

The following flow is the basic cleaning process for single wafer cleaning.

1. Wafer setting / 2. Ultrasonic spot shower

The water coming out of the white circle in the photo is called spot cleaning, and this is an ultrasonic transducer, and the water passing through it becomes ultrasonic water that removes dirt, including where the water hits and flows.

3. Scrub cleaning

After ultrasonic cleaning, scrubbing is performed with brush rollers. This roller acts like a rinse, lifting dirt with ultrasonic waves and then completely removing it with scrubbing.

4. Ultrasonic spot shower

Ultrasonic cleaning is performed once again as a finishing touch.

5. Spin drying

The table is rotated at high speed to dry.

6. Inspection

7. Deaerated and Packing

Batch cleaning

There are work sinks inside the equipment, starting from the left side viewed from the front of the equipment, and a total of five cleaning tanks: a storage tank, a chemical tank, a QDR tank, an OF tank, and a hot water tank. This equipment have a heater and ultrasonic generator 38 kHz/600 W in the chemical tank, an ultrasonic generator 160 kHz/600 W in the OF tank, and a heater in the hot water tank. Currently, the basic wafer cleaning operation in batch mode is performed in the following flow.

1. Hand scrub cleaning

Use a PVA sponge at the sink to perform hand scrubbing.

2. Storage in liquid

After hand scrubbing, it is stored in liquid (pure water) in a storage tank so that it does not dry out.

3. Chemical cleaning

It is transferred from the storage tank to the chemical liquid tank, and the chemical liquid cleaning is performed by chemical liquid + heating + ultrasonic waves.

4. QDR

After chemical cleaning, QDR (Quick Dump Rins.) is performed, in which the tank is filled with pure water at once, and the tank is quickly drained and rinsed.

5. OF water rinse

After QDR, OF water washing is performed by continuously flowing pure water into the tank at the same time as ultrasonic cleaning and rinsing while overflowing.

6. DRY

Finally, it is put into a hot water tank, and the stage is pulled up at a speed of 0.5 to 1 mm/sec to dry it out.

Wafers are placed in carriers and cleaned in each tank.

TDC’s Cleaning Equipment

TDC has the following wafer cleaning equipment in house.

| HOZAN | Clean Booth | 10m×5m ISO Class3 (Particular Size 0.1μm) |

| HOZAN | Clean Booth | 6m×3m ISO Class3 (Particular Size 0.1μm) |

| ORGANO | Ultra-pure water System | UC–2600 |

| HORIBA | Water Quality Analyzer | LAQUA WQ330 |

| Temtec | Wafer Cleaning System | 1 |

| In-house | Wafer Cleaning System | 1 |

| ELGA | Ultra-pure water System Purelab Chorus |

60L |

| KOKEN | Clean Bench ISO Class1 | Table Koach |

| Japan airtech | Clean Booth | 6m×3.5m ISO Class 3 (Particular Size 0.1μm) |

with nano-level precision polishing.

and production from single units to mass production.

Related page

- What is a chuck table? | Basic information and description of types, Processing accuracy at TDC

- Copper polishing

- Precision processing of crystal materials and glasses

- Polishing after thermal spraying

- Mirror Finishing/Mirror Polishing

- Sapphire polishing

- Polishing of plastic/acrylic resin

- Polishing after surface treatment/coating

- Precision parts processing

- KEYENCE measuring instruments used at TDC

- Precision Cleaning Service

- Symbol used for polishing

- SUS (stainless steel) material test piece/specimen

- Polishing of SiC

- Polishing of titanium

- Cylindrical grinding/cylindrical polishing

- Mold Processing

- Precision machining of ceramics

- ガラスエポキシ(ガラエポ)の精密加工

- Type of polishing process

- 真鍮の精密加工・研磨加工

- What is the accuracy that can be achieved by polishing?

- Principle of polishing process

- Semiconductor Wafer Cleaning

- Ultrapure Water Cleaning

- Bruker “Dimension Icon”

- Talysurf

- Talyrond

- Dial gauge

- Precision processing of resin and plastic

- Polishing process for Resin

- Precision Measurement

- Mirror-finishing for aluminum

- Mirror-finishing for plastic/acrylic resin

- Wafer Cleaning Equipment

- Mirror Polishing for Stainless Steel/SUS304

- Metal polishing process

- Mitutoyo measuring instrument used in TDC

- Polishing of Aluminum

- Optical Nano Gauge

- TDC’s precision machining

- 微細加工とは? | 基礎知識と加工方法の解説

- What is CMP

- What is polishing?

- About Lapping and Polishing