What is cutting

Here’s some basic knowledge about cutting and TDC (TDC) cutting examples.

What is cutting

Cutting is a one of methods to machine metals.

There are three main types: turning, milling, and drilling, and the equipment and machines used differ depending on the shape and size of the target product. Also, when performing each cutting operation, select whether it is a “single-blade tool” with one blade or a “multi-blade tool” with multiple blades.

In addition to being able to obtain high precision in cutting as well as polishing, there is also the aspect that it is environmentally friendly, such as chips that are no longer needed due to cutting can be recycled.

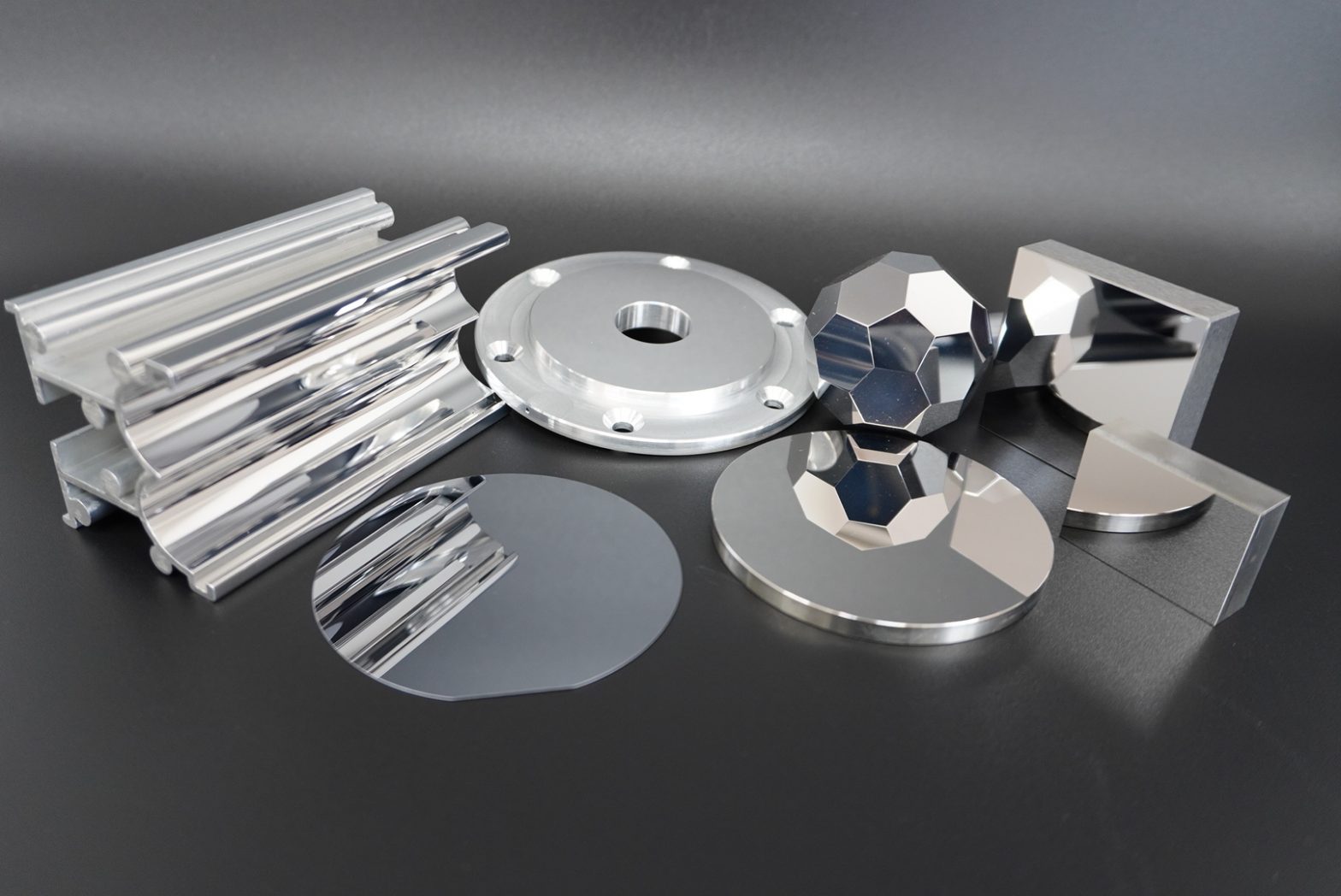

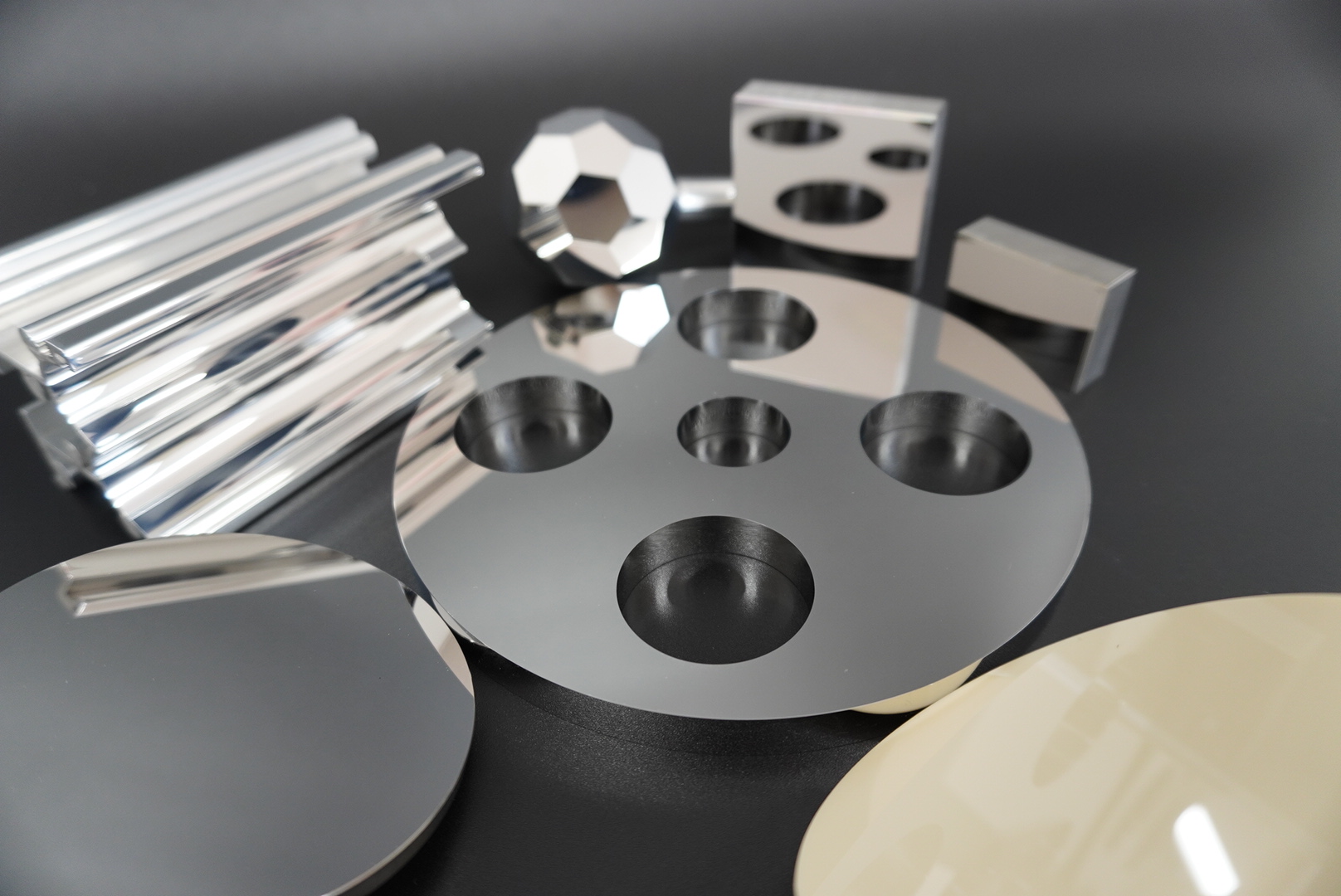

TDC’s cutting processing

Accumulating our unique know-how, we have established the world-class polishing processing techniques in the field of ultra-precise lapping/polishing. TDC offers one-stop shopping for complex parts and components requiring machining, grinding, lapping, and polishing applied to various shapes and materials.

- Flexibility to work with our customers from prototypes and R&D to full production.

- Offering one-stop shopping for all processing such as machining and shaping, lapping, polishing.

- Applying wide variety of materials from soft resin to hard sapphire.

How we do cutting

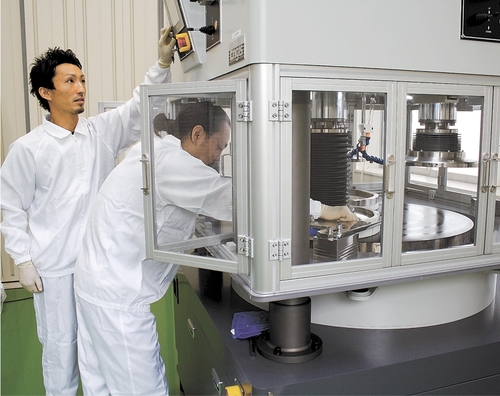

With a machine tool called a machining center that can perform combined machining, we can finish cutting out materials such as test pieces and substrates with high precision, as well as general cutting such as drilling and drilling.

In addition, TDC has a track record of cutting for 50 to 60 years as a post-process of die casting. High-precision cutting is possible because we have a lot of know-how and experience.

Materials

Compatible with a wide variety of materials by combining cutting and polishing and grinding

| Metals | Stainless Steel / Superalloy / Copper / Titanium / Aluminum / Molybdenum / Tungsten/ Nickel / Tantalum etc. |

| Ceramics | Al2O3 / ZrO2 / SiC / Si3N4 / SiO2, Also Coating and Plating are acceptable. |

| Crystalline Material | BK7/ Crystal/ PYREX/ Quartz / Si/ SiC /GaN/ Sapphire |

| Resin | Engineering Plastics / PEEK/ PMMA /PEFE |

Processing Achievement

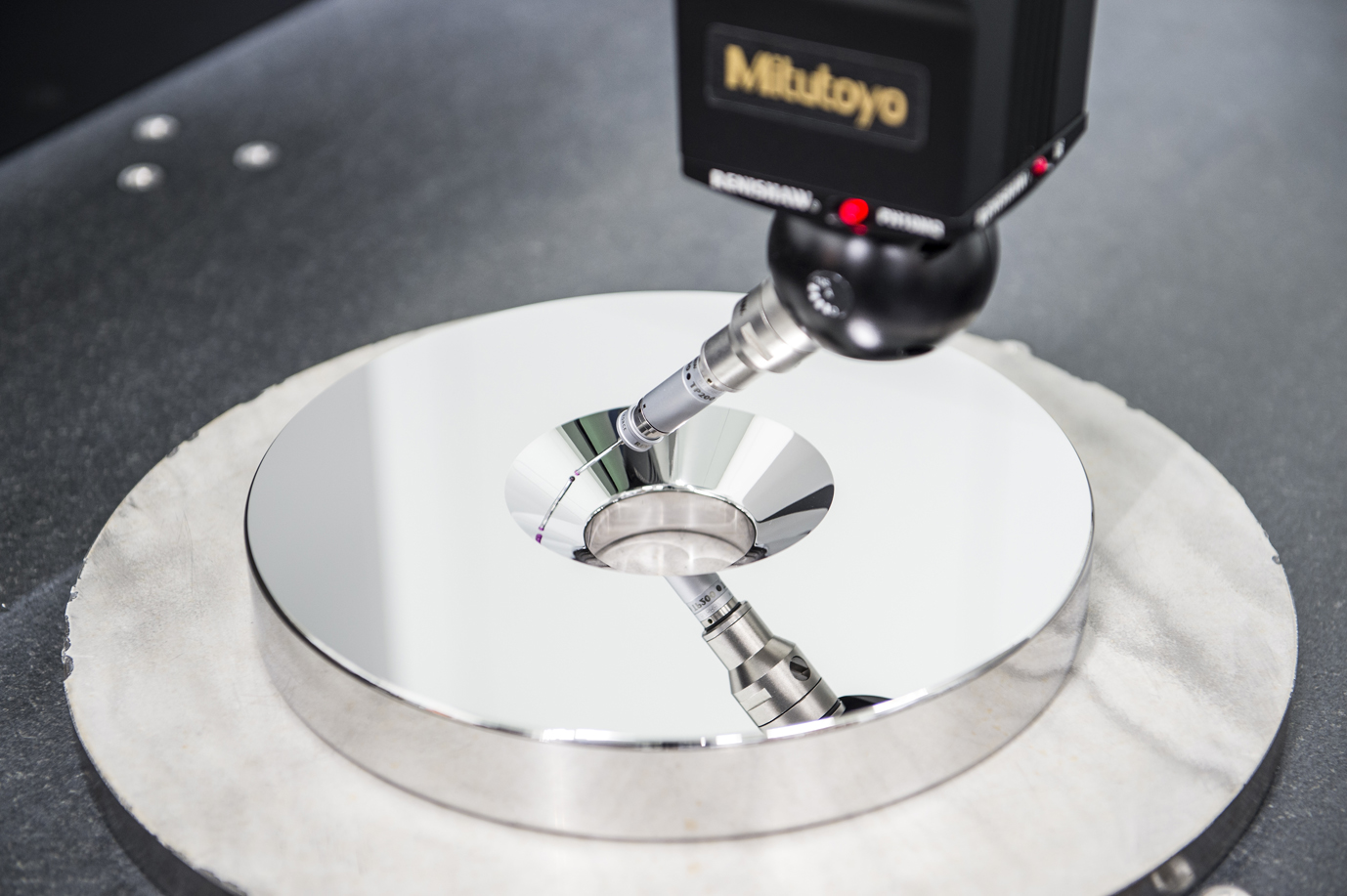

Processing accuracy that can be achieved by combined processing of cutting, grinding, and polishing

| Thickness Tolerance | ±0.1 um |

| Dimension Position Accuracy |

±0.5 um |

| Perpendicularity | 0.5 um |

| Parallelism | 0.1 um |

| Flatness | 0.1 um |

| Surface Roughness | Ra0.01 um |

| Straightness | 1 um |

Processing Facility

Processing accuracy that can be achieved by combined processing of cutting, grinding, and polishing

Production Capability

| Equipment | Size | Quantity |

| Machining Center | 400×200 | 2 |

| Milling Machine | 250×1,000 | 3 |

| Lathe | φ80 | 2 |

| Lathe | φ65 | 1 |

| Lathe | φ100 | 1 |

| Lathe | φ180 | 1 |

and ohters.

Flat surface Grinding Machine

(MAX 1500mm)

| Equipment | Size | Quantity |

| Nagase | 1500×600 | 1 |

| Okamoto | 600×300 | 1 |

| Okamoto | 600×400 | 1 |

| Okamoto | 600×500 | 1 |

| Sanshin’s Rotary Polishing | φ750 | 2 |

Slicing Machine

| Equipment | Size | Quantity |

| Okamoto 420 | 200×350 | 3 |

| Okamoto 3G | 200×350 | 2 |

with nano-level precision polishing.

and production from single units to mass production.

Cutting method / principle

Typical cutting methods include” lathe “where a tool is applied to a rotated product,” milling “which is performed by fixing the product and rotating the tool and moving the cutting tool, and fixed product. There are three types of “drilling” to make holes in.

A lathe is used for “turning” and is used to machine round objects. On the other hand, in “milling”, a milling machine, a machine center, etc. are adopted, and it is mainly used for square processing. In addition, a drilling machine or milling machine is used for drilling.

It is necessary to use each machine tool for each process and each processing purpose. However, if we use machining center, we can offer these combined machining and cutting can be done automatically using a program, so it is possible to perform cutting that is difficult to do efficiently and manually.

Types of cutting

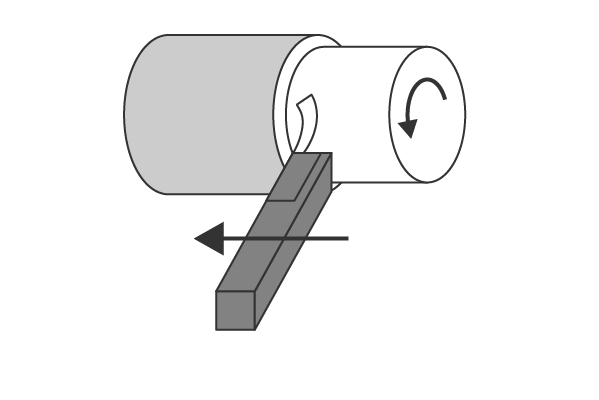

Turning

Turning is a method of rotating (turning) the target product and applying a cutting tool to turn it. We use a “lathe” to fix and rotate the product and a tool called a “bite”. There are various types of tools such as high-speed tool steel tools, carbide brazing tools, and throw-away tools, which are used according to the purpose of machining. There are also four processing methods: “outer diameter processing”, “thread cutting”, “inner diameter processing”, and “parting off”.

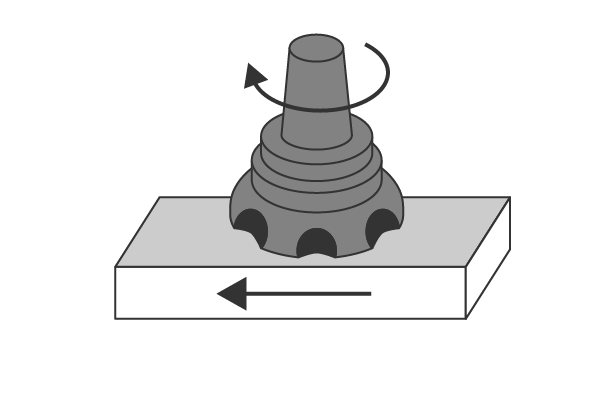

Milling

Milling is a method of rotating the blade, which is the opposite of turning. With the product fixed, we will cut using a rotating blade.

A special machine called a milling machine or milling machine is used for processing. Use different tools according to the purpose, such as “front milling cutter” for flat surface machining, “flat milling cutter” for T-groove machining and dovetail machining, and “end mill” for step / side machining / keyway machining.

The target products are plate-shaped products, box-shaped products, square products, and other processing methods that are often used for squares.

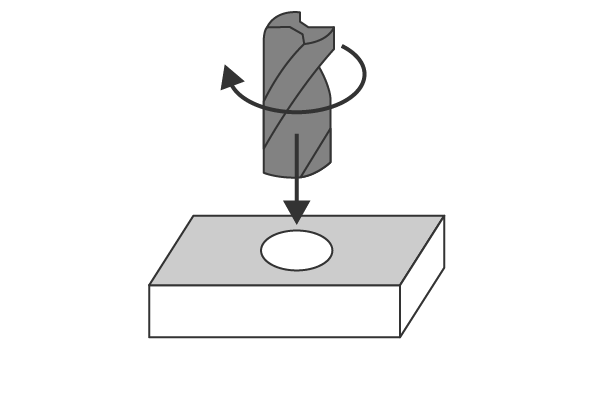

Drilling

Drilling refers to the process of drilling holes in a fixed product by rotating a tool.

The tools used are a drilling machine for fixing the product, a drill for making a hole, and a reamer for shaping the hole.In addition to this, there is cutting oil (or engine oil) that smooths and cools the machined parts during work.

Drilling is used for bolt holes and shaft holders, and taps can be used instead of drills to drill screw holes.

External processing

External processing generally refers to a processing method that performs cutting by shaving the outside.

Face milling and side milling on a milling machine, outer diameter milling of the side surface of a cylindrical material, and end face milling of the end face of a material are also included in external shape processing.

internal processing

In contrast to external machining, cutting that processes the inside of the material is called internal machining.

Most of the machining is inside the hole, but “boring”, which widens the hole in the drilling process, also belongs to internal machining.

threading

Thread processing is a cutting technology that enables the processing of male and female threads.

punching

Stamping is a processing method in which after processing the outer and inner shapes of a sheet material to be processed, the outermost periphery is processed and removed.

Unlike press processing, which punches out at once, it has the great advantage of being able to create steps.

On the other hand, there is a disadvantage that the processing time is significantly longer and the manufacturing cost is higher.

Scraping

Scraping is a processing method that grinds a perfect plane by scraping the workpiece.

Unlike grinding, which cuts the surface with a machine using a whetstone, it is a cutting method that requires advanced technology because it is done manually using a tool similar to a chisel.

This method is often used for workpieces that require precision machining, such as base plates and machine tool tables, because it creates a flat surface by scraping the surface of the metal at a level of 1 um.

Machine used for cutting

There are two main types of cutting methods.

“Turning” in which a tool is applied to a rotated material, and “Turning” in which a tool is rotated while the material is fixed.

A machine tool called a “lathe” is used for turning, and a “milling machine” is mainly used for milling.

Lathe

A lathe is a typical machine tool used for turning. There are “NC/CNC lathes” that can process using programs using numerical control devices, and “vertical lathes” that can process heavy materials more stably.

With a general-purpose lathe, pre-processing setup is easy, so additional work can be performed smoothly, and since measurement and cutting can be performed alternately, it is easier to check the accuracy during processing than with a program-driven NC/CNC lathe. , has the advantage of being easy to adjust the accuracy.

However, since variations in operator skill and product accuracy tend to occur, it is common to use NC/CNC lathes when performing mass processing while maintaining constant quality.

Milling Mchine

A milling machine is a machine tool that performs milling with a rotating tool, and is often used for processing square objects.

The most commonly used general-purpose milling cutter is the “vertical milling machine,” which is suitable for processing three-dimensional materials. In addition, there are “horizontal milling machines” whose main axis is horizontal to the ground, and “universal milling machines” that can perform complex machining such as gear and drilling.

As with lathes, general-purpose milling machines are easy to set up in advance, but when machining many surfaces, it is necessary to change the setup each time. The disadvantage is that it takes time.

Advantage of cutting

“Cutting is not limited by the thickness of the material like sheet metal and stamping. Any shape can be processed according to the purpose as long as the product to be processed fits in the machine used. In milling and drilling, the machining speed of the spindle and the compatibility between the blade and the material can be adjusted according to the machining target.

The advantage is that it can process a wide variety of materials such as resin as well as metals such as iron and stainless steel.

What we can do with cutting

If it is a lathe machining specialized for round shape machining, it can handle precision machining of bolts and shafts.

On the other hand, in the case of milling, the milling machine can be adjusted mainly according to the square material and material, so it is possible to process not only grooves and sides but also complicated shapes. Also, in drilling, it is said to be suitable for machining screws, bolts, shaft holders, etc.

Items that cannot be machined

On the other hand, materials that cannot be machined are brittle and fragile materials such as ceramics, and materials that are sticky and elastic such as rubber.

Cutting can process a wide range of materials, such as other metal materials, wood, and some resin materials, but it is necessary to be careful because there are cases where the cost is high depending on the material.

Basically, it is better to think that the cost will increase because it is difficult to cut hard objects.

Noted

In general manufacturing company, there are restrictions on the size and field of cutting that can be handled, so caution is required when making a request.

In order to meet the needs of all customers, TDC does not limit itself to cutting, but also supports precision machining with various technologies and processing methods regardless of material and shape, so please contact us once.

Cutting service in TDC

“Cutting depends on the shape and size of the object to be machined, and the machine used and the method used.

Therefore, if you are not familiar with the construction method, you may not be able to perform the optimum processing for the product.TDC Co., Ltd. has accumulated unique technological development and know-how in various processing, and can handle all shapes. We can handle all the precision processing that our customers demand, so please feel free to contact us.

with nano-level precision polishing.

and production from single units to mass production.

Related page