Quality Assurance

We assure our precision quality by rating our products with the world’s highest level of measurement environment.

In precision manufacturing, it is essential to guarantee its quality by applying reliable inspection tools.

TDC guarantees all accuracy such as Roughness, Flatness, Parallelism, and Tolerance by inspecting all products during the process.

All data will be sent with the item for Quality assurance.

TDC`s Quality Assurance

We pack the product and measurement data carefully, together with our sincerity, hoping they will meet the needs of all our customers.

We will continue to improve our quality in every aspect, not only in accuracy of the products and in evaluation technology, but also in careful and prompt customer service, price and delivery time.

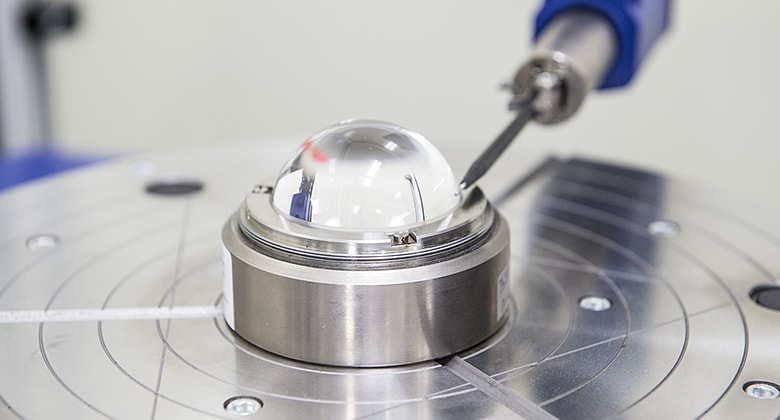

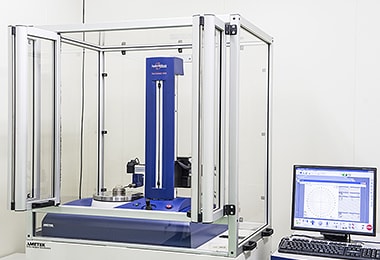

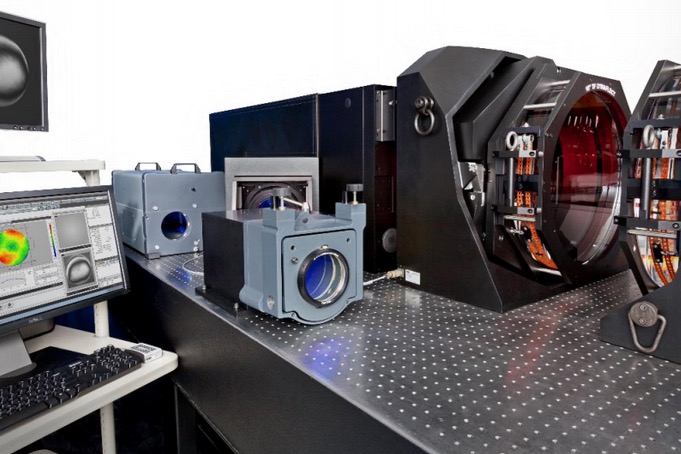

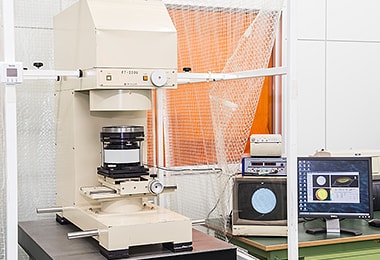

Wide variety of equipment for quality assurance

※ TDC’s measuring instrument is set in 3 rooms which are temperature-controlled (21 +/- 1 degrees and 21 +/- 2 degrees). [Celsius]

Taylor Hobson

Taylor Hobson Talysurf CCI SunStar

Taylor Hobson Talylondl 395

| Talysurf CCI SunStar |

Non-contact Optical 3D Profiler |

| Talylondl 395 | High Accuracy Gage |

| Talyvel5 | High Accuracy Gage |

Bruker

| Dimension Icon | AFM |

ZYGO

| new view 9000 | Optical surface profiler |

| 18inch Large Aperture System | Laser Interferometer Verifire MST Reflectivity:4% – 99% Measured Objects:flat, back, transmitted wavefront error, homogeneity of refractive index |

Mizojiri

| Laser Interferometer FT-200U FT-100U FT-200S |

Flatness non-contact inspection |

KEYENCE

| GT2-H12KL | High-Accuracy Digital Contact Sensor |

| VHX-6000 | Digital Microscope |

| LM-1000 | High Accuracy Image Dimension Measurement System |

Mitutoyo

Mitutoyo Ultra High Accuracy CNC CMM LEGEX9106

Mitutoyo Ultra High Accuracy CNC CMM CRYSTA-Apex

| Ultra-High Accuracy CNC CMM LEGEX9106 |

High Accuracy High-speed driving 3D- co-ordinate Measuring Machines X900*Y1000*Z600 |

| Ultra High Accuracy CNC CMM CRYSTA-Apex S7106 |

High Accuracy 3D- co-ordinate Measuring Machines X705*Y1005*Z605 |

| Ultra High Accuracy CNC CMM CRYSTA-Apex S544 |

High Accuracy 3D- co-ordinate Measuring Machines X505*Y405*Z405 |

| MF-UB2010D | Measuring Microscope (200*100, Z=150) |

| Surftest SV400, SJ400 | Contact Surface Roughness Tester |

| Others | Micrometer, Vernier Caliper, Gauge Block |

Hamamatsu photonics

| Optical nano gauge C13027 | thickness measurement system |

Inspection Quantity

TDC uses reliable measurement equipment’s and encloses inspection data at the time of delivery.

Parallelism・Flatness・Perpendicularity・Size・Roundness・ Cylindricity

| Production Quantity | Inspection Quantity |

| less than 10 pcs | 20% |

| 10 pcs or more | 10% |

| 100 pcs or more | 5% |

※ We basically measure all products with <±0.002mm.

Surface Roughness

one sample for each batch

If you have any questions or requests for measurement date, feel free to contact us.

with nano-level precision polishing.

and production from single units to mass production.