Solutions for precision machining in aerospace

Introduction of the technology for precision machining in aerospace and aerospace field

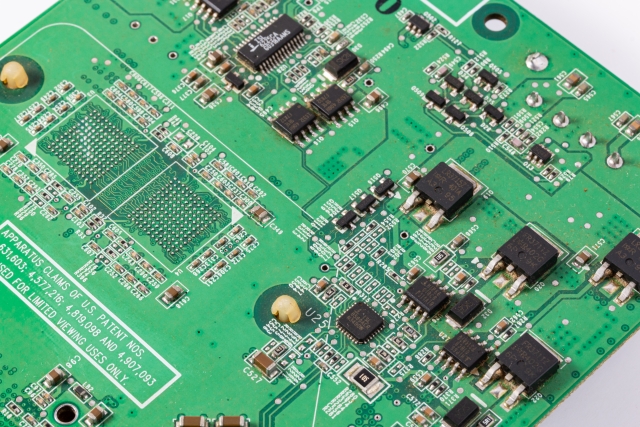

Aviation equipment related parts and precision processing

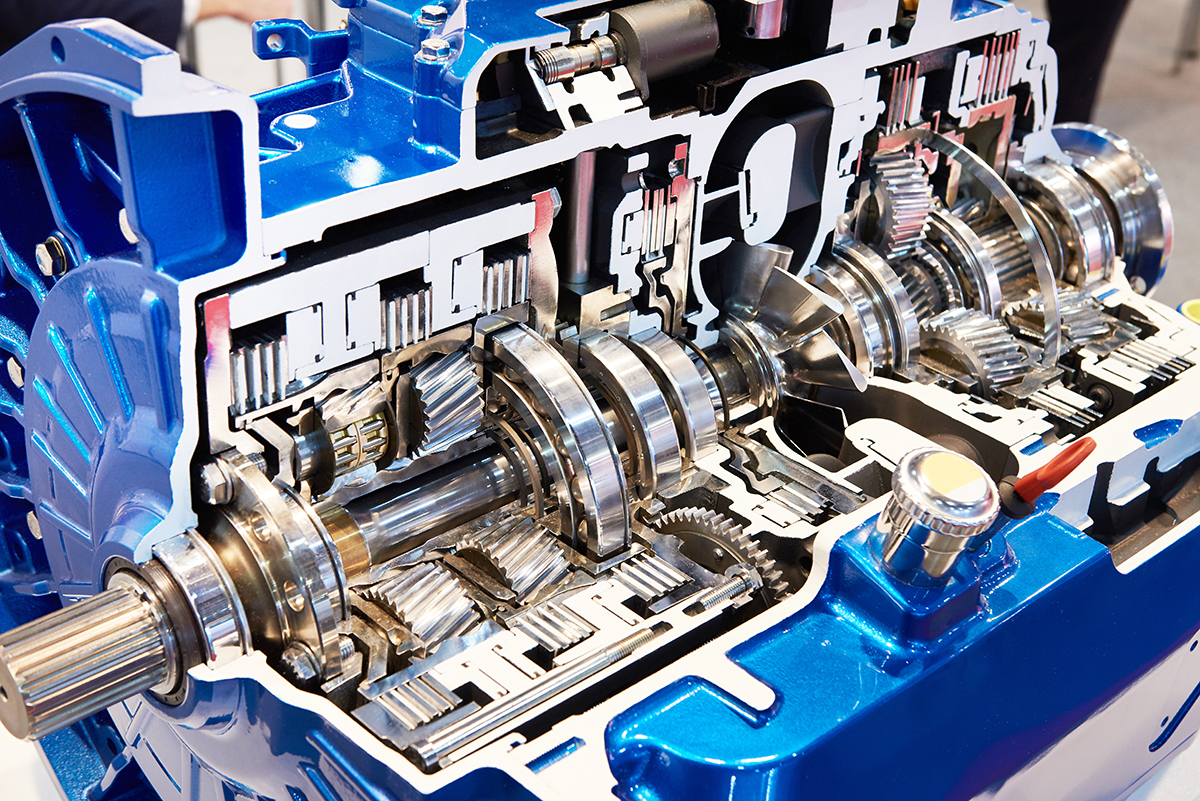

Aircraft are undergoing improvements such as structural strengthening and weight reduction year by year.

For that purpose, technology that can process so-called “difficult-to-cut materials” such as titanium alloys, Inconel, and Hastelloy is indispensable.

These are the materials used for aircraft-related parts, including aircraft body parts, jet engine parts, and special jigs, and their shapes are complicated.

In particular, knowledge of cutting conditions for materials, tool selection, etc. and high-precision machining technology on the order of microns are required.

What are aviation equipment parts?

In the aviation field, jet engine parts and special jigs.

In the space field, parts used for rockets, special jigs, space station parts, etc.

These are parts that require ultra-high precision and low cost in addition to weight reduction. In the aviation field, jet aircraft are constantly being improved, such as miniaturization and fuel reduction, so they are required to be cutting-edge and of high quality.

There are cases where quality certification for aircraft, which is difficult to obtain, is required.

Solutions for precision machining in aerospace

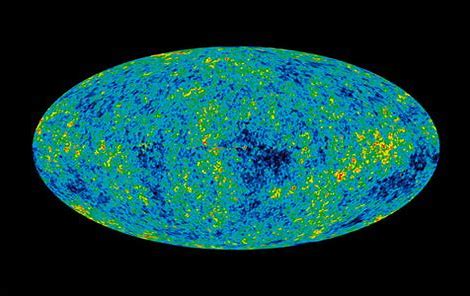

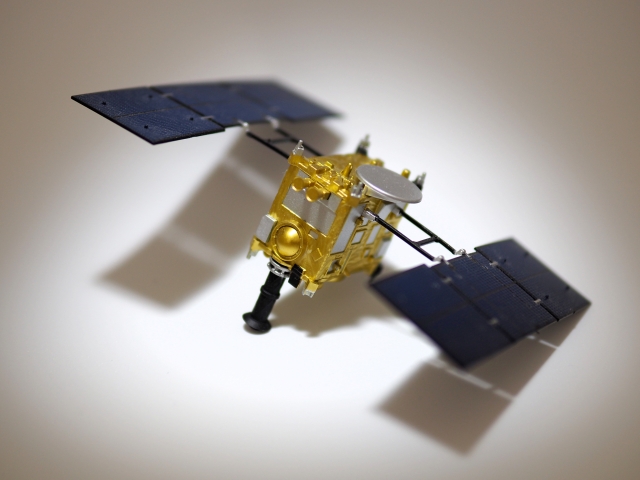

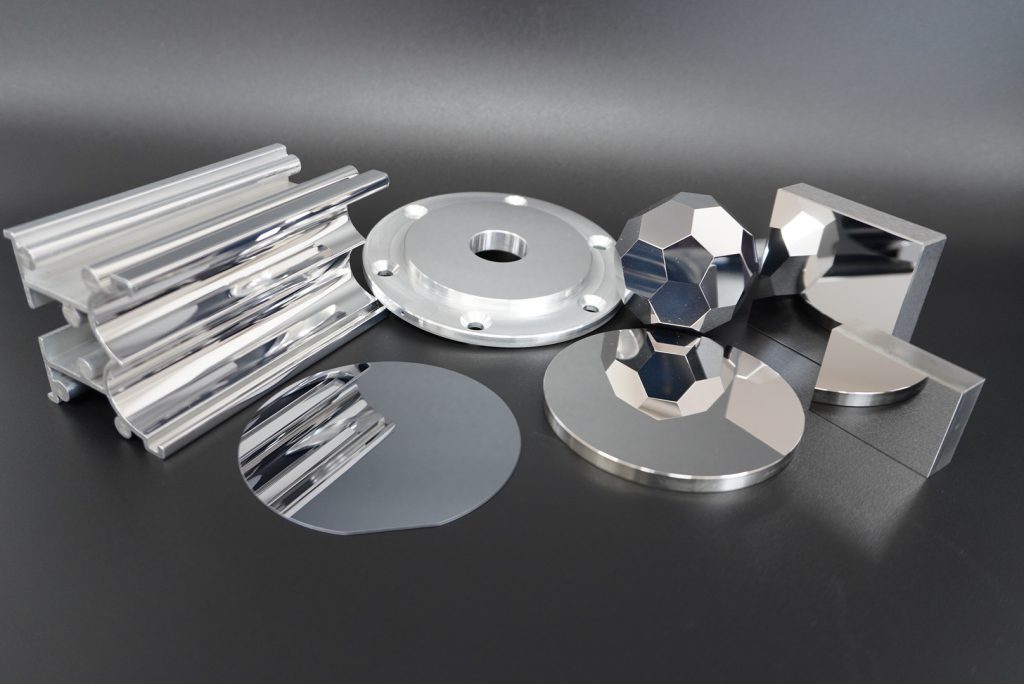

TDC’s ultra-precision process technology is also playing an important role in research and development in the space field.

We have many achievements such as manufacturing ultra-precision bearing balls for the ultimate rocket engine research, manufacturing reflective mirrors for special telescopes used in gravity wave observation facilities, and improving the surface condition of the inner surface of the Hayabusa2 sample collection container.

Commitment to aerospace solutions

We can manufacture parts for basic research, experiments, and analysis, which are the basis of technological capabilities in the aerospace field, and can handle a wide variety of products from test pieces to

prototypes.

In addition, it is possible to process into a wide variety of shapes and materials that cannot be realized by other companies, and by owning the world’s highest level of high-precision measuring machine, we have

established a quality assurance system that supports ultra-high precision.

If you have any issues regarding aerospace solutions, please feel free to contact TDC.

with nano-level precision polishing.

and production from single units to mass production.

Related page