What is Surface Roughness

Introducing the best values of TDC mirror finishing and basic knowledge about surface roughness.

《Click here for the actual values of surface roughness.》

・Metal

・Resin

・Ceramics

・Glass

・Semiconductor

・Coating

・Others

What is surface roughness?

The surface of the workpiece has complex undulations with continuous peaks and valleys of different heights, depths, and intervals. Those with large undulations are called “flatness”, and those with small undulations are called “surface roughness”.

Surface roughness affect not only the precision of processed products, but also the gloss and texture of the surface, so they are one of the factors that influence the product image and product brand.

Especially in the field of ultra-precision machining, not only machining accuracy but high surface treatment ability is required, so the surface roughness is extremely important.

Measurement Methods

There are basically two types of Measurement Methods for surface roughness; one is contact type that uses a stylus and non-contact type that uses a laser or light.

Contact measurement method

A method of measuring the surface condition of a part by bringing the tip of a stylus into contact with the object to be measured. Detects vertical changes and displacements of the stylus and records the surface roughness.

In addition to being able to obtain a clear shape waveform because it is touched directly, it has the advantage of being able to measure long distances.

The standard for evaluating and analyzing surface roughness is “JIS B 0601 (ISO4287)”.

Non-contact measurement method

The “non-contact type” is a method of measuring surface roughness using light or laser instead of a stylus. There are multiple measurement methods for non-contact type due to the difference in the principle of measurement method. In addition to surface roughness, there are many that measure the shape, and by converting the measurement results into three-dimensional data, various measurements such as “height”, “flatness”, and “plane profile” can be performed.

The non-contact type has the major advantage of being able to solve the problems of the contact type, such as wear of the stylus, indentation on the object, and limitation of the minimum measured value. Is also a feature.

The standard for evaluating and analyzing surface roughness is “ISO 25178”.

Surface Roughness Parameters

Surface roughness use different calculation formulas (parameters) depending on the measurement content.

Typical parameters for surface roughness are as follows.

Ra

It is a parameter in the height direction called “arithmetic mean roughness”, and the arithmetic mean roughness when the contour curve is a roughness curve is called “Ra”.

A part of the roughness curve is used as the reference length, and the unevenness of that section is expressed as an average value.

Since the average value is used, it is not easily affected by one scratch, and it is a parameter that can obtain stable results when evaluating surface roughness.

It is written as Sa in “ISO 25178”.

Rz

It is a parameter in the height direction called “maximum height”.

A part of the roughness curve is used as the reference length, and it is calculated by the sum value of the highest part and the deepest part in the section.

It is possible to check the presence or absence of protruding scratches, and together with Ra, it is one of the indicators of quality stability.

In “ISO 25178”, it is written as Sz.

Rq(Rms)

This is a parameter called “root mean square roughness”.

There are always peaks and valleys in the surface roughness of an object, and the average roughness on the peak side (height direction) is calculated.

In “ISO 25178”, it is written as Sq.

| Standard | ISO 25178 | JIS B 0601-2001 (ISO 13565-1) |

| Maximum profile peak height | Sp | Rp |

| Maximum profile valley depth | Sv | Rv |

| Maximum height of profile | Sz | Rz |

| Arithmetical mean height | Sa | Ra |

| Root mean square deviation | Sq | Rq |

| Skewness | Ssk | Rsk |

| Kurtosis | Sku | Rku |

| Spatial Parameters | Sal、Str、Std | – |

| Hybrid Parameters | Sdq、Sdr | RΔq |

Necessity of smooth surface

Measurement of surface roughness is important not only for controlling the finished state and appearance quality of processing, but for controlling product life and mechanical efficiency.

By measuring surface roughness such as Ra / Rz / Rq, you can mainly know the following functionality.

・ Appearance

Appearance such as scattered light reflection and glare.

・ Air density

The roughness between the contact surfaces has an effect on leakage from gaps.

・ Texture

・ Friction force

・ Adhesiveness

Optimal coating for packaging and adhesives. Coating adhesion.

・ Print quality

Paper texture and ink ride.

・ Noise / vibration

Vibration of the surface that rolls at high speed.

・ Easy to peel off

Easy to peel off the mold and molded product.

・ Optical performance

Disturbance or scattering of refraction of luminous flux.

·Abrasion resistance

Ease of scraping due to load concentration during sliding.

・ Fatigue fracture / strength

Strength against fatigue fracture due to stress concentration.

・ Joint surface rigidity

Increased deflection due to load concentration on the joint surface.

TDC’s surface roughness results

It is a list of surface roughness results of each material that has been mirror-polished by TDC.

We would gladly handle the materials that are not on this list.

Please feel free to contact us!

with nano-level precision polishing.

and production from single units to mass production.

Metal

| 材質 | Ra (nm) | Rz (nm) | Sa(nm) | Sz(nm) |

| FC250 | 2.179 | 11.58 | – | – |

| Fe | 0.529 | 3.357 | – | – |

| Fe-Ni36 | 0.881 | 4.82 | – | – |

| SPCC | 1.01 | 5.457 | – | – |

| DC53 | 0.794 | 7.267 | – | – |

| S35C | 2.503 | 13.42 | – | – |

| S45C | 0.608 | 3.727 | – | – |

| S50C | 0.518 | 3.543 | – | – |

| SK-3 | 0.586 | 3.76 | – | – |

| SK-4 | 0.769 | 4.74 | – | – |

| SKD11 | 0.641 | 4.5 | – | – |

| SKD61 | 0.608 | 3.017 | – | – |

| SUS301 | 0.419 | 2.467 | – | – |

| SUS303 | 0.342 | 2.109 | – | – |

| SUS304 | 0.308 | 1.95 | 1.84 | 38 |

| SUS310 | 0.494 | 3.513 | – | – |

| SUS316 | 0.37 | 2.3 | 0.5 | 3.1 |

| SUS316L | 0.534 | 3.653 | – | – |

| SUS321 | 0.498 | 2.653 | – | – |

| SUS329J4L | 4.707 | 23.963 | – | – |

| SUS403 | 1.554 | 8.703 | – | – |

| SUS410 | 0.673 | 4.677 | – | – |

| SUS420J2 | 0.363 | 2.427 | – | – |

| SUS430 | 0.221 | 1.393 | – | – |

| SUS440C | 0.381 | 2.76 | – | – |

| SUS444 | 0.64 | 3.96 | – | – |

| SUS447J1 | 1.067 | 7.483 | – | – |

| SUS630 | 0.451 | 3.007 | – | – |

| SUS836 | 0.503 | 3.547 | – | – |

| S-STAR | 0.402 | 2.2 | – | – |

| S-STAR(HRC52) | 0.537 | 3.74 | – | – |

| S-STAR(HRC33) | 0.646 | 3.777 | – | – |

| D-STAR | 0.664 | 3.93 | – | – |

| NAK55 | 0.651 | 4.677 | – | – |

| NAK80 | 0.33 | 3.212 | – | – |

| HPM31 | 0.623 | 3.263 | – | – |

| HPM31(HRC58~62) | 0.593 | 4.097 | – | – |

| HPM38 | 0.311 | 1.993 | – | – |

| HPM38(HRC52~54) | 0.403 | 2.39 | – | – |

| HPM38(HRC50) | 0.591 | 4.117 | – | – |

| HPM38(HRC52) | 0.35 | 2.07 | – | – |

| CENA1 | 0.442 | 3.19 | – | – |

| CENA-V | 0.551 | 3.163 | – | – |

| MAT21 | 0.546 | 2.817 | – | – |

| HAP10 | 1.364 | 7.987 | – | – |

| HAP10(HRC62~64) | 1.421 | 9.663 | – | – |

| HAP40(HRC64~66) | 1.39 | 8.14 | – | – |

| M333 | 0.471 | 3.18 | – | – |

| STAVAX | 0.33 | 2.13 | – | – |

| ELMAX | 0.9 | 5.83 | – | – |

| POLMAX | 0.528 | 4.073 | – | – |

| Pure Cu | 0.219 | 1.213 | 0.674 | 5 |

| C1011 | 0.48 | 2.76 | – | – |

| C1020 | 0.303 | 1.61 | – | – |

| C2801 | 6.825 | 34.043 | – | – |

| C3604BD | 3.066 | 24.623 | – | – |

| Phosphor bronz | 0.712 | 3.57 | – | – |

| BeCu | 0.88 | 5.05 | – | – |

| Pure Al | 0.23 | 1.6 | 0.8 | 4.8 |

| A1050 | 0.815 | 5.043 | – | – |

| A1070 | 0.957 | 5.217 | – | – |

| A1100 | 0.87 | 4.85 | – | – |

| A2219 | 0.962 | 6.343 | – | – |

| A5052 | 0.404 | 2.24 | 0.841 | 4.2 |

| A5056 | 1.265 | 6.55 | – | – |

| A6061 | 0.627 | 4.287 | – | – |

| A7075 | 1.056 | 6.287 | – | – |

| Ni (Polycrystal) | 0.376 | 2.43 | 3.5 | 35 |

| Ni (Singlecrystal) | 0.864 | 5.75 | – | – |

| NiTi | 0.628 | 3.377 | – | – |

| Ni718 | 0.566 | 3.72 | – | – |

| Ni720 | 1.502 | 9.383 | – | – |

| NiCo | 0.488 | 3.527 | – | – |

| NiFe | 12 | 169 | – | – |

| Pure Ti | 0.38 | 2.5 | – | – |

| 64Ti | 0.328 | 1.81 | – | – |

| βTi | 0.349 | 2.18 | – | – |

| TB340C | 0.868 | 6.973 | – | – |

| PK | 1.57 | 9.36 | – | – |

| SUJ2 | 0.527 | 3.45 | – | – |

| SKS3 | 0.943 | 5.58 | – | – |

| SCM415 | 0.604 | 3.567 | – | – |

| SCM420 | 0.61 | 3.87 | – | – |

| SCM420H | 0.898 | 5.247 | – | – |

| SCM435 | 2.324 | 14.103 | – | – |

| SCM440 | 1.152 | 5.977 | – | – |

| SCr15 | 3.337 | 19.13 | – | – |

| SCr20 | 0.723 | 4.963 | – | – |

| SCr420 | 1.845 | 10.883 | – | – |

| SNCM20 | 1.152 | 6.147 | – | – |

| SNCM439 | 0.596 | 3.977 | – | – |

| SACM645 | 0.628 | 3.977 | – | – |

| SNMN432 | 0.608 | 3.857 | – | – |

| YSM | 0.663 | 4.192 | – | – |

| SKH51 | 0.47 | 3.4 | – | – |

| SKH55 | 3.08 | 23.35 | – | – |

| SKH57 | 3 | 18 | – | – |

| Palladium | 0.739 | 5.043 | – | – |

| Vanadium | 1.1 | 6.5 | – | – |

| Niobium | 0.495 | 3.33 | – | – |

| Rhodium | 0.545 | 3.577 | – | – |

| Inconel® | 0.417 | 2.623 | – | – |

| HASTELLOY | 0.421 | 2.597 | 3 | 34.6 |

| 42 Alloy | 0.514 | 3.65 | – | – |

| Ag | 0.864 | 5.49 | – | – |

| Au | 1.582 | 10.347 | – | – |

| Pt | 0.586 | 4.237 | – | – |

| Co | 0.807 | 5.3 | – | – |

| CoCr | 47 | 470 | – | – |

| CoNiCrMo | 1.803 | 9.063 | – | – |

| COBARION | 0.423 | 2.493 | – | – |

| Kovar | 0.43 | 3.053 | – | – |

| Stellite® | 4.564 | 24.71 | – | – |

| Ge | 0.66 | 4.48 | – | – |

| Mg Alloy | 3.63 | 24.1 | – | – |

| Sn | 1.305 | 8.9 | – | – |

| Zn | 0.91 | 5.827 | – | – |

| Metalic Glass | 0.28 | 1.837 | – | – |

| MA22 | 0.473 | 2.81 | – | – |

| Cr | 0.31 | 2.1 | – | – |

| Te | 3.976 | 23.253 | – | – |

| 80W-20Cu | 8.3 | 47.2 | – | – |

| Ta | 0.25 | 1.87 | – | – |

| Mo | 0.467 | 3.72 | – | – |

| W | 0.455 | 2.833 | – | – |

| W-Mo Alloy | 1.641 | 10.843 | – | – |

| W0.5%Mo | 1.413 | 9.717 | – | – |

| W1.9%Mo | 1.625 | 11.077 | – | – |

| W25%Mo | 1.082 | 6.717 | – | – |

| W50%Mo | 2.177 | 12.047 | – | – |

| W56%Mo | 1.788 | 11.007 | – | – |

| Invar | 0.711 | 3.74 | 0.8 | 10.5 |

| Super Invar | 0.405 | 2.367 | – | – |

| Hf | 0.751 | 4.48 | – | – |

| Cemented Carbide | 0.375 | 2.308 | – | – |

| SPRON | 0.26 | 1.101 | – | – |

| ELGILOY | 0.644 | – | – | – |

| NdFeB | 2.889 | 63.127 | – | – |

| PD613 | 0.47 | 3.44 | – | – |

| BiSbTe | 4.162 | 72.26 | – | – |

| VANADIS60 | 1.315 | 8.373 | – | – |

| VANADIS23(HRC63~65) | 1.655 | 12.073 | – | – |

| Nimowal | 0.85 | 4.83 | – | – |

| LEX-ZERO | 0.746 | 4.307 | – | – |

| Cu-T Alloy | 3.2 | 18 | – | – |

| TW340 | 0.497 | 3.44 | – | – |

| Stenless Invar | 0.642 | 4.04 | – | – |

| ASP23 | 1.588 | 8.31 | – | – |

| ASP23(HRC63~65) | 1.422 | 10.747 | – | – |

| ASP30(HRC65~66) | 1.31 | 8.893 | – | – |

| YH75 | 5.96 | 31.197 | – | – |

| W-5Re Arroy | 1.155 | 6.047 | – | – |

| W-10Re Arroy | 3.242 | 14.103 | – | – |

| KN40 | 1.594 | 13.85 | – | – |

| ATM100 | 1.699 | 10.61 | – | – |

| AMS4928 | 26 | 161 | – | – |

| Pd | 0.854 | 5.037 | – | – |

| Brass | 3.579 | 14.407 | – | – |

| C-22 | 0.491 | 3.973 | – | – |

| K-M38 | 0.68 | 4.37 | – | – |

Resin

| Materila | Ra (nm) | Rz (nm) |

| Acrylic | 0.99 | 7.04 |

| ABS | 4.972 | 29.637 |

| COP | 2.317 | 19.9 |

| PTFE | 1.918 | 12.663 |

| PES4100G | 1.698 | 11.247 |

| PC | 3.7 | 28.72 |

| PEEK | 1.002 | 6.809 |

| PEEK450G | 1.785 | 10.807 |

| Vespel | 1.96 | 14.1 |

| Polyimide | 1.42 | 11.9 |

| polyester | 3.693 | 33.963 |

| PPS | 1.41 | 9.96 |

| PDMS | 1.191 | 9.177 |

| PP | 1.615 | 10.13 |

| ORGA | 1.937 | 12.487 |

| SUMI-EPOXY | 5.256 | 82.863 |

| Iupilon® | 3.852 | 57.597 |

| Polymer Monolith | 54 | 500 |

| Glass Epoxy | 1.736 | 17.81 |

| Epoxy | 2.137 | 12.59 |

| POM | 48.0 | 489.0 |

| ULTEM | 1.884 | 9.007 |

| Carbon included PTFE | 64 | 500 |

| AZP resin | 2.14 | 23.8 |

| PVDF | 43.38 | 334.46 |

| Meldin 7001 | 55 | 467 |

Ceramics

| Material | Ra (nm) | Rz (nm) | Sa(nm) | Sz(nm) |

| GDC | 1.176 | 7.823 | – | – |

| Alsima L | 1.922 | 28.927 | – | – |

| NEXCERA | 2.722 | 81.173 | – | – |

| SiC | 0.401 | 2.1 | 1.5 | 11.287 |

| CVD-SiC | 0.488 | 3.25 | – | – |

| Si3N4 | 0.507 | 4.32 | 0.8 | 5.7 |

| Barium Titanate | 0.549 | 1.816 | – | – |

| AIN | 0.733 | 5.073 | – | – |

| ZrO2 | 0.474 | 2.773 | – | – |

| Transparent Alumina | 0.8 | 6.5 | – | – |

| Carbon | 4.5 | 26.4 | – | – |

| G540S | 10.26 | 75.74 | – | – |

| 92% Al2O3 | 3.797 | 25.6 | – | – |

| 99.5% Al2O3 | 1.017 | 7.987 | – | – |

| 99.6% Al2O3 | 1.053 | 7.37 | – | – |

| 99.7% Al2O3 | 2.6 | – | – | – |

| Al2O3/ZrO2 | 7 | 39 | – | – |

| Sintered Alumina | 0.848 | 5.633 | – | – |

| Ferrite | 0.874 | 6.627 | – | – |

| Sialon | 7.908 | 208.59 | – | – |

| Glassy Carbon | 0.669 | 4.557 | – | – |

| CEPLA | 2.325 | 17.967 | – | – |

| Ruby | 0.724 | 5.107 | – | – |

| Black Al2O3-ZrO2 | 7.637 | 117.343 | – | – |

| Shapal® | 158.0 | 1159.0 | – | – |

| TiO2 | 0.884 | 10.42 | – | – |

| SS501 | 1.984 | 10.297 | – | – |

| Cordierite | 1.018 | 7.217 | – | – |

| Apatite | 1.289 | 29.673 | – | – |

| LLZT | 0.485 | 3.33 | – | – |

| Mg2SiSn | – | – | 0.8 | 4.4 |

| Si impregnated SiC | 2.567 | 17.71 | – | – |

| SiN | 0.649 | 4.527 | – | – |

| BZYb | 2.679 | 24.647 | – | – |

| BZCY | 2.931 | 25.943 | – | – |

| SiSiC(高比剛性セラミックス) | 35.3 | 480.42 | – | – |

Glass

| Material | Ra (nm) | Rz (nm) | Sa(nm) | Sz(nm) |

| Fused quartz | 0.295 | 2.047 | 0.63 | 4.4 |

| BK7 | 0.725 | 5.647 | – | – |

| TEMPAX Float® | 0.426 | 3.067 | – | – |

| Soda-Lime Glass | 0.73 | 5.4 | – | – |

| CLEARCERAM™-Z | 0.609 | 3.757 | – | – |

| Zerodur | 0.541 | 4.217 | – | – |

| borosilicate glass | 0.707 | 7.181 | – | – |

| Pyrex | 0.487 | 3.267 | – | – |

| crown glass | 0.46 | 3.14 | – | – |

Crystal (Semiconductor/Optics)

| Material | Ra (nm) | Rz (nm) | Sa(nm) | Sz(nm) |

| AISi | 0.775 | 6.17 | – | – |

| Si | 0.129 | 0.723 | – | – |

| Quartz | 0.6 | 4.41 | – | – |

| GAGG | 0.526 | 3.653 | – | – |

| Sapphire | 0.4 | 2.9 | 1.3 | 9.8 |

| LiNb03 | 0.366 | 2.313 | – | – |

| YIG | 0.442 | 3.007 | – | – |

| LiTa | 0.232 | 1.18 | – | – |

| YAG | 0.442 | 3.007 | – | – |

| Y3Al5O12 | 1.689 | 9.073 | – | – |

| GAN | 0.573 | 4.15 | – | – |

| SiC (Singlecrystal) | 0.07 | – | – | |

| PG | 16 | 240 | – | – |

| SiGe | 0.829 | 4.477 | – | – |

| CVD-SiC | 0.38 | 3.6 | – | – |

| Bi2Te3 | 4.335 | 29.93 | – | – |

| Spinel | 0.87 | 3.6 | – | – |

| CTGS (Singlecrystal) | 0.301 | 2.137 | – | – |

| Ge | 0.295 | 2 | – | – |

| Diamond | 0.331 | 1.897 | – | – |

| Mg2SiSh | 1.82 | 10 | – | – |

Coating

| Material | Ra (nm) | Rz (nm) |

| Cr Plating | 0.29 | 1.75 |

| Ni-P | 0.263 | 1.93 |

| PFA | 2.152 | 14.597 |

| Cu | 0.299 | 1.86 |

| Alumite | 1.154 | 12.947 |

| Al | 127.0 | 1218.0 |

| PTFE | 26.0 | 364.0 |

| Al2O3 Thermal Spraying | 0.638 | 75.453 |

| TiC | 1.01 | 4.91 |

| FEP | 6.311 | 60.66 |

| PBI | 6.46 | 70.93 |

| YSZ Thermal Spraying | 1.243 | 10.667 |

Others

| Material | Ra (nm) | Rz (nm) |

| Stone Plate Thermal Spraying | 267.0 | 2060.0 |

| Pebble | 171.0 | 1336.0 |

| Lapis Lazuli | 13.814 | 307.02 |

| PCD | 5.65 | 159.7 |

| Arkansas stone | 10.853 | 217.933 |

After mirror finishing, we will use the in-house surface roughness measuring machine and ship the data together.

We use AFM (Bruker), new view 9000 (ZYGO), Tali Surf CCI SunStar (Taylor Hobson), and Surf Test (Mitutoyo) according to the application and request.

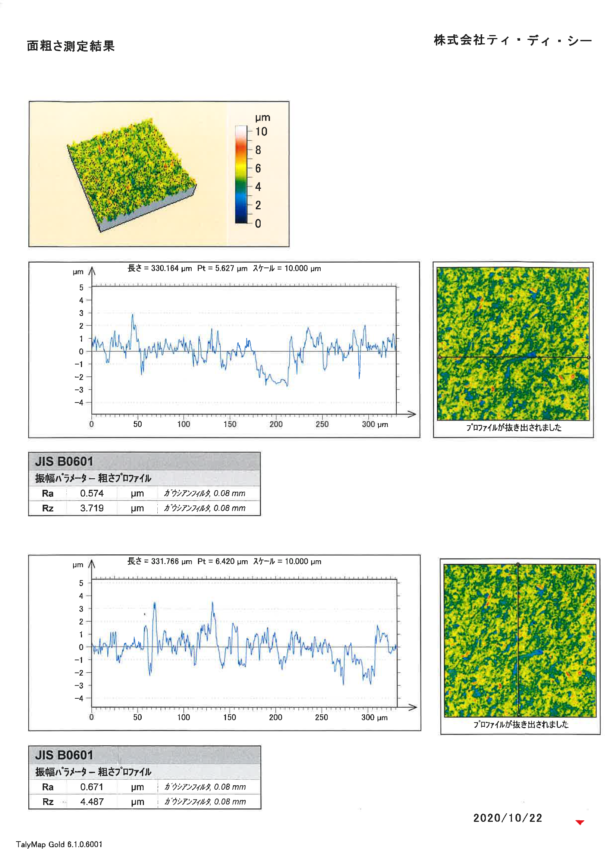

Surface Roughness Data Sample

- Measuring Instrument :Talysurf CCI SunStar

- Taylor Hobson

- Non-contact Optical 3D Profiler