Measurement Equipment

In precision manufacturing, it is essential to guarantee product quality using reliable inspection tools.

TDC inspects all products with measurement tools below.

※ TDC’s measuring instrument is set in 3 rooms which are temperature-controlled (21 +/- 1 degrees and 21 +/- 2 degrees). [Celsius]

Taylor Hobson

| TalysurfCCI3000 CCI Sunstar |

Non-contact Optical 3D Profiler |

| Talylondl 395 | High Accuracy Gage |

| Talyvel5 | High Accuracy Gage |

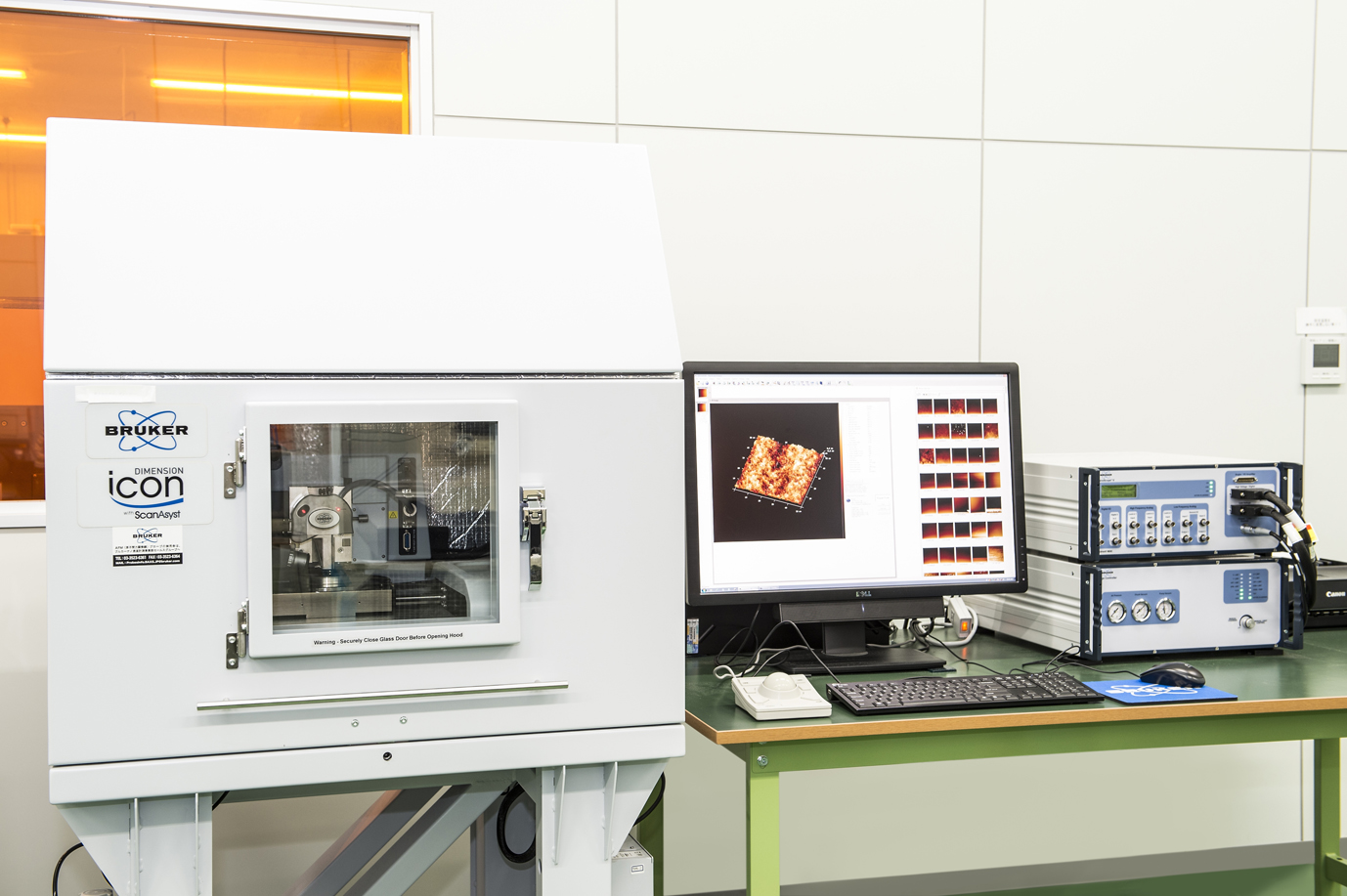

Bruker

| Dimension Icon | AFM |

ZYGO

| new view 9000 | Optical surface profiler |

| 18inch Large Aperture System | Laser Interferometer Verifire MST Reflectivity:4% – 99% Measured Objects:flat, back, transmitted wavefront error, homogeneity of refractive index |

| Verifire™ XL | φ300 Laser Interferometer |

Mizojiri

| Laser Interferometer FT-200U FT-100U FT-200S |

Flatness non-contact inspection |

KEYENCE

| GT2-H12KL | High-Accuracy Digital Contact Sensor |

| VHX-6000 | Digital Microscope |

| LM-1000 | High Accuracy Image Dimension Measurement System |

Mitutoyo

| Ultra High Accuracy CNC CMM LEGEX9106 |

High Accuracy High-speed driving 3D- co-ordinate Measuring Machines X900*Y1000*Z600 |

| Ultra High Accuracy CNC CMM CRYSTA-Apex S7106 |

High Accuracy 3D- co-ordinate Measuring Machines X705*Y1005*Z605 |

| Ultra High Accuracy CNC CMM CRYSTA-Apex S544 |

High Accuracy 3D- co-ordinate Measuring Machines X505*Y405*Z405 |

| MF−UB2010D | Measuring Microscope (200*100,Z=150) |

| Surftest SV400, SJ400 | Contact Surface Roughness Tester |

| Others | Micrometer, Vernier Caliper, Gauge Block |

Hamamatsu photonics

| Optical nano gauge C13027 | thickness measurement system |