Solutions for precision machining in measuring instruments and machine tools

We will introduce precision machining solutions in the field of measuring instruments and machine tools provided by TDC.

What is a measuring equipment?

General measuring equipment refers to equipment that measures physical quantities and changes in time, mechanics, heat, electromagnetics, and optics, as well as weights and measures that measure length, volume, and weight.

Measuring instruments are indispensable for companies that manufacture processing and precision parts, and the accuracy of products can be improved by using more accurate measuring instruments.

What is a machining tool?

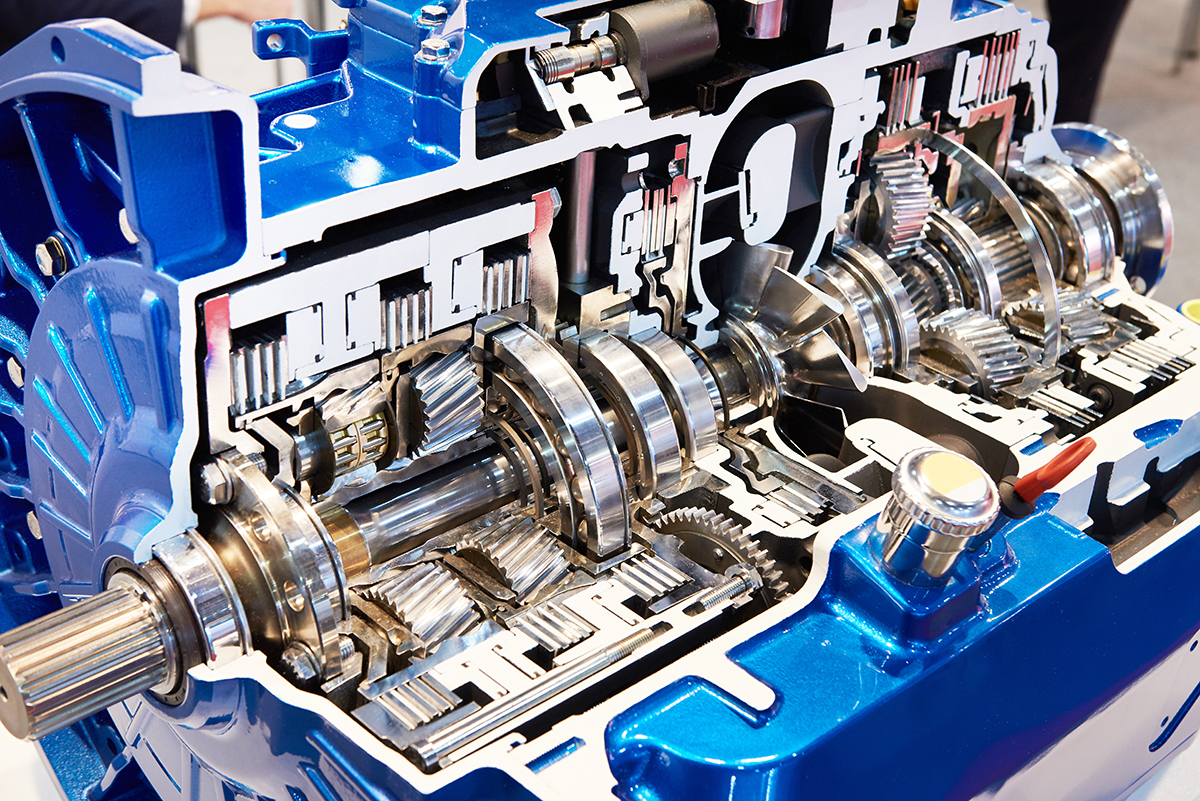

A machine that pierces, cuts, and polishes a product is called a” machine tool. “

In the past, these processes were performed by operating the handle of the worker, but due to labor shortages and improvement of work efficiency, many NC machine tools that are automated and have stable accuracy are now being introduced.

NC machine tool is an abbreviation for “Numerically Control”. When translated, it means numerical control, and the machining performed by steering wheel operation is quantified and automated by issuing a command to the device. Machining contents such as spindle speed and machining conditions, and machine operation control based on it are performed.

In recent years, there is also a machine tool called a CNC (Computerized Numerical Control) machine tool that has a numerical control function by a computer.

Precision machining in measuring equipment and machining tools

Machining accuracy is the most important for measuring equipment and machining tools. Parts made using highly accurate equipment naturally have high accuracy.

However, the parts used in these devices are also made by measuring instruments and machine tools.

What you need to know is the “copying principle” of machine tools.

This “maternal principle” is that “the precision of the machines and parts produced is determined by the precision of the machine tools that produce them.” In other words, it has the characteristic that it is not possible to make parts with precision that exceeds that of measuring instruments and machine tools.

Therefore, in order to make highly accurate measuring instruments and machine tools, more accurate measuring instruments and machine tools are required.

TDC’s solution in measuring equipment and machining tool

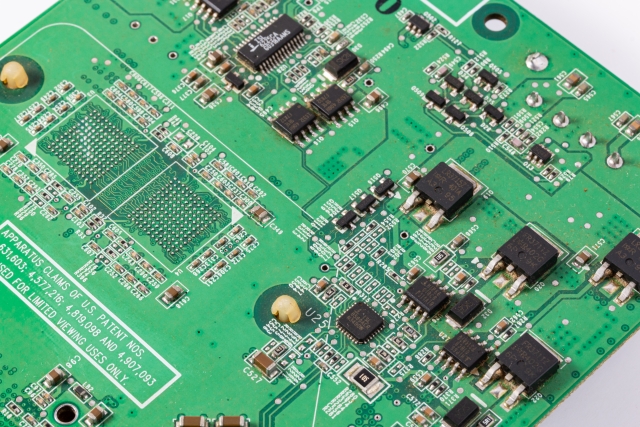

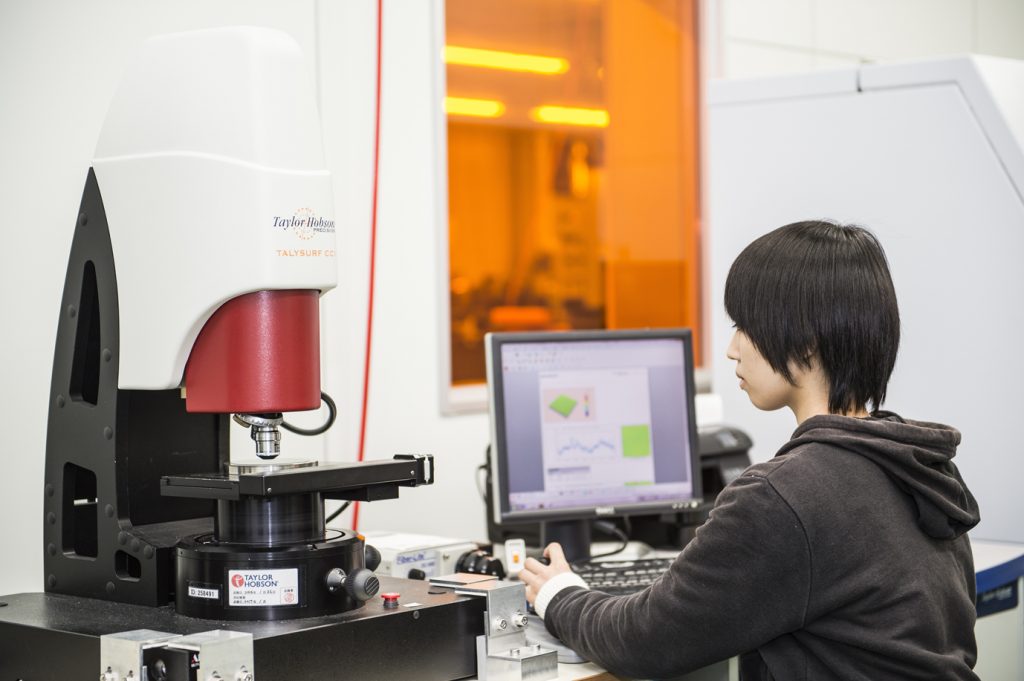

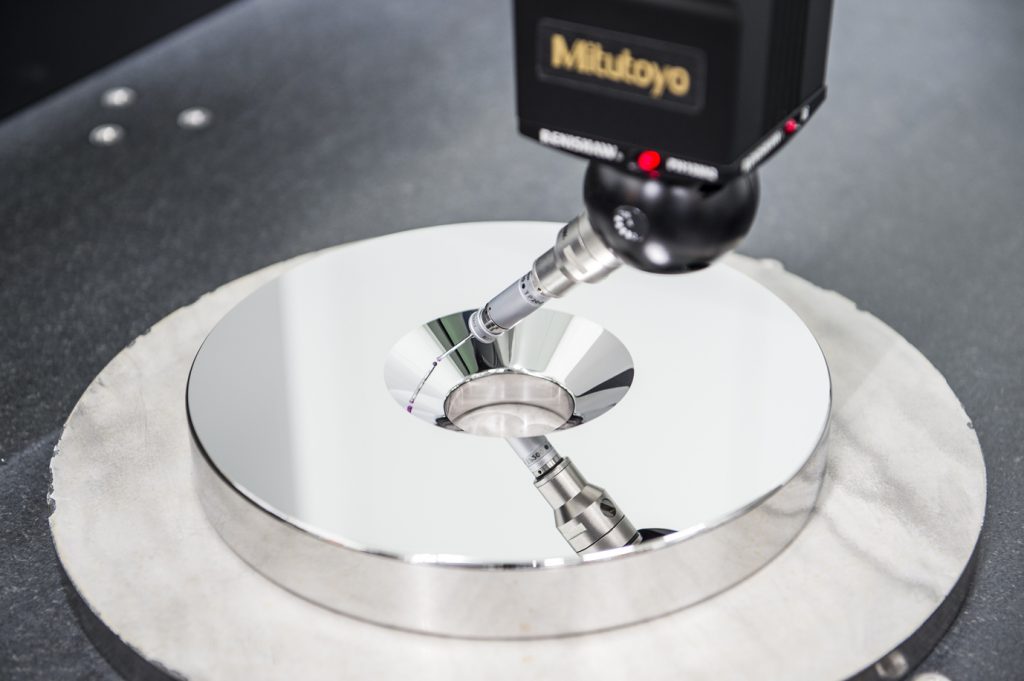

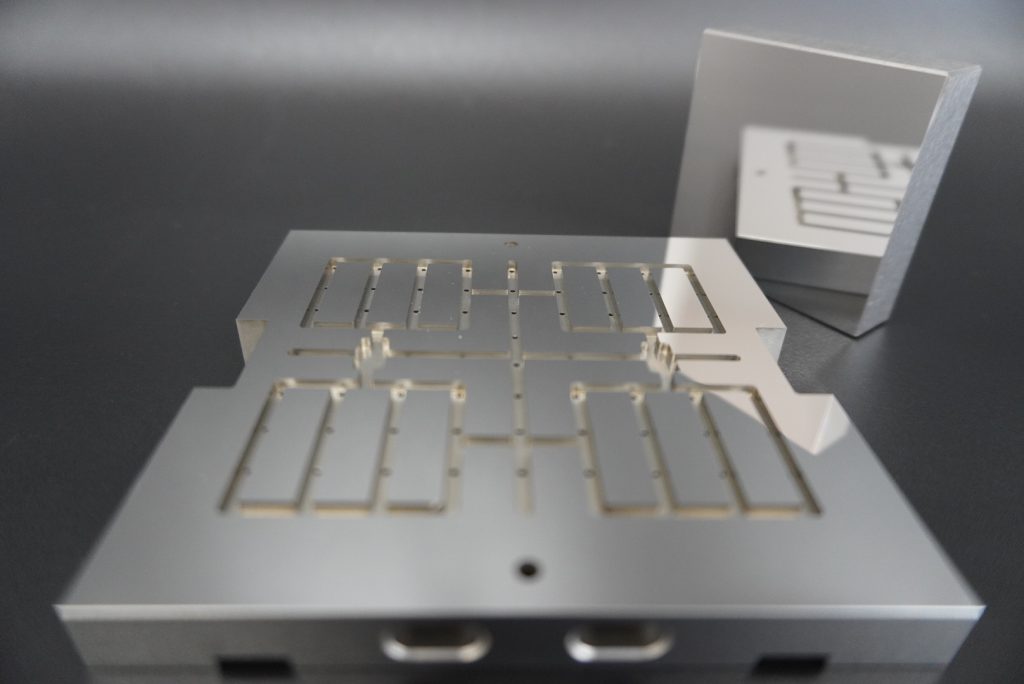

As a measuring instrument / machine tool solution, we have created precision-finished surface plates, precision machining of XY stage spindles, precision feed rails, positioning jigs, glass scales for encoders, etc., using precision dimensional control technology. It is widely used for measuring equipment and machine tool parts.

Guaranteeing flatness and positioning are indispensable issues for measuring instruments and machine tools. TDC provides solutions that enable more precise measurement and work.

In addition to correcting the jigs, surface plates, suction plates, etc. in use by polishing, we also manufacture new products in a batch from material arrangement to quality control.

Commitment to measuring equipment and machine tool solutions

TDC guarantee a wide area for flatness, which is important for measuring equipment and machine tools.

In addition, it is possible to obtain high-precision flatness even with special materials and soft materials that are difficult for other companies to make, and to obtain sharp edge flatness without sagging to the edge of the board. can do.

Since a new type of measuring machine has been introduced, the accuracy is high, and it is possible to aim for even higher accuracy.

with nano-level precision polishing.

and production from single units to mass production.

Related page