Solutions for precision machining in semiconductor manufacturing equipments

We will Introduce the precision machining solutions for semiconductor manufacturing equipment provided by TDC.

What is semiconductor manufacturing equipments?

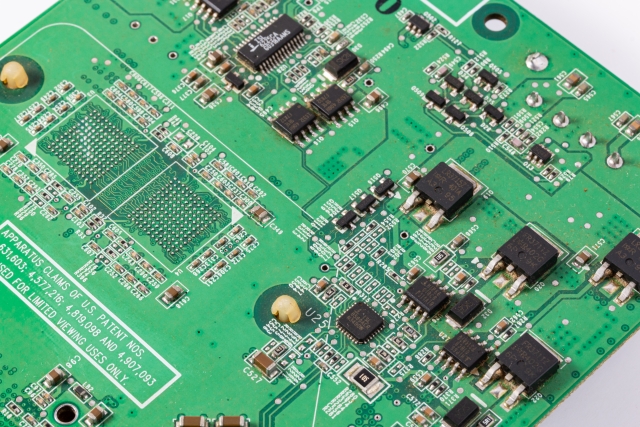

Semiconductors are an essential technology used to enrich our lives, such as controlling PCs, smartphones, automobiles, white goods such as refrigerators and washing machines, and infrastructure such as electricity and gas.

Semiconductors are used in various fields, but their processing requires extremely fine precision.

Its units are much smaller than millimeters (mm), micrometer (um), or nanometer (nm), which is invisible with the naked eye.

Since it is as fine as the atomic and molecular levels, a dedicated semiconductor manufacturing device is required to manufacture semiconductors.

Precision machining in semiconductor manufacturing equipment

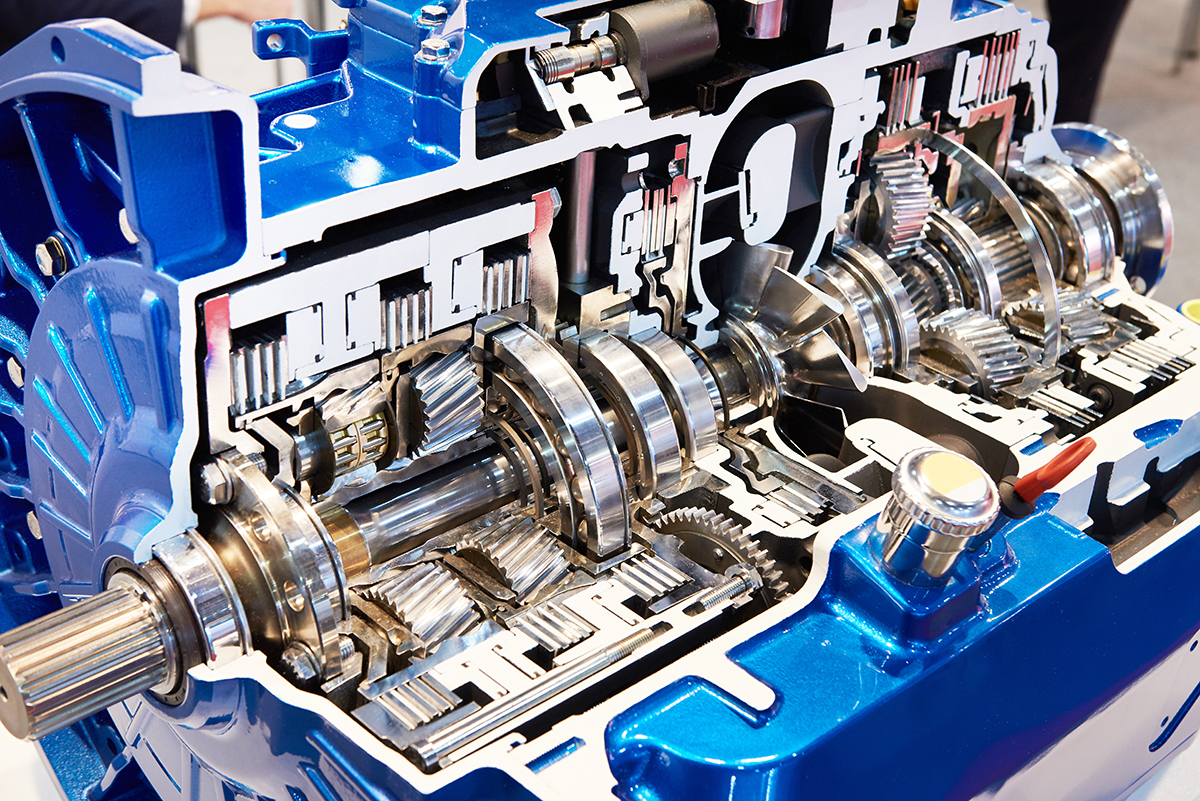

Many semiconductors are used in precision machinery, so their precision and durability are required.

Therefore, even one component used in semiconductor manufacturing equipment requires more precise precision.

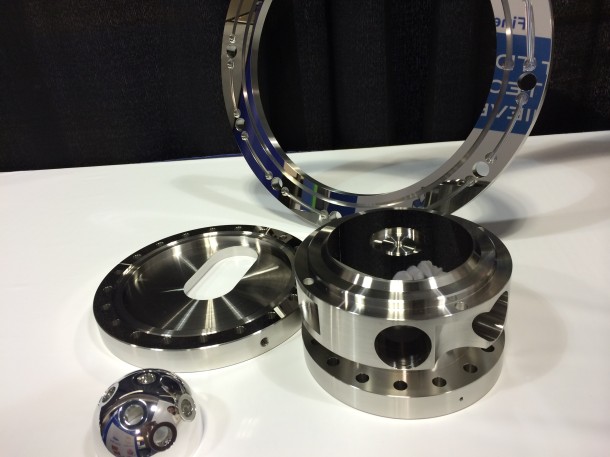

Parts used include suction plates, chambers, wafer transfer arms, and wafer table positioning devices.

In particular, the above parts used in semiconductor manufacturing equipment are required to have a very high level of durability. In addition to stainless steel and aluminum, the materials used include difficult-to-cut materials such as titanium, Inconel (nickel alloy) and ceramics.

Solution for Semiconductor Manufacturing Equipments

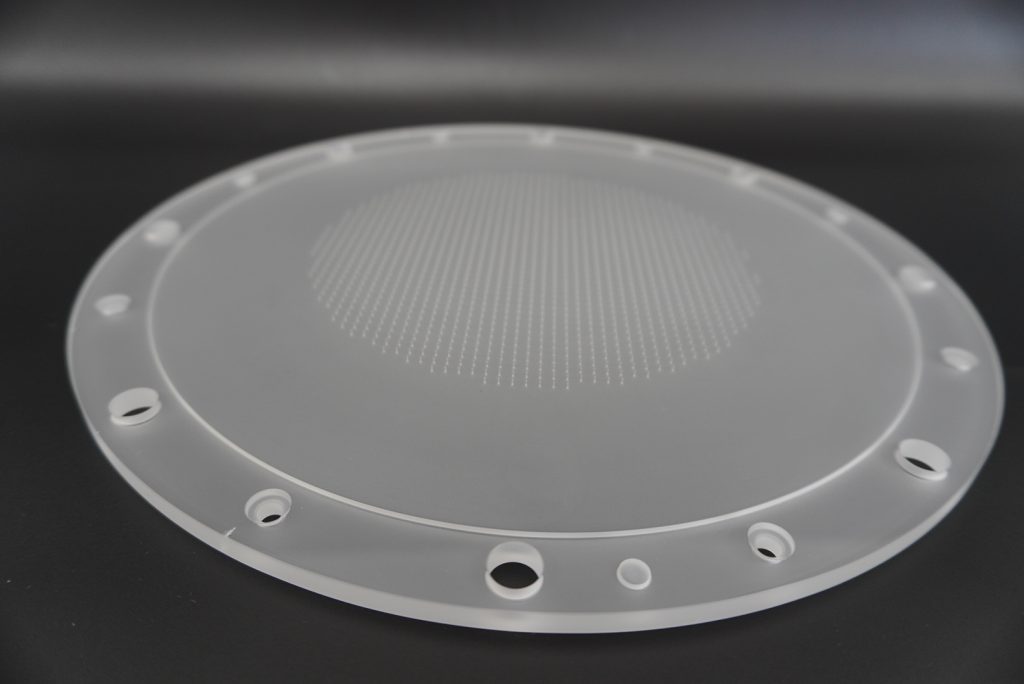

TDC’s semiconductor manufacturing equipment solution technology can provide not only manufacturing of element parts of semiconductor-related equipment, but also complex processing such as precision stage wafers.

In addition to reducing costs by manufacturing precision stages and high-precision parts, the precision of precision stages can be improved by processing the surface roughness and flatness with the highest precision.

Commitment to semiconductor manufacturing equipment solutions

TDC simultaneously realize complex elements such as surface roughness, flatness, dimensions, and angles using precision polishing.

TDC’s commitment to semiconductor manufacturing equipment solutions makes it possible to manufacture ultra-high-precision parts even with complex shapes using these technologies.

In addition, we are aiming for extreme areas such as surface roughness, flatness, parallelism, dimensional accuracy, and angle tolerance, and we also support various materials such as metals, ceramics, resins, glass, and new materials.

Please contact TDC for precision machining issues in semiconductor manufacturing equipment solutions.

with nano-level precision polishing.

and production from single units to mass production.

Related page