Precise Mirror Polish Surface on Roll and Shaft

What is super precise mirror polished rolls and shafts

TDC’s super precise mirror polished rolls and shafts

Precise Mirror Polish Surface on Roll and Shaft

TDC technology achieves nano-level surface roughness without defects, fogging, and distortion while maintaining dimensional and shape accuracy. It dedicates to higher precision of molds for nano imprint and high-performance film manufacturing.

In addition to stainless steel, nickel, glass. titanium and pure aluminum can also be processed.

High-precision mirror rolls are essential when manufacturing high-performance films such as wearable devices that measure electrocardiographic and blood glucose levels and electronic devices such as RF tags.

It is also used in scenes that require panel processing with less fogging and reflection, such as the recent coronavirus infection prevention sheet and face shield.

Why TDC is the best for mirror-polished rolls/shafts?

- Applicable to Nanoimprints and high function films

- Polishing cylinders completely eliminating scratches and frosts

Do you have problems with damage and noise on the surface of a printing roll before fine and precise patterning is applied? Recent research and development of high-performance films have contributed to the development of finer patterns. Finer patterns brought about a new problem of increased NGs, subtle damage or noise which used to be ignored are now frequently being unaccepted.

Although cylindrical grinding process also achieves mirror surface, it does not satisfy the requirement for a perfect surface without any damage and noise. TDC developed a brand-new machine in house which realizes a perfect surface without any damages, noises or frosted marks.

Specification

- A brand-new machine for precise mirror surface developed in house

- Ra1 nm, Rz 10nm (in case of SUS304)

- Outer diameter φ500㎜ max. Length L=3,000 m max.

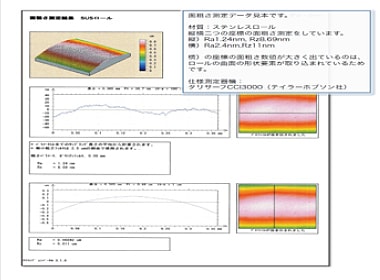

Measurement data of surface roughness (SUS304)

Example<Polishing outer diameter>

Size: φ100mmxL200mm Material :Stainless Steel 304 Outer Size tolerance :±2.5um Straightness:±0.5um

※Final accuracy is subject to the materials and the accuracy of primary process.

Feature of Super Precise Roll’s Process

| Materials | Stainless Steel, Nickel, Aluminum, Titanium, Quartz Glass, Cemented Carbide, Ceramics, Resins Surface Coatings (Nickel Plating, Hard Chrome Plating) |

| Outer Diameter | Max : 500mm |

| Length | Max : 3,000mm |

| Surface Roughness | Ra1nm、Rz10nm |

| Accuracy Guaranteed | Scratch free, Mirror finish, Size Tolerance, Cylindricity, Coaxiality |

| Application | Mold for Films, Mold for Nano-in-print |

Materials

Stainless Steel / Titanium / Aluminum / Glasses

Surface with coating such as Ni, Cr, HCr are also acceptable.

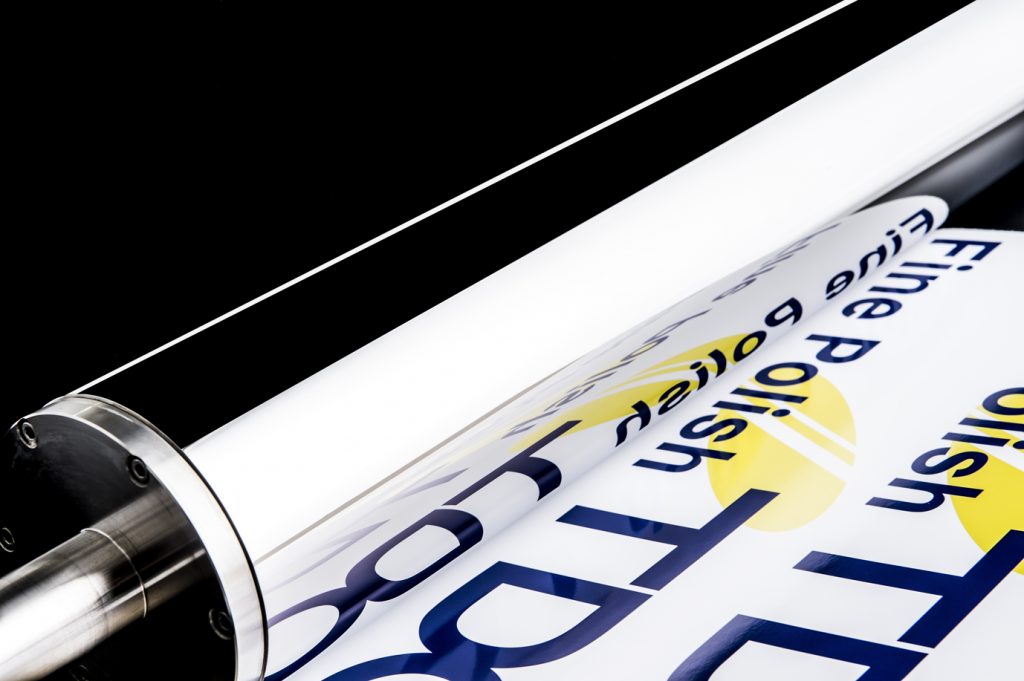

Stainless steel roll. Mirror polished product.

Available from one piece to mass production.

Maximum length is 3,000 mm.

Processing Achievement

| Outer surface roughness | Ra1nm, Rz10nm (SUS304, glass etc.) |

Less than Ra 0.010μm is available on aluminum surface.

Download in PDF

TDC is the best for mirror-polished rolls/shafts

TDC is able to respond to short delivery times according to the desired delivery date, and has accumulated unique technological development and know-how in processing, making it possible to respond to any shape.

If you have any technical issues, please take advantage of these technologies developed by TDC.

Please feel free to contact us for any concerns and inquiries regarding our mirror-polished rolls/shafts.

Related page