Precision Measurement

This page provides basic knowledge about precision inspections and measurements performed at TDC. For more information on TDC’s surface roughness results, please refer to “What is Surface Roughness ” and “What is the Precision Achievable through Polishing? page.

Contents

TDC’s Precision measurements

TDC provides “ultra-precision lapping and polishing” on consignment, which we have established through years of accumulated know-how and unique technological development, and performs the following precision measurements during processing.

- Surface roughness measurement

- Flatness measurement

- Surface roughness measurement by AFM

with nano-level precision polishing.

and production from single units to mass production.

Surface roughness measurement

The surface of a workpiece is subject to complex undulations, which are a series of peaks and valleys of different heights, depths, and intervals. Large undulations are called “undulations” and minute undulations are called “surface roughness” . Surface roughness also affects product life, machine efficiency, and surface gloss and feel. Therefore, “surface roughness measurement” is an indispensable measurement method, especially in the field of ultra-precision machining. There are two main types of surface roughness measurement methods: contact and non-contact.

- Contact measurement

The surface roughness is measured by directly tracing a sample with a pointed diamond needle called a contact

stylus, which is widely used for surface roughness measurement.

- Non-contact measurement

Light-based systems, such as laser microscopes using the confocal method and white light interferometers using the white light interferometry method.

Since TDC owns both of these measuring instruments, we can handle any kind of surface roughness measurement.

Flatness measurement

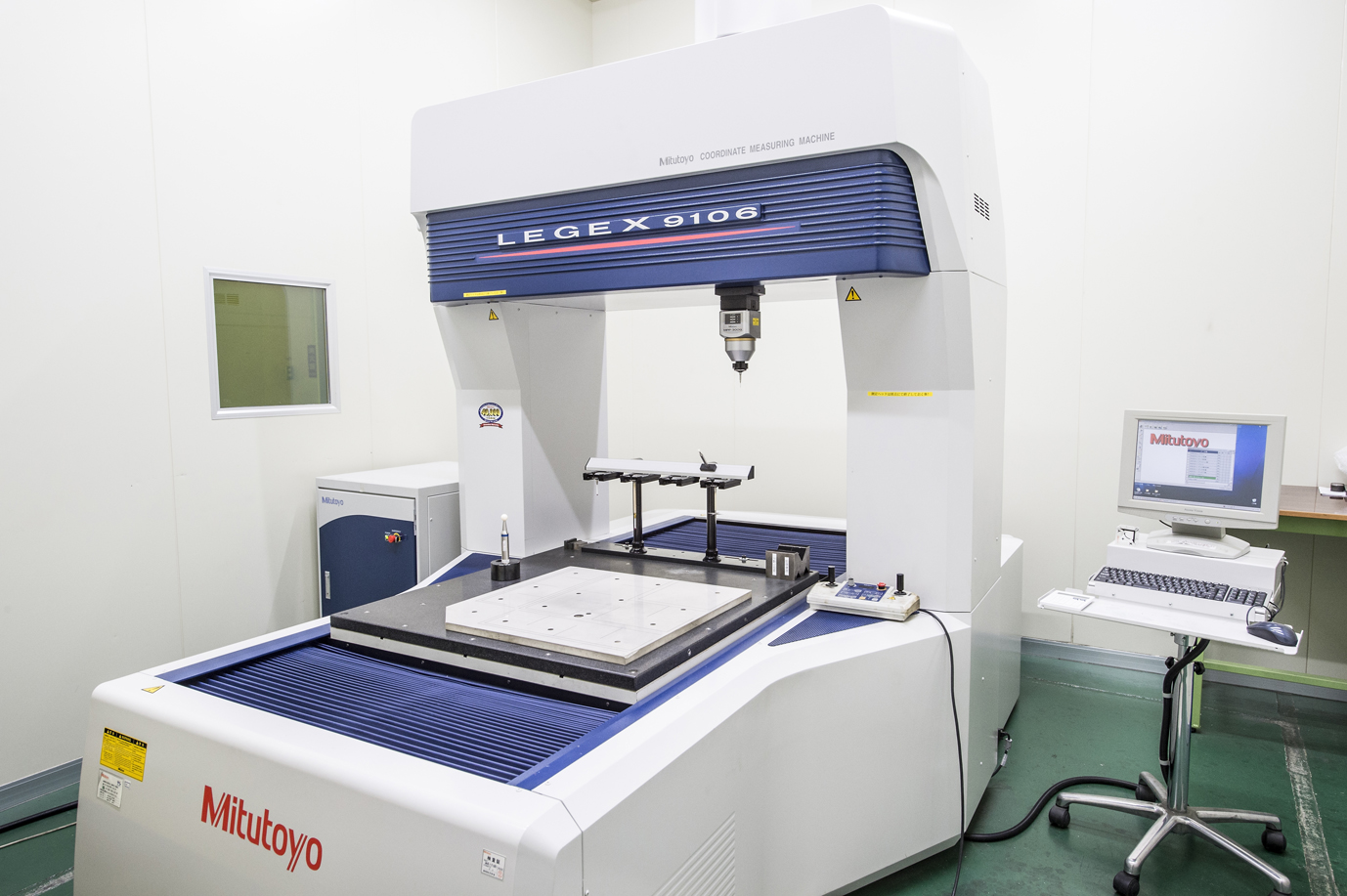

TDC has received many projects that require “higher precision flatness than other companies. TDC owns flatness measuring machines such as “CMMs” and “laser interferometers” and uses them appropriately according to the customer’s requirements and specifications of the workpiece. In addition to measurement, we can also provide services such as flatness correction processing, precision machining for each geometric tolerance, mirror surface processing, and prototype manufacturing.

Surface roughness measurement by AFM

AFM (Atomic Force Microscope) is a type of scanning probe microscope. By scanning a microscopic probe over the surface of a film, the force between the surface of the sample and the atoms of the probe is converted into an electrical signal to observe the surface topography. It is a method to measure nano-scale unevenness in three dimensions and can measure a wide range of samples from insulators to soft organic materials, such as metals, semiconductors, and oxides.

What is precision measurement?

Although there is no clear definition of precision measurement, it generally refers to the measurement or inspection during or after machining of the dimensions, shape, surface irregularities, etc. of machine parts that require precision machining techniques. In addition to the aforementioned measurement methods, various other methods are mainly used for precision measurements, including the following :

- Coordinate Measuring Machine / CMM

- Image Measurement

- Contour measurement

- 2D CAD measurement

- 3D CAD measurement

- Geometric Tolerance Measurement

Coordinate Measuring Machine / CMM

Using a three-dimensional coordinate measuring machine, the dimensions of drawings and 3D models are measured. It can be used for a wide range of products from small parts to large products that require precision, and is one of the measurement methods for which data is demanded regardless of the industry.

Image Measurement

Non-contact two-dimensional measurement is performed using an image measuring machine and image measurement probe. Non-contact measurement methods using lasers include height measurement, contour shape measurement, programmed automatic measurement, and multi-point measurement. The image measurement probe, which is attached to the probe head of the CMM, enables non-contact 2D image measurement of products that cannot be measured by ordinary image measuring machines, such as large-sized printed matter and film products.

Contour measurement

Contour measurement uses contour and image measuring machines, CMMs, and optical 3D digitizer scanning measurements to trace the surface of parts, molds, and other components to obtain contour shape data. Dimension measurement and coordinate calculation can also be performed by processing the imported data into calculations on dedicated software.

In precision measurement, the following words are often used.

- Error

The value obtained by subtracting the “true value” from the error

measurement is called the error. The “approximate value” is treated as the error. - Accuracy

Refers to small bias. The degree of agreement between the true value and the average of the measured values is sometimes called accuracy. Accuracy is also means an overall term that includes the accuracy and precision of the values or measurement results expressed by measuring instruments. - Precision

Small precision variation. It is treated as an indication of the degree of agreement of the measured values, regardless of the true value. - Repeatability

Refers to the degree to which individual measurement values agree when the same measurement quantity of the same measurement target is repeated several times in a short period of time by the same person using the same measuring instrument. - Reproducibility

Refers to the degree of agreement of measurement values when the measurement target, measuring instrument, measurement conditions, etc. are changed once, the initial conditions are set, and the measurement is performed again at a different time.

with nano-level precision polishing.

and production from single units to mass production.

- What is a chuck table? | Basic information and description of types, Processing accuracy at TDC

- Copper polishing

- Precision processing of crystal materials and glasses

- Polishing after thermal spraying

- Mirror Finishing/Mirror Polishing

- Sapphire polishing

- Polishing of plastic/acrylic resin

- Polishing after surface treatment/coating

- Precision parts processing

- KEYENCE measuring instruments used at TDC

- Precision Cleaning Service

- Symbol used for polishing

- SUS (stainless steel) material test piece/specimen

- Polishing of SiC

- Polishing of titanium

- Cylindrical grinding/cylindrical polishing

- Mold Processing

- Precision machining of ceramics

- ガラスエポキシ(ガラエポ)の精密加工

- Type of polishing process

- 真鍮の精密加工・研磨加工

- What is the accuracy that can be achieved by polishing?

- Principle of polishing process

- Semiconductor Wafer Cleaning

- Ultrapure Water Cleaning

- Bruker “Dimension Icon”

- Talysurf

- Talyrond

- Dial gauge

- Precision processing of resin and plastic

- Polishing process for Resin

- Precision Measurement

- Mirror-finishing for aluminum

- Mirror-finishing for plastic/acrylic resin

- Wafer Cleaning Equipment

- Mirror Polishing for Stainless Steel/SUS304

- Metal polishing process

- Mitutoyo measuring instrument used in TDC

- Polishing of Aluminum

- Optical Nano Gauge

- TDC’s precision machining

- 微細加工とは? | 基礎知識と加工方法の解説

- What is CMP

- What is polishing?

- About Lapping and Polishing