Solutions for precision machining in automobiles

Introducing precision machining solutions in the automotive field provided by TDC

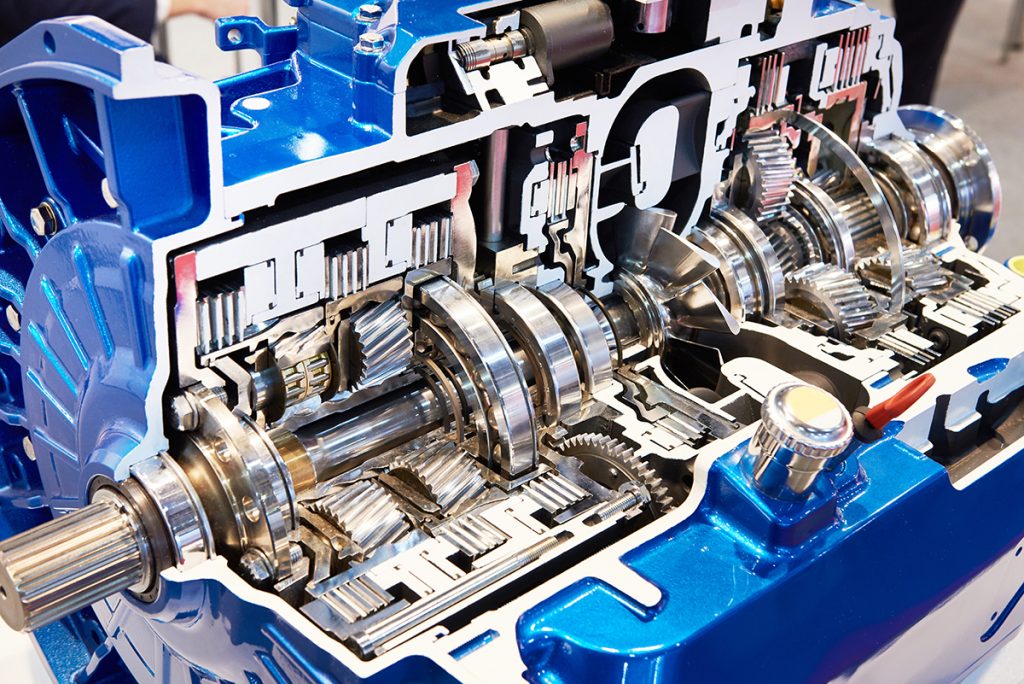

Features of automobile parts

We need parts that make up an automobile in various places, from parts around the engine to parts around the transmission.

What all parts have in common is that they all require highly precise processing techniques such as polishing, cutting / grinding, and surface treatment.

For example, let’s take a look at the ball welded parts found in automobile flood control equipment.

It is important not only to process to reduce the accuracy and hardness, but also to process with high accuracy so that cracks and burrs due to friction welding do not occur.

It is also known that the difficulty of processing automobile parts increases depending on the materials used. It is said that there are always issues for increasing productivity of automobile parts, such as cost reduction and efficiency improvement in processing as mass production.

Precision machining in automobile parts

Many automobile parts are directly linked to electrification, fuel efficiency, noise, exhaust gas, etc., and it is not uncommon for any part to have a more accurate shape.

There are also remarkable demands for miniaturization and weight reduction, and there is a demand for higher performance and higher performance component manufacturing.

In precision machining, it is essential to achieve high precision at the same cost as well as miniaturization of dimensions, and it is a market where new technology is constantly required.

Solutions for automotive

We meet the needs of the automobile industry, such as manufacturing test pieces for R & D and manufacturing jigs and tools.

As an automobile solution, TDC has so far made molds for hybrids, electrification, autonomous driving, fuel cells, prototype parts such as hydrogen, test pieces for R & D, jigs and tools, test pieces, shims, gears, head-up displays.

Commitment to automotive solutions

High-precision machining is possible for difficult-to-process materials such as hardened steel and cemented carbide, and difficult-to-process shapes.

Regardless of the material, such as metal, ceramics, resin, glass, and semiconductor materials, we will assist you in prototyping and improving various parts using ultra-precision mirror surface technology.

Please contact TDC for precision machining issues in automotive solutions.

with nano-level precision polishing.

and production from single units to mass production.

Related page