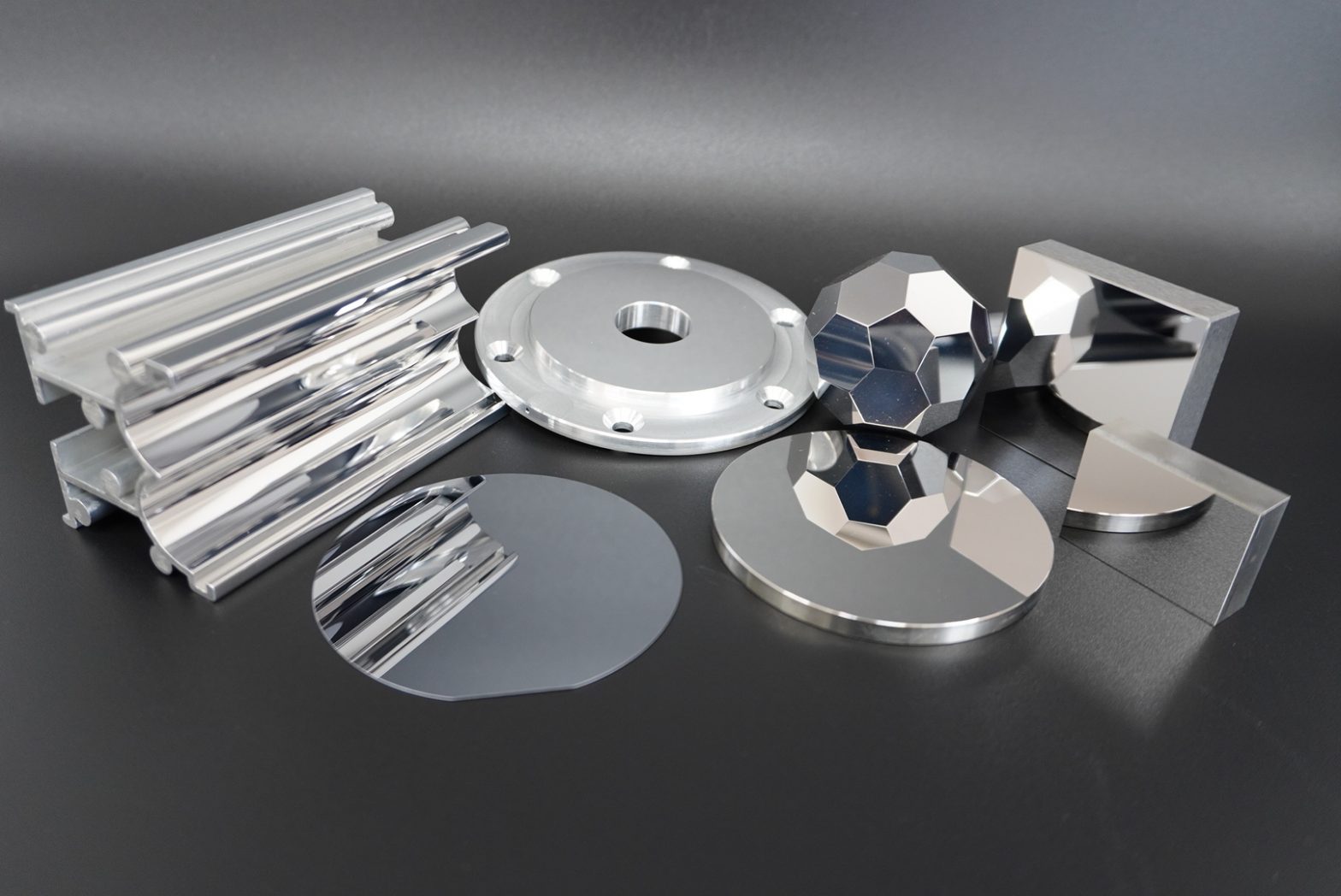

Precision lapping service / ultra precision lapping service

Here is some basic knowledge about ultra precision polishing technology and some applications for our service.

What is the difference between “precision polishing service” and “ultra-precision polishing service”?

The processing that requires high-precision lapping technology is basically divided into two types “precision polishing” and “ultra-precision polishing”.

In general, “precision polishing” means the polishing method that can achieve microscale processing accuracy of up to 1/1000 mm.

On the other hand, “ultra-precision polishing” refers to the method which can achieve nanoscale processing accuracy of up to 1/1000 um.

What is precision polishing service?

Precision polishing is generally defined as “polishing in micron units”, and it is manufacturing that requires how precisely an arbitrary shape can be machined using various tools and machines.

It is a delicate work that requires accuracy in units of several microns to several dozens of microns, and engineers needs high-level skills to choose the most applicable

processing method such as polishing, grinding, and cutting method and machines to meet customers needs.

Wide range of materials are available.

What is ultra-precision polishing service?

“Ultra-precise polishing” means a polishing method that can achieve accuracy at the nanoscale of 1/1000 um, which is one step further than precise polishing. Because of that, it is a one of most difficult polishing method to carry out unless all conditions are met, such as a measurement tools with strictly temperature controlled environment and the applicable use of special tools and equipment.

Ultra-precision polishing generally covers the processing of precision machine parts and optical parts such as semiconductor wafers and lenses for cameras, however TDC can accept any request.

Points for ultra precision lapping

The points to achieve high-precision processing that requires dimensional tolerance in micrometer units are as follows.

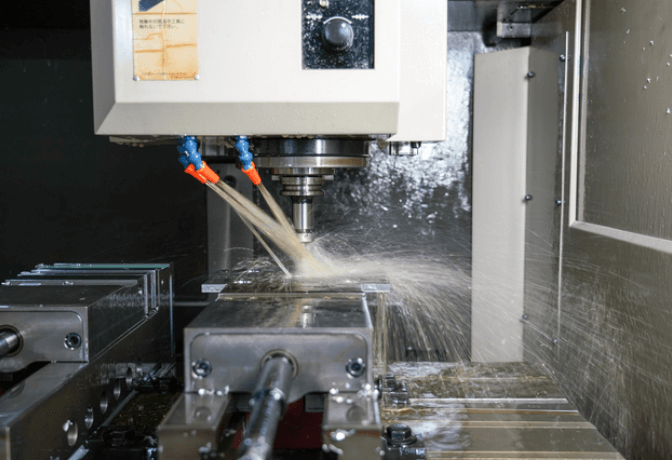

machine tool resolution

Machine tools have a characteristic called “maternal principle”, and the accuracy of the machined parts is determined by the accuracy of the machine tools that machine the parts. Therefore, in order to machine high-precision parts, a machine tool for ultra-precision machining that can process with a higher resolution than the parts is required.

Only a limited number of processing suppliers have ultra-precision machine tools. In order to achieve high-precision machining, it is important to check the machine tools owned by machining suppliers.

For processing machines owned by TDC, please refer to the “Processing Equipment” page.

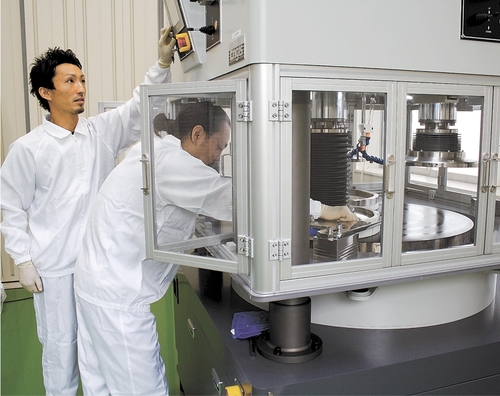

Clean environment to maintain quality

High-precision machining requires thorough temperature and humidity control, and a clean environment that prevents particles from adhering to the workpiece.

In order to perform high-precision machining, a facility environment that takes measures against all natural environments, such as a constant temperature environment and vibration, is necessary, and these are necessary for the entire facility where the machine tool is installed.

For the clean environment that TDC boasts, please refer to the “Processing Equipment” page.

Quality assurance by measurement and measurement at the nano level

In high-precision machining, not only the precision of the machining itself, but also quality assurance by measuring whether the accuracy is achieved is one of the essential elements.

For example, with a measuring instrument whose measurement accuracy is unstable at 100 micrometers or less, it is not possible to guarantee processing accuracy of several micrometers.

In order to measure and measure high-precision parts, it is necessary to have an ultra-precision measurement device that can measure with a resolution that is higher than the dimensional tolerance of the part.

For the high-performance measuring instruments owned by TDC, please refer to the “Measurement Equipment” page.

Types of general precision machining and high-precision machining

| Types of precision machining and high-precision machining | feature |

| Polishing | It is mainly used as a process to produce a more precise surface roughness. Lapping polishing enables the surface of the workpiece to be polished with high precision, while buffing enables the surface of the workpiece to be polished quickly. |

| Grinding | It has high dimensional accuracy and can be finished to a smooth surface. High-precision machining can be easily performed due to the small amount of machining, temperature rise, and residual stress. |

| Cutting | It is used for processing products that require complex shapes and precision. Typical processing methods include milling, lathe processing, and drilling. |

| EDM | It is a processing method that melts and removes the workpiece by the heat of the discharge by causing an electric discharge between the material and the electrode. The finer the electrode, the more precise machining is possible, but the disadvantage is that the machining speed becomes slower. |

| Honing | It is possible to finish the inner surface of the hole of the object with high roundness and cylindricity. |

| Thermal spray | By applying heat and spraying molten or semi-molten material, a functional film can be formed on the surface of the workpiece. |

| plasma processing | It is a precision processing method that uses plasma energy. In addition to cutting and drilling, it is also used for welding and surface treatment. |

| Laser Cutting | By using a laser beam, it is a processing method that can cut even complex shapes with high precision. It is used for small-lot processing of high-precision products. |

| Shot blast | It is a processing method that roughens the surface of the object by spraying granular projection material at high speed. This gives the surface a matte, satin finish. |

Accuracy of precision lapping and ultra precision lapping

Precision machining and high-precision machining can achieve machining accuracy on a scale of 1/1000 mm = 1 um (micrometer) at maximum.

In other words, precision processing can be regarded as a processing technology in the microscale world.

Furthermore, ultra-precision machining can achieve machining accuracy on a scale of 1/1000 um at maximum. Since 1/1000 um = 1 nanometer, precision processing and ultra-precision processing are technologies for micro- and nanoscale processing.

| precision lapping | ultra precision lapping | |

| tolerance | ≦+/-0.005mm | ≦+/-0.0005~0.001mm |

| roughness | Ra ~0.01um | Ra ≦ 0.01 um |

| geometric tolerance | ≦0.005~0.01mm | ≦0.0005~0.001mm |

precision lapping and ultra precision lapping can achieve accuracy on a scale of 1/1000 mm = 1 um (micrometer) at maximum.

In other words, precision processing can be regarded as a processing technology in the microscale world.

Furthermore, ultra precision lapping can achieve accuracy on a scale of 1/1000 μm at maximum.

For a detailed explanation of accuracy, please also check the “What is Surface Roughness” page.

Necessity ofprecision lapping and ultra precision lapping

Parts that require precision machining and high-precision processing have characteristics such as “reliability”, “strength”, “flexibility of shape” and “miniature lot”.

Applications that require these properties are:

- Parts for machine tools, semiconductor manufacturing equipment, various measuring instruments, etc.

- Automotive parts that transmit power without waste, mechanical parts that can withstand long-term use, etc.

- Parts that are required to be produced in ultra-precision and minute lots for use in devices and equipment in IT and mechanical engineering.

- Parts that support advanced movements such as aircraft engines and machine parts

These parts require a high level of quality through precision machining.

Machine tools that produce various parts also require ultra precision lapping

Products made from metal, such as automobiles, aircraft, and digital equipment, require machine tools that can drill, cut, and process metal parts.

It is no exaggeration to say that the quality and accuracy of all products depend on the quality and accuracy of the parts used in product assembly.

Therefore, precision machining is indispensable for the machine tools themselves that manufacture parts. In order to produce high-quality products and parts, machine tools, which are called mother machines for many products and parts, require high precision and performance.

Examples of precision processing / industries that require precision processing

Products manufactured by ultra precision lapping play an active role in various industries

The following industries are the main delivery destinations of precision processed products.

- semiconductor

- car

- nanotechnology

- MEMS micromachine technology

- Industrial equipment/inspection equipment/measuring equipment

- optical equipment

- Electronic equipment/electronic components

- Medical equipment/analytical equipment

- Next-generation energy development field

- Aerospace

- Chemical-related equipment/technology

- pharmaceutical equipment

In general, requests for ultra-precision processing are mainly from the “semiconductor field” and “optical field”, but TDC receives many requests from other fields as well.

In the field of semiconductors, nano-micrometer scale processing is required for etching semiconductor substrates, etc. In the field of optics, surface roughness and shape errors of lenses are finished at the nano level.

Nano-level precision is also required for molds for lenses, making this a field that requires ultra-precision processing.

Precision processing and high-precision processing for each material

Nano-level accuracy in precision and high-precision machining is greatly affected by the material of the workpiece.

Since the processing method differs greatly depending on the material, when requesting precision processing and high-precision processing, it is best to select a contractor that can handle all processing methods.

Here, we introduce materials that are often cited as objects for precision machining and high-precision machining.

Precision and high-precision machining of difficult-to-cut materials

Materials with a low machinability index, which quantitatively indicates how difficult it is to cut, are generally said to be difficult-to-cut materials, such as cemented carbide and tungsten.

However, in machining that requires nano-level accuracy, such as precision machining and high-precision machining, it is necessary to have various conditions such as machine tools, tools, and technology and know-how to handle them. is considered a non-informative indicator.

Therefore, when requesting precision and high-precision machining of difficult-to-cut materials, it is best to keep in mind the past achievements in machining difficult-to-cut materials and technical capabilities.

Precision and high-precision machining of silicon carbide (SiC)

Silicon carbide (SiC) is the hardest among fine ceramics and has excellent properties such as mechanical strength, heat resistance, and wear resistance.

It is one of the materials that has been in increasing demand in recent years, but because of its hardness, it takes a long time to process and is prone to chipping.

SiC is a difficult-to-cut material that easily causes tool wear when using ordinary tools. When nano-level precision processing is required, advanced technology and specialized tools are required.

TDC’s precision lapping service / ultra precision lapping

In our ultra precision polishing process, we use a surface grinding machine and a lapping machine. We have received many requests to improve the flatness and parallelism of precision stages and tables used in semiconductor manufacturing equipment and precision measuring machines. By our ultra-precision polishing, we simultaneously achieve two or more geometrical tolerances such as flatness, parallelism, dimensional tolerance, surface roughness, and squareness on the nano-order. In addition to lapping and polishing machines, we use special equipment and jigs and tools developed by our company. They are used as semiconductor manufacturing equipment parts and optical parts that require the ultimate in high precision.

We handle ceramics, metals, and glasses, stone surface plates as well, in such processing.

with nano-level precision polishing.

and production from single units to mass production.

Related page