Semiconductor Wafer Cleaning

This page explains “semiconductor cleaning,” one of the most important processes that determine the quality of semiconductors.

Contents

What is Semiconductor Cleaning?

Semiconductor cleaning is a cleaning and drying process to remove contaminants and adhesives from the surface of semiconductors. It is no exaggeration to say that semiconductor cleaning determines the quality of semiconductors, and thus is the process that plays the most important role in semiconductor manufacturing.

Importance of Semiconductor Cleaning

Since semiconductors are manufactured through a number of processes, contaminants and adhered materials are generated in each process, which significantly affects the quality of semiconductors. It is said that semiconductor cleaning accounts for about 30% of the entire process, and is a very important process that changes productivity depending on how well it removes contaminants. In other words, it is no exaggeration to say that improving the quality of cleaning leads to improvements in semiconductor technology and performance.

Drying Processing in Semiconductor Cleaning

Drying processing, one of the cleaning processes, prevents moisture from remaining on the semiconductor surface and prevents particles (dust), metals, and organic matter from adhering to the wafer. This is an important process that requires the same level of quality as cleaning.

Types of Contaminants Removed in Semiconductor Cleaning

The main types of contaminants and adhering matter removed during semiconductor cleaning are as follows半導体洗浄で取り除く主な汚染物質・付着物の種類は、以下となります。

- Simple dust and dirt

When wafers are removed from their packaging, dust and dirt called “particles” adhere to the wafers from the air outside the factory. The maximum size is several micrometers and the minimum is 0.1 micrometer or less. - Metal contamination

This refers to evaporated sodium molecules and trace amounts of heavy metal atoms contained in the chemicals used in the plant. - Organic contamination

This refers to carbon contained in human dandruff and grime, trace amounts of carbon molecules contained in chemical solutions used in factories, etc. Bacteria in pure water piping is also a form of organic pollution. - Fats and oils

This term refers to the oil contained in human sweat. - Natural oxide film

When a wafer is exposed to air, its surface combines with oxygen in the air to form an oxide film of 10 to 20 nm (1/100,000 to 2 mm). This oxide film contains impurities from the atmosphere and is treated as one of the contaminants.

General Semiconductor Cleaning Process

Although cleaning and drying are generally the same thing, the cleaning process varies widely depending on the type and characteristics of semiconductors. The following is an example of a typical cleaning process.

- Wafer fabrication

- Cleaning

- Film deposition

- Cleaning

- Resist Coating

- Exposure & Phenomena

- Etching

- Resist Stripping

- Cleaning

- Inspection and assembly

Cleaning Equipment Used for Semiconductor Cleaning

Wet stations are lined with tanks containing chemical solutions and pure water, and contaminants are cleaned and dried by immersing a large number of wafers together in these tanks. Drying units include “spin dryers,” which dehydrate wafers by centrifugal force of rotation, similar to dehydration in a washing machine, and “IPA vapor dryers,” which evaporate water together with alcohol by evaporation. IPA is an abbreviation for “isopropyl alcohol,” and vapor means “steam” in English.

One-bath Wet Station

A “one-bath wet station” is a type of wet station that performs both chemical cleaning and pure water rinsing in a single tank. The advantage of the one-bath wet station is that wafers are not exposed to the atmosphere because, after cleaning with chemicals, the chemicals are pushed out with deionized water before rinsing.

Batch and Single Wafer Cleaning Equipment

Wet station-like equipment that cleans many wafers at once is called “batch cleaning equipment. In contrast, equipment that cleans wafers one at a time is called “single wafer cleaning equipment.

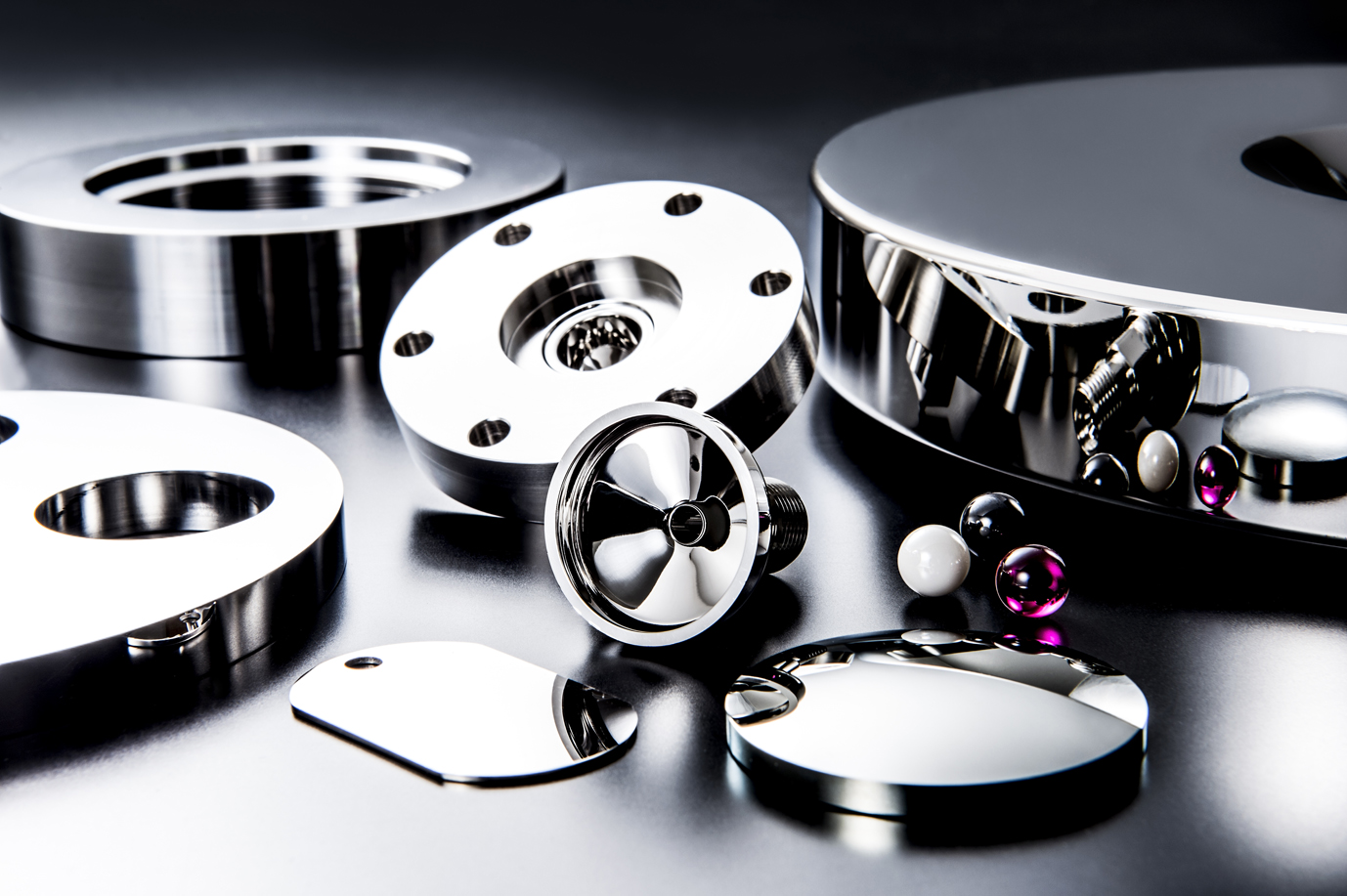

TDC’s semiconductor cleaning equipment

The following two models of “Precision Cleaning at TDC” can clean semiconductor wafers. We have both single wafer and batch type cleaning equipment.

| Brand | Equipment | |

| Temtec | Wafer cleaning equipment (batch type) | 1 unit |

| In-house | Wafer cleaning equipment (single wafer type) | 1 unit |

TDC possesses clean environment and precision cleaning technology capable of cleaning semiconductor wafers. Please refer to the “Precision Cleaning Service” for more information on TDC’s precision cleaning capabilities.

Feel free to contact us if you have any problems with semiconductor wafer cleaning

TDC also offers precision cleaning of semiconductor wafers. We clean wafers in a clean environment using ultrapure water and specialized cleaning systems to minimize particle adhesion. We can provide services from a single wafer, so please feel free to contact us.

TDC Information