Precision Polishing Service

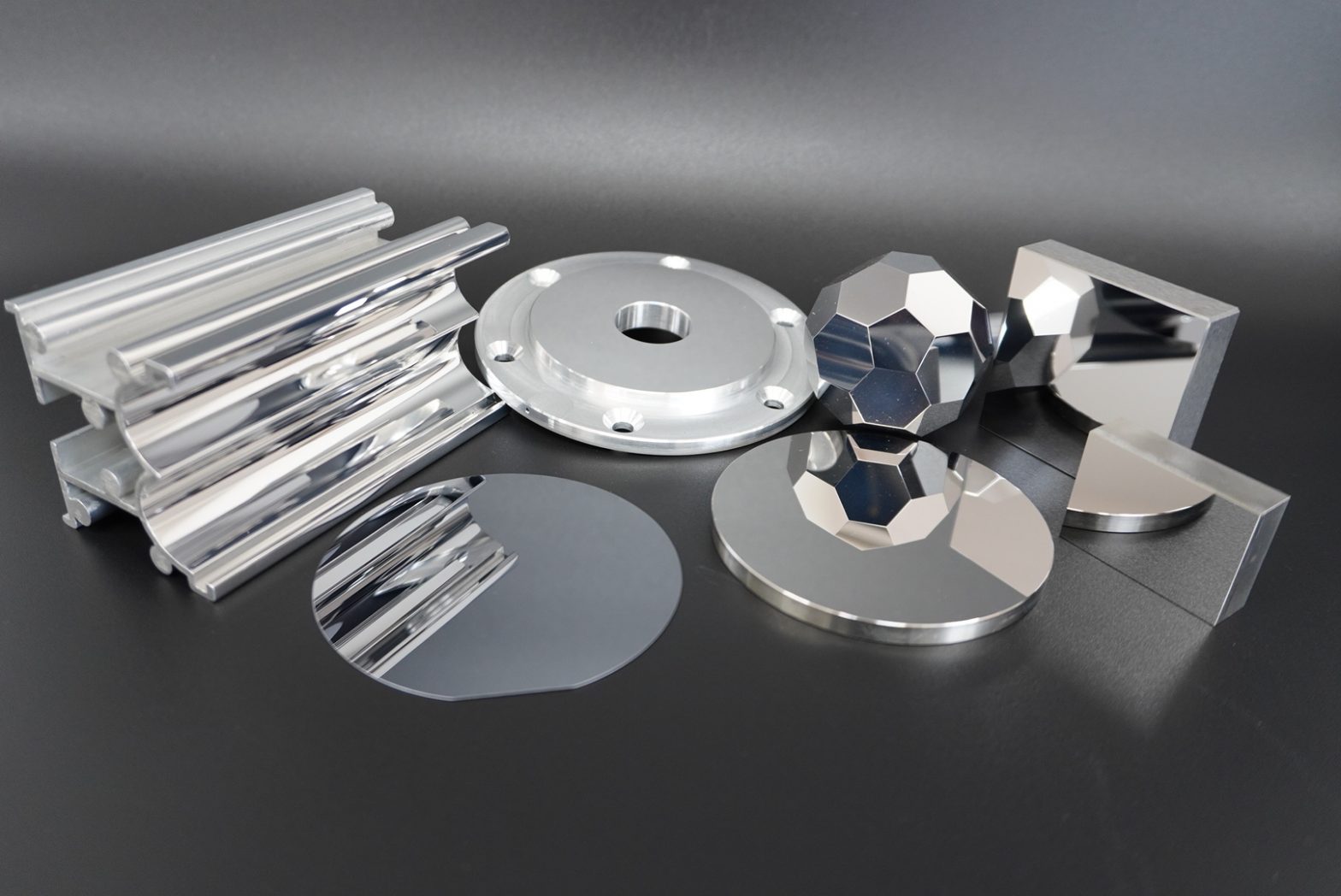

Introducing TDC’s precision grinding/polishing technologies and our extensive track record of processing examples.

For more details on our core capabilities, please also visit our “Ultra-Precision Polishing and Machining Services” page.

Contents

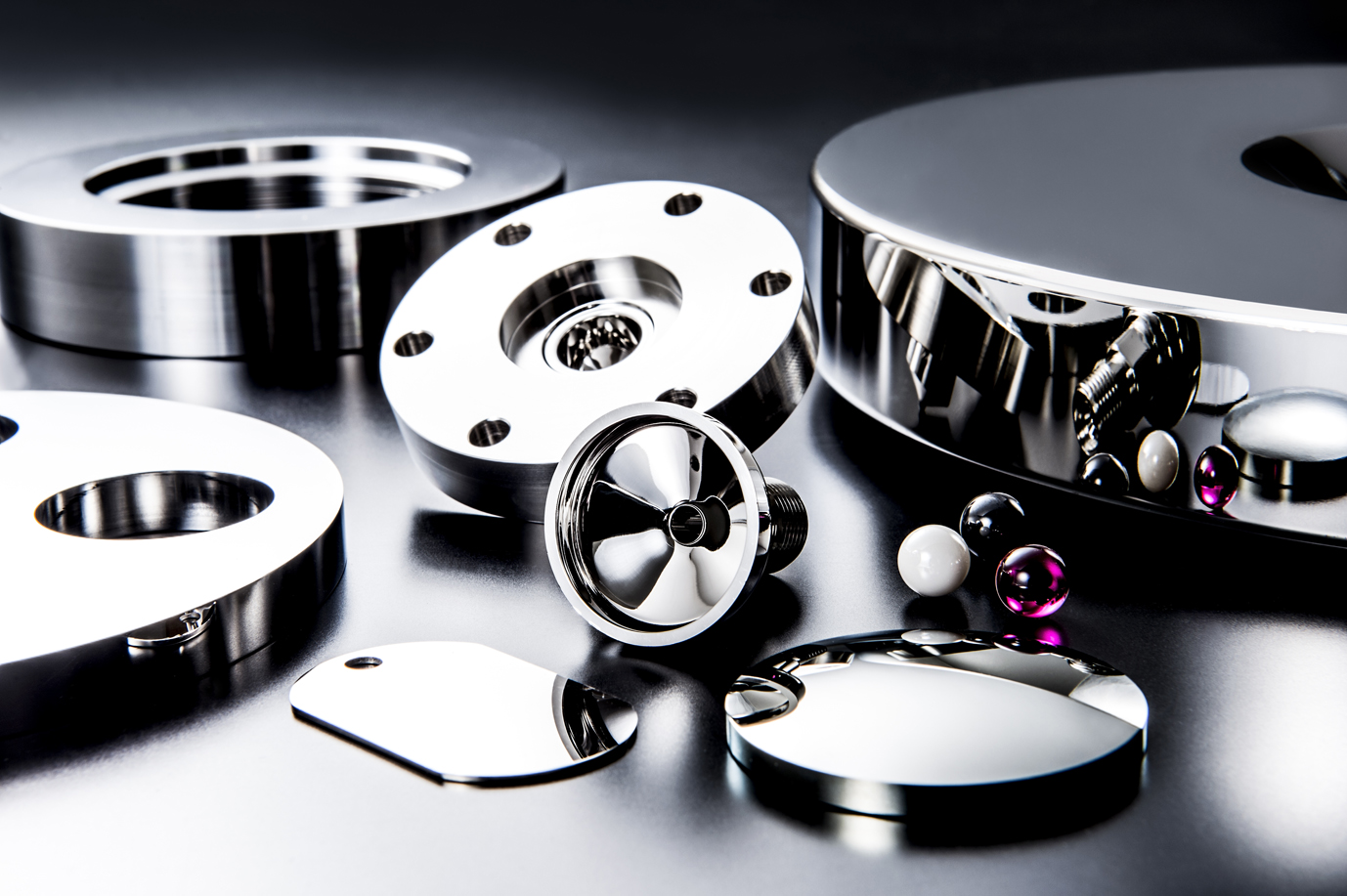

Key Features of TDC’s Polishing Services

TDC is equipped with ultra-high-precision polishing machinery, including lapping machines. Our advanced polishing technologies allow us to meet the most demanding precision requirements of our clients.

- Proven Track Record Across Industries: With a wealth of experience in fields such as electronics, semiconductors, optics, medical, aerospace, automotive, and energy, we leverage our unique expertise to solve challenges in the latest cutting-edge technologies.

- Exceptional Surface Roughness: We achieve surface roughness of Ra 1 nm and Rz 4 nm through ultra-precision polishing and lapping on all shapes, including flat, curved, and internal/external cylindrical surfaces.

- Multi-Factor Precision: While ensuring superior surface roughness, we also deliver high precision across other critical factors, such as parallelism of 100 nm, flatness of 30 nm, dimensional accuracy of ±100 nm, and angular tolerance of ±3 arcseconds.

Materials

| Metals | Stainless Steel / Superalloy / Copper / Titanium / Aluminum / Molybdenum / Tungsten/ Nickel / Tantalum etc. |

| Ceramics | Al2O3 / ZrO2 / SiC / Si3N4 / SiO2, Also Coating and Plating are acceptable |

| Crystalline Material | BK7/ Crystal/ PYREX/ Quartz / Si/ SiC /GaN/ Sapphire/LiTaO3/LiNbO3/ |

| Resin | Engineering Plastics / PEEK/ PMMA /PEFE |

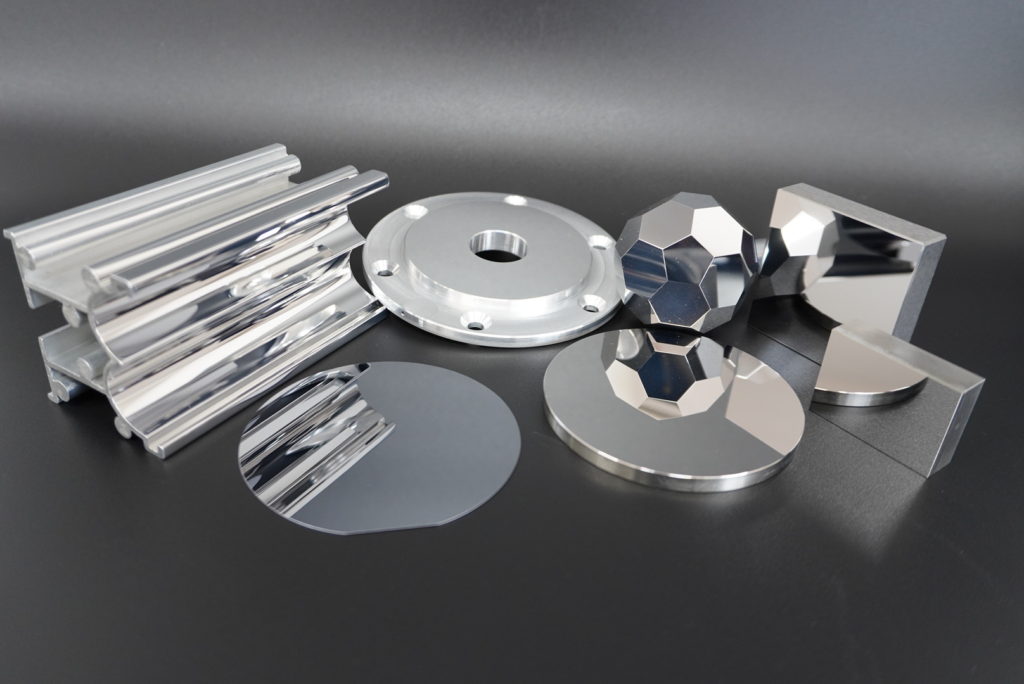

Processing Achievement

φ100x5mmt

| Polishing | Lapping with GC | |

| Flatness | 0.1 μm | 1 μm |

| Roughness(Ra) | 1 nm | Pear skin Finish/ Frost |

| Parallelism | 1 μm | 2 μm |

| Tolerance | ±0.5 μm | ±1 μm |

Please visit the page below to view TDC’s surface roughness Performance Data.

Applications

Explore our representative polishing case studies showcasing TDC’s technical capabilities.

For more information on our extensive track record and achievements, please visit the pages below:

Processing Examples: Precision Machining by Material

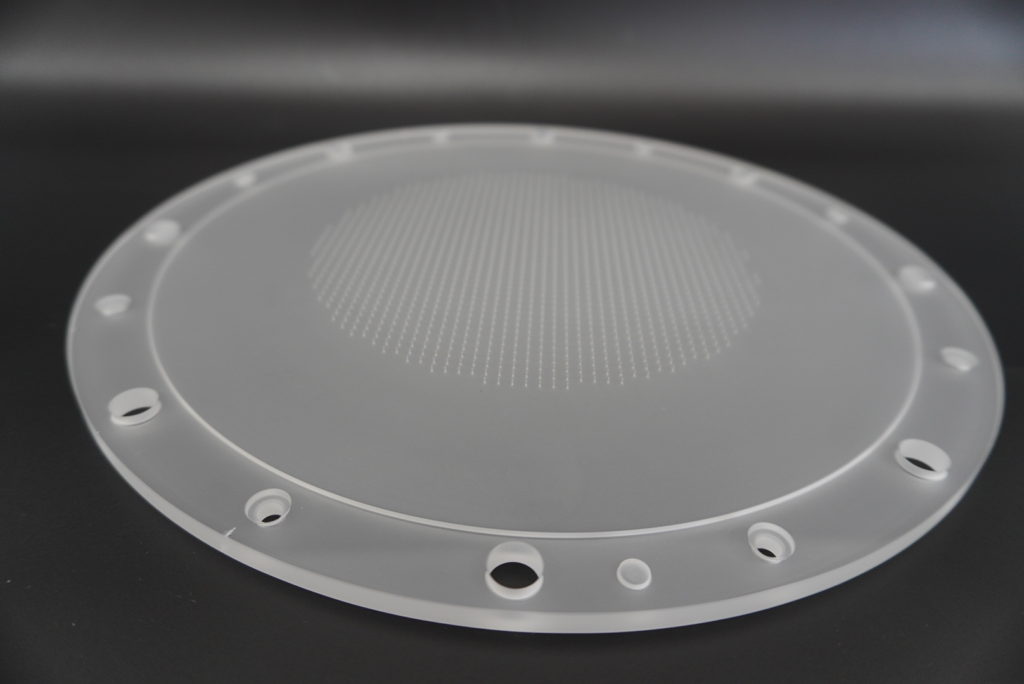

Wafer chuck plate, precision table

We process positioning plates and plates that require precision, which are used in semiconductor manufacturing equipment and precision measuring machines. It is possible to finish the flatness, parallelism, and dimensional tolerance with high accuracy, and to create the desired surface roughness such as smooth surface and satin ground.

Various crystal wafers

We perform precision CMP and thin polishing of wafers made of various materials such as silicon, sapphire, SiC, and diamond. We support from 1 sheet to small lots for experimental research to mass production.

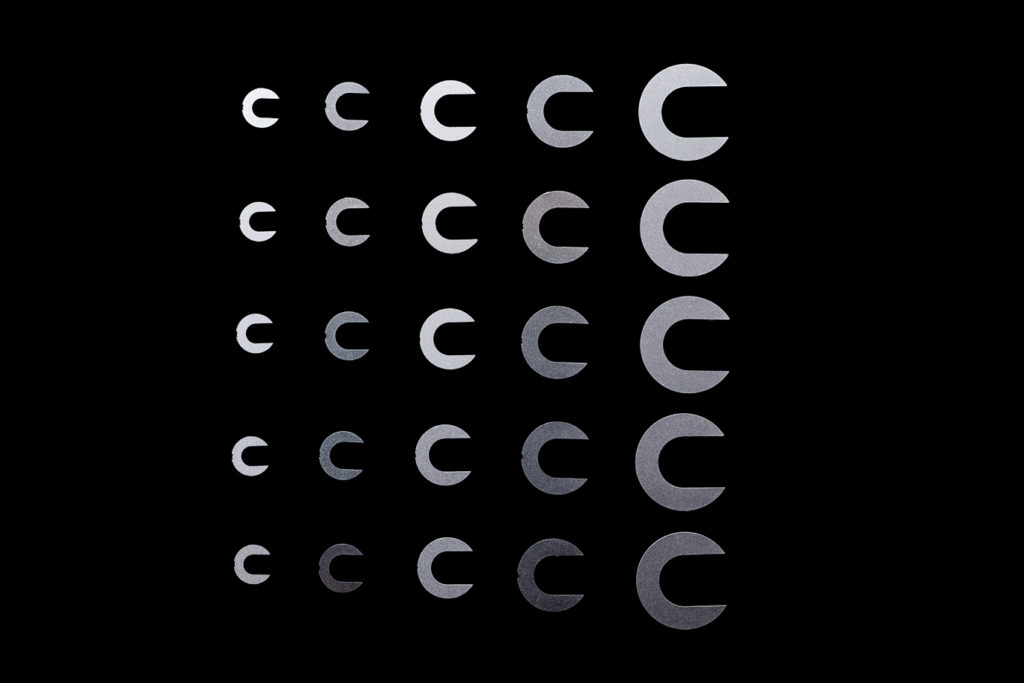

Shim

We manufacture shims that guarantee high accuracy such as ± 0.5 μm and ± 1 μm with thickness variations of 1 μm in the field where precise assembly is required, such as precision measuring machines, electronic devices, and medical devices,

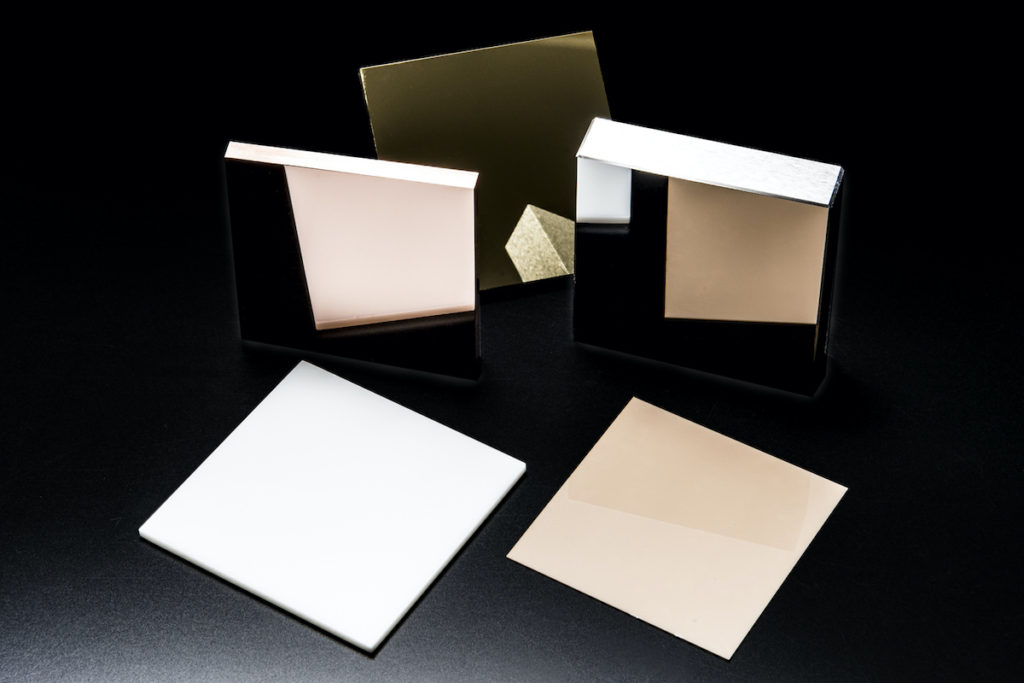

Test piece

Processing of test pieces used for friction and wear tests and tensile tests is also compatible with various materials. We also accept quick delivery.

Surface plate

We perform precision machining of surface plates used as reference planes in assembly and inspection that require an absolute flatness. In addition to stone surface plates and ceramic surface plates, we offer thermal spraying surface plates.

Mold

It is used in the production of various products such as plastic working, press working, and injection molding, and we perform precision polishing of dies where precision is extremely important. we handle not only flat surfaces but also complex shapes and uneven lens shapes.

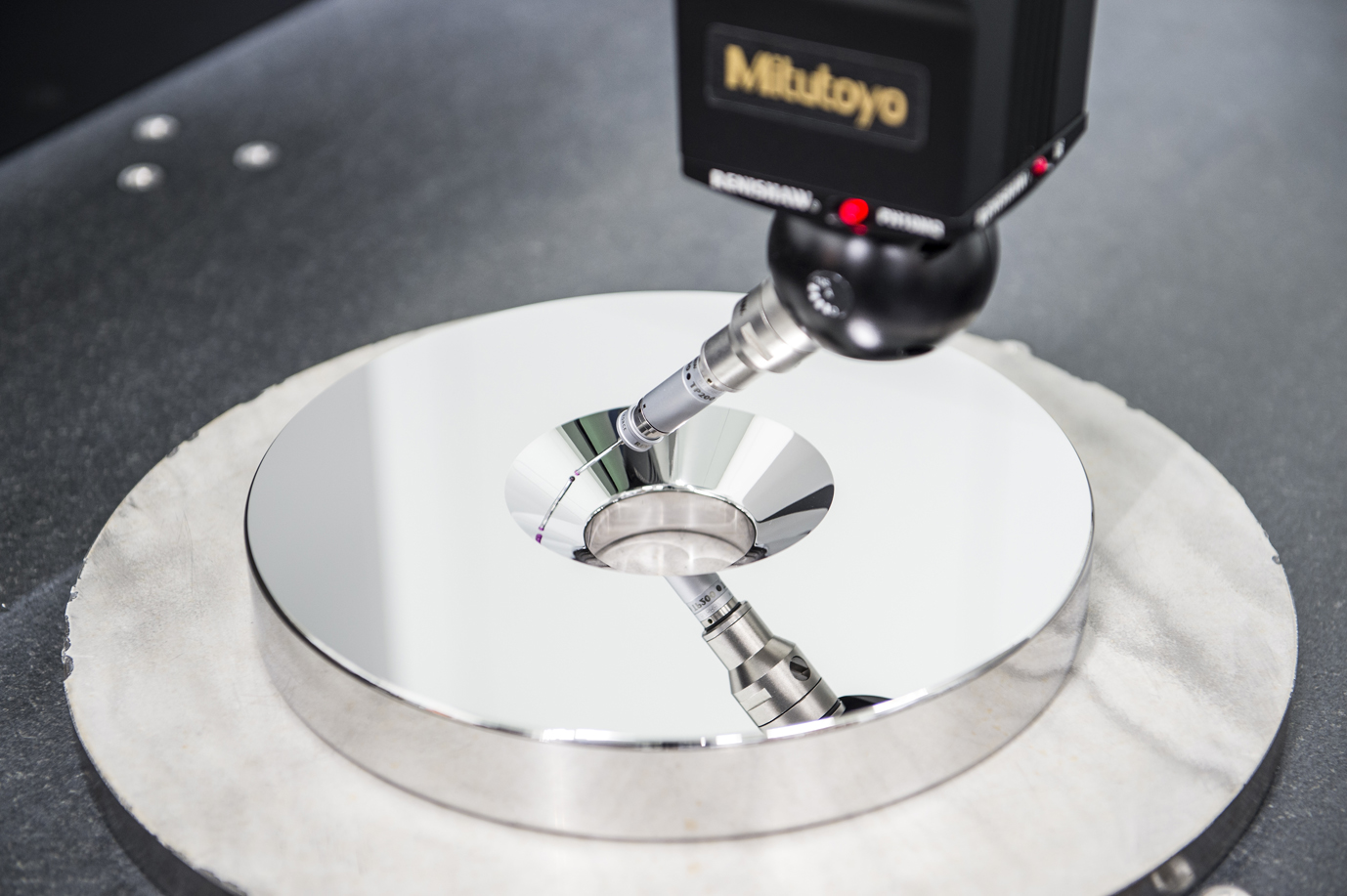

Sphere

We also process spheres for high-precision bearings and measuring probes. Ultra-precision can be achieved even for spherical surfaces where sphericity and surface roughness are crucial.

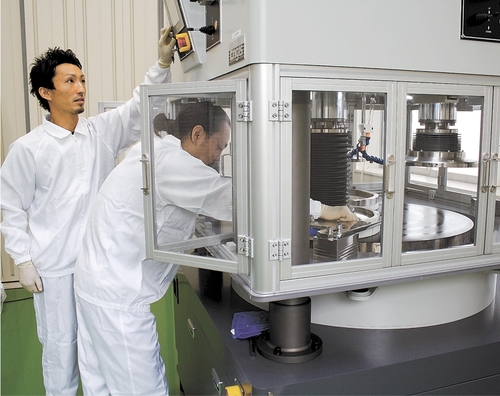

TDC’s polishing technology

Overview of Polishing Services

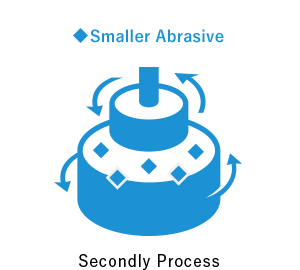

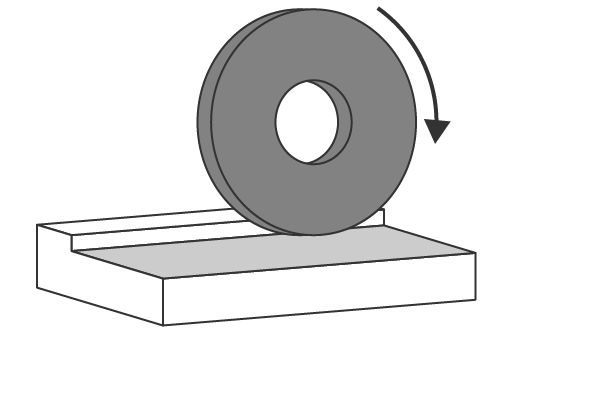

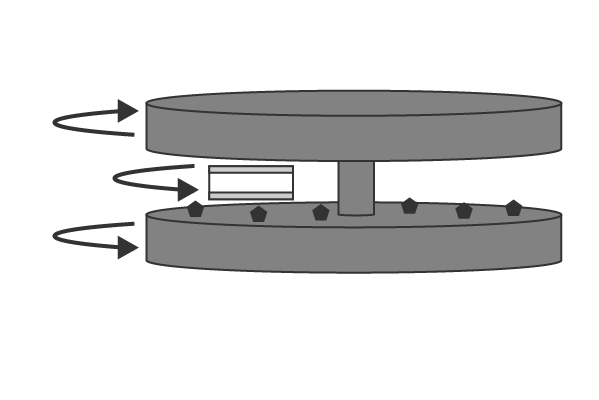

TDC provides a wide range of precision polishing services, with a primary focus on lapping. In the lapping process, workpieces are placed on a flat, disc-shaped platform called a “lap plate.” An abrasive liquid (slurry) is introduced while pressure is applied from both top and bottom to perform the polishing. Both the lap plate and the workpieces rotate, and as the process nears completion, we transition to progressively finer abrasive grains to achieve the final required precision.

By adjusting the degree of polishing and the composition of the slurry based on the desired accuracy, material, and shape of the workpiece, we enable precision machining at both the micrometer and nanometer scales.

We offer the world’s highest level of ultra-precision machining and ultra-precision lapping, such as surface roughness, parallelism, flatness, and dimensional accuracy.

Polishing Processing

Here is our manufacturing processing.

Feel free to send us the drawings for inquiry and we will support all processing.

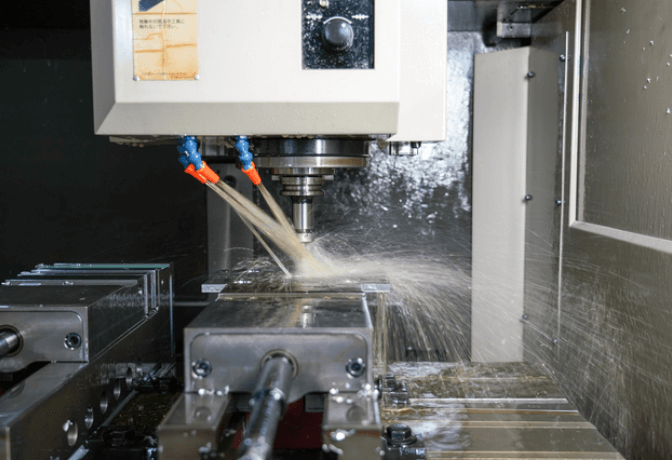

1.Cutting

Make the shape of a thing using a cutting tool such as cutting tools, drills, or end mills. We can change the shape quickly and greatly.

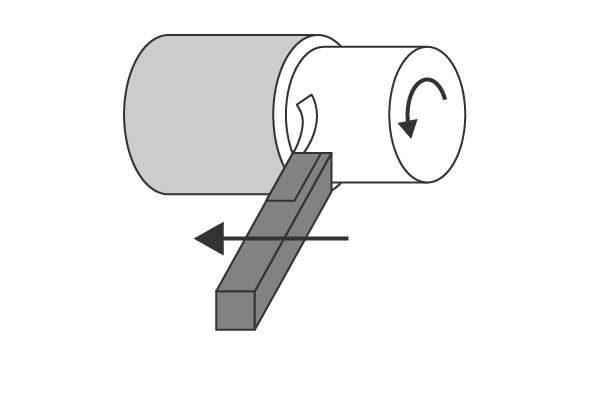

2.Grinding

Use fixed abrasive grains (grinding stones) to shape the object. Enable us to efficiently create the required dimensions, shape, and roughness.

3.Polishing

By slightly polishing the object using free abrasive grains (slurry), we can finish with the specified tolerance, surface roughness, and shape accuracy.

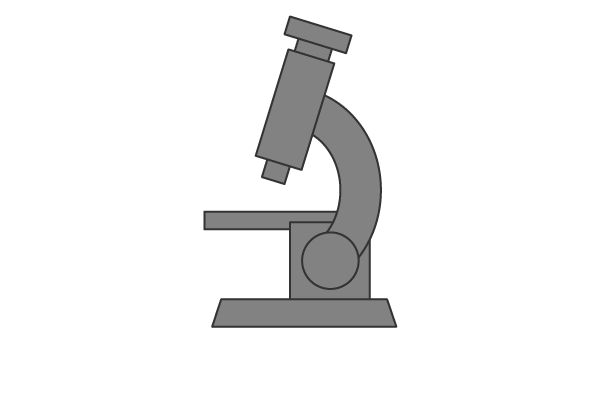

4.Inspection

Using the world’s highest level evaluation equipment, measurement is performed by professional staff in a measurement room at 20 ± 2 ° C and in a clean environment.

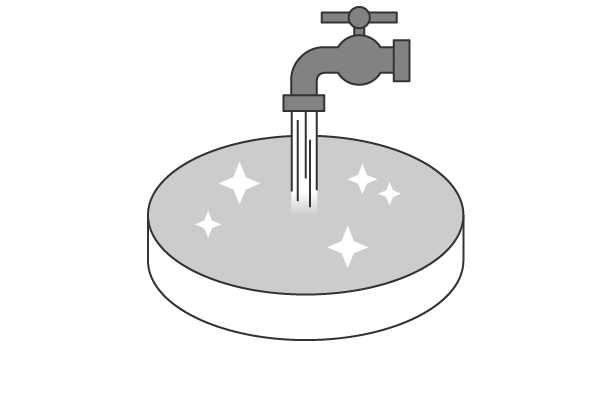

5.Cleaning

Ultrasonic cleaning is performed so that there are no visual stains or deposits.

6.Quality Assurance

Specialized staff check each final product one by one and carry out thorough quality control. We will deliver the inspection data as an attachment.

7.Shipping

TDC’s ultra precise lapping/polishing technology enables us to realize high precision manufacturing.

The ultra-precision polishing technology enables high-precision manufacturing in various elements.

- We deal with wide range of materials such as metals, ceramics, crystal materials, and resins in the size of □ a few micron to □ 800 mm.

- We realize ultra-precision polishing and ultra-precision lapping with surface roughness Ra1 nm and Rz4 nm for shapes such as flat surfaces, curved surfaces, and inner and outer diameters of cylinders.

- For other processing elements such as “parallelism 100 nm”, “flatness 30 nm”, “dimensional accuracy ± 100 nm”, “angle ± 3 seconds”, and “sphericity 50 nm” while clearing advanced “surface roughness”. High precision is possible.

- Our technology is used for cutting-edge technologies in various fields such as electronic components, semiconductors, optics, medical care, aviation, space, automobiles, and energy.

Regardless of the material and shape, we can handle precision processing by our polishing service.

Please feel free to contact us for more information.

Empower your projects with

nano-scale precision polishing.

― we’ve got you covered ―

Material procurement / Test pieces

Any materials & shapes / Hard-to-cut materials

Single to mass production

TDC Information

Related page