Antireflection film/Non-reflection film

This page introduces an overview of anti-reflection films and non-reflection films, and TDC’s mold polishing technology that is essential for anti-reflection film production.

Contents

What are anti-reflection film and non-reflection film?

Anti-reflection film and non-reflection film refer to films that achieve anti-reflection performance by forming a coating that changes the refractive index of light and a concave-convex structure that scatters light on a base film.

Since it can prevent the reflection of visible light, it can be applied to one or both sides of glass, acrylic, displays, etc. to suppress light and glare to a level of almost no reflection and improve visibility.

Application of anti-reflection film/non-reflection film

Anti-reflection films and non-reflection films are used in a variety of applications, including the following.

- Showcase for exhibits, etc.

- painting framed

- Glass and acrylic plates in front of the ticket office and cashier counter

- TV or computer display monitor

- automotive in-vehicle display

- Acrylic partition for new coronavirus infectious disease measures

Especially in recent years, the demand for anti-reflection film for acrylic partitions, which are used as a countermeasure against infectious diseases, is increasing in restaurants, TVs, media, etc.

Representative anti-reflection film technology “Moth Eye Film”

Moth-eye film is one of the anti-reflection film technologies.

Moth-eye film is a high-performance anti-reflection film that can significantly reduce reflections by forming a nano-sized fine projection structure on a base film and continuously changing the refractive index.

This structure is also called a moth-eye type anti-reflection film because it applies the property of a moth’s ommatidium, which reflects almost no light.

In this way, elucidating the excellent structures and functions of living things and nature and applying them to science and technology is called “biomimetics.” Development is progressing.

“Mirror finishing of the mold” is essential for the production of moth-eye film

Nanoimprint, a microfabrication technology that can transfer patterns of several tens of nanometers, is used for structures with fine unevenness such as moth-eye films.

In order to pattern a moth-eye structure using nanoimprinting, it is essential to apply a mirror finish to the mold.

For this reason, mirror-finishing of molds is essential for the production of anti-reflection and non-reflection films, including the production of moth-eye films.

Leave the mold polishing for anti-reflection and non-reflection films to TDC

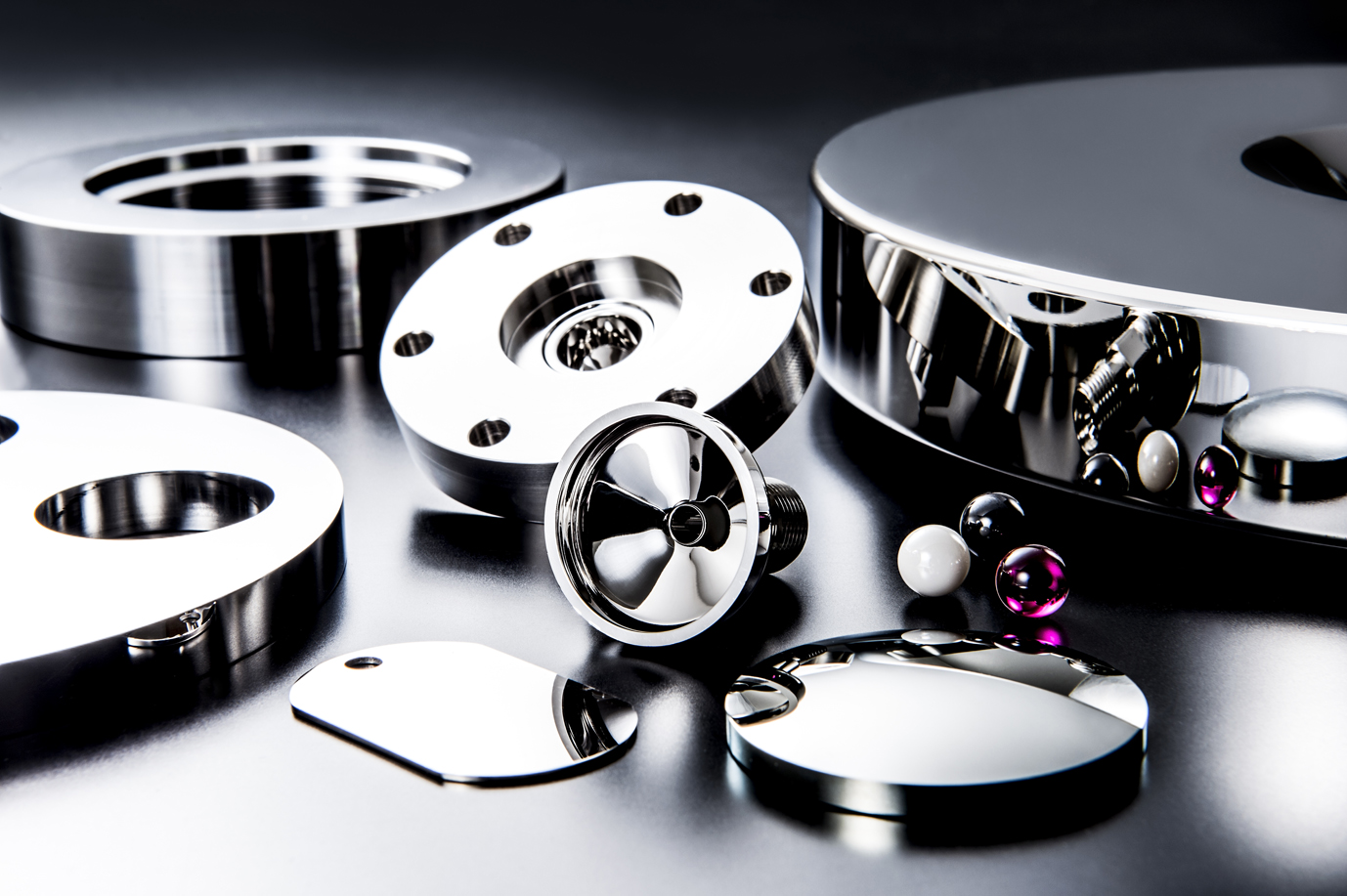

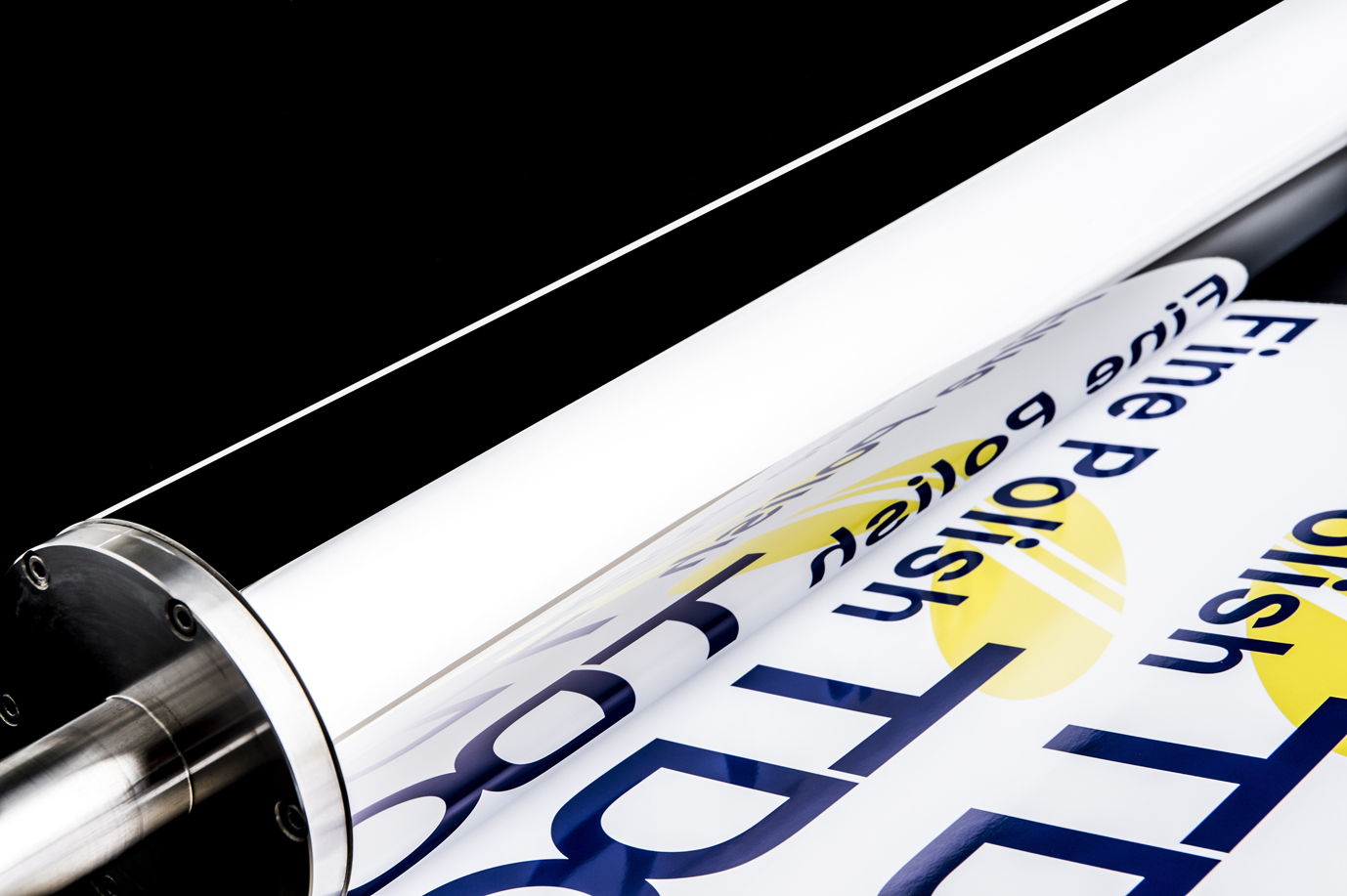

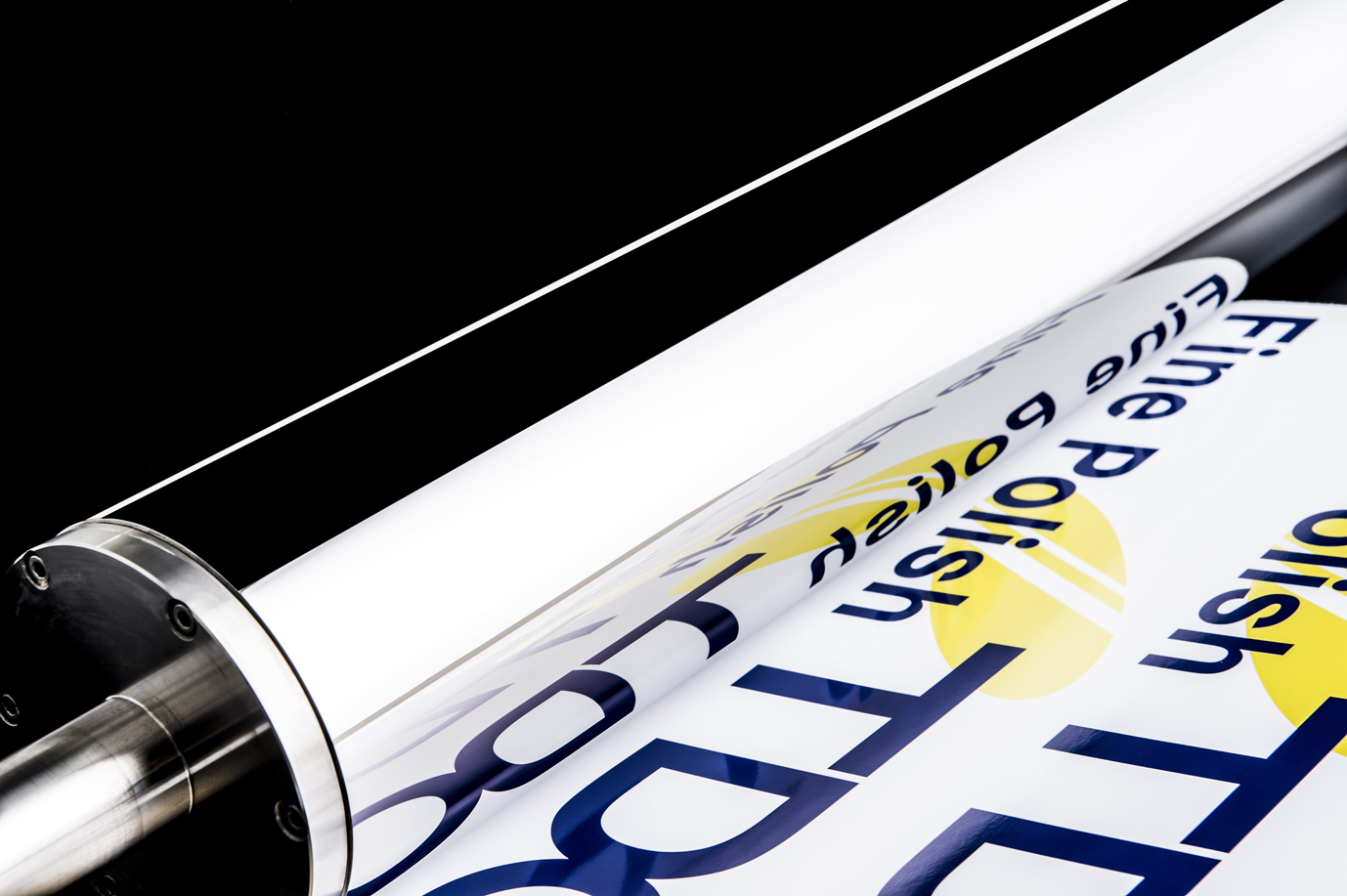

As a nanotechnology solution, TDC offers polishing of roll molds for nanoimprinting.

We have developed equipment and technology that can handle the inner and outer diameters of rolls, which was previously thought to be impossible, and have achieved high precision molds for nanoimprint and high-performance film manufacturing.

It is possible to perform precise polishing without compromising accuracy even with wide rolls, and because of this quality, we have received many requests for mold polishing of anti-reflection and non-reflection films.

If you are looking for a higher quality anti-reflection/non-reflection film, please make use of TDC’s high-precision mold mirror-finishing.

TDC Information

Related page