Precision processing, polishing, ultra-precision polishing – precision processing services

Introduce basic knowledge about precision polishing and ultra-precision polishing, and TDC’s precision processing examples.

What is the difference between precision polishing and ultra-precision polishing?

Processing that requires high-precision polishing technology can be broadly classified into two types: “precision polishing” and “ultra-precision polishing”.

In general, “precision polishing” refers to polishing that can achieve a microscale processing accuracy of 1/1000 mm (millimeter) at maximum.

On the other hand, we define “ultra-precision polishing” as a polishing process that can achieve nanoscale processing accuracy at a maximum scale of 1/1000 um (micrometer).

What is precision polishing?

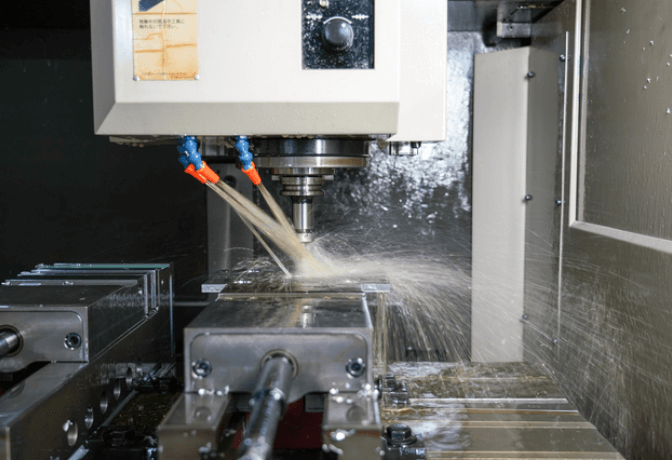

In general, precision polishing is defined as “polishing in micron units”, and it is a processing work that requires the ability to precisely cut out any shape using various tools and machines.

It is a delicate work that requires precision on the order of several microns to several tens of microns, and requires a high level of technology, such as selecting machines and polishing, grinding, and cutting methods according to the product to be processed and its accuracy. It is said that there are various things that can be processed, such as ceramics and hard metals.

What is ultra-precision polishing?

It is a polishing process that can achieve precision at the nanoscale of 1/1000 μm (micrometer), which is one step further than the microscale of several microns to several tens of microns, which is the condition of precision polishing. It is called “ultra-precision polishing”.

Ultra-precision polishing processing is generally applied to the processing of precision machinery parts and optical parts such as semiconductor wafers and lenses for cameras, but TDC can accept any request.

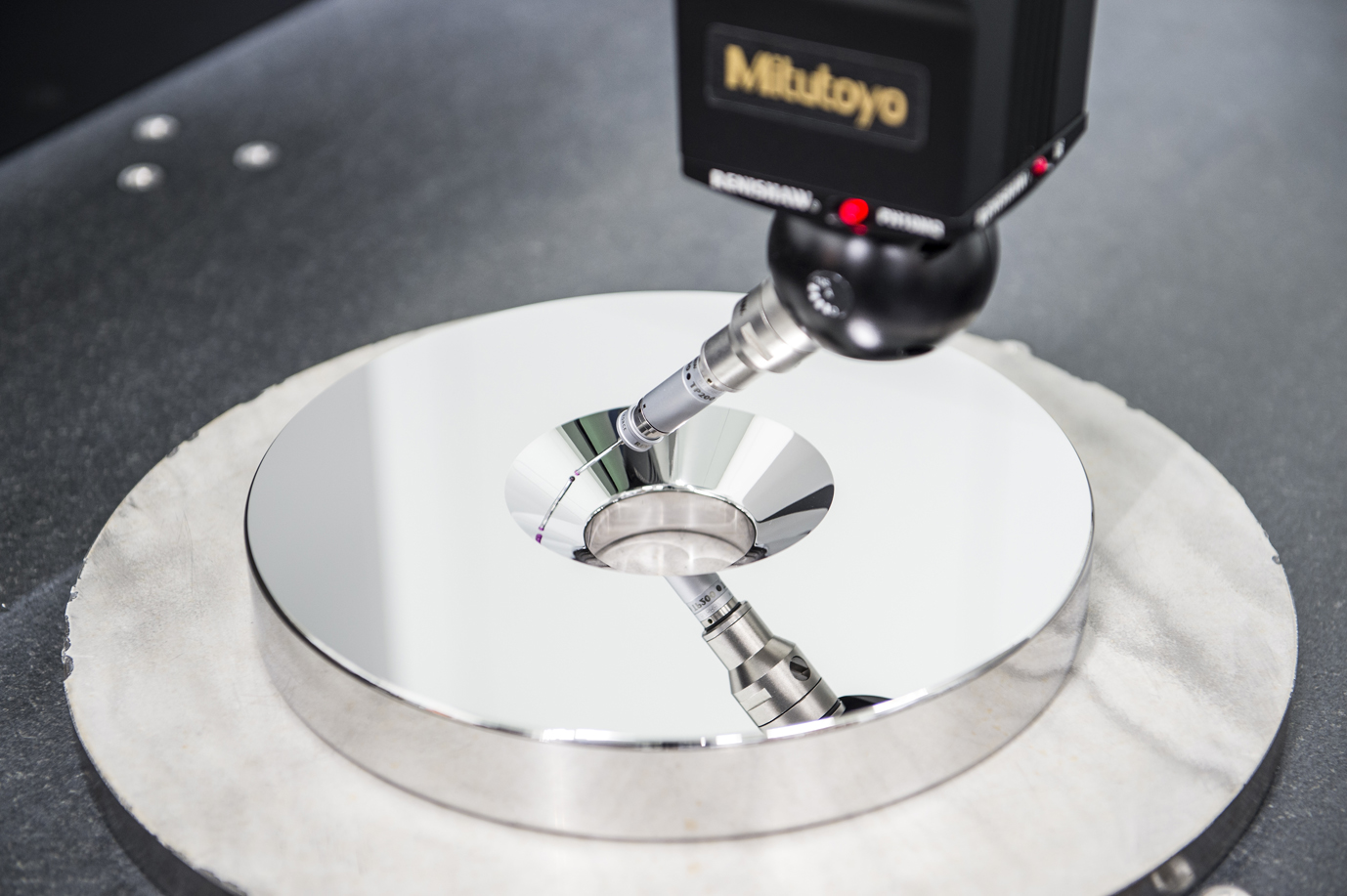

Since nano-level processing accuracy is required, it is a polishing technology that is difficult to implement unless all conditions are met, such as the use of a measurement environment with thorough temperature control and the use of dedicated tools and equipment.

What is the definition of precision machining?

Precision machining is generally performed by applying pressure, machining, plastic working, etc. to a wide variety of materials such as metals, plastics, ceramics, rubber, and wood with machines, tools, dies, etc. It refers to the processing technology that produces the shape.

In addition to directly processing products and their parts, it is also used to manufacture precision tools and dies for processing parts into predetermined shapes.

Precision machining is a core technology that forms the basis of the manufacturing industry, and the technical level of machining and forging machines, which are the core of machining, has a great impact on the competitiveness of other industries.

Precision machining accuracy

Precision machining can achieve machining accuracy on a scale of up to 1/1000 mm = 1 μm (micrometer).

In other words, precision machining can be regarded as a machining technique in the microscale world.

Furthermore, ultra-precision machining can achieve machining accuracy on a scale of up to 1/1000 μm. Since 1/1000 μm = 1 nanometer, precision machining and ultra-precision machining are technologies for micro-nanoscale machining.

| precision machining | super precision machining | |

| tolerance | ≦±0.005mm | ≦±0.0005~0.001mm |

| roughness | Ra ~0.01um | Ra ≦ 0.01 um |

| Geometric tolerance | ≦0.005~0.01mm | ≦0.0005~0.001mm |

*The values in the table are for reference only, and we do not strictly distinguish between precision machining and ultra-precision machining.

*Difficulty varies depending on complex factors such as shape, material, and required accuracy.

The need for precision machining

Parts that require precision machining have characteristics such as “reliability,” “strength,” “degree of freedom in shape,” and “small lots.”

The applications for which these characteristics are required are as follows.

- Parts for machine tools, semiconductor manufacturing equipment, various measuring equipment, etc.

- Automobile parts that transmit lean power, mechanical parts that can withstand long-term use, etc.

- Parts that are required to be produced in ultra-precision and small lots, which are used in equipment and devices in IT and mechanical engineering.

- Parts that support advanced motion such as aircraft engines and mechanic parts

These parts are required to have a high level of quality due to precision machining.

Machine tools that produce various parts also require precision machining

Metal-based products such as automobiles, aircraft, and digital devices require machine tools for drilling, shaving, and processing metal parts.

And it is no exaggeration to say that the quality and accuracy of all products depend on the quality and accuracy of the parts used in product assembly.

Therefore, precision machining is indispensable for the machine tool itself that manufactures parts. In order to produce high-quality products and parts, machine tools, which are also called mother machines for many products and parts, require high precision and performance.

Cases of precision machining ・ Industries that require precision machining

Products manufactured by precision processing are active in various industries.

The following industries are the delivery destinations for major precision processed products.

- semiconductor

- Automobile

- Nanotechnology

- MEMS micromachine technology

- Industrial equipment / inspection equipment / measuring equipment

- Optical equipment

- Electronic devices / electronic components

- Medical equipment / analyzer

- Next-generation energy development field

- Aerospace

- Chemistry-related equipment / technology

- Pharmaceutical equipment

In addition, the main applications for ultra-precision machining are generally from the “semiconductor field” and “optical field”, but TDC has received many requests from other fields as well.

In the semiconductor field, nanomicrometer-scale processing is required for etching on semiconductor substrates, and in the optical field, the surface roughness and shape error of lenses are finished at the nano level.

Nano-level precision is also required for lens dies, which is a field that requires ultra-precision machining.

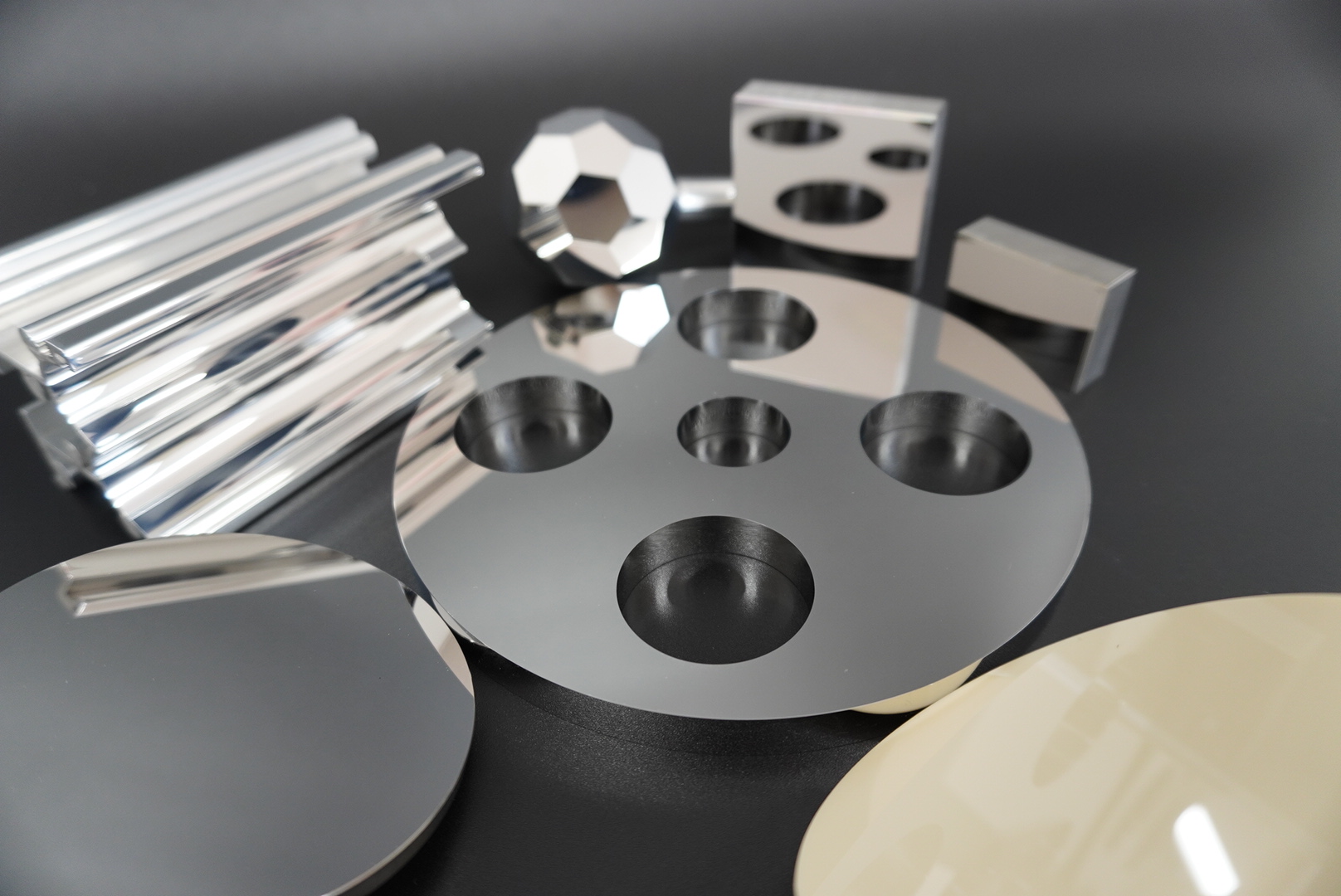

TDC precision machining and ultra-precision machining

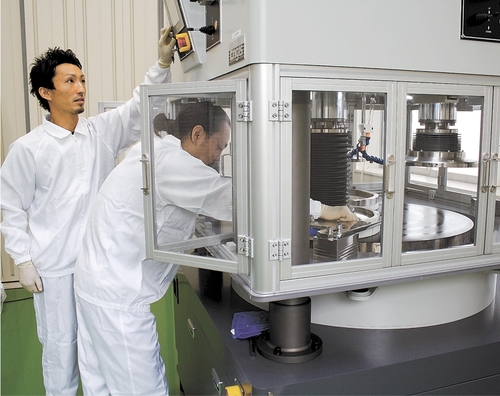

Our precision polishing process uses surface grinders and lapping machines. We have received many requests to improve the flatness and parallelism of precision stages and tables used in semiconductor manufacturing equipment and precision measuring machines.

In ultra-precision polishing processing, it is possible to simultaneously realize two or more geometrical tolerances such as flatness, parallelism, dimensional tolerance, surface roughness, and perpendicularity in nano-order. In addition to lapping machines and polishing machines, we use our own proprietary equipment and jigs. They are used as components for semiconductor manufacturing equipment and optical components that require the ultimate in high precision.

In addition to ceramics, metals, and glass, we have many achievements in this kind of processing for materials such as stone surface plates.

with nano-level precision polishing.

and production from single units to mass production.

Related page