What is CMP

This page is introducing the basic knowledge of CMP processing.

CMP is a processing method that smooths the surface of the product by the synergistic effect of a chemical and mechanical approach. It is widely used mainly in the semiconductor field.

What is CMP

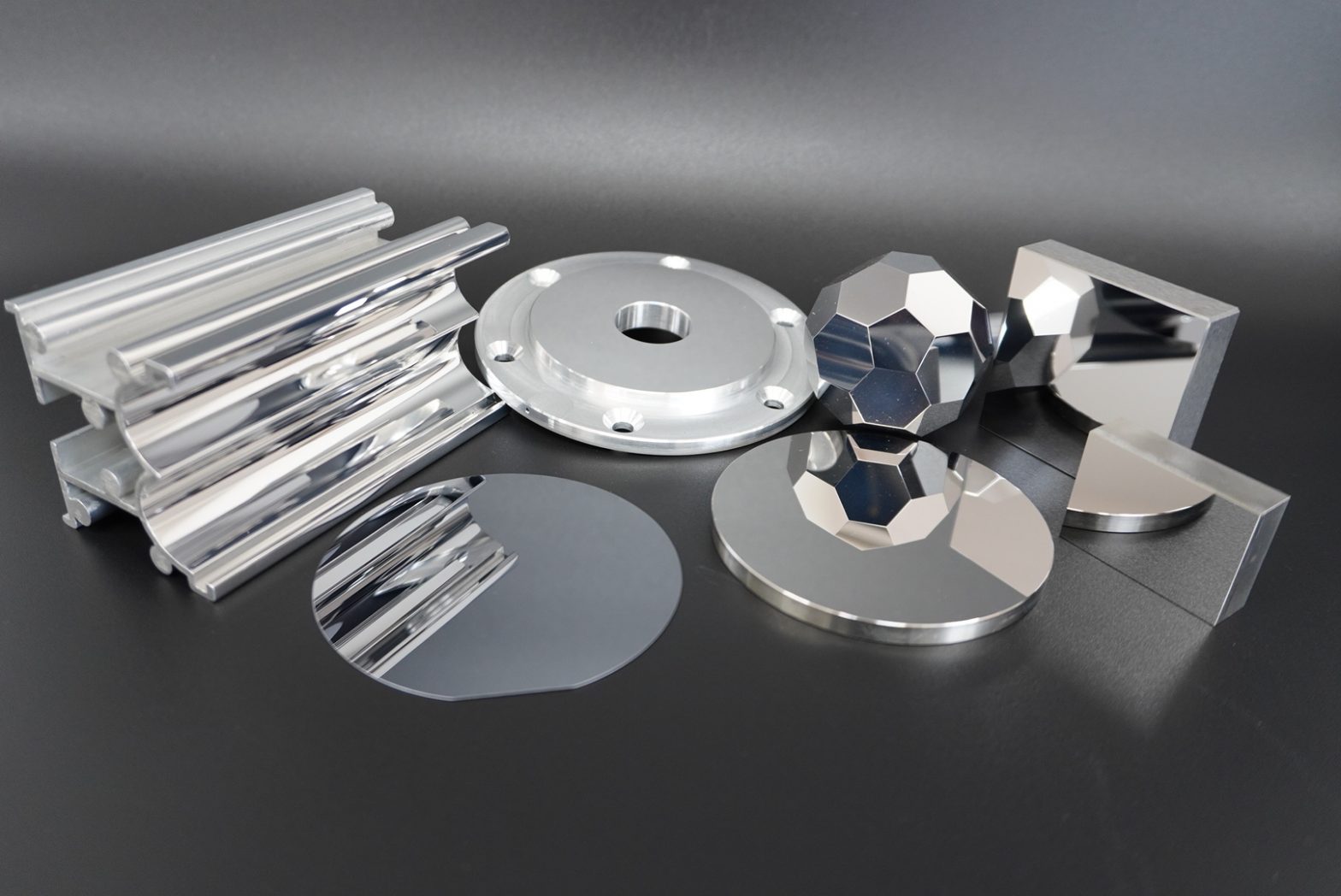

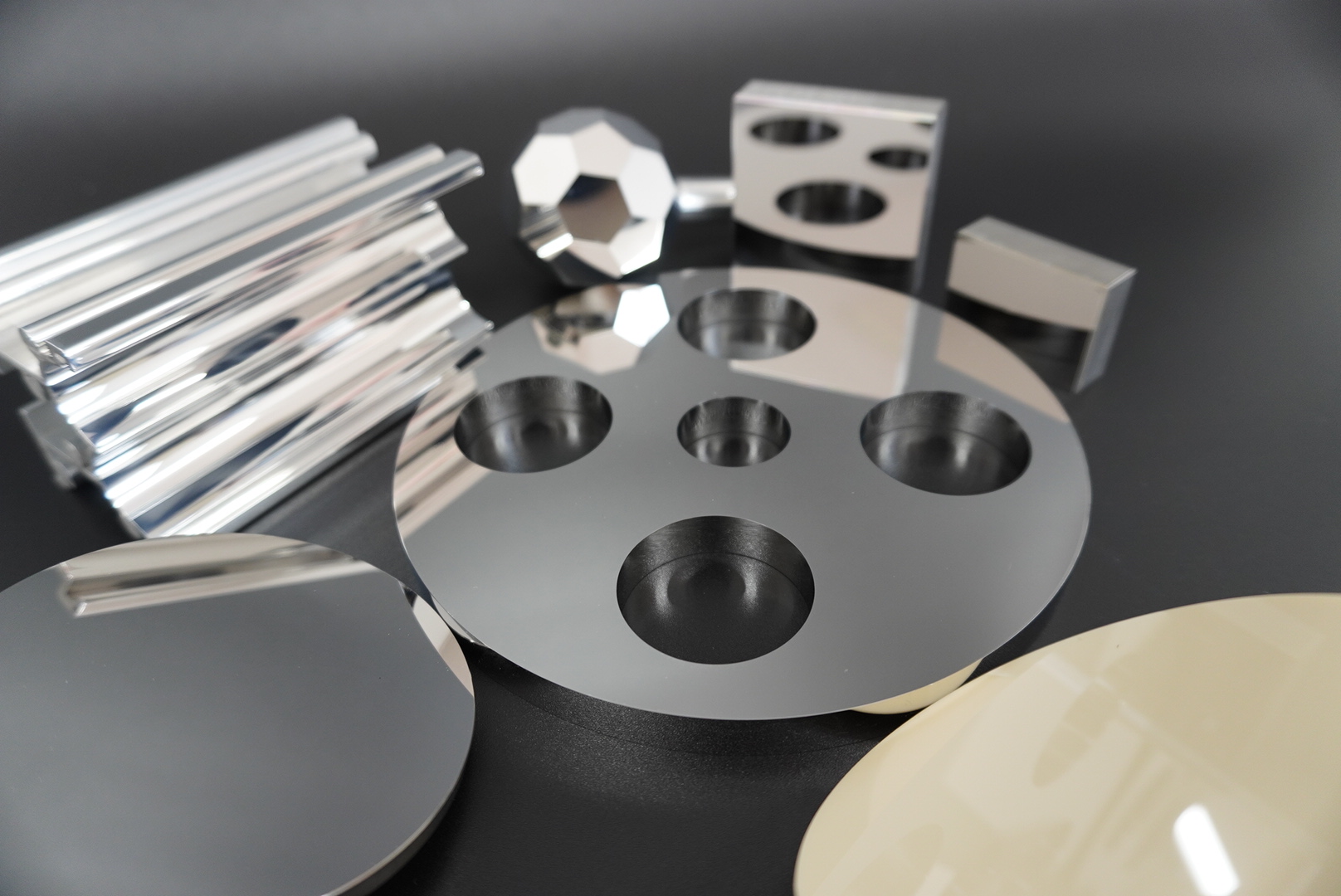

One of the advantages of CMP processing is that the surface roughness can be adjusted at the atomic level.

By rearranging the composition of the slurry (slurry = mixture of solid abrasive grains in a liquid), different substances existing on the same substrate can be polished together, and also it is possible to polish only the selected substances.

This technology is widely used mainly in the semiconductor field.

Examples of some applications are wafers for power devices and MEMS devices, polishing of difficult-to-cut materials such as SiC and GaN.

TDC’s CMP processing

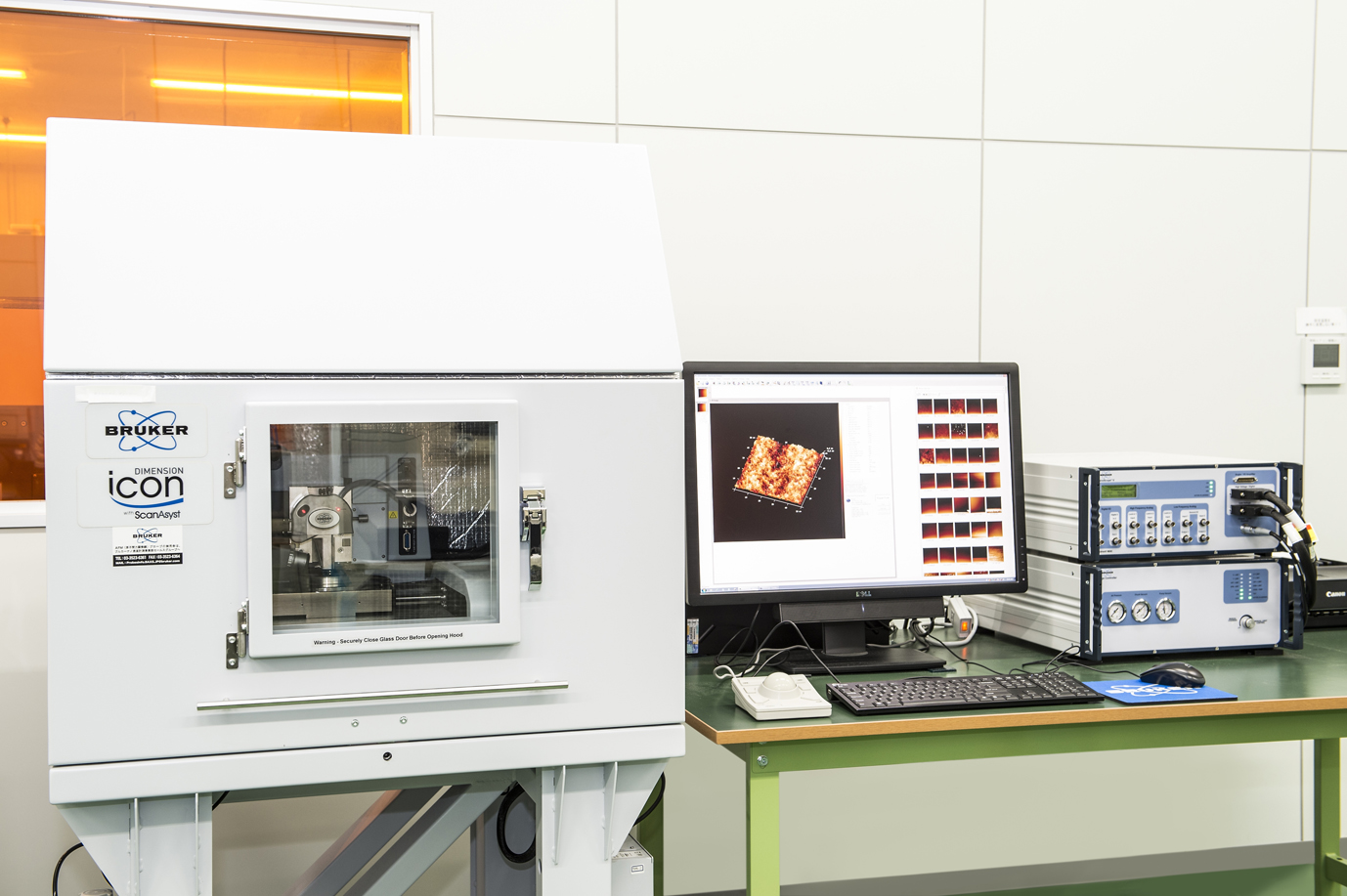

TDC’s “ultra-precision polishing” means not only lap polishing, but also CMP processing

We will select the most suitable processing method according to the customer’s needs.

please feel free to contact us once as we can respond to requests for processing using CMP.

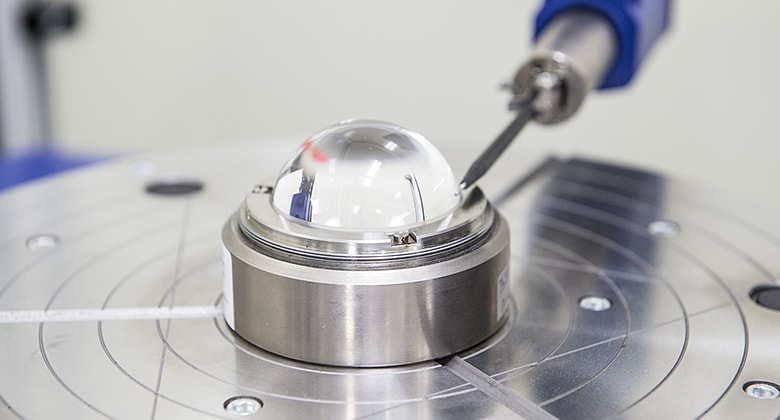

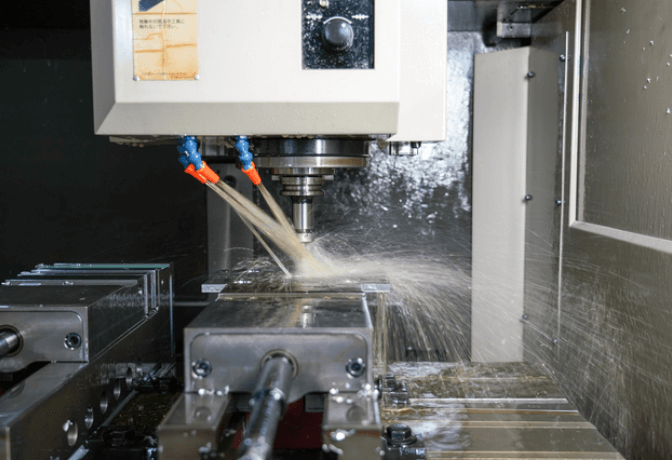

How the CMP process works

Unlike general polishing, CMP processing uses a chemical approach with slurry (suspended free abrasive grains) processing solution and a mechanical approach that uses abrasive grains such as silica, alumina, and zirconia to polish at the same time. By doing so, it refers to a way to make the surface of the product smoother.

Another feature is that the speed and quality of polishing can be improved due to the synergistic effect of each.

It is a technology used for finishing precision equipment such as chemical mechanical flattening of SiC substrates and wafers.

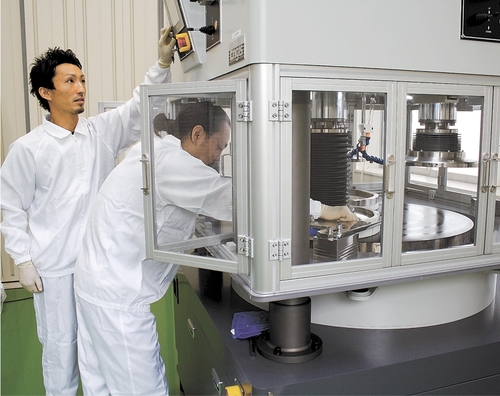

CMP in TDC

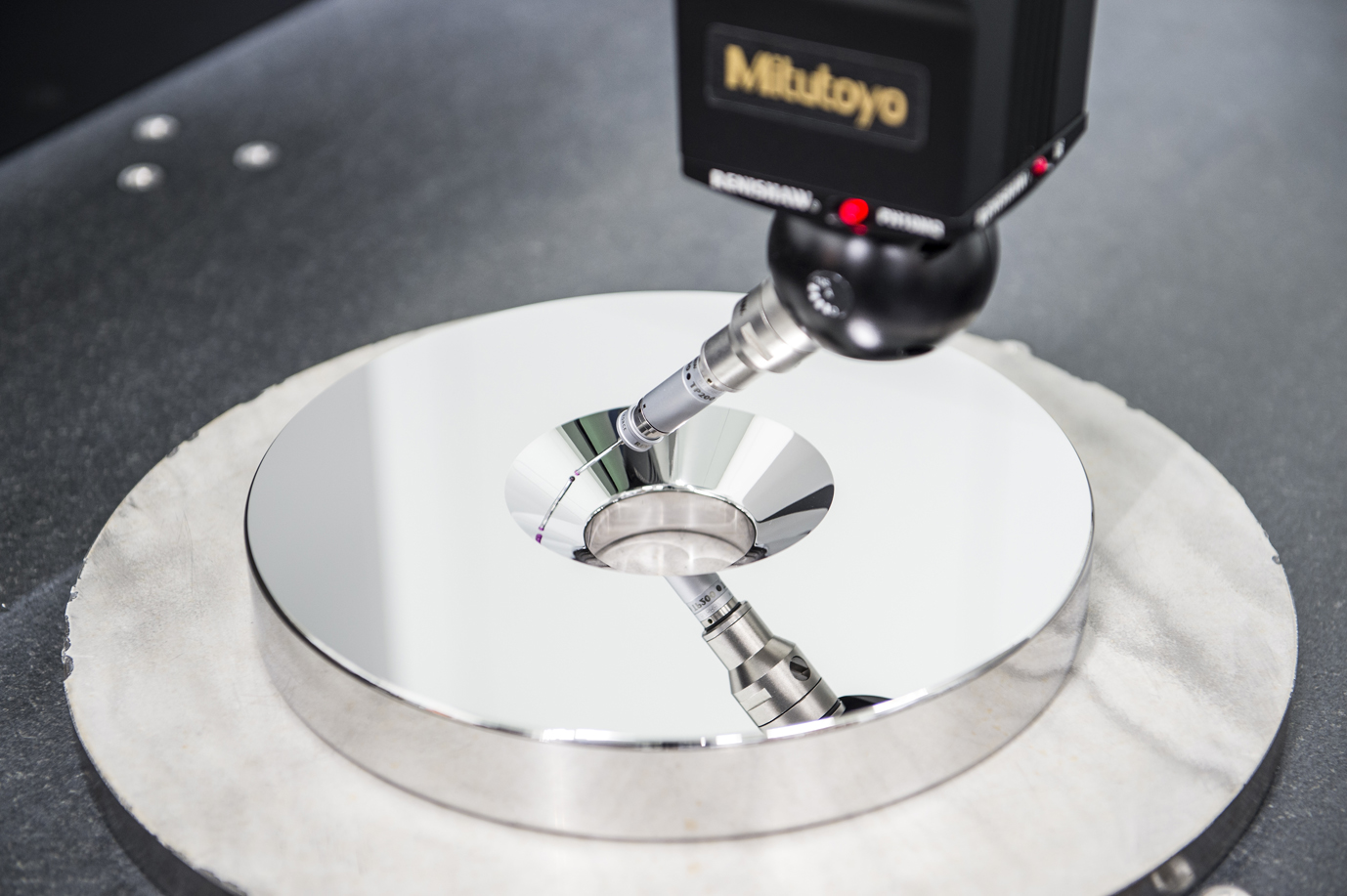

CMP processing is a synergistic effect of chemical and mechanical approaches that makes the surface of the product smooth.

Therefore, if you are not familiar with the construction method, you may not be able to perform optimal processing for the product.

TDC can deliver products according to your desired delivery date, and has accumulated unique technological development and know-how in processing, making it possible to handle any shape.

Please feel free to contact us for any inquiries regarding processing or basic concerns.

Related page

- Precision lapping service / ultra precision lapping service

- Polishing service

- What is Grinding

- What is cutting

- What is a chuck table? | Basic information and description of types, Processing accuracy at TDC

- Copper polishing

- Polishing after thermal spraying

- Sapphire polishing

- Polishing of plastic/acrylic resin

- Polishing after surface treatment/coating

- Symbol used for polishing

- Polishing of SiC

- Polishing of titanium

- Cylindrical grinding/cylindrical polishing

- Type of polishing process

- What is the accuracy that can be achieved by polishing?

- Principle of polishing process

- Polishing process for Resin

- Metal polishing process

- ステンレスの研磨加工

- What is CMP

- What is polishing?

- About Lapping and Polishing