What is polishing?

Here is the basic knowledge of polishing.

Contents

What is polishing?

Polishing is the one of the ways to make the surface smooth. It is the processing to give gloss to the product and usually adopted as the final process of machining processing. Diamond polishing is also famous for its method using diamond abrasive grains called slurry.

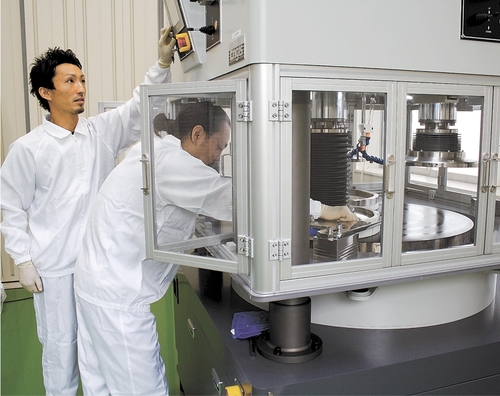

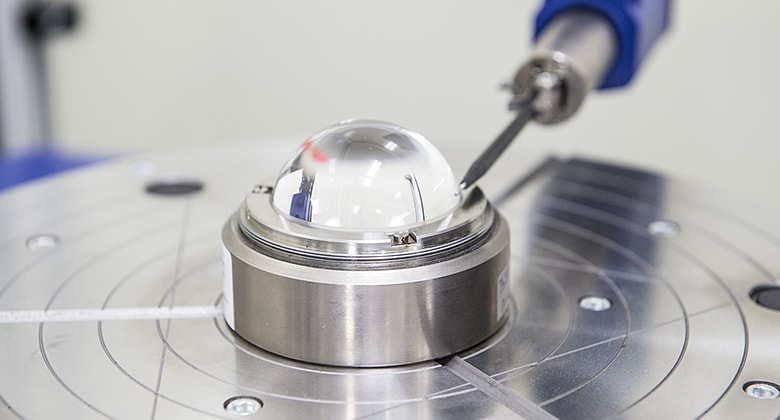

TDC’s polishing

In TDC’s precision polishing and ultra-precision polishing, in addition to lap polishing, polishing is also incorporated depending on the precision and processing purpose.

We will select the most suitable processing method according to the customer’s needs. Our polishing not only gives the surface roughness and luster, but also realizes ultra-precision accuracy by removing a very small amount. Please feel free to contact us as we can respond to ultra-high precision requests.

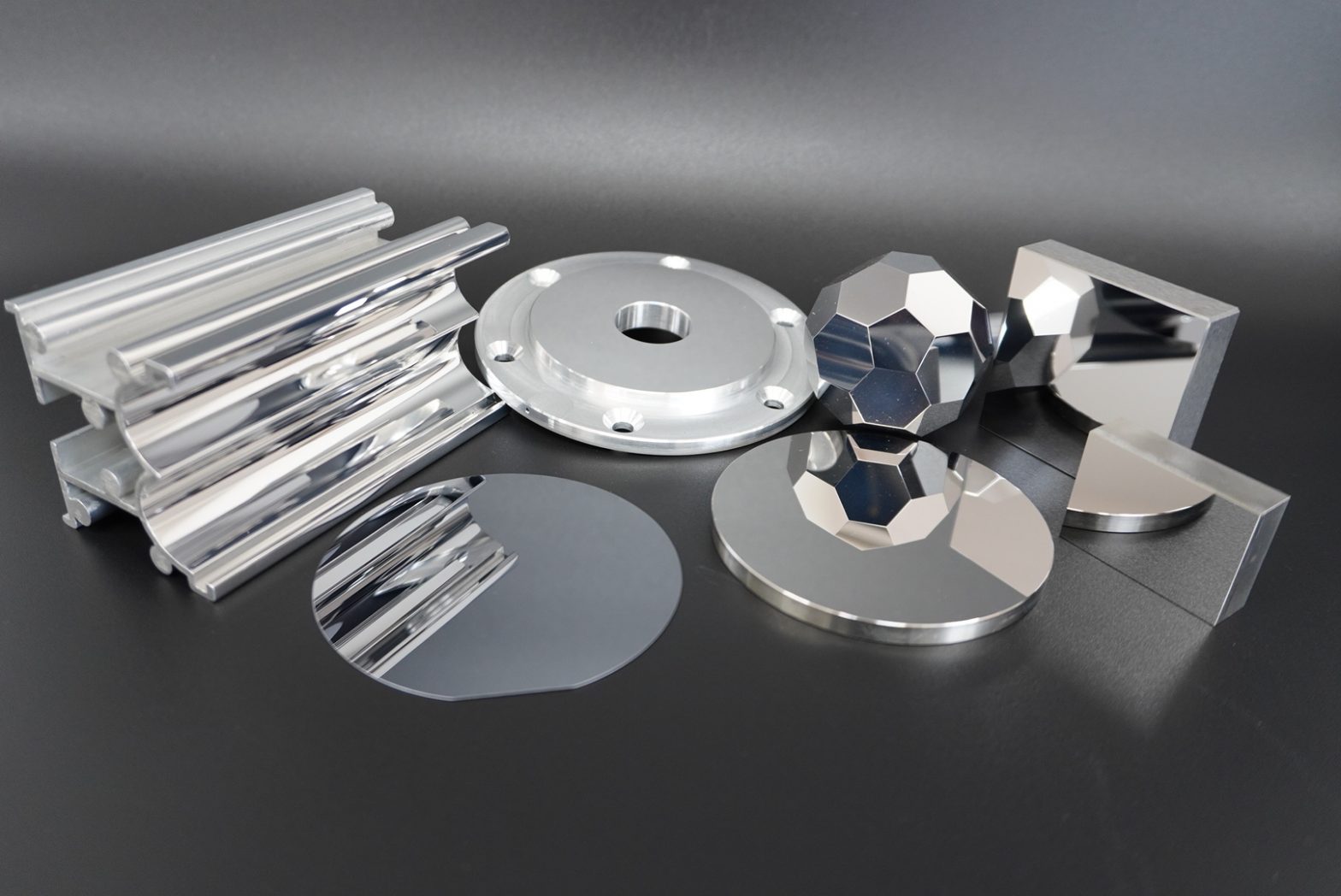

Main materials for polishing processing

| Metal | Steel materials in general, carbide, stainless steel, copper, titanium, aluminum, molybdenum, tungsten, nickel, tantalum, and other metals |

| Ceramics | Polishing of coated surfaces such as thermal spraying of alumina, zirconia, sapphire, silicon, silicon carbide, and silicon nitride is also possible. |

| Crystal | Glass in general, silicon, SiC (silicon carbide), sapphire, GaN, etc. |

| Resin | Various engineering plastics, polyimide, Teflon, etc. |

with nano-level precision polishing.

and production from single units to mass production.

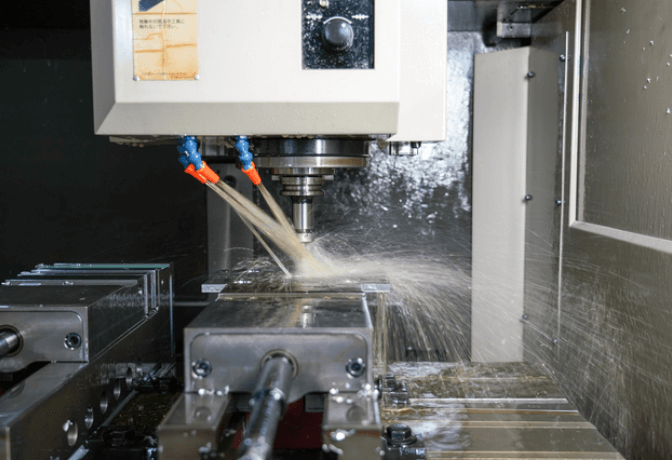

Polishing method / processing principle

Polishing is a delicate method that requires higher accuracy than lapping.

Construction methods include mechanical polishing and chemical mechanical polishing (CMP). Since the product is polished using fine abrasive grains and soft pads, it is characterized by being able to perform mirror processing without generating scratches, cracks, or alteration layers.

There is also what is called diamond polish, which uses diamond abrasive grains to achieve both processing efficiency (removal speed) and surface roughness.

By the way, it may be necessary to note that the word polishing in the field of optics may mean polishing the surface and finishing / cleaning.

Three theories on the polishing process principle

There are three theories for the main processing mechanism of polishing: the microcutting theory, the surface flow theory, and the chemical action theory.

The microcutting theory is interpreted as mechanical, the surface flow theory is interpreted as thermal, and the chemical action theory is interpreted as chemical action and effect.

In addition, these effects are more likely to act in combination rather than independently.

micro cutting theory

The theory is that the crushing action of abrasive grains, which are abrasives, scrapes off protruding parts of the object to be processed to flatten it.

As the abrasive grains are pressed into the surface of the workpiece, plastic deformation occurs preferentially at the contact points with the abrasive grains. This phenomenon occurs all the time, especially with metallic materials that are susceptible to plastic deformation.

In addition, even in the case of non-metallic brittle materials such as ceramics, which are mainly subject to brittle fracture, plastic deformation occurs when the abrasive grains are extremely small and the indentation depth is shallow.

surface flow theory

The surface flow theory is the theory that polishing occurs when the contact point softens at high temperature and melts due to the heat generated by the deformation of the object to be processed and the friction with the tool.

It is said that the fluidized bed hides the cutting traces and microcracks remaining on the surface of the workpiece, giving the surface a mirror finish.

chemical theory

The theory of chemical action is that a chemical reaction occurs between the abrasive grains, the polishing liquid, and the workpiece, and the abrasive grains remove the resulting hydration layer to smooth the surface. It was proposed in the 1930s as a mechanism for polishing glass.

A soft silica gel layer is formed on the glass surface by the action of the polishing liquid (water), and this soft gel layer is removed by the fine cutting action of the abrasive grains. Once the original glass surface is exposed, the action of water again produces a silica gel layer. The idea is that polishing is done by repeating this mechanism.

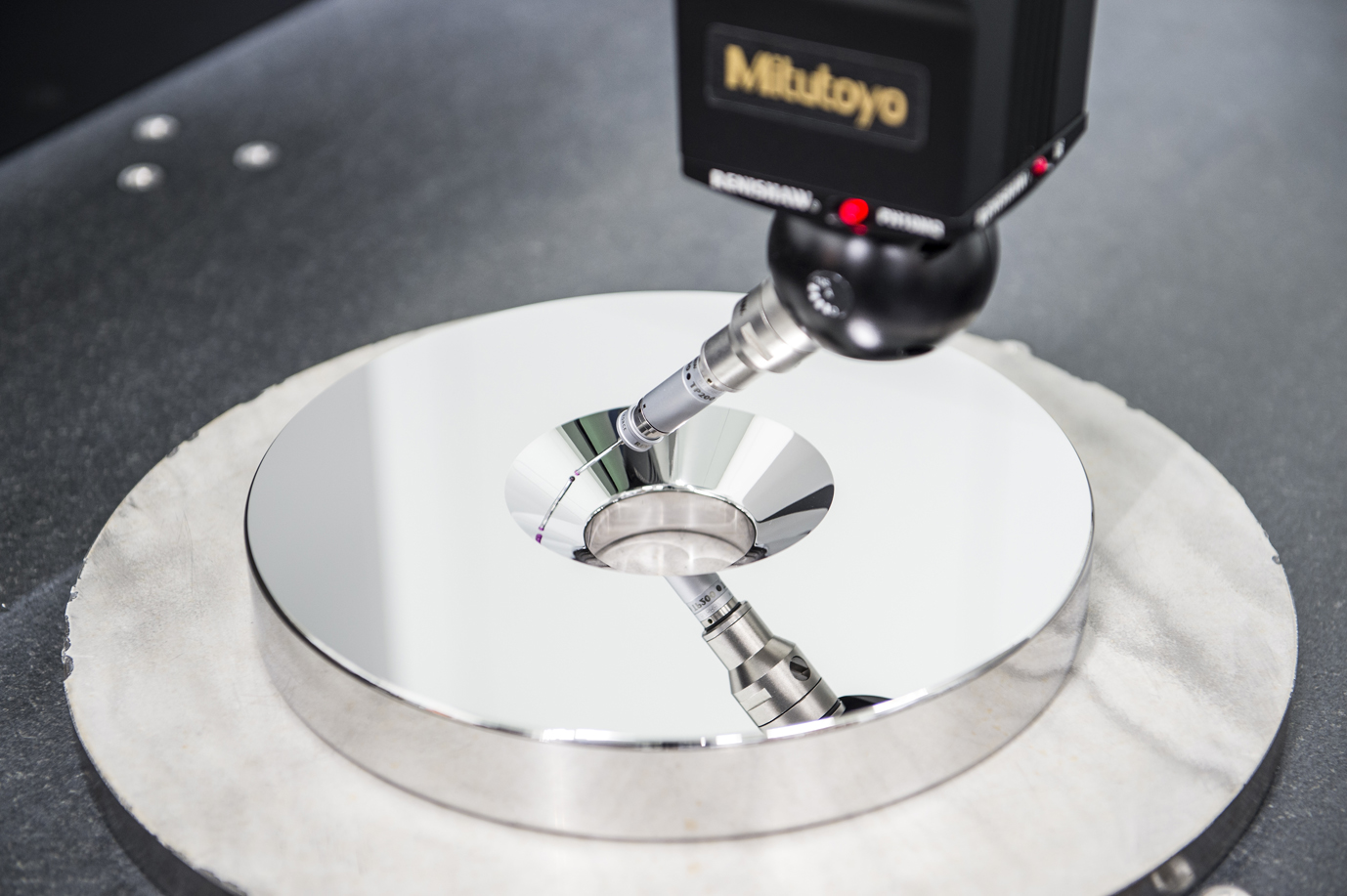

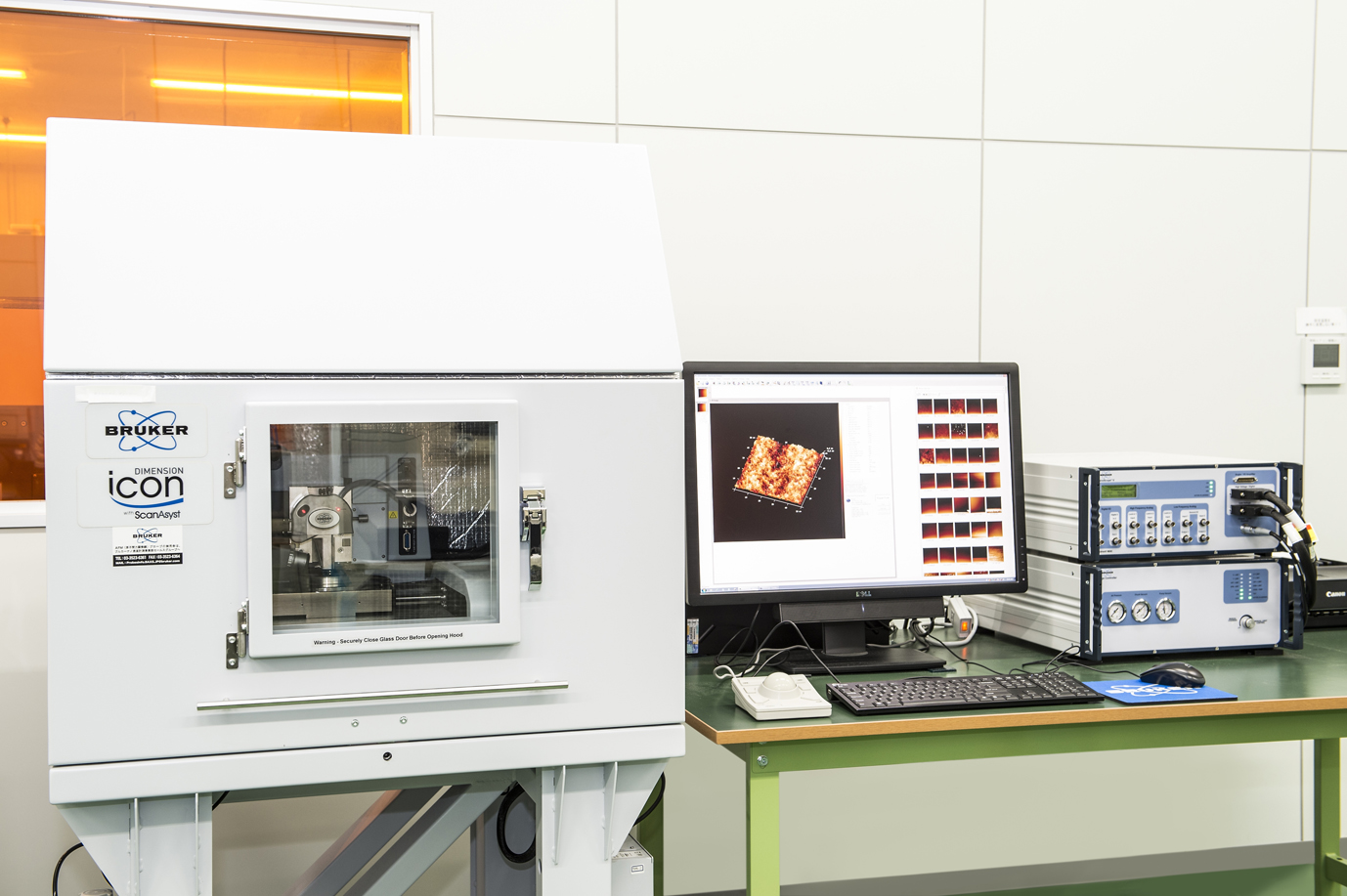

What is the difference between polishing and CMP?

CMP processing refers to chemical polishing

The difference from general polishing is that while using a processing liquid to chemically dissolve the surface of the product, mechanical polishing with abrasive grains such as silica and zirconia is performed at the same time to obtain a smoother polished surface.

A synergistic effect is obtained from the combined action, which improves the speed and quality of polishing. It is also used for flattening the surface of semiconductor wafers because it has extremely low distortion during processing.

TDC is the best for Polishing

It is a processing method that requires high technology because it uses construction methods such as mechanical polishing and chemical mechanical polishing (CMP). Therefore, if you are not familiar with the construction method, you may not be able to perform optimal processing for the product.

TDC can deliver products according to your desired delivery date, and has accumulated unique technological development and know-how in processing, making it possible to handle any shape.

Please feel free to contact us for any inquiries regarding processing or basic concerns.

with nano-level precision polishing.

and production from single units to mass production.

Related page

- Precision lapping service / ultra precision lapping service

- Polishing service

- What is Grinding

- What is cutting

- What is a chuck table? | Basic information and description of types, Processing accuracy at TDC

- Copper polishing

- Polishing after thermal spraying

- Sapphire polishing

- Polishing of plastic/acrylic resin

- Polishing after surface treatment/coating

- Symbol used for polishing

- Polishing of SiC

- Polishing of titanium

- Cylindrical grinding/cylindrical polishing

- Type of polishing process

- What is the accuracy that can be achieved by polishing?

- Principle of polishing process

- Polishing process for Resin

- Metal polishing process

- What is CMP

- What is polishing?

- About Lapping and Polishing