Mirror-finishing for aluminum

This page introduces TDC’s mirror polishing process for plastic/acrylic resins.

Please refer to the following page for our self-developed technology utilizing TDC’s mirror polishing process.

Please also refer to the “Polishing service” for more information on TDC’s polishing services.

Contents

Mirror polishing for aluminum

Aluminum is widely used in fields requiring high gloss and high smoothness, such as reflective mirrors and vacuum equipment parts. In recent years, the trend toward higher quality has been rapidly advancing, and nano-level precision is now required in aluminum processing.

TDC’s mirror polishing technology for aluminum

Aluminum is a material that is often used for equipment parts that require high precision, but some materials are soft and prone to sagging, making it difficult to achieve high precision. TDC’s unique processing methods and know-how enable us to perform high-precision mirror polishing on all types of aluminum materials.

We are capable to finish the surface roughness to less than Ra1nm without any sagging to the utmost limit. In addition to achieving high-precision surface roughness, our ultra-precision polishing technology and high-precision measuring machines also allow us to excel in complex precision such as parallelism, flatness of 30 nm, dimensional tolerance, and angular tolerance.

We handle a wide variety of shapes, from one piece to mass production, and not only sheet materials, but also rolls, shaft inner and outer diameters, thin foils, and uneven surfaces.

TDC’s mirror polishing service for aluminum

Case1 : Mirror surface test piece for various aluminum materials

We produce mirror surface test pieces of various aluminum materials from pure aluminum to ultra high duralumin (A7075).

- Feature: We produce ultra-precision mirror substrates of any material.

- Machining accuracy: Ra1nm or less to about Ra3nm (depending on material)

Case 2 : Ultra-precision aluminum mirror-polished roll

Aluminum is considered difficult to precision-machine because the higher the purity, the more likely it is to be scratched, but TDC can also perform mirror finishing on rolls and shafts.

- Features: Scratch-free mirror finish while controlling cylindricity, roundness, and dimensional tolerances.

- Surface Roughness: Ra1nm to Ra5nm or less (depending on material)

- Application: ex. Molds for high-performance films

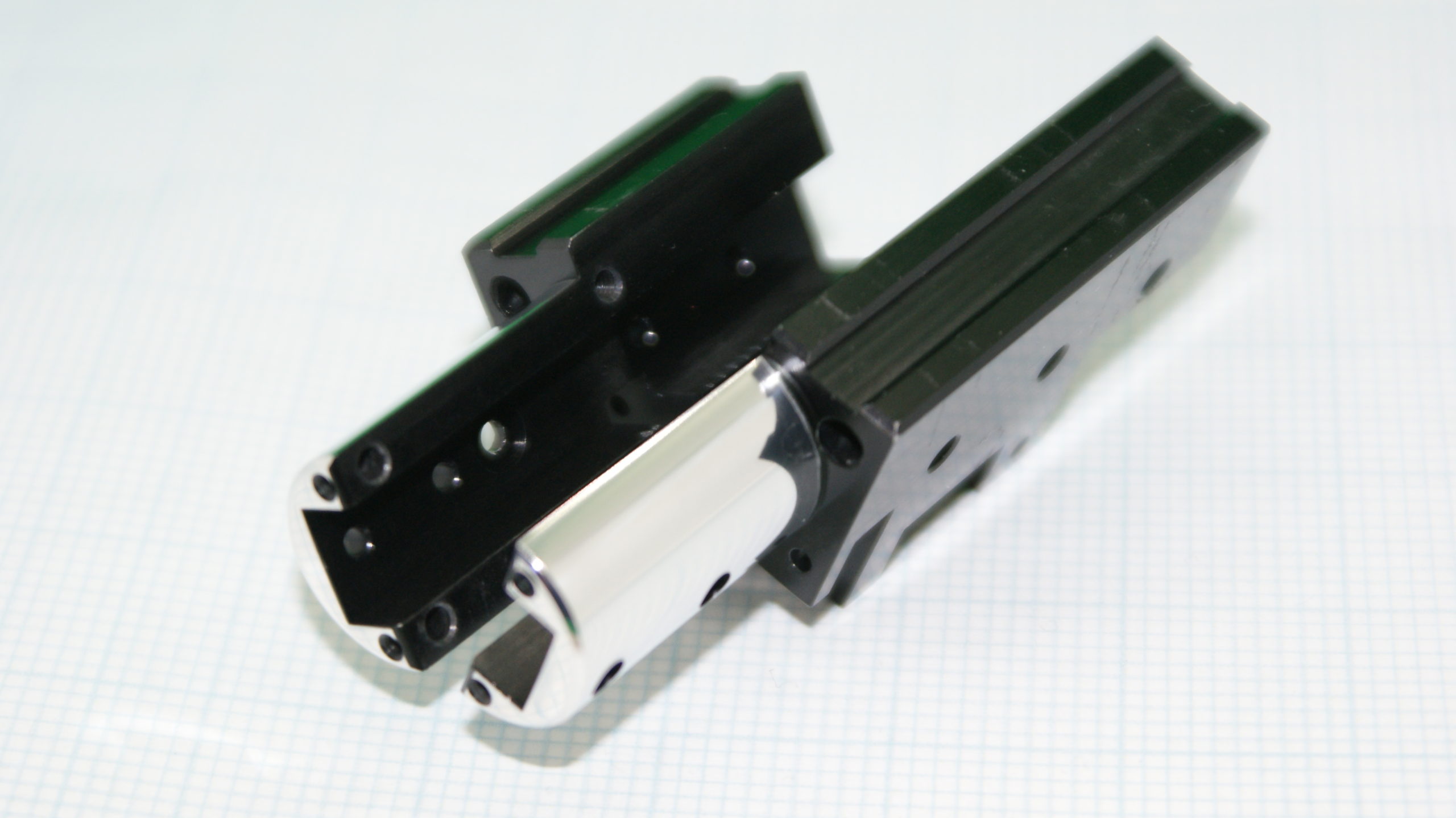

Case 3 : Precision mirror-finished cylindrical rolls / Precision mirror-finished cylindrical shafts

TDC’s polishing process technology has achieved nano-level surface roughness while maintaining dimensional and shape accuracy, resulting in precision mirror-finished cylindrical rolls / precision mirror-finished cylindrical shafts. Polished to the point that defects, fogging, and distortion are eliminated, the molds for nanoimprinting and high-functional film production are made to high precision.

| Spec |

-Developed original polishing equipment that automatically polishes the outside diameter of cylindrical shapes. |

| Materials |

Aluminum and other metals (stainless steel, nickel, titanium, quartz glass, cemented carbides, etc.), various ceramics, Coated surface (nickel plating, hard chrome plating, etc.) |

| Diameter | up to 500mm |

| Length | up to 3,000mm |

| Surface Roughness | Ra1nm、Rz10nm |

| Guaranteed Accuracy | scratch-free, mirror finish dimensional tolerance, cylindricity, coaxiality, etc. |

| Application |

Molds for film molding, molds for nanoimprinting, etc. |

Case 4 : Precision Polishing of Long Metal Foil

TDC’s original polishing machine achieves nano-order surface roughness even on lengths longer than 100 meters for precision mirror foil / long metal foil precision polishing. We have also realized cost reductions through continuous production in long lengths, and can produce metal foils with surface roughness at the single-nanometer level in lengths as long as 100 meters.

| Spec |

-Developed an original automatic mirror finishing system that continuously feeds, polishes, and winds up long tape-type metallic foil. |

| Materials |

Aluminum, SUS304, brass, copper, nickel, molybdenum, Hastelloy, etc., and other materials are being expanded sequentially. We will manufacture upon your request in terms of material, length, thickness. |

| Surface Roughness | Ra 1.5nm, Rz 10nm (SUS304) |

| Size | width up to 300 mm, length is available upon request. |

Feel free to contact TDC for mirror polishing for aluminum

TDC can handle mirror polishing of any aluminum material, with our material-specific processing know-how and accumulated polishing technologies. If you have any questions and inquiries, feel free to contact us. We would be happy to talk to you soon!

with nano-level precision polishing.

and production from single units to mass production.