Mirror Polishing for Stainless Steel/SUS304

We will introduce the mirror polishing process and services for stainless steel/SUS304.

Please refer to the following page for our self-developed technology utilizing TDC’s mirror polishing process.

Please refer to the following page “Polishing service” for more information on TDC’s polishing services.

Contents

Mirror Polishing for Stainless Steel/SUS304

Mirror-polishing of stainless steel requires higher difficulty, that is, requires more sophisticated polishing techniques and equipment, than other materials such as iron. Mirror polishing of stainless steel is mainly categorized into the following two types.

- Mirror finishing aimed at facilitating surface treatment such as hairline processing or alumite treatment. A mirror-like surface finish is obtained with scratches completely removed.

- Mirror finishing aimed at simply obtaining a beautiful appearance. Representative examples include mirror polishing of the back surfaces of iPods and stainless steel tumblers. Another benefit of this type is that smoothening of a product surface results in increased smoothness of the product.

Mirror Polishing Procedure of Stainless Steel

In precise mirror finishing and lapping that are employed at TDC, both a workpiece and a lapping plate rotate. The abrasive grains of the abrasive compound (slurry) are changed stepwise to smaller ones as the procedure proceeds toward the finishing step from the lapping step. TDC’s precision mirror finishing in the units of microns enables the world’s most advanced manufacturing in terms of surface roughness, parallelism, flatness, dimensional accuracy, and so on.

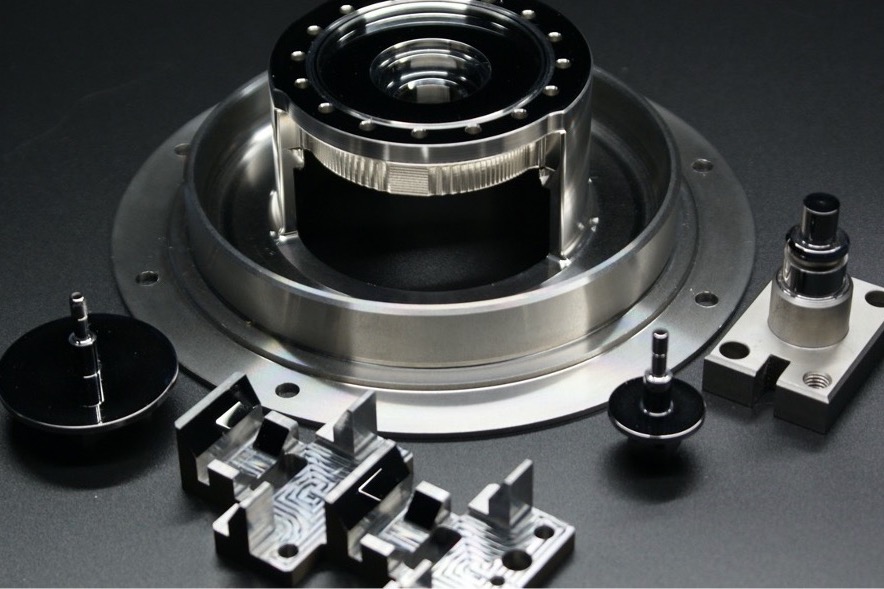

TDC’s Stainless Steel Mirror Polishing Technology

Although stainless steel is made of various materials, TDC can perform high-precision mirror polishing on any stainless steel material, regardless of the types of materials, using our unique processing methods and know-how. Not only can we achieve a surface roughness of Ra1nm, but we also specialize in complex precision grinding with parallelism of 100nm, flatness of 30nm, dimensions of ±100nm, and angles of ±3 seconds using our ultra-precision polishing technology and high-precision measuring machines. We can handle not only plates but also various shapes such as rolls, shaft inner/outer diameters, thin foils, and uneven surfaces, etc. We can flexibly handle from 1 piece to mass production. so please feel free to contact us for more information.

with nano-level precision polishing.

and production from single units to mass production.

Cases of TDC’s Stainless Steel Mirror Polishing Service

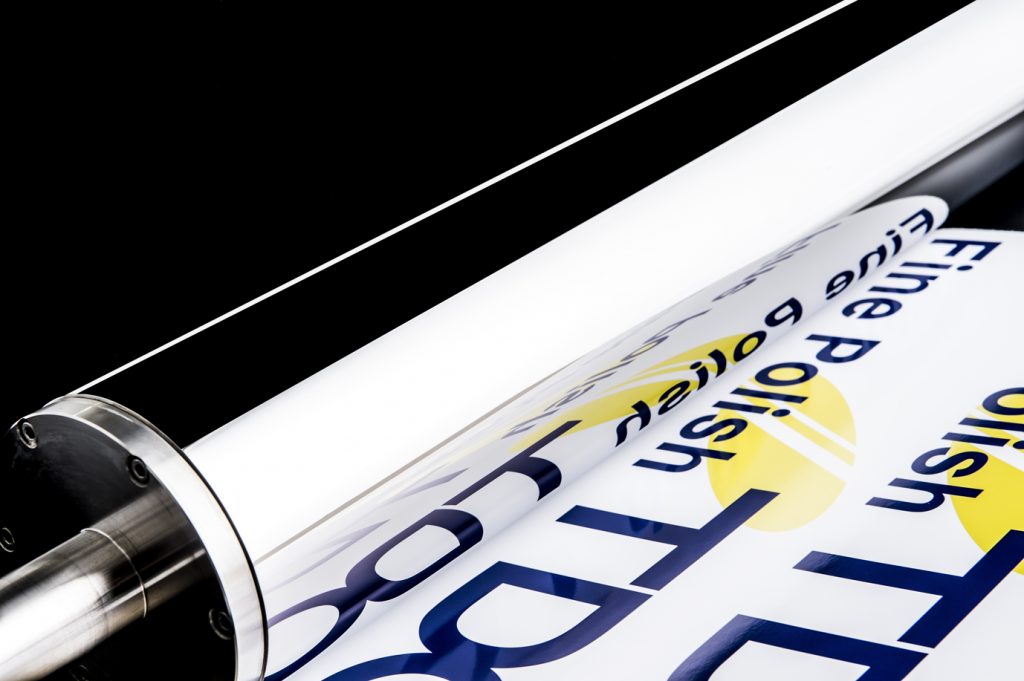

Super precise mirror polished rolls and shafts

TDC’s polishing process technology has achieved nano-level surface roughness while maintaining dimensional and shape accuracy, resulting in precision mirror-finished cylindrical rolls / precision mirror-finished cylindrical shafts. By polishing until defects, fogging, and distortion are eliminated, TDC is able to achieve high precision in molds for nanoimprinting and high-performance film manufacturing.

| Materials | Stainless Steel, Nickel, Aluminum, Titanium, Quartz Glass, Cemented Carbide, Ceramics, Resins Surface Coatings (Nickel Plating, Hard Chrome Plating) |

| Outer Diameter | Max 500mm |

| Length | Max 3,000mm |

| Surface Roughness | Ra1nm、Rz10nm |

| Accuracy Guaranteed | Scratch free, Mirror finish, Size Tolerance, Cylindricity, Coaxiality |

| Application | Mold for Films, Mold for Nano-in-print |

Super Precision Foil Polishing

TDC’s original polishing machine achieves nano-order surface roughness even on lengths longer than 100 meters for precision mirror foil polishing. Cost reduction by continuous production in long lengths is also realized, and metal foils with surface roughness single nano-level can be produced in lengths as long as 100 meters.

| Specification | ・Uniquely developed automatic mirror finishing equipment that continuously feeds, polishes, and winds long tape-type metallic foil. ・Ra1.5 nm, Rz10 nm (SUS304) ・Width up to 300mm (Please contact us if you need more than 300mm) |

| Materials | Stainless Steel, Aluminum, Brass, Copper, Nickel, Molybdenum, Hastelloy, Titanium We will manufacture according to your requests in terms of material, length, thickness, etc. |

| Surface Roughness | Ra 1.5nm, Rz 10nm (SUS304) |

| Size | Width up to 300mm, Length will be up on spec. |

Feel free to contact as for any questions

Stainless steel is a material that tends to be used for device components that need to be produced with high precision. Our company, TDC has accumulated an abundance of experience in processing stainless steel. Various types of stainless-steel material are available. Having original processing methods and expertise, TDC is capable of mirror-polishing any type of stainless steel material with high precision.

Please feel free to contact us if you have any questions and inquiries.

with nano-level precision polishing.

and production from single units to mass production.