SPECIAL STORY |Unique Technology originated from Trial and Error

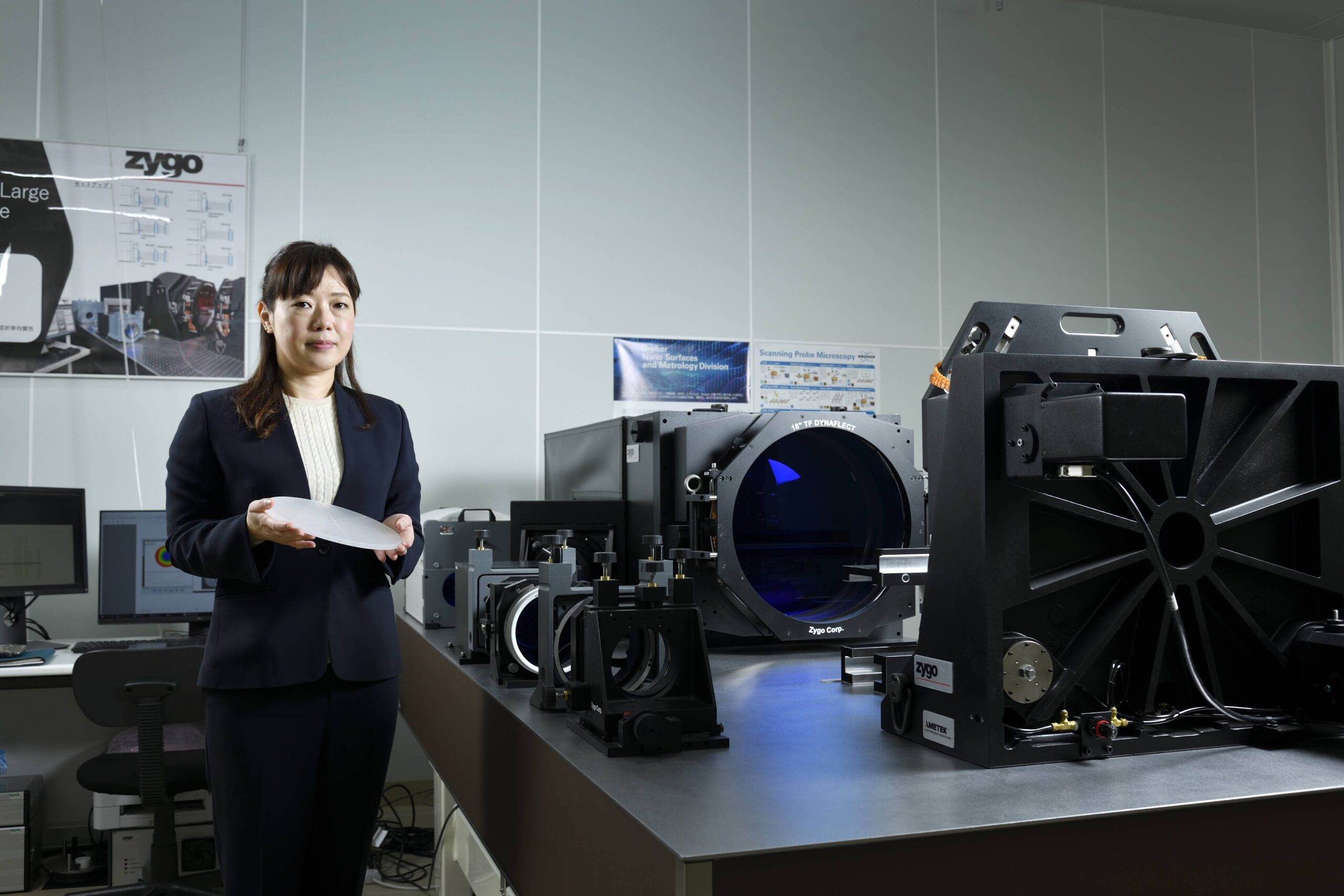

Yuko Akahane, President of TDC, tells the back story of our manufacturing.

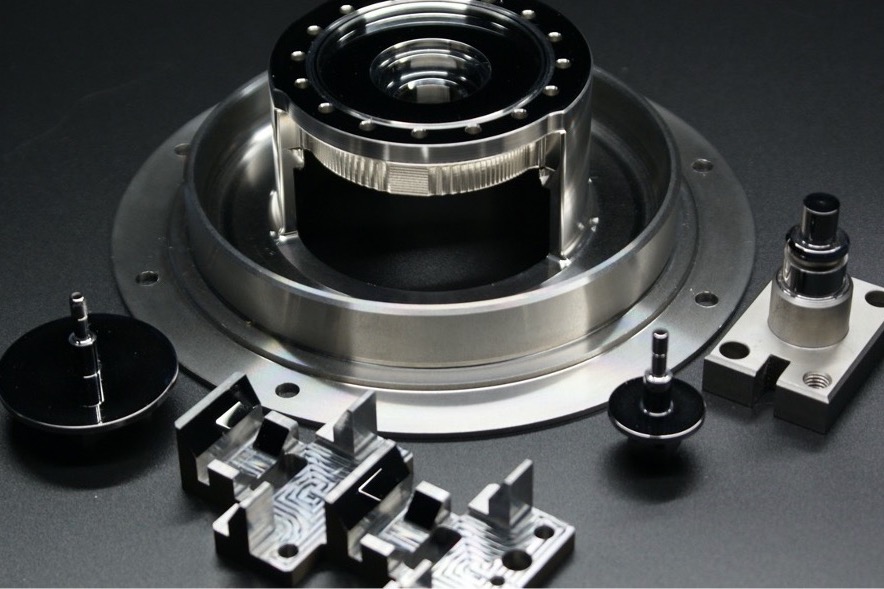

In this issue, we will discuss some of the efforts that led to the creation of our unique technology.

Contents

Challenges are the source of growth.

Creating technologies that do not exist in the world will lead to our growth

We have developed a variety of technologies, but we did not start out with a unique technology.

Since we were a latecomer to the polishing industry, we felt that we could not do the same thing as other companies. So we asked if there were any difficult jobs that no one else wanted to do and received orders for them.

In the process, we began to receive orders from customers who asked us, “Well, can you do this kind of processing?” And then we started getting orders for difficult jobs that no one else wanted to do. Naturally, we could not do difficult jobs at first. We did not have the know-how or the specialized machines to do so.

However, TDC’s motto is “Never say we can’t do something. Even if we think it is impossible to do a job, we will give it a try. In the spirit of “STAY FOOLISH,” we try without thinking about theories. Well, I really mean “FOOLISH” (laughs), but there are many things that can only be understood by trying.

The technology that emerged from the challenges we received from everyone ended up becoming our original technology.

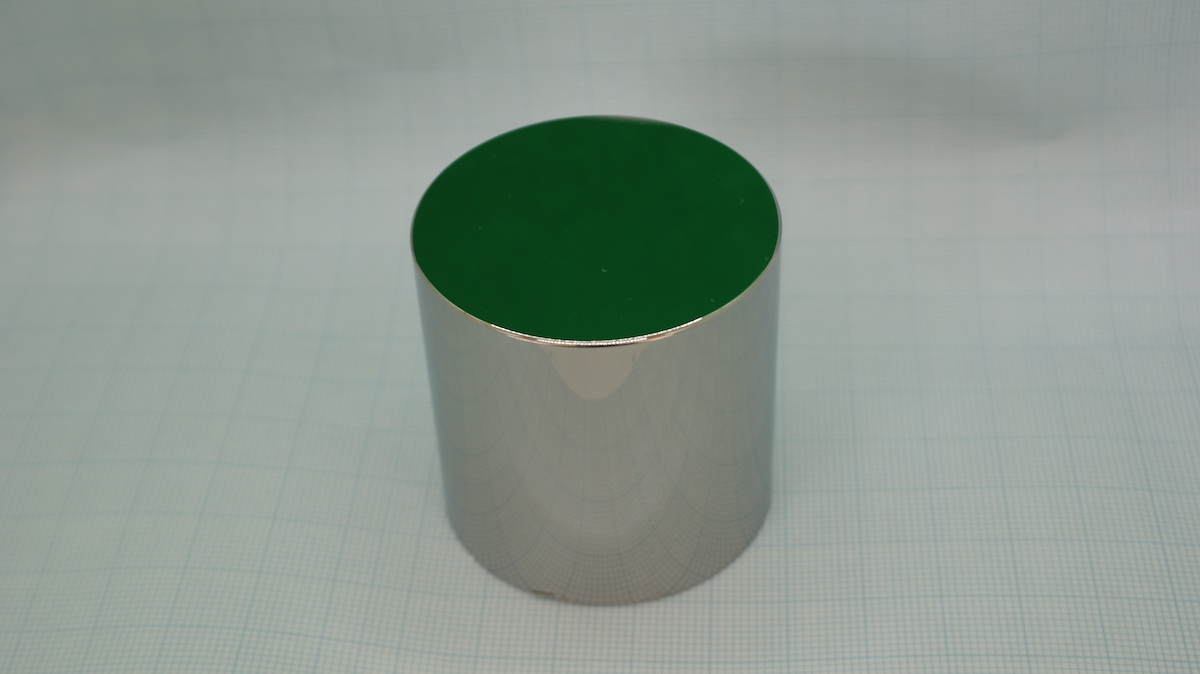

A material that is supposed to be non-luminous becomes mirror-like.

Trial and error sometimes goes beyond theory.

A materials that is not supposed to get final surface succeeded in mirror-polished.

Trial and error sometimes goes beyond theory.

About 20 years ago, we got inquiry like this.

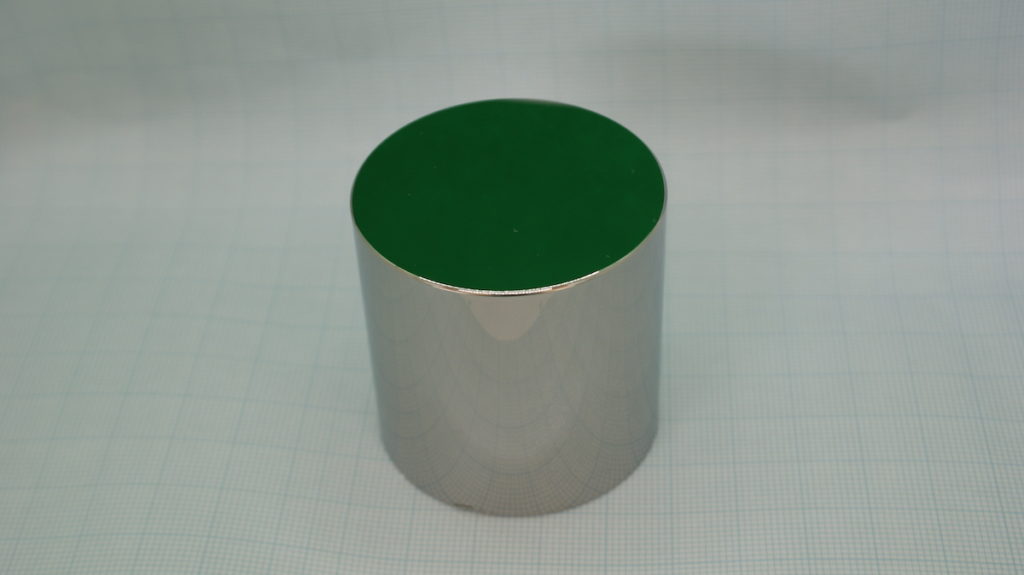

One time, we received an order from a customer to mirror-finish pure titanium. I asked the factory engineer to do it, but the usual method didn’t work at all, and the piece was covered with scratches.

I wondered why, so I looked it up in a book on metal materials and found that “titanium is a material that does not shine even when polished. When I learned this later, I thought I had asked for the wrong thing, but after a while, the technician brought it back to me and said, “It glows” (laughs).

I was surprised, “What? I was surprised, but he told me that he had been experimenting with various abrasives and mixing them. At that time, I thought to myself, “What is considered right in the world is not always true. I realized that new knowledge is born.

The result of this experiment was that we achieved a Ra of less than 5 nm on pure titanium, and we were awarded the “3rd Miyagi Monozukuri Grand Prize”.

Not bound by stereotypes and engaged in manufacturing.

Technology that is considered “only one” means that we are trying to create technology that does not yet exist in the world. Therefore, what is needed there is flexibility. Knowledge is a must, but it is not that important.

Rather, I believe that we should try, fail, think about what went wrong, and try again. I believe that such an attitude is the most important thing in manufacturing.

We currently have employees who are from 18 to 79 years old, many of them are engineers who graduated from local high schools. When they first joined the company, most of them had no knowledge of polishing or precision processing. However, they have talked and taught each other, and within a few years, they have acquired excellent technical skills and achieved results that amaze me.

We have developed a technology that can be called “only one,” but I do not believe that we have established our own technological capabilities.

There are still many things in the world that are considered impossible. However, we believe that growth comes from completing tasks that are “impossible” or “no one has ever done this before,” so we would be happy to receive more and more inquiries about difficult tasks in the future!

Related page