SPECIAL STORY | Ultra-precision polishing of nano-order with “visualization” and onsite communication

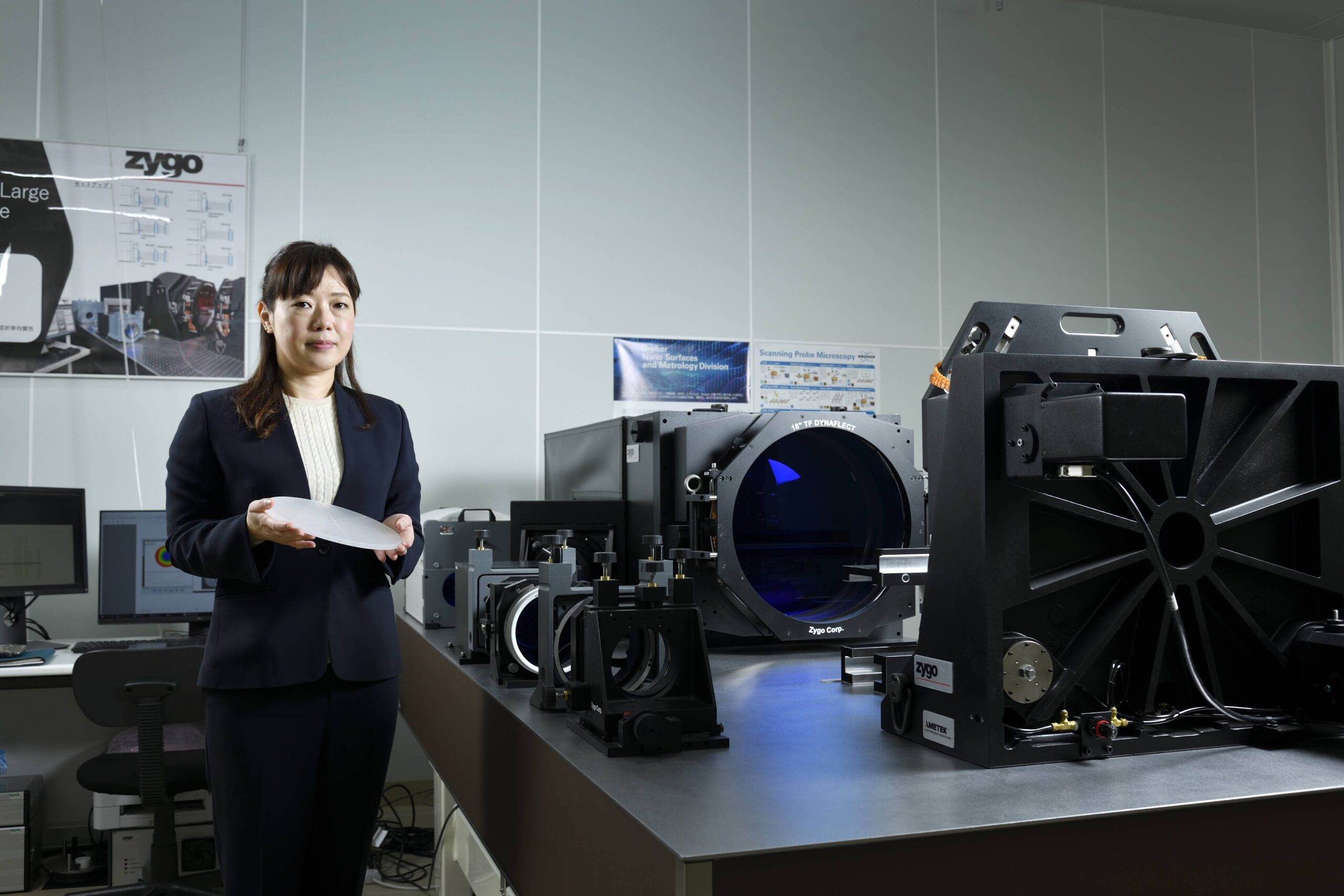

CEO Yuko Akabane tells the back story of our manufacturing. In this episode, we would like to introduce our efforts in the field that support our technical capabilities.

Contents

Determining nano-order precision through repeated processing and measurement

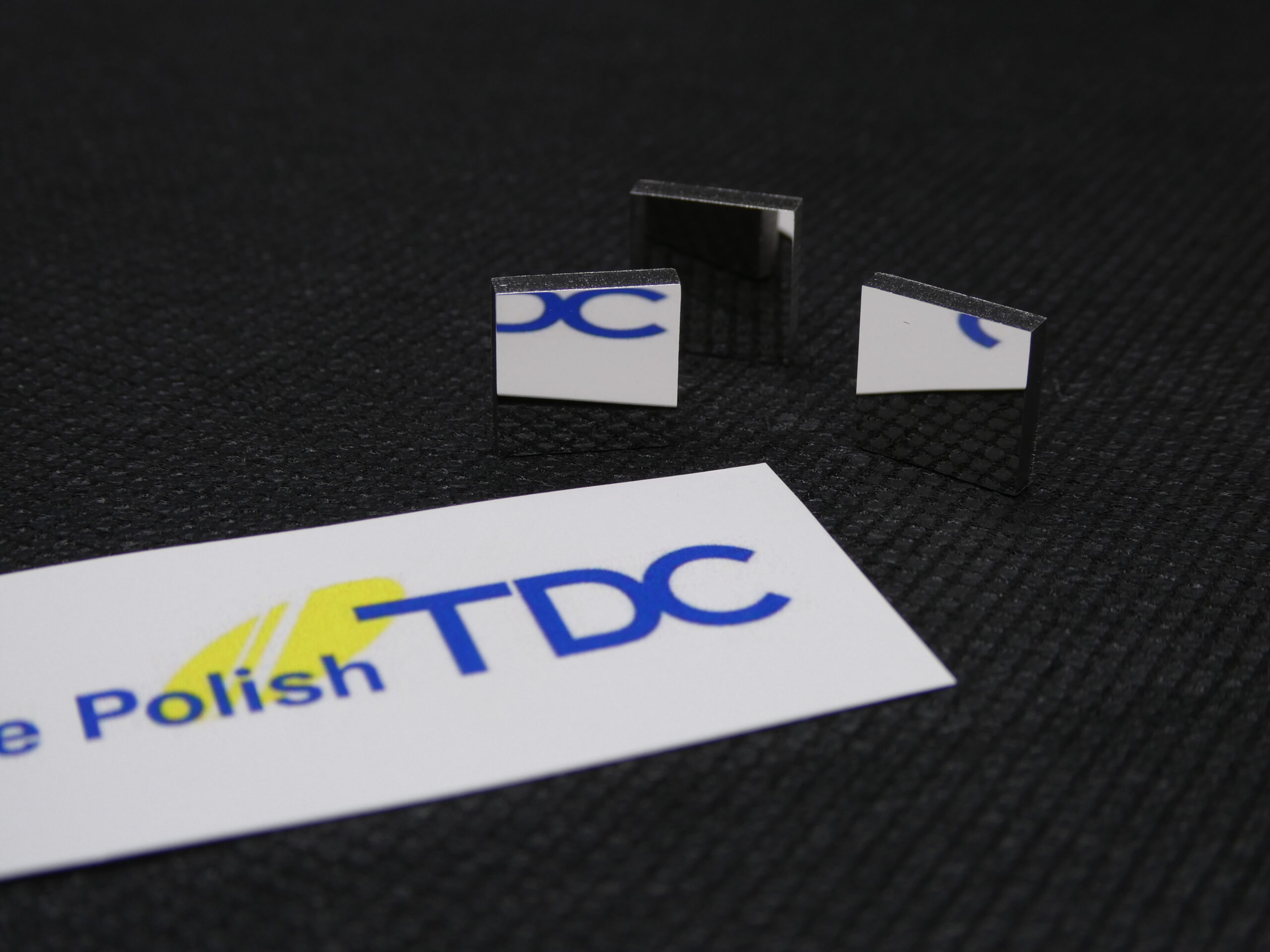

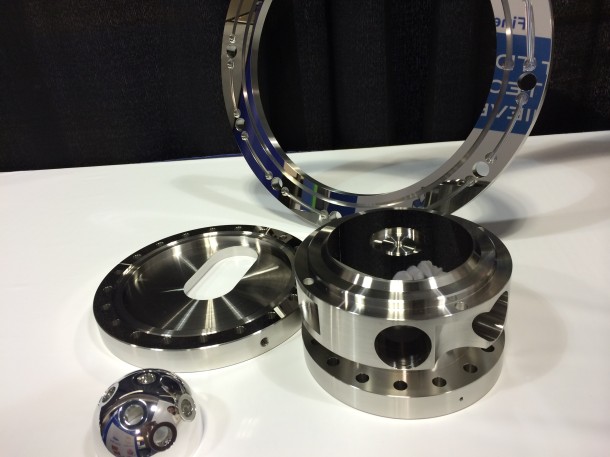

T.D.C. offers ultra-precision polishing at the Ra1nm level for all kinds of materials and shapes. Thankfully, we have received orders from various cutting-edge fields such as semiconductor-related, electronic components, medical equipment, and aerospace.

We also manufacture many one-of-a-kind products that require special processing, and our engineers’ “muddy” work is indispensable in this process.

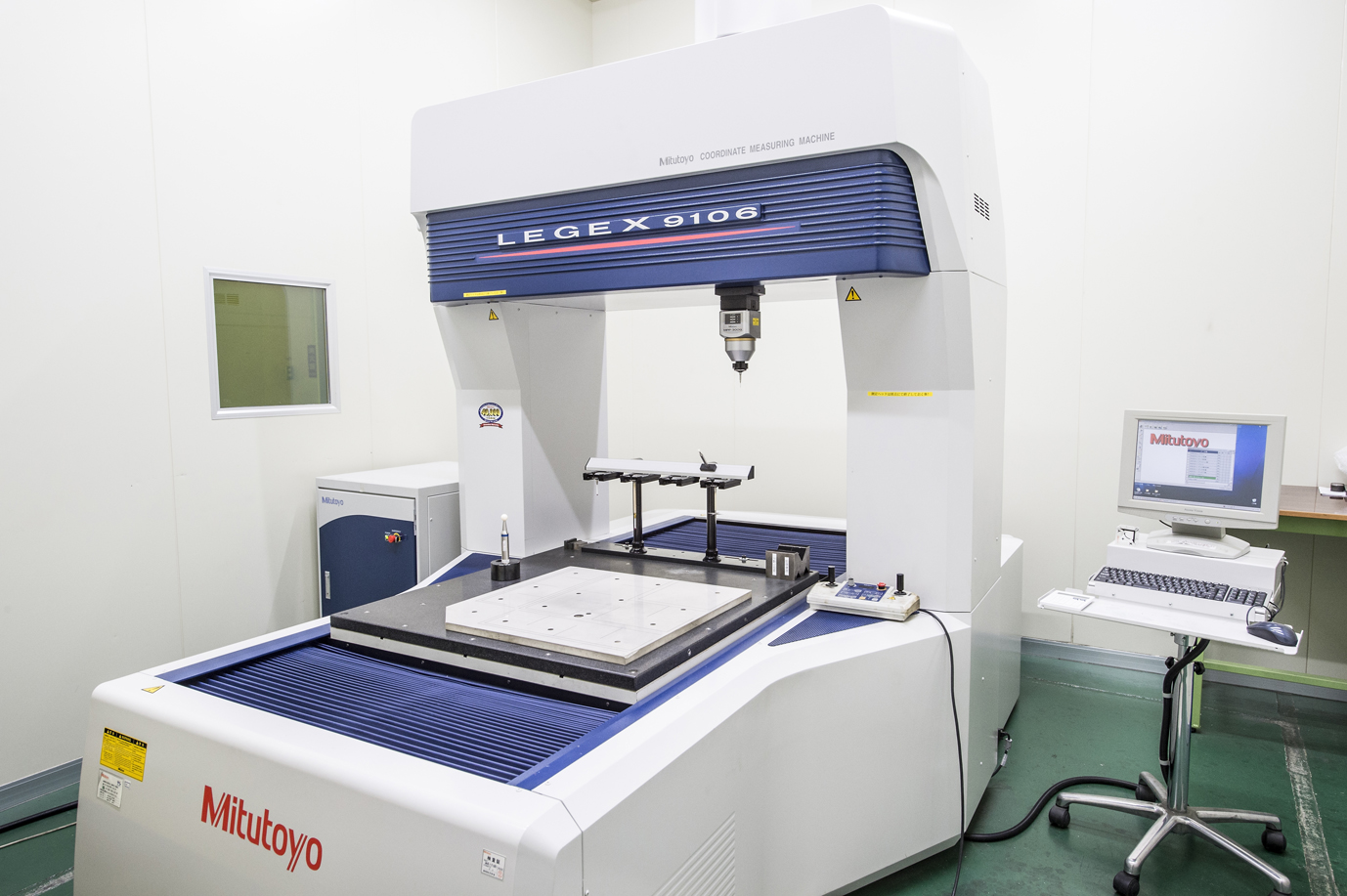

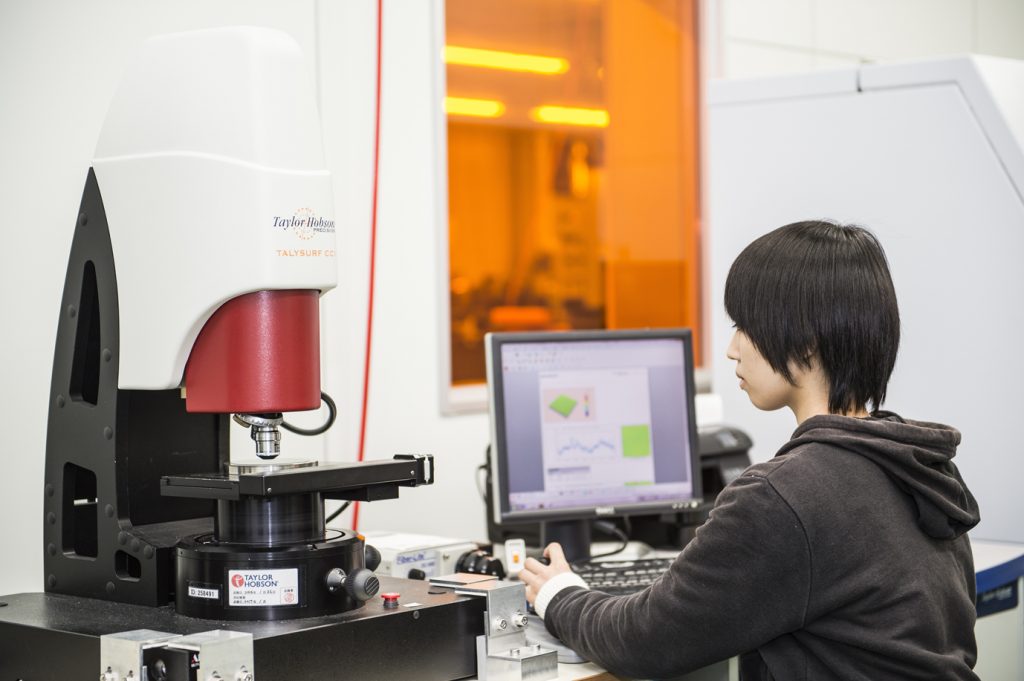

When our technicians perform polishing, they also perform measurement as a set, repeating the process of machining, measuring, machining, and measuring. In this process, ultra-high-precision measuring machines are important. (For more information on our measuring machines and equipment, please refer to the “Equipment List and Quality Assurance“.)

Nano-order measurement is an extremely delicate process, and measuring instruments cost tens of millions of dollars, with the most expensive machines costing more than a hundred million dollars. The measuring instruments are like those found in university laboratories, and if they break, it would be a disaster (laughs).

Measurement visualizes changes that cannot be seen with the naked eye

Measurement, in other words, means visualization. When we measure the changes in the shape of an object on a nano-order scale, we can see “what kind of change occurred when we did what? becomes visible.

If an object is rubbed even slightly, its shape changes slightly, but such subtle differences cannot be seen with the naked eye. However, by measuring with a measuring instrument, we can see even the slightest change, such as a change in the surface when friction is caused by this amount, or a slight change in temperature when polishing. When you can see these changes, you can actually feel the phenomenon yourself.

You don’t look at the data measured by an expert later, so you can confirm on the spot that “something has changed here” as a result of your own polishing, and you can think about why. You think, “Maybe this is the reason,” and try the same thing one more time, and sure enough, the same change occurs. That’s how they take measurements many times a day. I believe that the repetition of this process is helping our engineers.

Chatting” here and there is an important form of communication at the work site.

In the past, difficult techniques were considered craftsmanship, and were something to be seen and stolen, not taught. However, in the case of our company, we place great importance on teaching carefully. Employees in their second year with the company teach first-year employees, for example, and they pass on what they know more and more. Teaching others helps me to organize my mind and to understand myself more deeply, which leads to the growth of the person teaching.

Continuing on from the earlier discussion of measurement, one of the places in the factory where conversations naturally begin is the measurement room with the measuring machines. There are several processing machines in the factory, and basically each person works alone, but everyone returns to the measurement room after finishing processing.

After finishing processing, everyone returns to the measurement room. and then they start chatting with the people nearby. On the other hand, if someone was having trouble and things didn’t seem to be going well, the people around them would come up to them and offer an idea, saying, “Well, why don’t you try it this way? and offer them ideas. Everyone is very irresponsible (laughs), but talking with others in this way sometimes leads to the realization of the person in question.

In fact, at T.D.C., we rarely have meetings where we sit down to talk. People are often surprised to hear that the leaders of each department, including myself, speak in a meeting that lasts at most 30 minutes a week. We just have a lot of standing around talking here and there. I think it is good that we are chatting at various places instead of having few proper meetings.

We have people of all ages working at our company, but both those who teach and those who are taught are equal, and we have a good relationship of trust. If there is something I don’t understand, I go and ask someone who is good at it, and sometimes I learn from someone who is younger than me.

I feel that such on-site communication is what is important.

Related page