Examples of polished items

This page introduces product examples of polishing processing by TDC.

See also the “Polishing service” page for basic information on grinding and TDC’s grinding.

Contents

- Examples of products and processing by TDC’s polishing process

- Product example 1: Carbide ultra-precision cube

- Product example 2: Pure Titanium Cylindrical Mirror Surface Processing

- Product example 3: Pure copper roll inner and outer diameter mirror surface processing

- Product example 4: Roll mold for nanoimprint

- Processing example 1: Precision polishing of bonding wafers

- Machining example 2: High-efficiency diamond polishing

Examples of products and processing by TDC’s polishing process

At TDC, we are ready to receive consultations on all kinds of polishing and precision processing with our extensive processing equipment and polishing know-how that we have cultivated so far.

In this page we would like to introduce just a few examples of polished products produced at TDC.

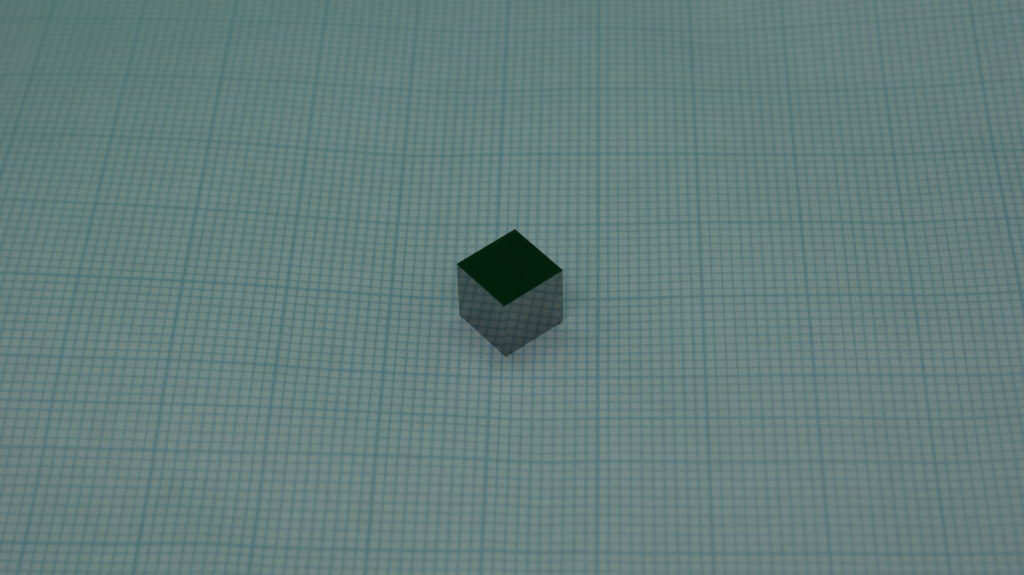

Product example 1: Carbide ultra-precision cube

Product Description

A 15 mm square carbide cube was produced by lapping. If you use normal cutting or grinding, burrs and chips will occur. Also, I think there are many people who imagine a sauce when using a polish. However, with TDC, it is possible to create a sharp edge even for such a small object, and finish all 6 surfaces smooth without scratches. The dimensional tolerance is ±0.001mm, and it has good repeatability and is suitable for mass production.

Accuracy

Dimensional tolerance +/-0.001 (mm)

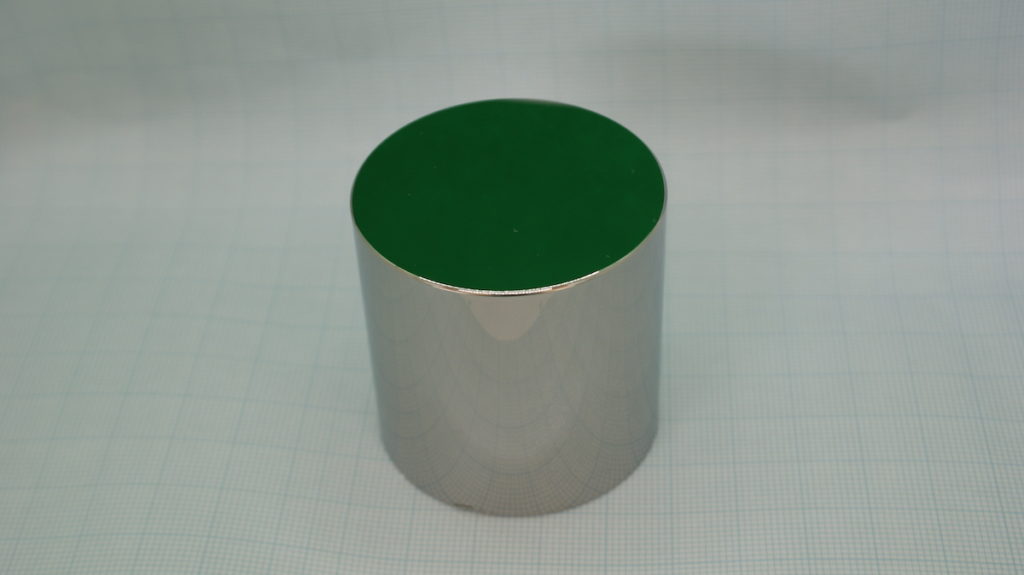

Product example 2: Pure Titanium Cylindrical Mirror Surface Processing

Product Description

A pure titanium 1kg weight master was polished to ±0.001g. It is also possible to adjust the weight and volume by polishing while controlling the removal amount by lapping polishing.

Accuracy

1kg weight master +/-0.001g

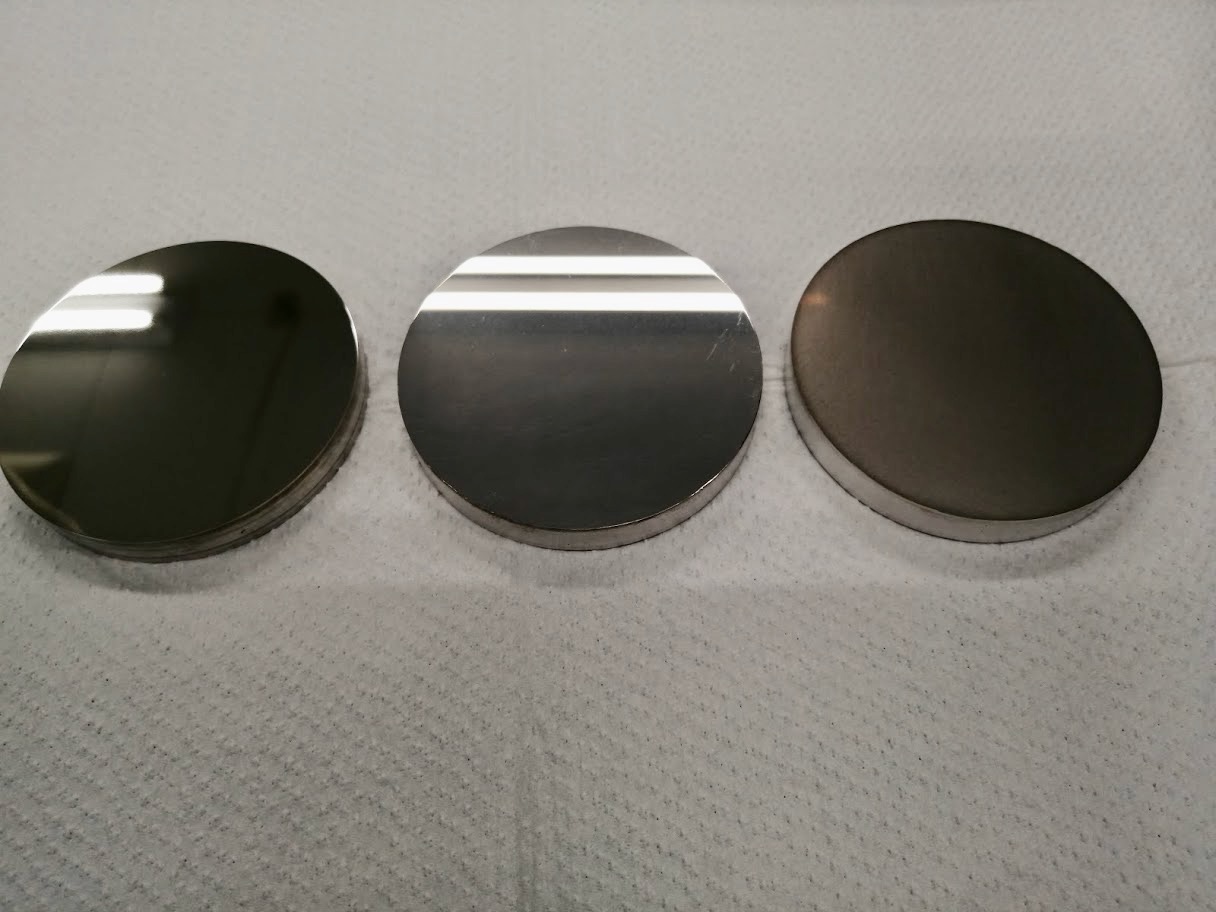

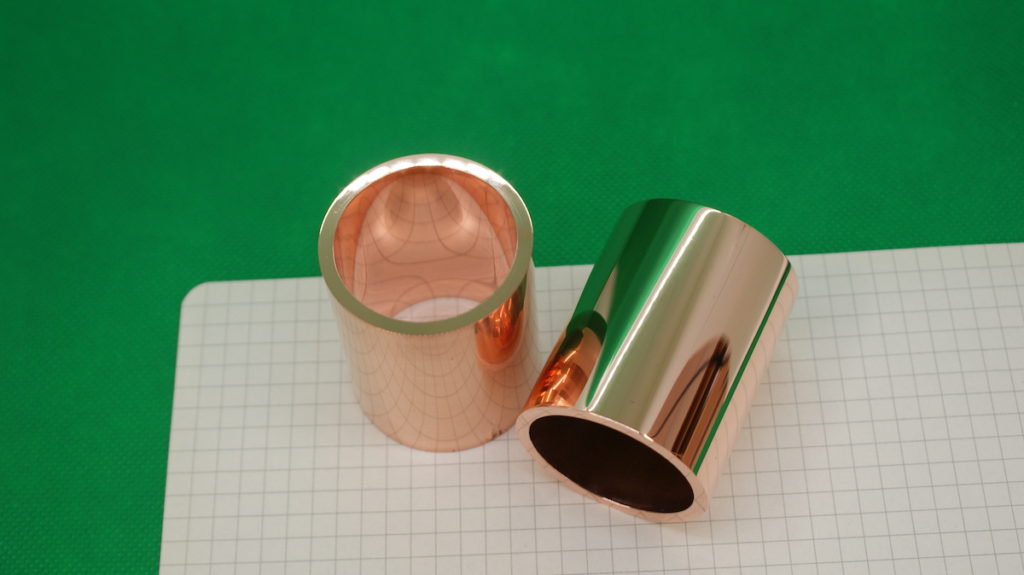

Product example 3: Pure copper roll inner and outer diameter mirror surface processing

Product Description

Polished the inner diameter, outer diameter, and both end faces of pure copper. At TDC, we are good at not only the outer diameter but also the inner diameter mirror surface processing, and it is possible to produce the same surface roughness as the outer diameter.

In addition, it is possible to finish extremely soft materials such as pure copper with high precision with our unique know-how.

Accuracy

Outer surface roughness Ra1nm or less Internal surface roughness Ra1nm or less

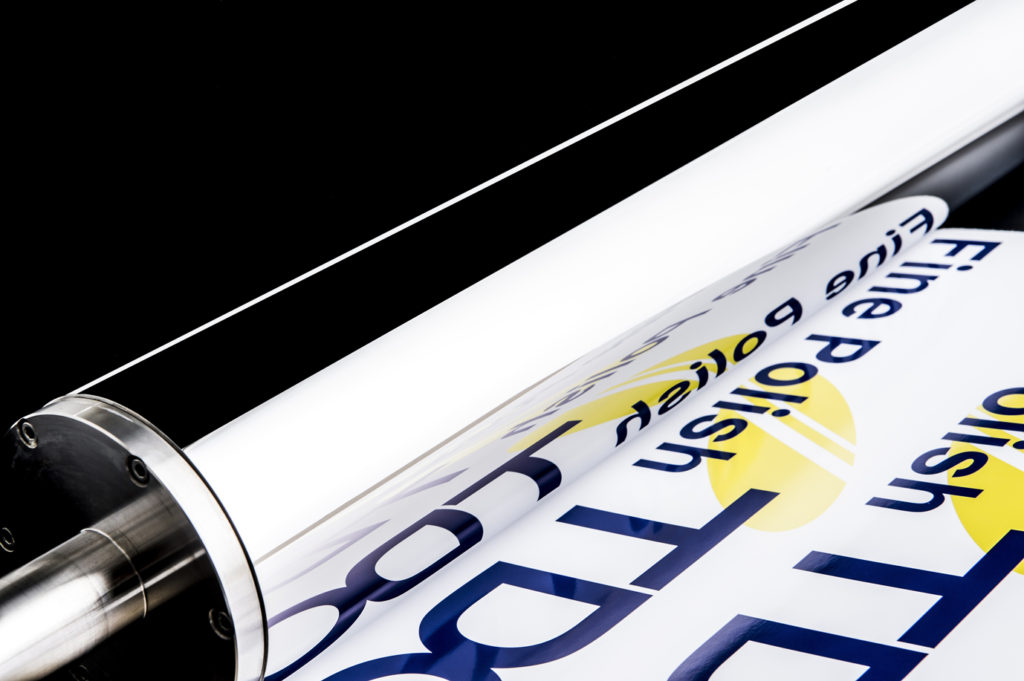

Product example 4: Roll mold for nanoimprint

Product Description

At TDC, we accept requests for mirror finishing of nanoimprint molds for producing non-reflective films and high-performance films.

While precisely controlling dimensions and shape accuracy, it is possible to achieve nano-level surface roughness without scratches or cloudiness regardless of the material.

In addition, it is compatible with various materials other than metals, and can produce surface roughness close to Ra1nm for most materials.

For more information, please refer to the “Precise Mirror Polish Surface on Roll and Shaft” page.

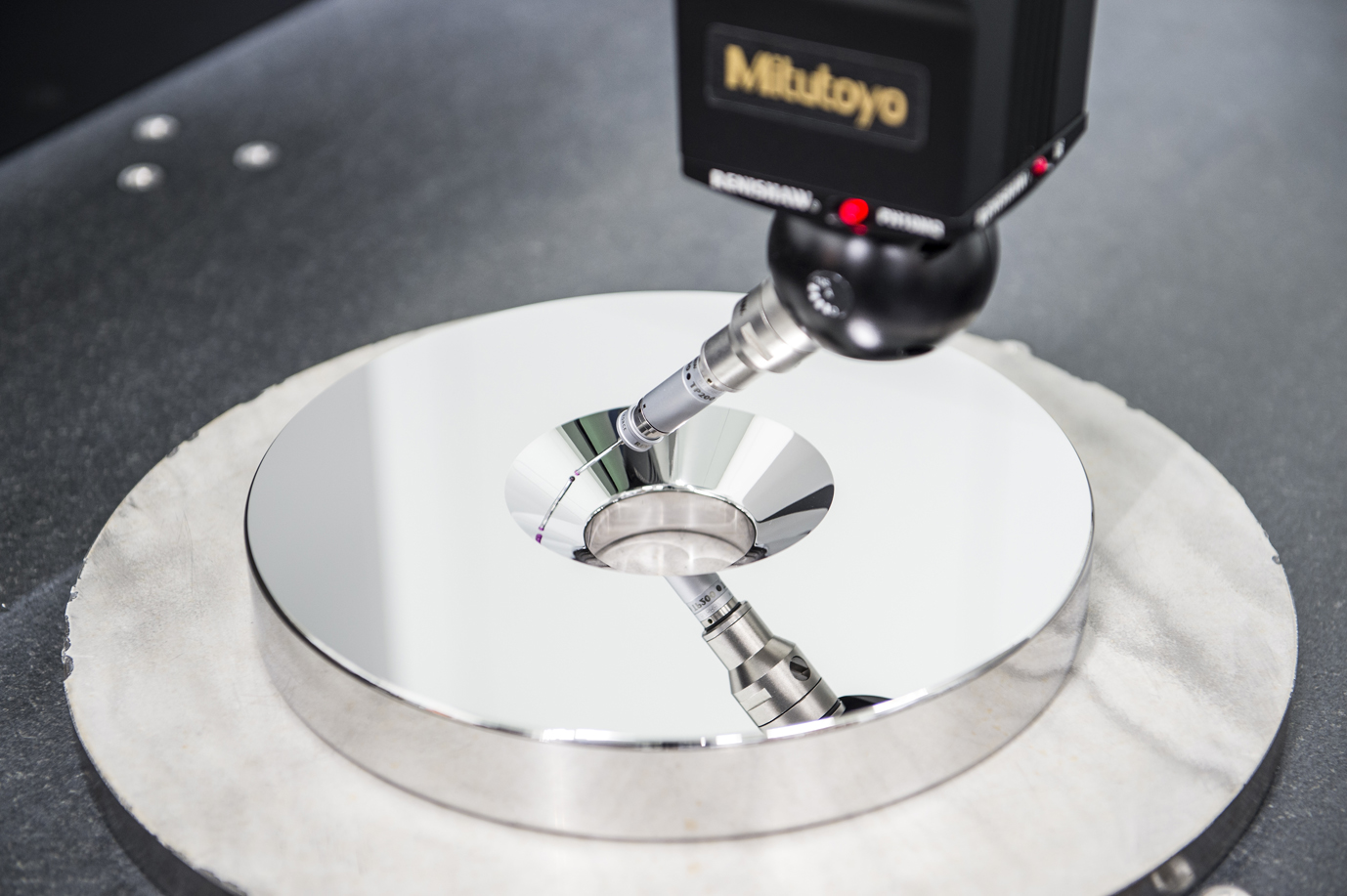

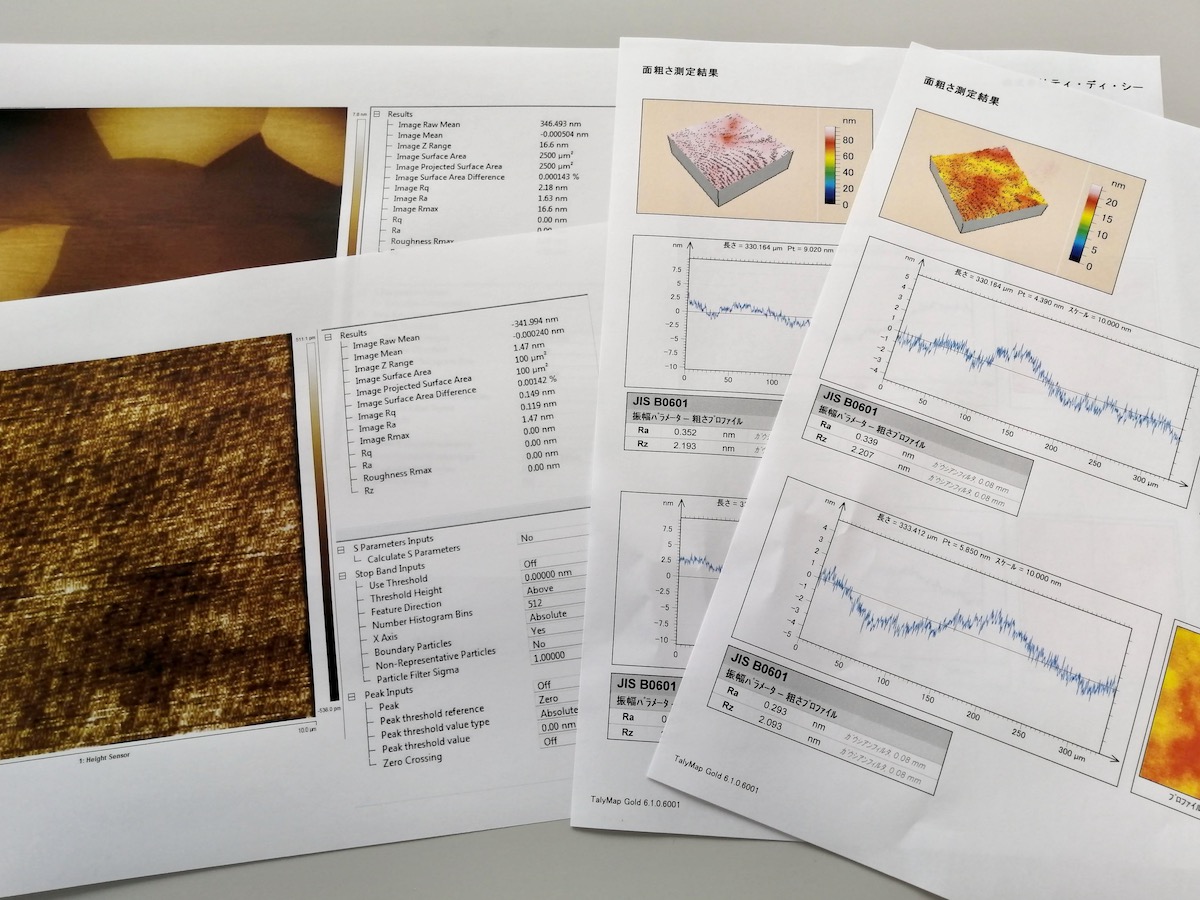

Processing example 1: Precision polishing of bonding wafers

Case study

First, we perform mirror polishing and precision cleaning on bonding substrates such as Si and SOI wafers.

After that, the customer performs bonding, and our company performs thinning polishing again.

We have a track record in precision polishing of bonding wafers down to a thickness of 1um.

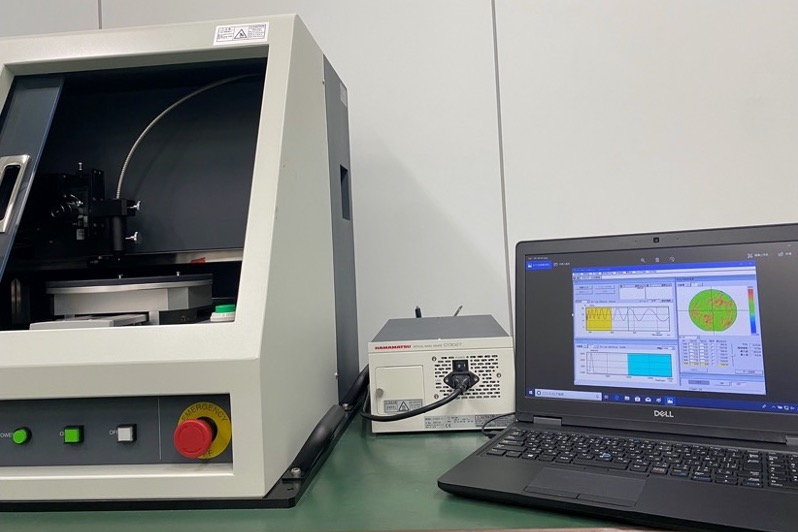

We have a high-precision measuring machine, so it is possible to reduce the thickness while controlling the in-plane thickness variation.

Material

- Si, SOI

- glass, crystal

- SiC, GaN

- diamond

- etc

precision cleaning

- Ultra-precise wafer cleaning in an ISO class-3 clean room

- Single-wafer equipment: 1 sheet or more

- Batch type equipment: for mass production

- Supports up to 6in

precision measurement

- Wafer surface accuracy/thickness measurement

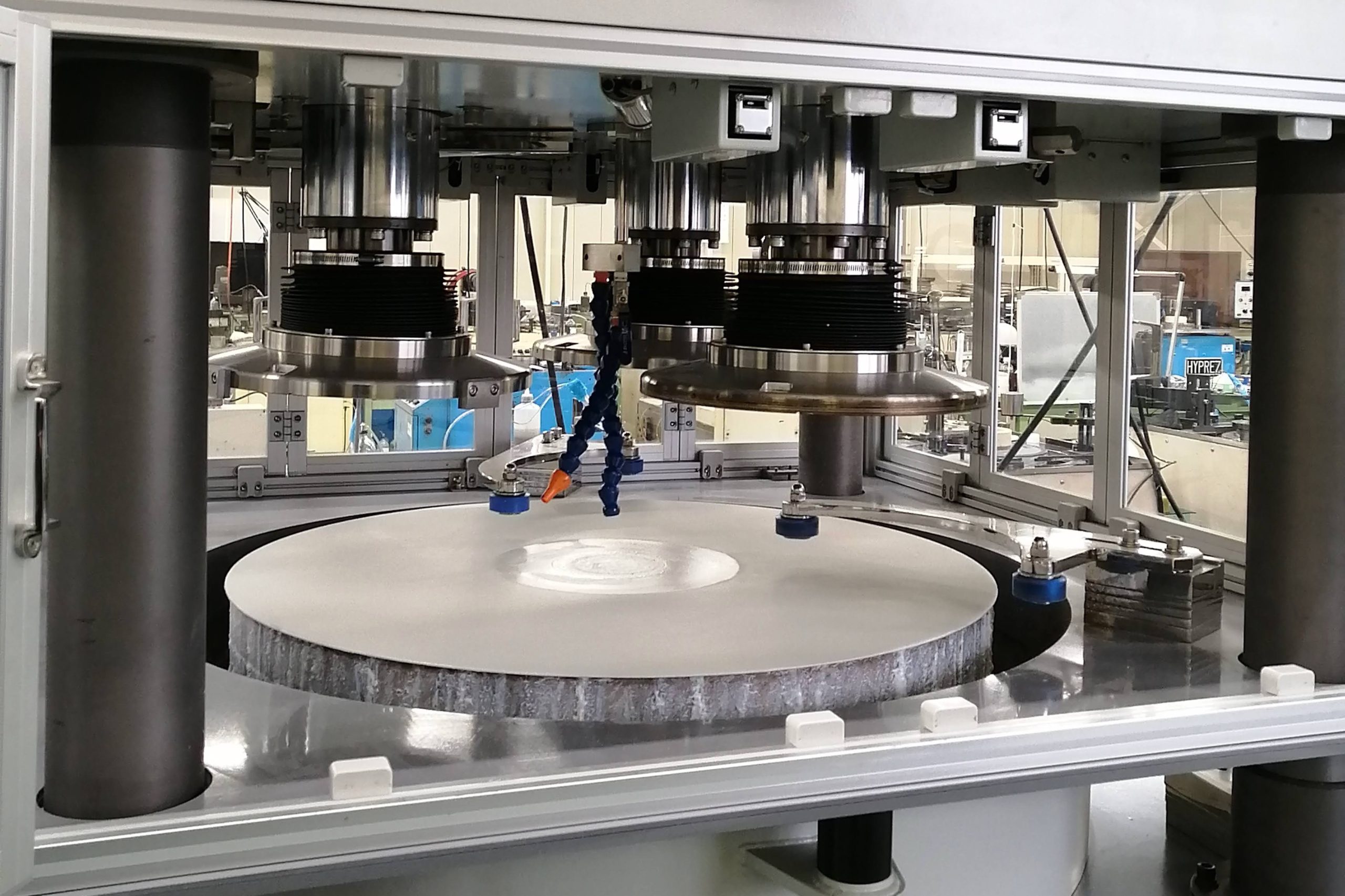

Machining example 2: High-efficiency diamond polishing

case study

Regardless of whether it is single crystal or polycrystal, it is possible to polish diamond substrates with high efficiency without damaging them.

Conventionally, a method called “Skaife” was commonly used to polish diamonds, but there were many problems such as breakage due to the forcible grinding with diamond abrasive grains, and it took a long time because it was hard. was

TDC has been working on research to solve this problem, and currently has a track record of “surface roughness Sa 0.2 nm or less” and “flatness 0.5 um or less” for a square 40 mm large area diamond.

with nano-level precision polishing.

and production from single units to mass production.

Related page

- Antireflection film/Non-reflection film

- Examples of polished items

- Examples of grinding products

- Case of a precision processing for Hayabusa2

- Precision polishing technology of Diamond wafers

- Application:NASA’s balloon project | TDC Corporation

- Application:the BICE P3 telescope for observing CMB | TDC Corporation