Type of polishing process

This page describes the types of polishing processes.

Please also refer to the “Polishing service” page for the polishing process performed at TDC.

Contents

Types of polishing processes performed by machines

Polishing requires precision, and there are various types of processing methods depending on the material and its precision.

The five typical polishing methods that are performed using specialized machines are as follows.

Lapping Polishing

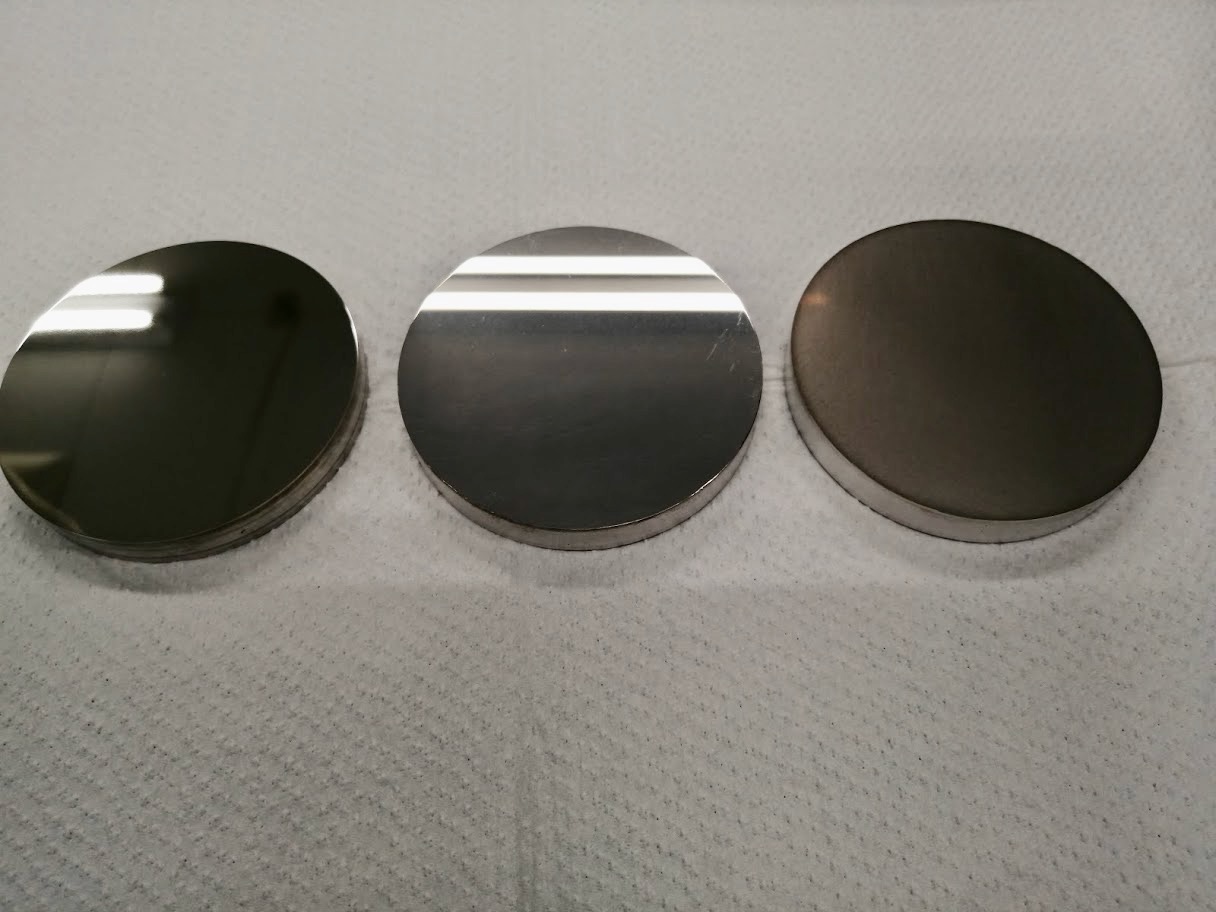

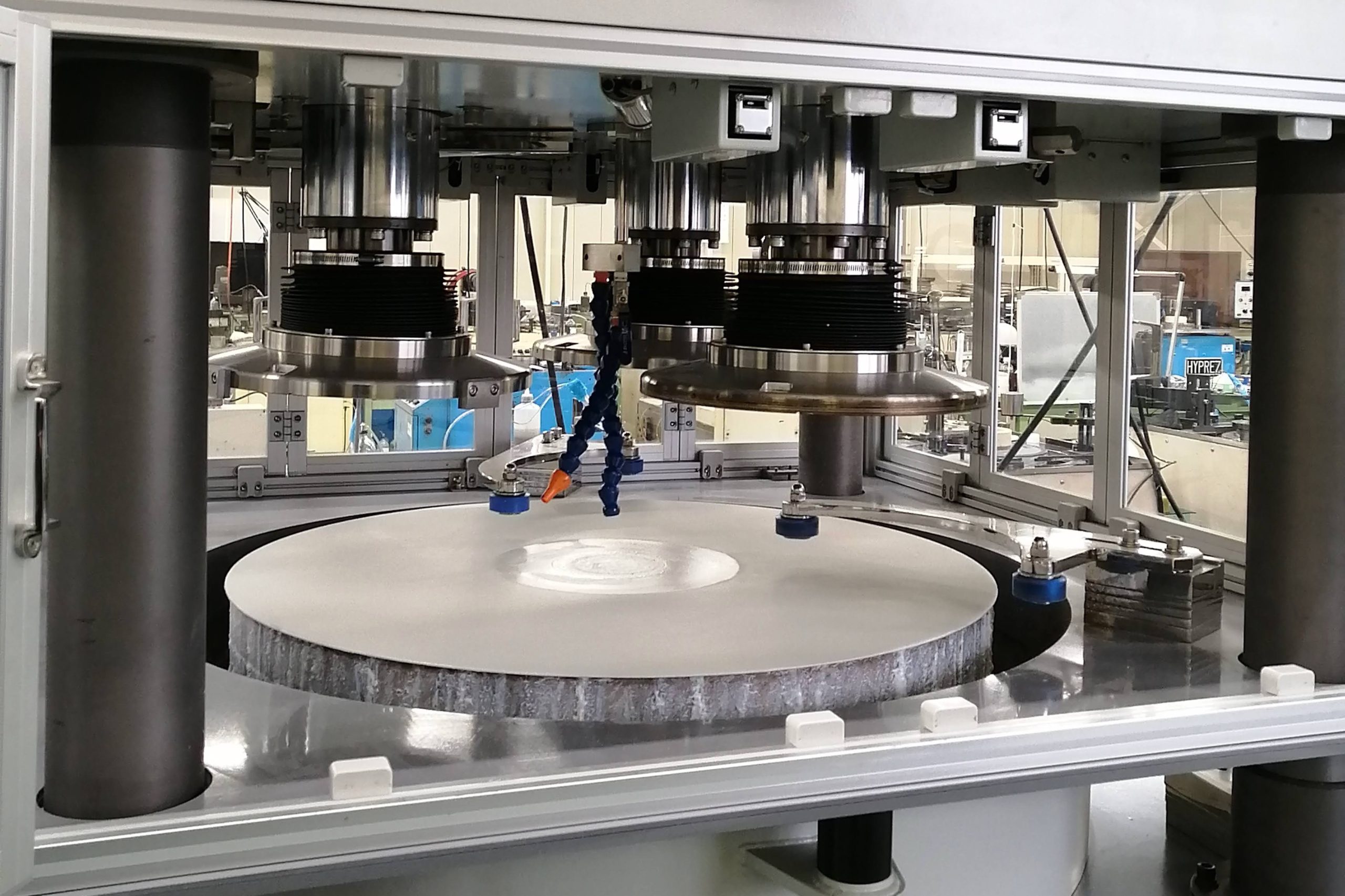

Lapping polishing is a method of polishing by placing the object on a flat table called a lapping machine and applying force from above to rub the abrasive grains contained in the abrasive and the workpiece.

Since lapping polishing enables precise planar processing, it is a polishing method suitable for workpieces where flatness is important, such as flat lens manufacturing, molds, precision jigs, and blades.

There is a “wet method” in which a liquid abrasive is poured in, and a “dry method” in which abrasive grains are embedded in a lapping machine.

Whetstone Polishing

Whetstone polishing is a polishing method that scrapes the surface by rotating a whetstone at high speed and bringing it into contact with the object to be processed.

Each whetstone is made up of small abrasive grains that act as blades and binders, and there are pores inside that allow chips to be discharged and cooled.

On the surface of the grinding wheel, which rotates at high speed, the abrasive grains are replaced while scraping the workpiece, enabling continuous grinding.

Barrel Polishing

In barrel polishing, a large machine is filled with a workpiece, a polishing stone, an abrasive called a “compound” that has cleaning and lubricating properties, and water, and the machine rotates and vibrates to scrape and polish the surface.

It is characterized by being able to polish a large amount at once, and is a suitable polishing method for polishing machine parts such as automobiles.

It is also used for “deburring”, which is the work of smoothing out thorns that occur after processing, and it can be said that it is suitable when you want to polish quickly at once rather than carefully finishing each one.

Buffing

Buffing is a polishing method in which an abrasive is added to a “buff” made of soft material such as cotton or felt to polish the surface.

It is mainly done in the finishing process such as “glossy” and “mirror finish”, and the buff material and type of abrasive are used according to the finishing request.

Buffing is suitable for products that need to be glossy, and since it uses a machine, it can polish even hard materials.

Electropolishing

Electrolytic polishing is a method of polishing by passing an electric current through an electropolishing liquid, which is an electropolishing solution.

Since it is a polishing method that smoothes the surface of the processed product by melting it rather than scraping it, it can be said to be suitable for cases where other polishing methods are difficult to handle.

Although it is suitable for stainless steel and aluminum materials, there are also disadvantages such as the limited metals that can be used and the high cost.

Manual polishing that can be seen in everyday life

When you think of polishing, you may imagine processing using factories and dedicated machines and equipment as introduced so far.

Of course, there is nothing wrong with processing when precision is required, but polishing actually exists around everyone’s life.

Here, we will explain the familiar polishing process that exists in everyone’s life.

Whetstone Polishing (manual work)

Whetstone to use when “the knife is not sharp enough”. This is also one of the best polishes. By sliding the blade on the whetstone, it is a polishing technique that brings back old or dull knives.

Although precision is generally not required, the whetstone used and the sharpening method change according to the workpiece.

Sandpaper

Sandpaper is a familiar item for those who do DIY and crafts. Also called sandpaper, this is one of the familiar polishing methods.

Sandpapers are numbered according to the coarseness of the abrasive, with grades below 100 being very coarse and numbers above 400 being finer.

Lens Polishing

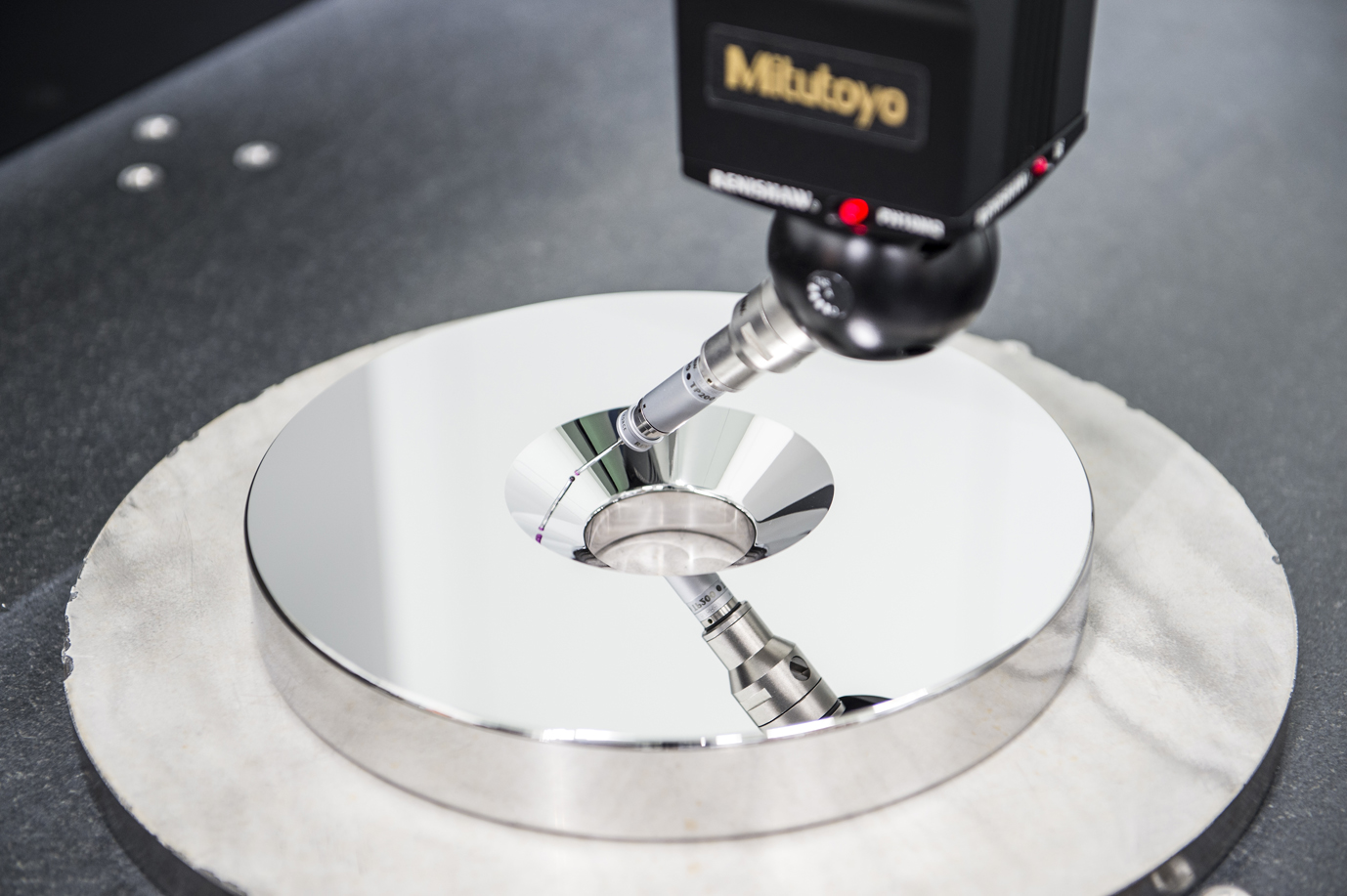

Although it is generally done by specialists, camera and microscope lenses are also one of the familiar polishing processes that are manually finished and polished in the final process.

A diamond polishing dish is used to give the final shape on a rotating workbench. After polishing, use a magnifying glass to visually check the finish.

Contact TDC for polishing processing

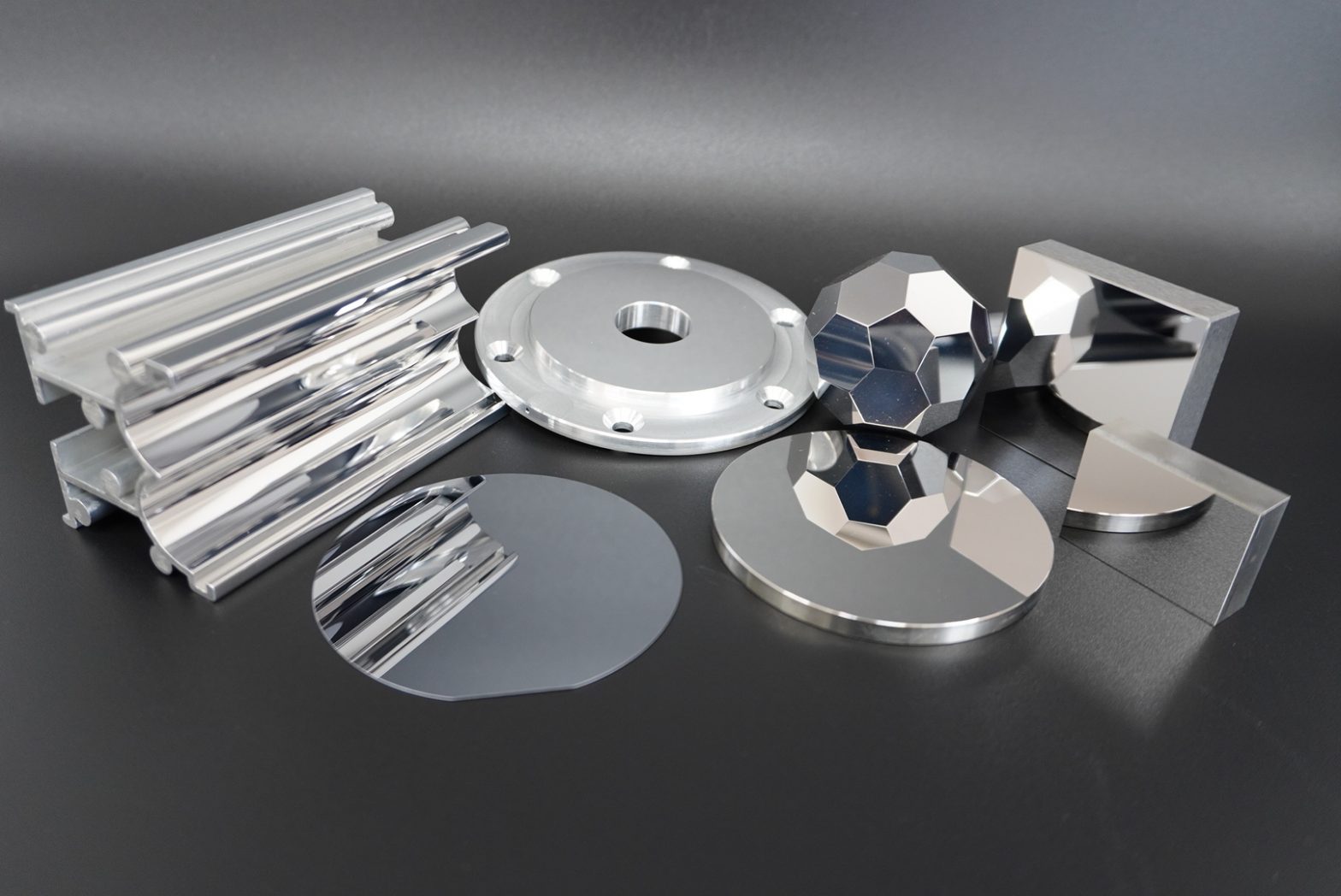

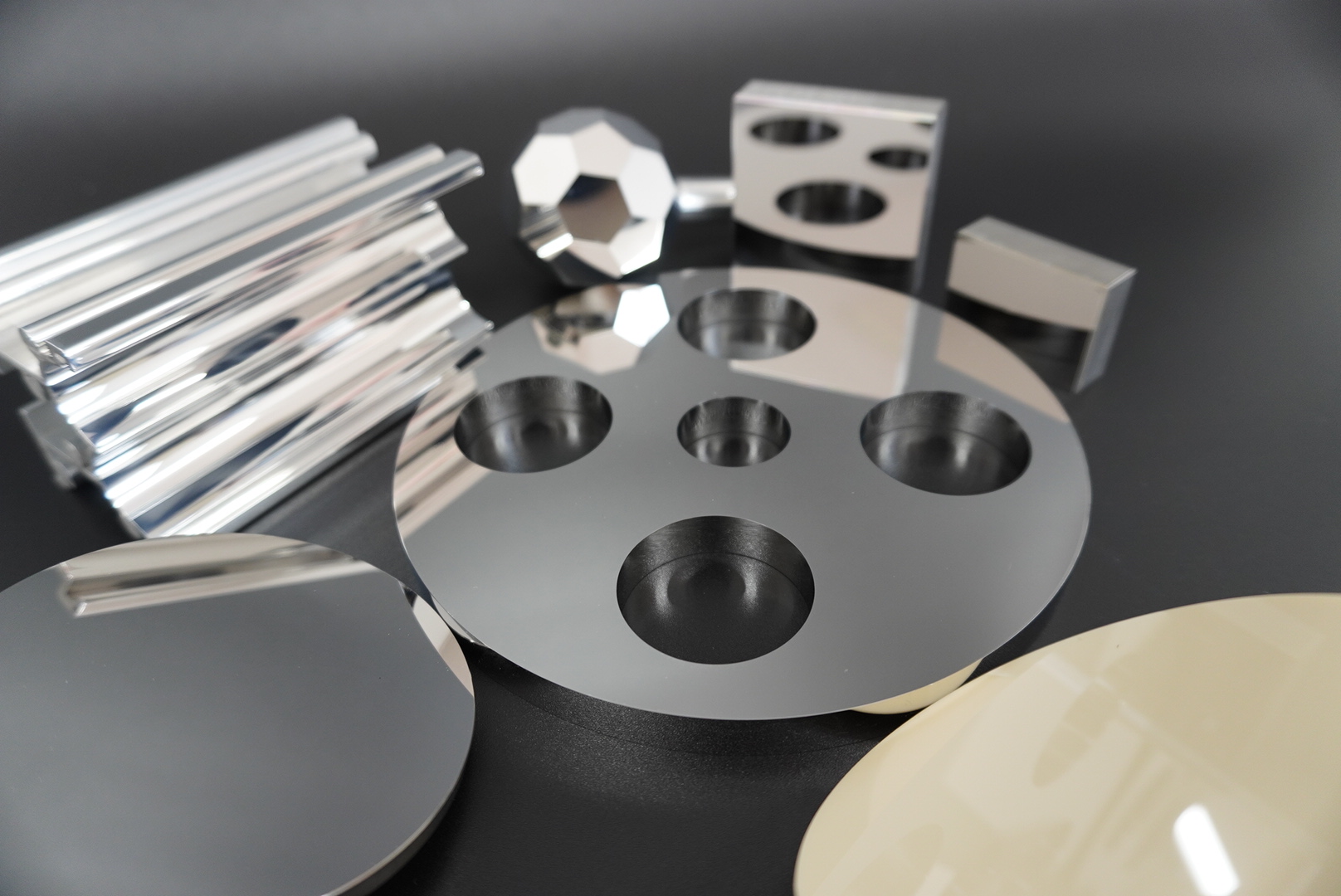

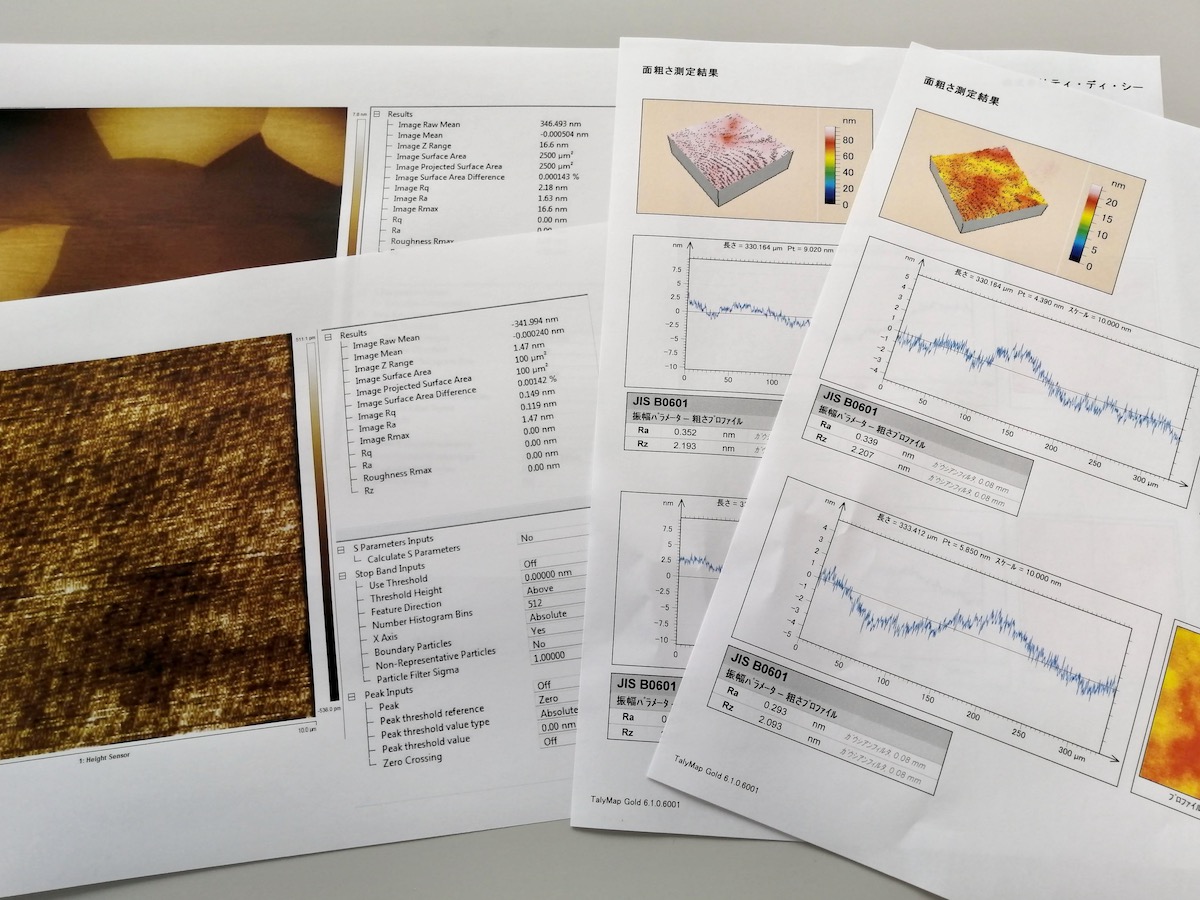

At TDC Co., Ltd., we have accumulated unique technology development and know-how in various processing, and we are able to respond and consult with processing of all surface roughness.

We can handle any kind of precision processing required by our customers, so please feel free to contact us.

with nano-level precision polishing.

and production from single units to mass production.

Please also refer to the “Polishing service” page for the polishing process performed at TDC.

Related page

- Precision lapping service / ultra precision lapping service

- Polishing service

- What is Grinding

- What is cutting

- What is a chuck table? | Basic information and description of types, Processing accuracy at TDC

- Copper polishing

- Polishing after thermal spraying

- Sapphire polishing

- Polishing of plastic/acrylic resin

- Polishing after surface treatment/coating

- Symbol used for polishing

- Polishing of SiC

- Polishing of titanium

- Cylindrical grinding/cylindrical polishing

- Type of polishing process

- What is the accuracy that can be achieved by polishing?

- Principle of polishing process

- Polishing process for Resin

- Metal polishing process

- What is CMP

- What is polishing?

- About Lapping and Polishing