What is the accuracy that can be achieved by polishing?

Here, we will explain the accuracy, surface roughness, and surface roughness that can be achieved by polishing.

Please also refer to the “polishing” page for the polishing process performed by TDC.

Please refer to the “Precision Measurement” page for the precision measurement performed by TDC.

Contents

What is the accuracy possible by polishing?

The accuracy that can be achieved by polishing varies greatly depending on the material, size, shape, heat treatment, etc. of the object to be processed.

The smallest machining example at TDC is a 0.05 mm square tiny dice. For large ones, the size of the grinding machine is 600 x 1,500 mm, and the size of the polishing machine (mirror surface processing machine) is about dia.1 meter.

Polishing / grinding for high-precision machining

It can be said that polishing / grinding is a processing method that can produce higher accuracy than any processing method.

For example, in polishing, it is possible to make adjustments in micron units such as um (micrometer) by selecting abrasive grains and processing methods according to the object to be processed, and this technology is often used in the final process of product processing. It has become.

In addition, grinding, which is performed as a process after “cutting” such as lathe processing and milling, is a processing method that scrapes the surface of the product, so it is possible to finish it smoothly and with less unevenness.

If you have any problems with high-precision machining, please contact TDC, which specializes in polishing and grinding, for consultation and request.

with nano-level precision polishing.

and production from single units to mass production.

表面粗さとは

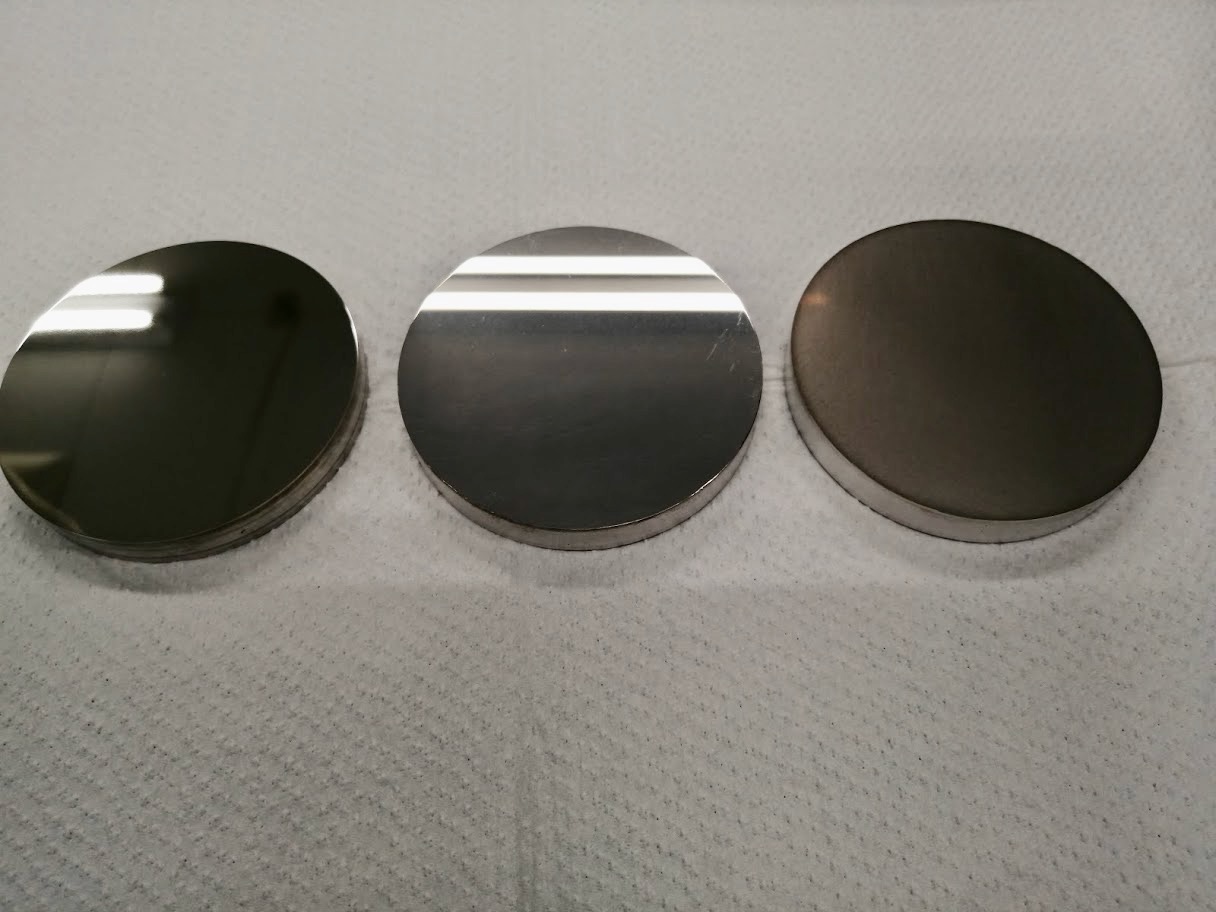

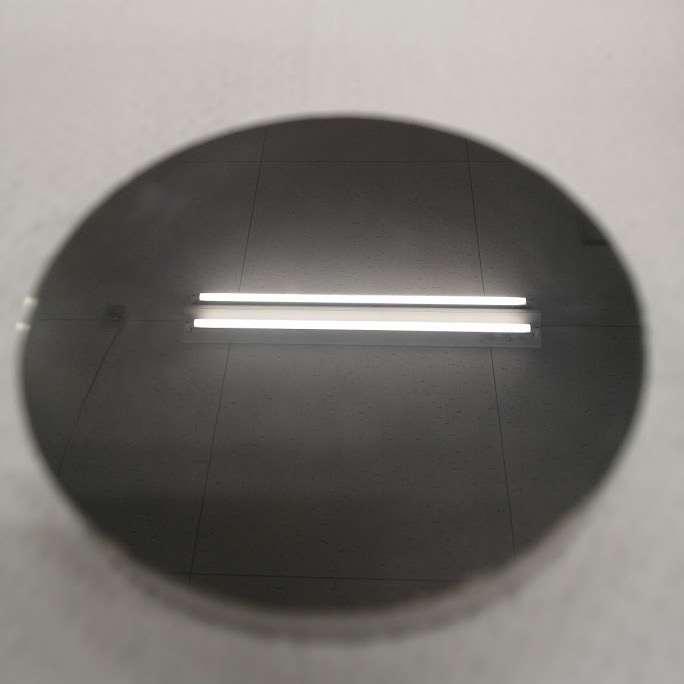

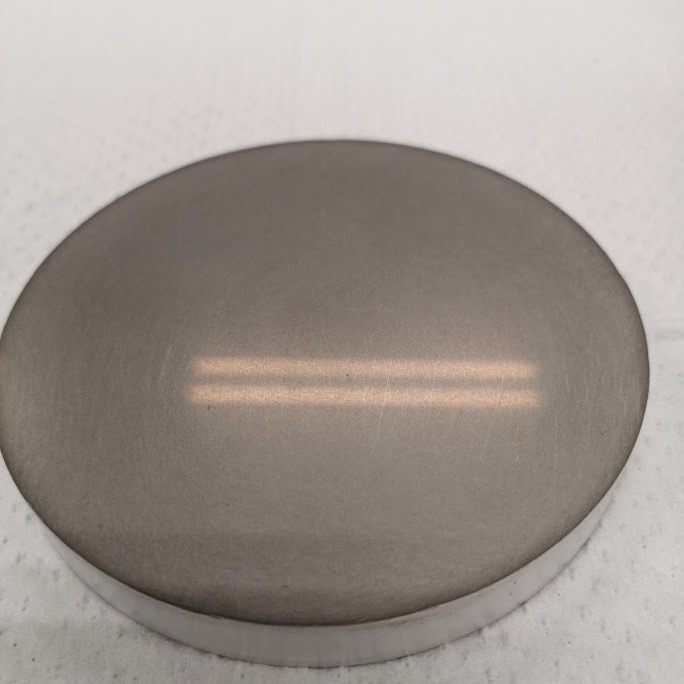

Photo: Difference in roughness of Φ3 inch aluminum substrate

Surface roughness expresses the unevenness (surface roughness) that always occurs on the surface after processing according to various standards.

If the surface roughness is large, the surface will be rough and the reflection of light will be dull. On the other hand, the smaller the surface roughness, the smoother the surface and the more it reflects light like a mirror.

Especially for products and parts where texture, texture, wear amount, airtightness, etc. are important, this surface roughness is an important index.

Click here for a list of TDC surface roughness and surface roughness results

Indicator / unit indicating surface roughness

There are various exponents and parameters to represent the surface roughness.

Among them, there are three typical indexes, “Ra”, “Rz”, and “Rmax”.

Ra (Arithmetic Mean Roughness)

The cross-sectional curve of the work piece is called the roughness curve. The Ra value is the average degree of unevenness from the center of this roughness curve (the surface of the workpiece).

Rz (maximum height)

Rz is calculated by measuring the peak and valley bottom of the roughness curve and adding the average deviations from the center m of each of the high peak and low valley bottom.

Rmax (10-point average height)

The reference length is calculated from the roughness curve, and the difference in height between the high part and the lowest part is Rmax.

For consultation on surface roughness and surface roughness, contact TDC.

TDC Co., Ltd. has accumulated unique technological development and know-how in various processing, and can handle and consult with processing of all surface roughness.

We will respond to all precision processing requested by our customers, so please feel free to contact us.

with nano-level precision polishing.

and production from single units to mass production.

- Precision lapping service / ultra precision lapping service

- Polishing service

- What is Grinding

- What is cutting

- What is a chuck table? | Basic information and description of types, Processing accuracy at TDC

- Copper polishing

- Polishing after thermal spraying

- Sapphire polishing

- Polishing of plastic/acrylic resin

- Polishing after surface treatment/coating

- Symbol used for polishing

- Polishing of SiC

- Polishing of titanium

- Cylindrical grinding/cylindrical polishing

- Type of polishing process

- What is the accuracy that can be achieved by polishing?

- Principle of polishing process

- Polishing process for Resin

- Metal polishing process

- What is CMP

- What is polishing?

- About Lapping and Polishing