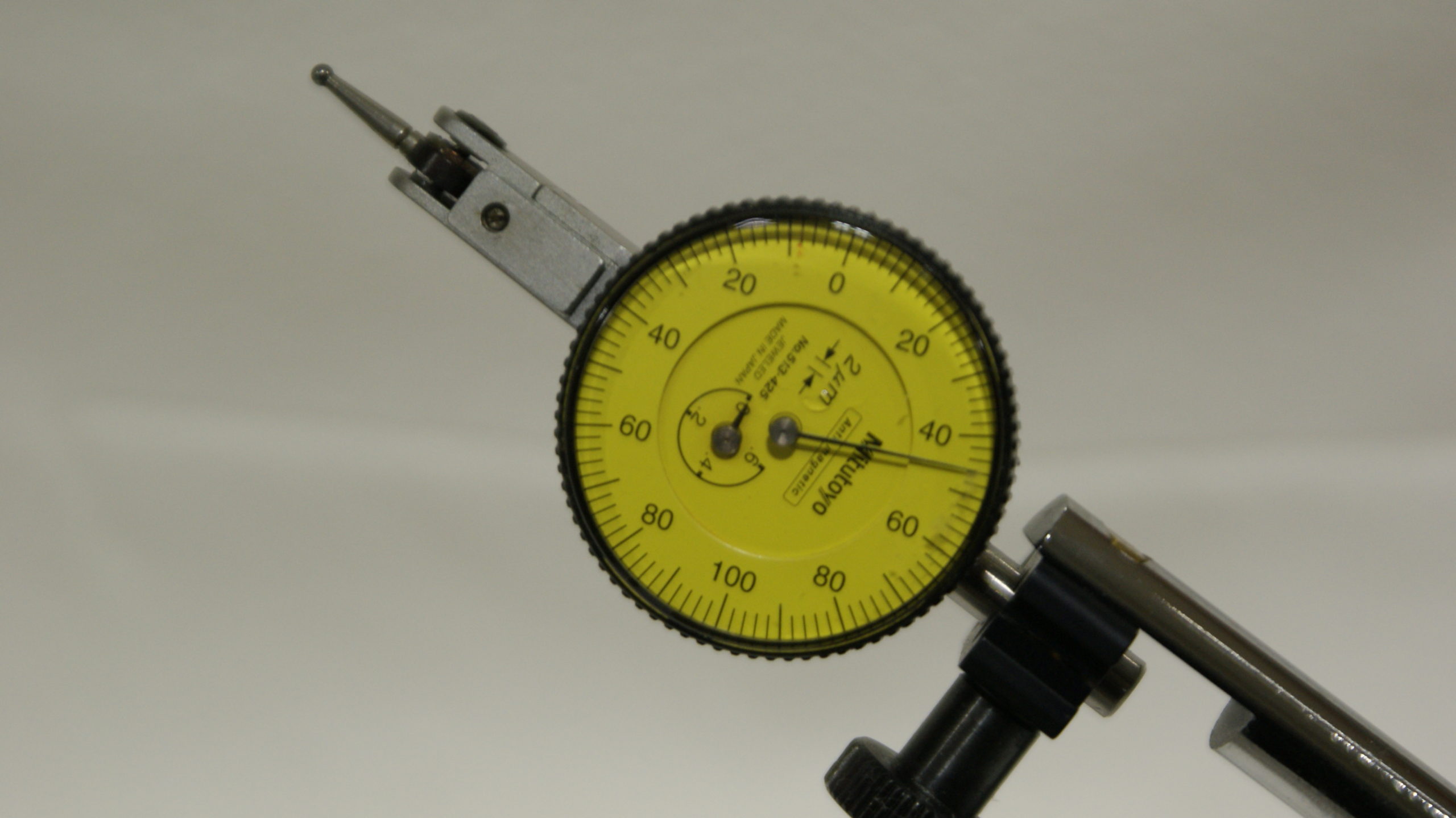

Dial gauge

On this page, we will introduce dial gauges used in TDC, starting with explanations about dial gauges.

For more information chek the “Measurement Equipment” page.

Contents

What is a dial gauge

A dial gauge is a measuring instrument that is used by attaching it to a measuring jig (stand) or precision equipment to accurately measure a short straight line distance.

In general, dial gauges are often used to measure the difference from the standard and to find parallelism, and are one of the measuring instruments widely used in manufacturing sites where dimensional accuracy is required.

It is also used to measure the deflection of the rotating shaft and the objects attached to it when using machine tools such as lathes.

Features of Dial Gauge

Unlike vernier calipers and micrometers, dial gauges are not used alone, but are used by fixing them to a stand or an object.

With proper installation, it is possible to measure geometric tolerances (flatness, roundness, inclination, coaxiality, concentricity, etc.) that indicate not only dimensional changes but also three-dimensional shapes.

Dial gauges, which have a precise internal structure but are easy to handle, are used in many manufacturing sites because highly reliable measurement values can be obtained when used in the correct measurement method.

Types of dial gauges

Dial gauges are broadly divided into analog and digital types.

- analog

The linear motion or circular motion of the spindle with a contact point is converted into rotary motion by gears, and the scale and needle indicate the magnitude of the motion. The measurement length is as short as 0-10mm, and is often used for comparative measurements. - digital

An encoder reads the linear or circular motion of a spindle with a stylus. The read value is displayed on the liquid crystal display.

In addition to analog and digital types, dial gauges also come in the following types.

- Spindle type dial gauge

- Lever type dial gauge

- digital indicator

- Spindle type dial gauge

Spindle type dial gauge

A spindle type dial gauge transmits the vertical movement to the dial when the spindle detects the unevenness of the object, and the internal gears called “rack gear” and “pinion gear” make the needle a dial gauge that displays the displacement.

Lever type dial gauge (test indicator)

A lever-type dial gauge that measures using the principle of leverage is also called a “test indicator”, and it is a type that transmits the angle of the spindle to the dial with an internal gear and the needle indicates the variation.

Lever type with a thin and small spindle can measure in narrow spaces where it is difficult to measure with the spindle type.

Since the measurement is performed within the range of movement of the lever, the measurement length is shorter than that of the spindle type, but the resolution is high, so it is used for comparative measurements that require higher accuracy.

digital indicator

A digital indicator that displays the amount of change on a dial gauge is called a digital indicator.

Since the internal digital linear scale uses a photoelectric system, it may break due to dropping or impact.

How to use the dial gauge and usage examples

When measuring with one dial gauge

A single dial gauge measures groove depth, steps, and thickness dimensions from the reference surface.

- Set the reference plane of the dial gauge to zero.

- It is possible to numerically measure uneven steps, heights, and depths from a reference surface.

*When using a granite surface plate, the object can be placed on the granite surface plate and the height of the object can be measured with the granite surface plate as the reference plane zero.

When measuring with multiple dial gauges

By setting multiple dial gauges on a long bar, you can measure the straightness of the surface.

- A large number of dial gauges are fixed at the same height on a reference plate or reference bar.

- The dial gauge is set to zero with a flat master or a straight master.

- By placing it on the object, you can check the flatness and straightness of the surface.

Problems with dial gauges

Dial gauges are general measuring instruments that are widely used in many fields, but they have the following problems due to their properties and structural features.

- Not suitable for multiple inspections

- Difficult to mount on metal processing equipment

- prone to measurement errors

- It takes a lot of man-hours to record and utilize measurement results

prone to measurement errors

Dial gauges may not measure properly if the attached arm is bent or if the angle of contact with the target is not appropriate.

It is also deduced that measurement errors are likely to occur depending on the installation position, settings, measurement method, etc.

Not suitable for multiple inspections

A dial gauge is attached to a stand or precision instrument for measurement.

Therefore, it has the disadvantage that it takes a long time to inspect when there are many points to be measured or objects to be inspected, and it is not suitable for mass inspection.

Difficult to mount on metal processing equipment

Dial gauges are vulnerable to dirt such as oil, liquids, and dust, so installation locations are limited.

It can be said that it is difficult to install it in metal processing equipment such as cutting and press processing.

It takes a lot of man-resources to record and utilize measurement results

Many dial gauges cannot record their results to a device such as a PC. Basically, measured values obtained with a dial gauge are recorded by visually confirming the needle, handwriting or manually entering data.

Therefore, there is a good chance that human error will occur in transcription and description, and many man-hours are required from measurement to recording and data utilization.

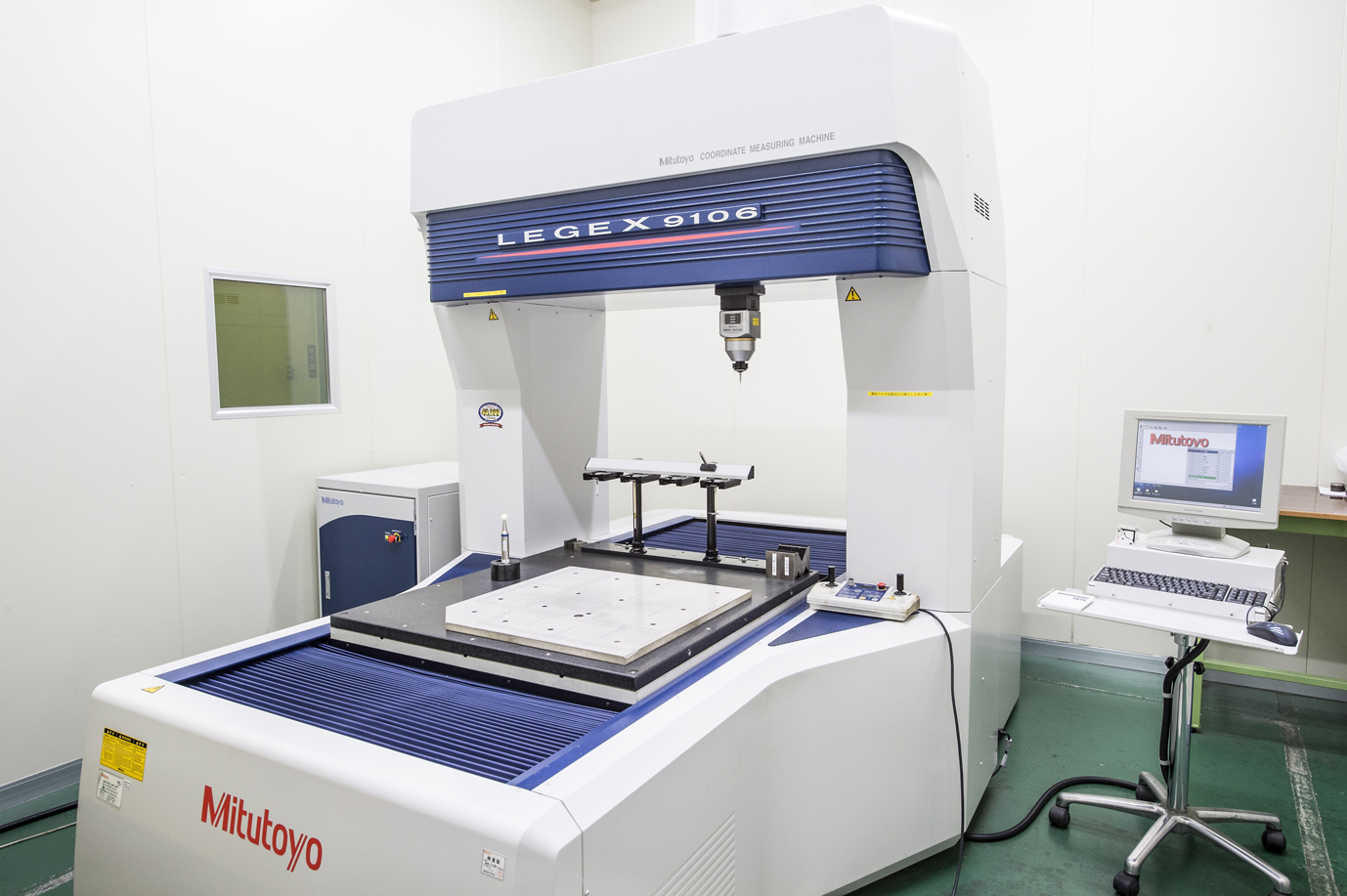

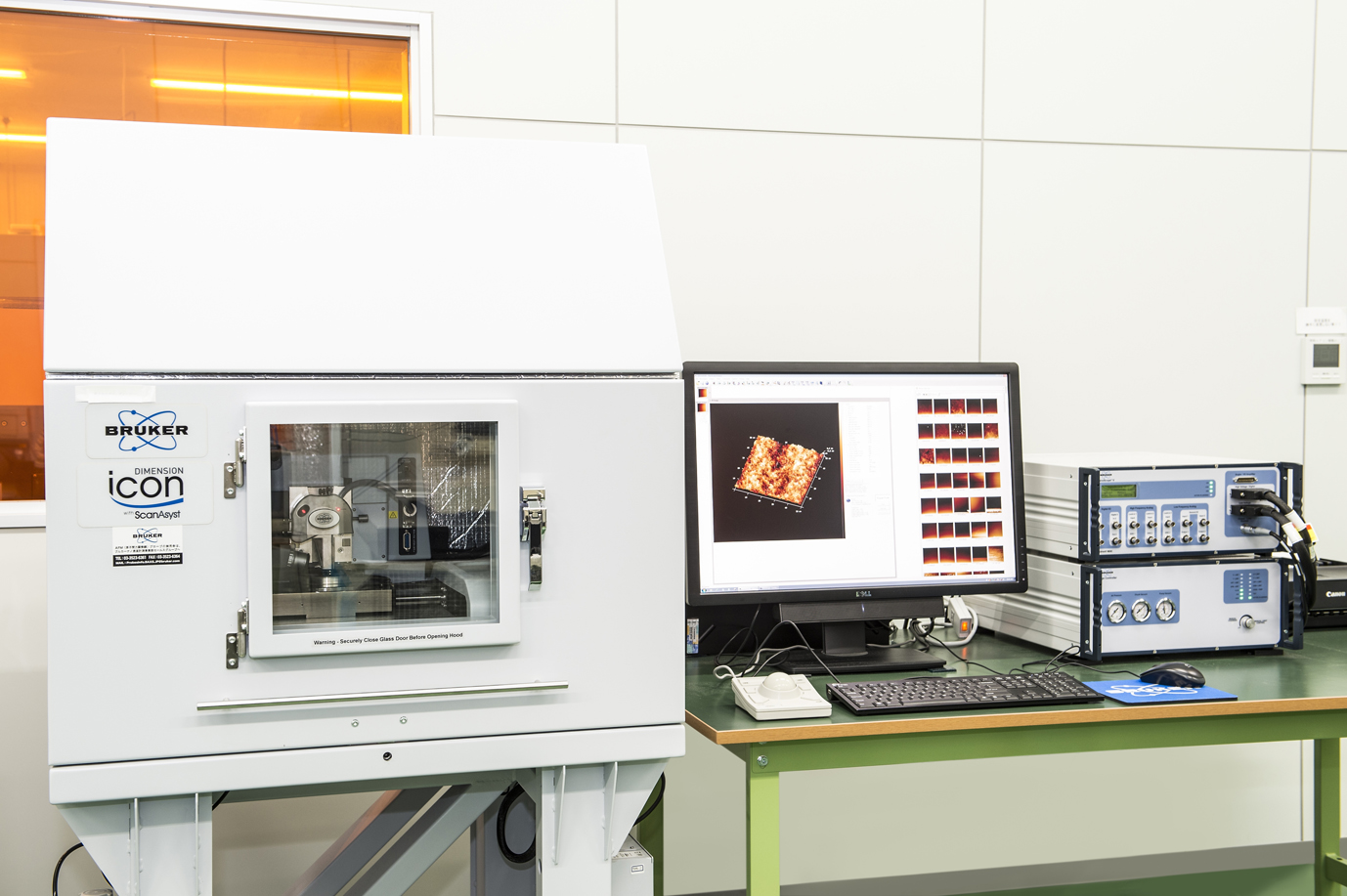

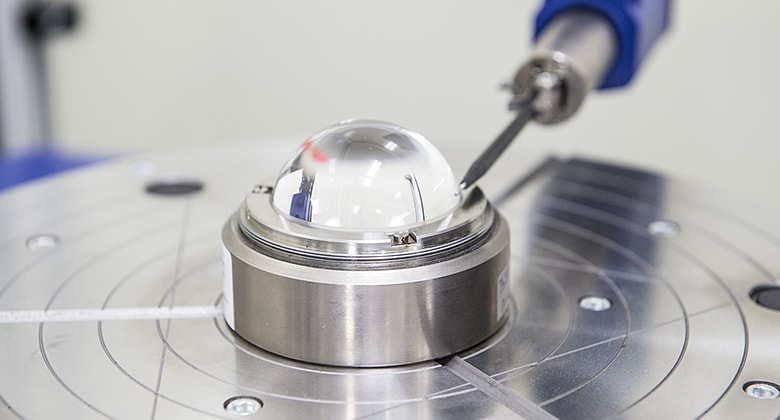

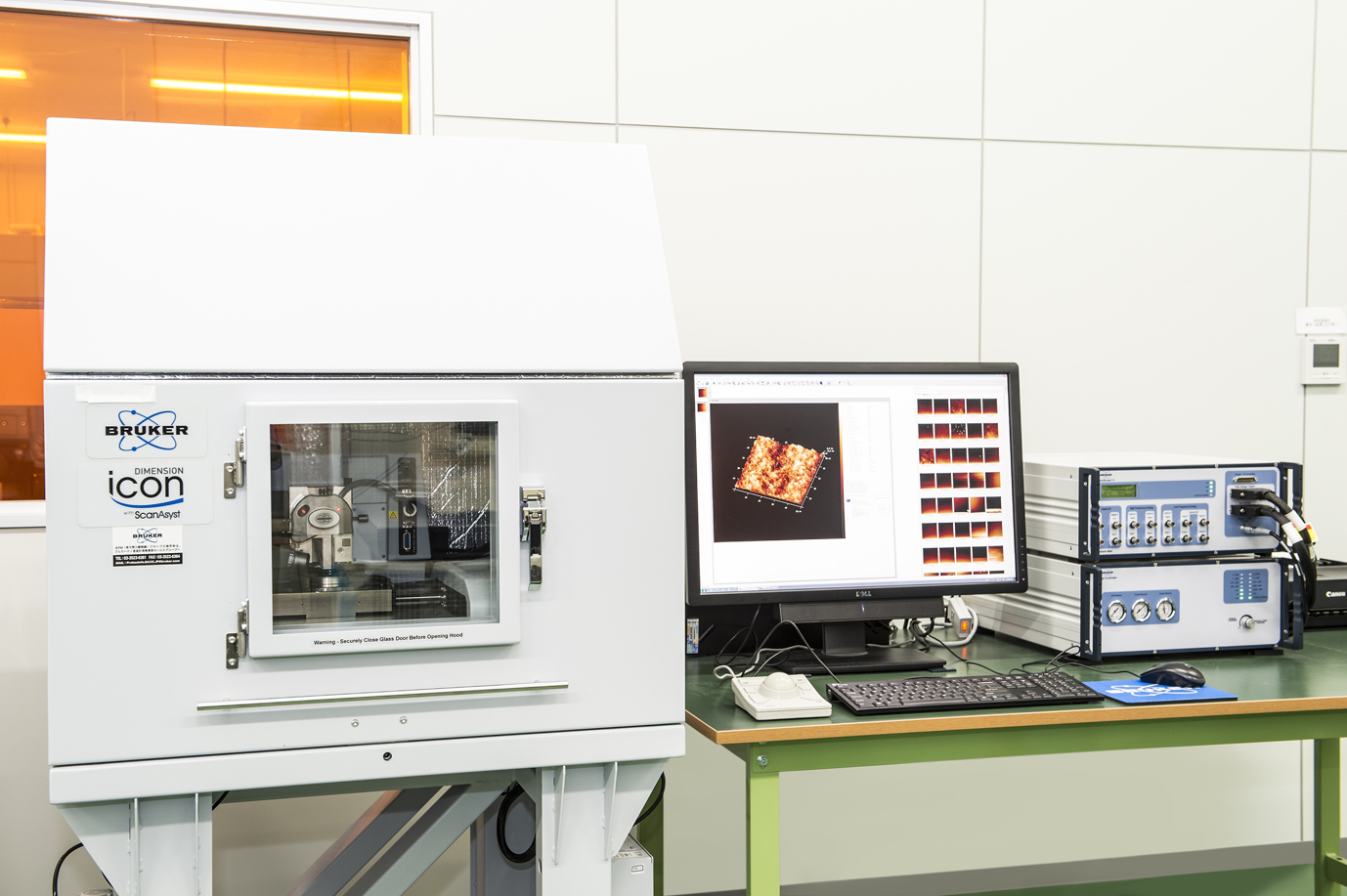

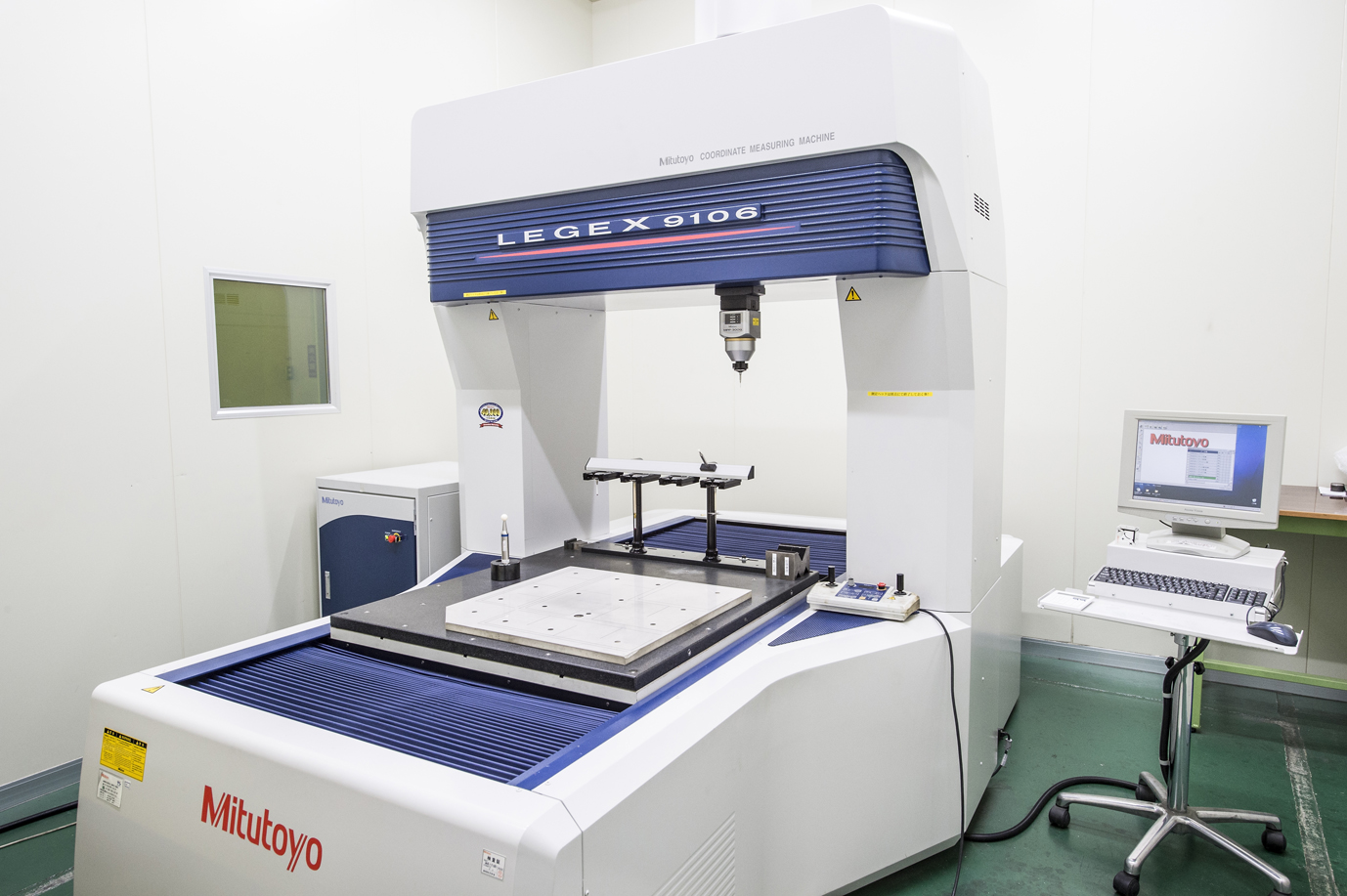

At TDC, in addition to measurements using dial gauges, which are general measuring instruments, we perform precision measurements for high-precision parts.

For our measuring instruments, please refer to the “Measurement Equipment” page.

- Measurement of high-precision parts (precision measurement)

- I want to perform multiple tests

- I want to measure metal processing equipment

- I want to utilize the measurement result data

Please feel free to contact TDC if you have any concerns such as the above, or if you want high-precision measurements that cannot be measured with a dial gauge.

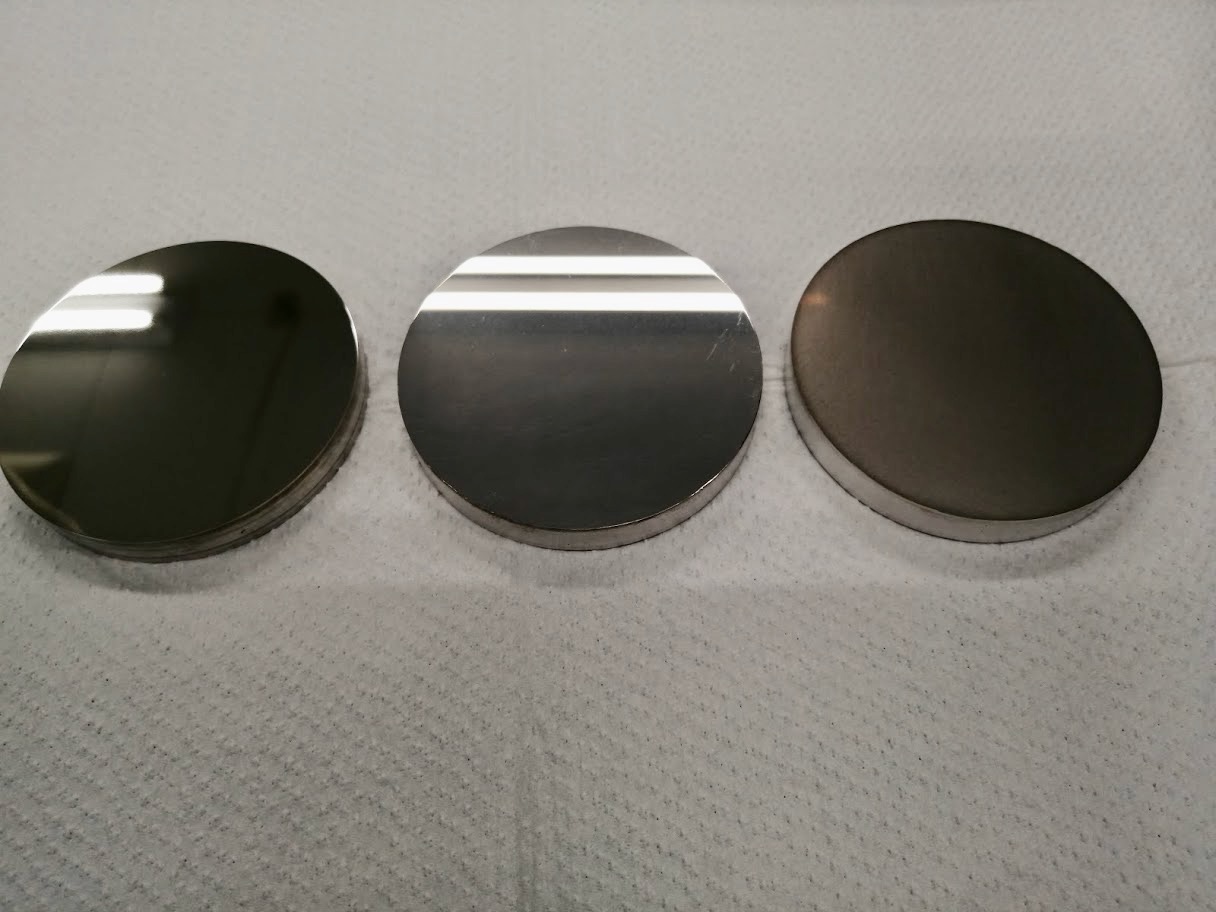

with nano-level precision polishing.

and production from single units to mass production.

Related page

.jpg)