ガラスエポキシ(ガラエポ)の精密加工

このページでは、TDC(ティ・ディ・シー)で行っているガラスエポキシ素材(ガラエポ)の精密加工をご紹介します。

TDCの精密研磨加工サービスについては、『精密加工研磨加工・超精密研磨加工-精密加工のサービス』ページもご覧ください。

Contents

ガラスエポキシ(ガラエポ)とは

ガラスエポキシとは、エポキシ樹脂(液体)をガラス繊維に含ませ、熱硬化処理を施することで積層板(積層棒)にした樹脂素材のことを指します。

難燃性、耐熱性、強度、優れた低導電率などを兼ね備えているため、板状のガラスエポキシはプリント基板の材料としても広く活用されています。

ガラスエポキシは略してガラエポと呼ばれるほか、エポキシガラスやエポキシガラス樹脂などと呼ばれることもあります。図面上では、「GFRP」と表記されることもあります。

GFRP

GFRPとは、ガラス繊維強化プラスチック/ガラス繊維強化樹脂のことを指し、ガラス(Glass)繊維(Fiber)で強化された(Reinforced)樹脂(Plastics)の頭文字よりこのように呼ばれます。

FRPの中で最も安価で、幅広い業界で用いられる繊維強化樹脂となっています。

ガラスエポキシ(ガラエポ)の特徴

ガラスエポキシ(ガラエポ)には、以下の特徴が挙げられます。

- 機械的強度が高い・剛性が強い

- 長寿命

- 熱伝導率・耐熱温度・電気特性・断熱・絶縁に優れる

- 薄くても反りにくい

- 180℃の大気中に2時間放置しても外観に変化が認められない

- 比重は1.75~1.85程度

- 絶縁抵抗は10(7)10(8)mΩ

- 吸湿性がある

- 外観は上下面は光沢があり滑らか

ガラスエポキシの材料性質

| 項目 | 試験方法ASTM | 試験条件 | 単位 | ガラス エポキシ FR-4 |

||

| 物性 | 比重 | D-792 | - | - | 1.80 | |

| 吸水率 | D-570 | E-24/50+D-24/23 | 0.10 | |||

| 電気的性質 | 耐電圧 | 常温 | D149 | D-240/24 | MV/m | 29 |

| 水中浸漬後 | 短時間法 | 34 | ||||

| 沿層耐電圧 | 常温 | D-149 | 短時間法 | MV/m | 6.6 | |

| 体積抵抗 | D-257 | Ω・m | 1011 | |||

| 表面抵抗 | D-257 | Ω | 1013 | |||

| 絶縁抵抗 | 常温 | D-257 | D-2/100 | Ω | 1.0×1013 | |

| 煮沸後 | 1.0×1012 | |||||

| 誘電率 | D-150 | 3GHz | - | 4.6 | ||

| 誘電正接 | D-150 | 3GHz | - | 0.050 | ||

| 耐アーク性 | D-495 | - | sec | 120 | ||

| 耐トラッキング性 | IEC 112 | - | V(CTI) | 350 | ||

| 電気絶縁の種類 | IEC | - | - | F | ||

| 熱的性質 | 熱伝導率 | C-177 | - | W/(m・K) | - | |

| 熱線膨張率 | 縦 | D-696 | 25~100℃ | 10-5/℃ | 2.1 | |

| 横 | ||||||

| 燃焼性 | UL94 | - | - | V-0 | ||

| 耐ハンダ性 | UTK法 | - | ℃/sec | 260×120 | ||

| 荷重たわみ温度 | D-648 | 1.82MPa | ℃ | 180 | ||

| 機械的性質 | 引張強度 | 縦 | D-638 | 破断 | MPa | 300 |

| 横 | 270 | |||||

| 引張伸度 | 縦 | D-638 | - | % | 3.0 | |

| 横 | 3.0 | |||||

| 曲げ強度 | 縦 | D-790 | 破断 | MPa | 720 | |

| 横 | 540 | |||||

| 曲げ変形率 | 縦 | D-790 | - | % | 4.1 | |

| 横 | 3.8 | |||||

| 曲げ弾性率 | 縦 | D-790 | - | GPa | 24.3 | |

| 横 | 20.0 | |||||

| せん断強度 | D-732 | - | MPa | - | ||

| アイゾット衝撃強度 | D-256 | ノッチ付 | J/m | 588 | ||

| ロックウェル硬さ | D-785 | Rスケール | - | 120 | ||

ガラスエポキシ(ガラエポ)の用途・活用される業界

ガラスエポキシ(ガラエポ)は前述のとおりプリント基板として利用されるほか、以下のような用途で活用されます。

- ICプリント基板

- 電子部品・電気機器の絶縁材・断熱材

- スペーサー

- ハニカムヒーター

ガラスエポキシ(ガラエポ)加工の注意点

ガラスエポキシは他の樹脂材料と比較し、非常に硬質な素材となります。

そのため、加工・切断を行うには、超硬材に使用するダイヤモンドカッターなどのツールを用いる必要があります。

また、ガラスエポキシ切断時には微粉末化した粉塵が飛散し、機械のモーター部や駆動部などに入りこんで加工機器が故障するケースもあるため、粉塵対策の設備やノウハウも欠かせません。

TDCでは、ガラスエポキシの加工にも対応が可能なダイヤモンドカッター、集塵機などを完備しています。

他社で断られたガラスエポキシ加工もお受けいたしますので、ぜひ一度TDCまでご相談ください。

with nano-level precision polishing.

and production from single units to mass production.

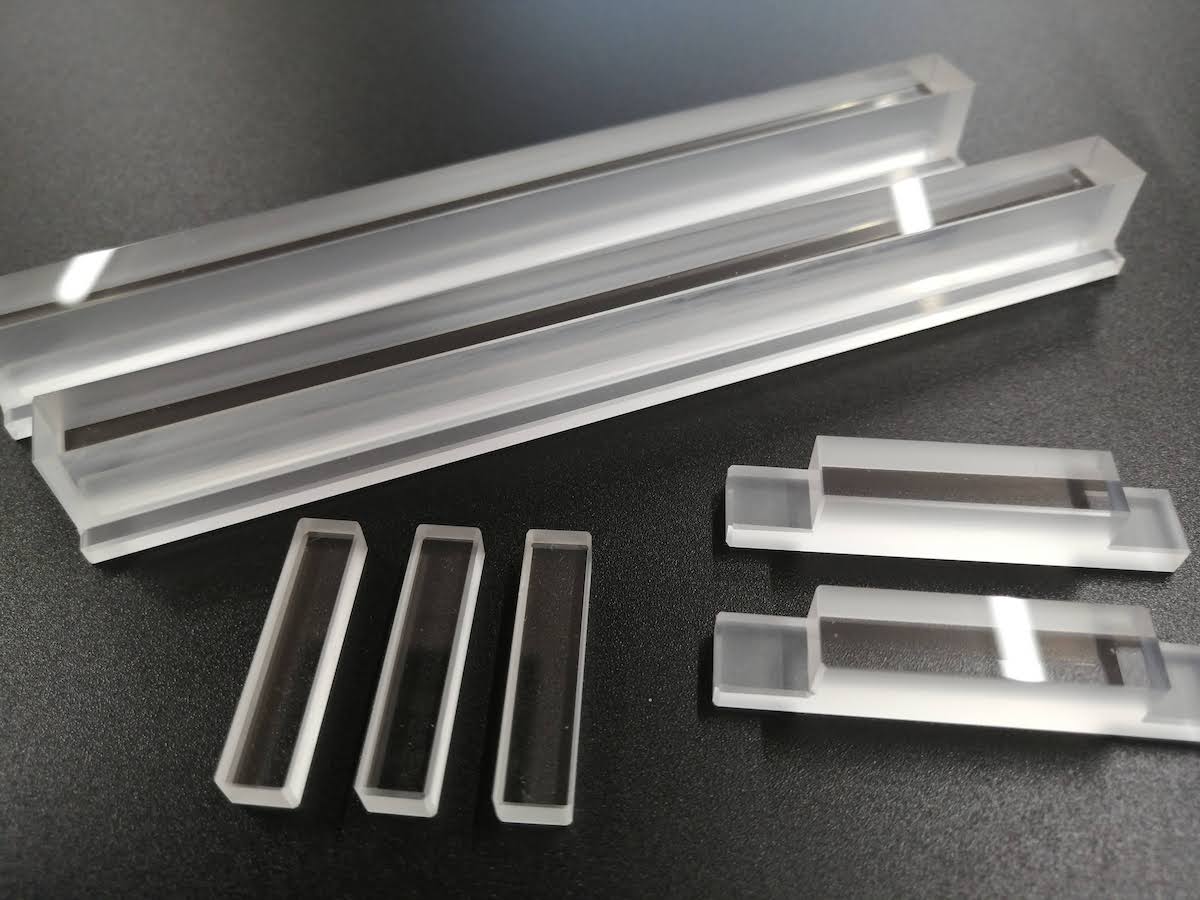

TDCのガラスエポキシ(ガラエポ)の精密加工例

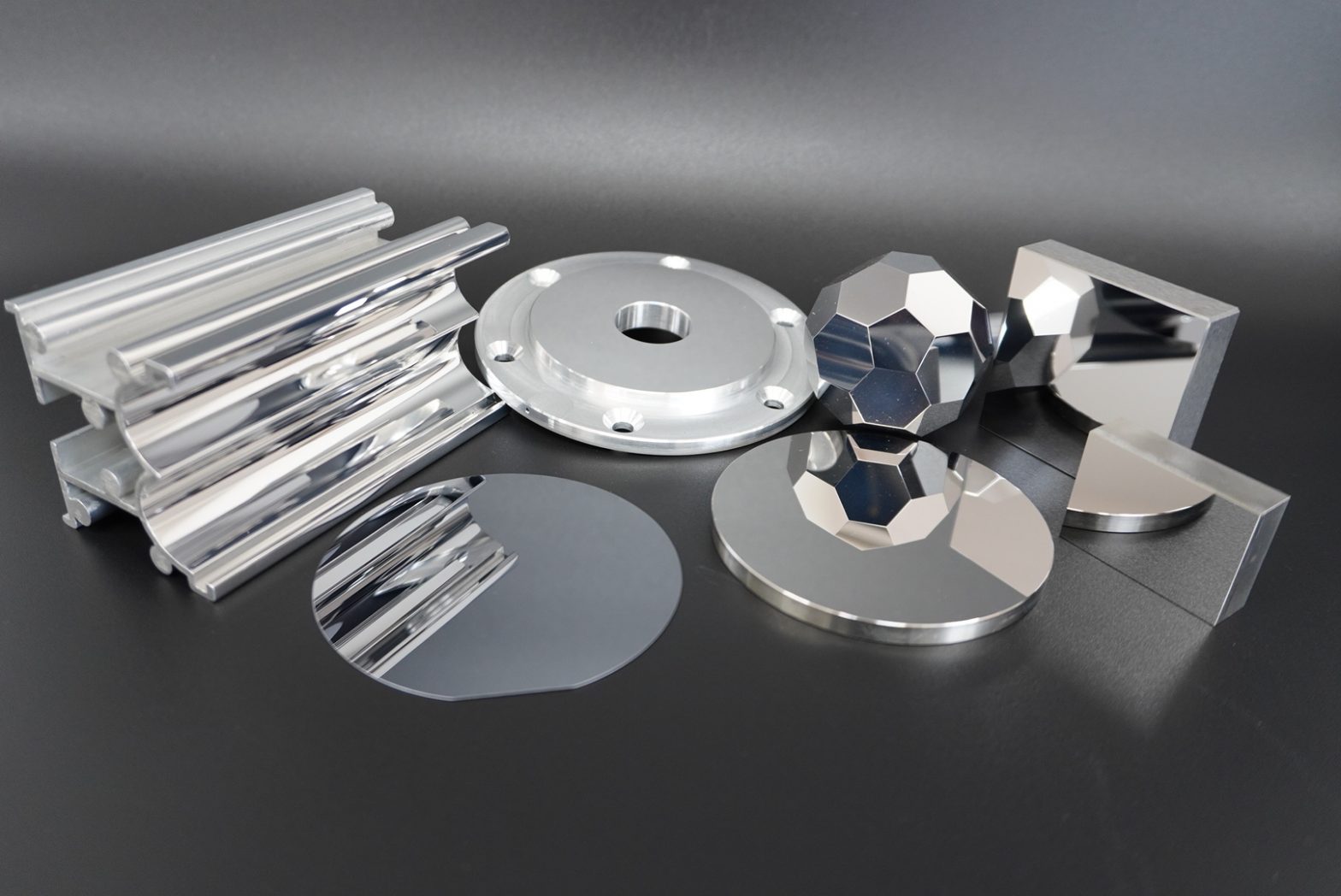

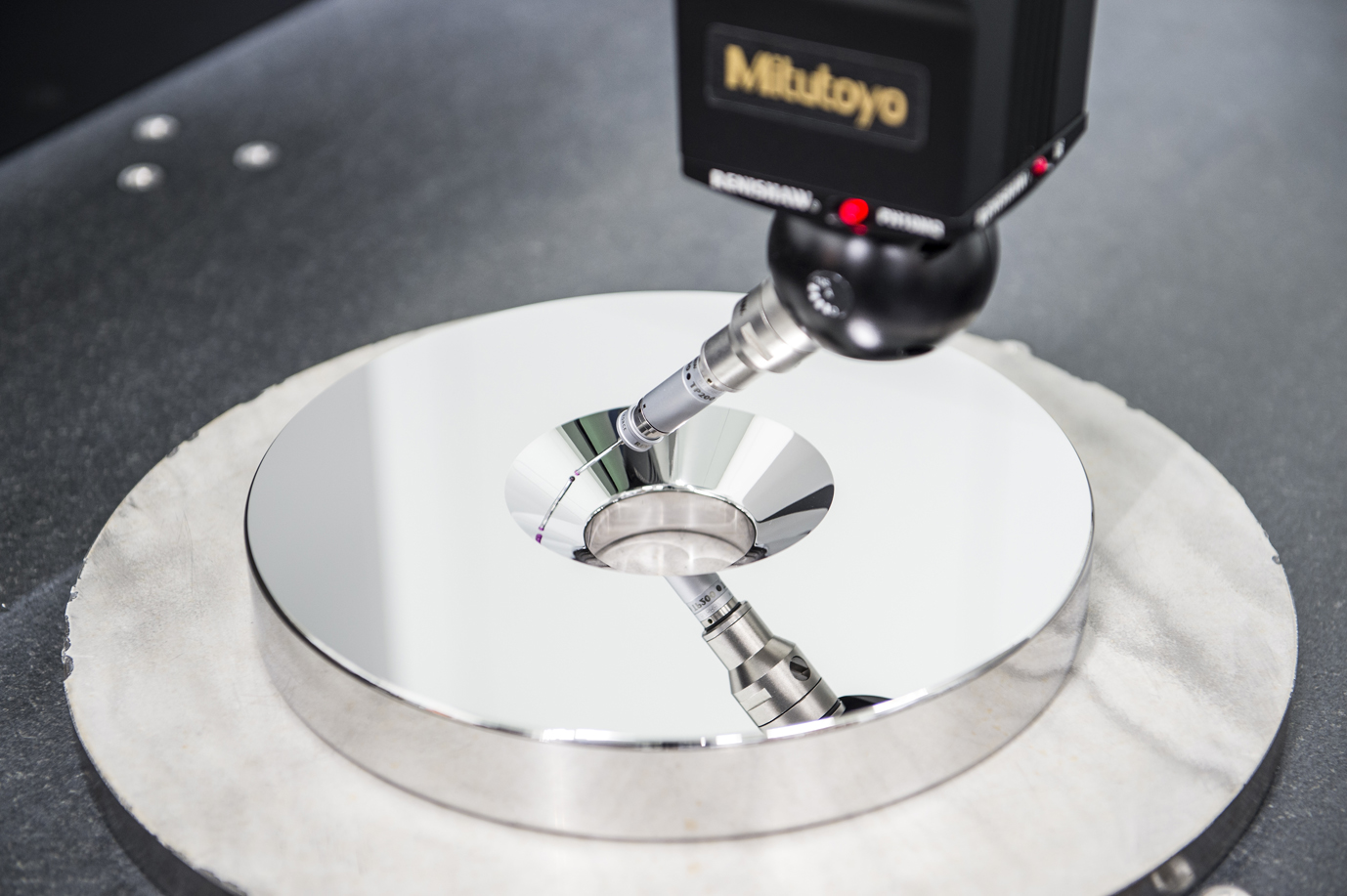

TDCにおけるガラスエポキシ(ガラエポ)の精密加工例をご紹介します。

材質に応じた加工ノウハウと、これまで蓄積された研磨加工技術により、あらゆる精度で対応が可能です。他社で断られたガラスエポキシ(ガラエポ)の加工案件も、ぜひ一度TDCにご相談ください。

その他材質についての加工実績は、下記ページよりご覧いただけます。

>>TDCの表面粗さ・面粗度実績

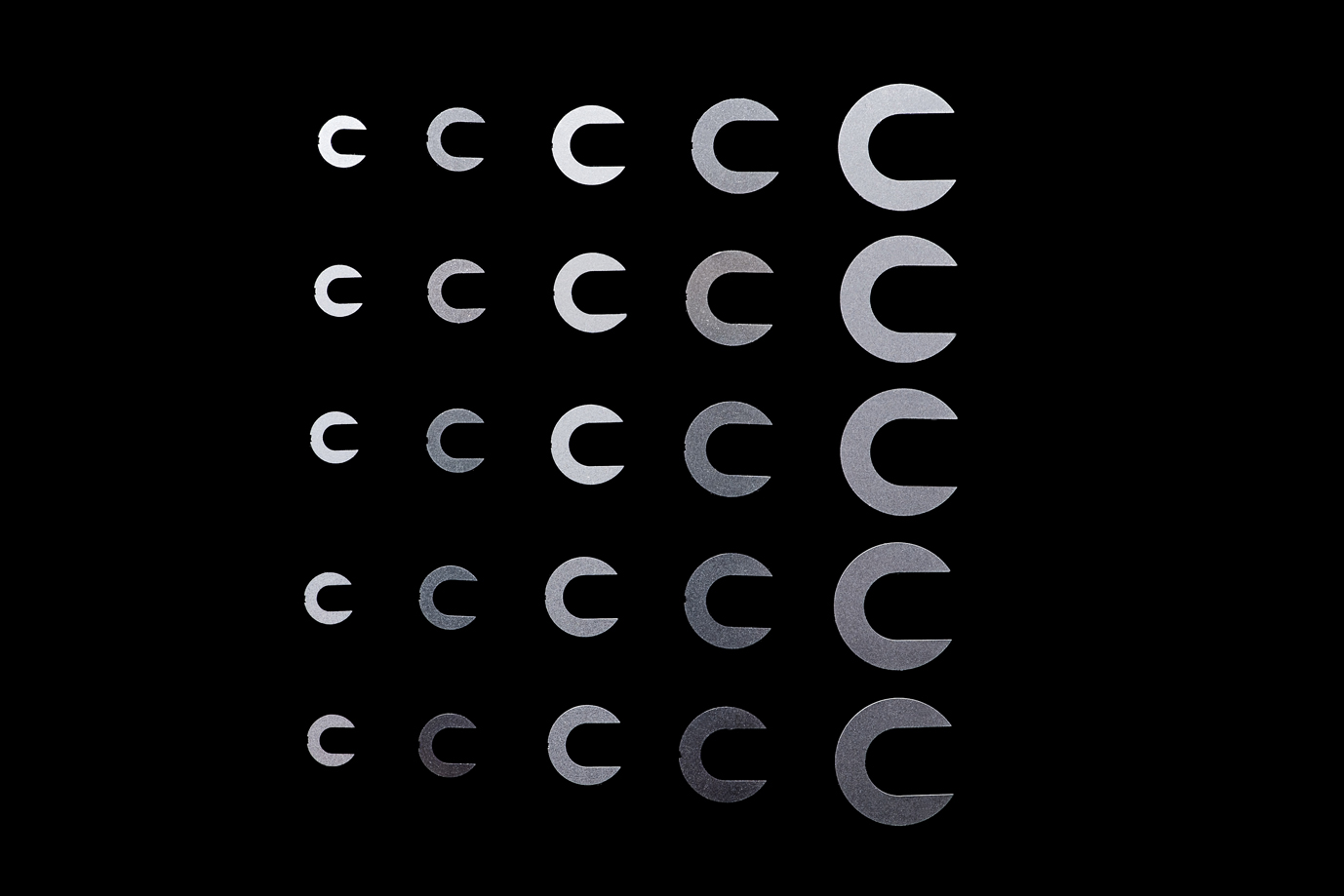

精密加工例①:ガラエポ試験片 薄化研磨

- サイズ:50 mm x 50 mm

- 仕様:厚み研磨 厚み0.6 mm → 0.5mm±0.01mm

- 材質:ガラエポ

- 加工内容:精密ラップにて厚みを100um落とし、ご希望の公差へ仕上げました。

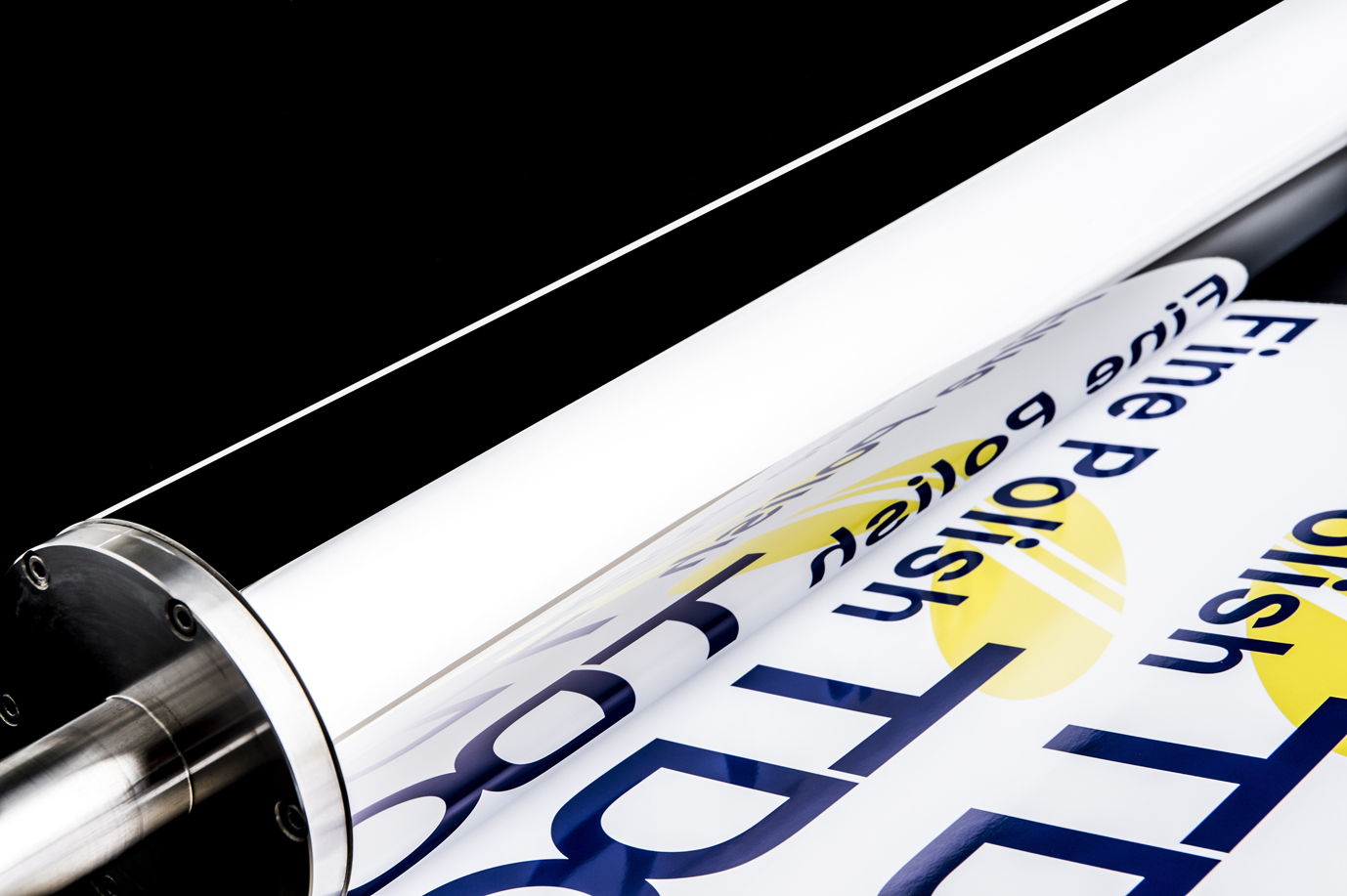

精密加工例②:ガラエポ Φ530mm大型基板 鏡面研磨加工

- サイズ:φ530 mm x 厚み 0.750mm

- 仕様:鏡面仕上げ、厚み±0.005mm へ仕上げ

- 材質:ガラエポ

- 加工内容:精密ラップにて加工面を鏡面仕上げ、厚み公差を±0.005mm に入れました。

Related page