真鍮の精密加工・研磨加工

このページでは、TDC(ティ・ディ・シー)で行っている真鍮素材の精密加工技術をご紹介します。

TDCの精密研磨加工サービスについては、『精密加工研磨加工・超精密研磨加工-精密加工のサービス』ページもご覧ください。

Contents

真鍮とは

真鍮とは、銅と亜鉛の合金のことで、別名「黄銅」と呼ばれます。英語では「brass(ブラス)」と呼ばれ、真鍮素材を用いた金管楽器による音楽編成隊のことを「ブラスバンド」と呼ぶ由来となっています。

一般的に、亜鉛が5~40%加えられたものが真鍮と定義されますが、銅と亜鉛の比率により色味が変化するのが特徴のひとつとなっています。

よく知られている真鍮には「七三黄銅」「六四黄銅」があり、それぞれ銅と亜鉛の割合がおよそ70:30、60:40となっています。亜鉛の比率によりその性質は変わってきますが、真鍮ならではの光沢があり展延性が高いのが特徴です。

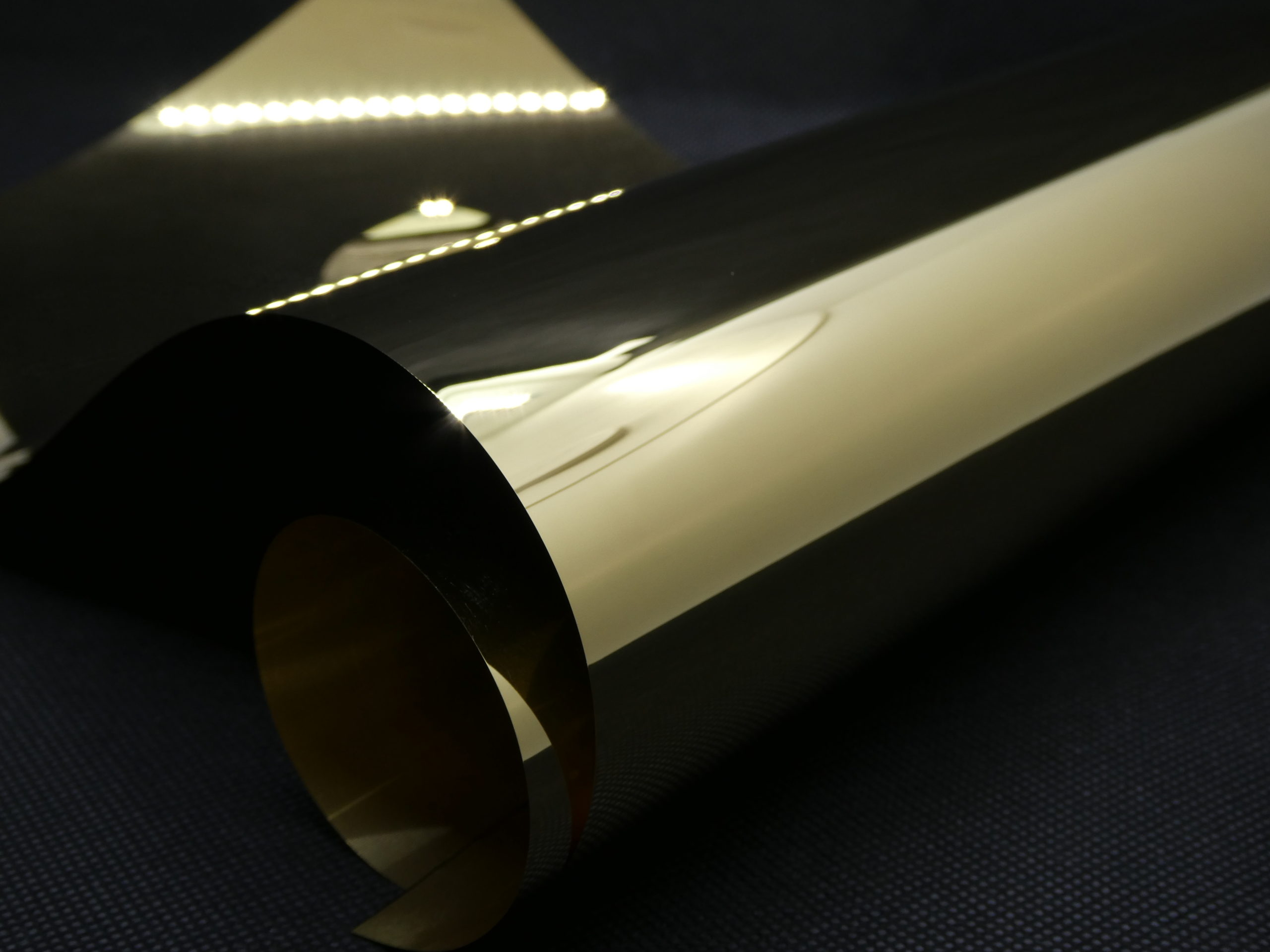

研磨や鏡面仕上げをおこなうことで金色の光沢が出ることからも、金の代用品として利用されることもあります。

真鍮の歴史

真鍮は紀元前から用いられはじめたと言われており、古代ローマ帝国では貨幣としても使われていました。

金のような美しい輝きを擁する真鍮はメッキとしても活躍し、古代ギリシア時代の科学者・アルキメデスが見破ったとされる「偽の金の王冠」もこの真鍮が使われていたとされています。

真鍮の特徴・加工特性

真鍮には以下の特徴や加工特性があります。

- 展延性

展延性柔らかい素材である真鍮は、圧縮する力や引っ張る力を加えても破損・破断が起こりづらいという特性を持ちます。そのため、プレス加工やベンダーでの曲げ加工なども行いやすく、電化製品から装飾品までさまざまなシーンで用いられています。 - 切削性

真鍮は微量ながら鉛や鉄も含んでおり、切断しやすく、削りやすいのも特徴です。この高い被削性により、精密加工を施す事も可能です。 - 電気伝導性

真鍮は銀と同等の電気伝導性を持ち、コンセントやコネクターなどの接点部にも利用されます。 - 熱間鍛造性

真鍮は常温で伸ばしても破損せず、加熱する事で複雑な形状に加工する事が可能です。

TDCで対応可能な真鍮の加工

TDCでは、真鍮に対して高精度研磨加工をおこなうことが可能です。

これまでに培ってきた研削や精密ラップ研磨技術を組み合わせることで、真鍮を用いた精密なモノづくりを行います。

TDCの真鍮精密加工の特徴

TDCの真鍮精密加工には、以下のような強み・特徴があります。

- 高精度な研磨技術

TDCが誇る精密研磨技術で除去量を制御することで、真鍮の加工においてもミクロン単位・ナノレベルでの超高精度な精密加工を実現しています。

切削や研削などの加工方法と比較しても、対象物に負荷をかけることなく、あらゆる形状への対応が可能です。 - 短納期・特急対応が可能

100台以上の研磨装置を所有することにより、大量ロットや複雑な加工であっても短納期を実現。

お急ぎの場合には、「特急対応」でのご相談にも対応させて頂きます。 - 小ロットからでもお気軽にご相談ください

1個からの小ロットでのご依頼、試作品の製作もお任せください。 - 100台を超える豊富な加工機械を所有

TDCでは、ラップ研磨機や平面研削盤などの研磨装置を100台以上所有。

マシニングセンター、フライス盤などの各種加工機も揃えているため、あらゆる加工にも対応が可能です。 - 研磨装置の約半数が自社製

100台以上ある研磨装置のうち約半数は自社製となり、「低コスト」で「高品質」なモノづくりを実現しています。

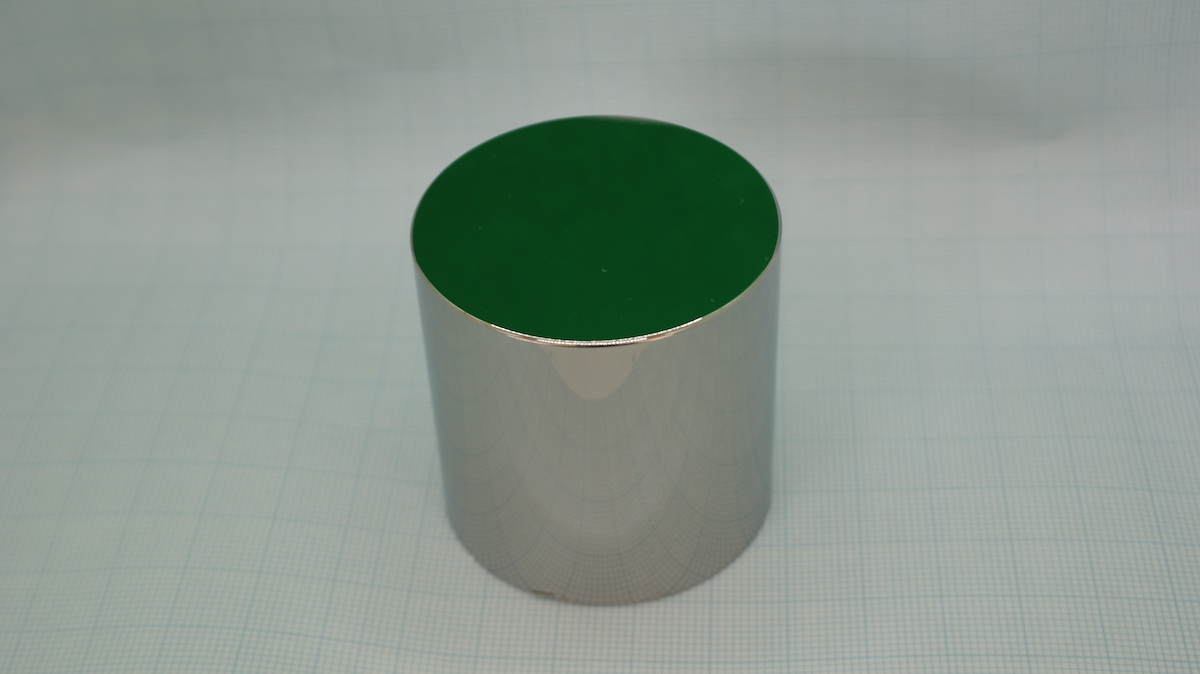

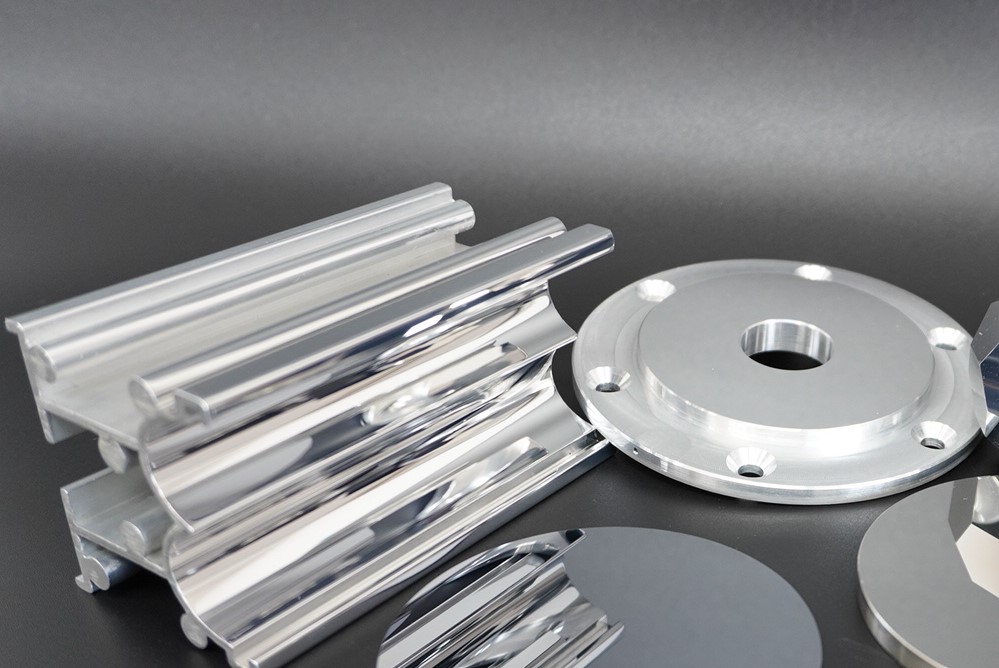

TDCの真鍮の精密加工例

TDCで加工・製作が可能な、代表的な真鍮の施工事例をご紹介します。

その他材質についての加工実績は、下記ページよりご覧いただけます。

>>TDCの表面粗さ・面粗度実績

精密加工例:電鋳マスターや金型、各種試験片、長尺鏡面箔など製作いたします。

- 仕様:Ra1nm以下、平面度0.001mm以下、平行度0.001以下など

ご希望の仕様に応じて、面粗さや平面度・平行度・寸法公差などの要素を組合せ、高精度なモノづくりが可能です。真鍮は銅に比べ硬度もあるので加工性も良く精度も出しやすいです。

ご支給材はもちろん、弊社で材料から手配することも可能です。1個~量産まで承ります。

真鍮の精密加工はTDCにご相談ください

TDC(ティ・ディ・シー)では、これまでに培ってきたミクロン単位での研磨・精密加工技術にて、あらゆる精度・形状の真鍮加工の課題を解決いたします。

真鍮素材を用いた金属加工や部品加工、表面に鏡のような光沢を出す加工まで、幅広い金属素材の精密加工に対応しております。ぜひ一度TDCまでご相談ください。

Related page