Precision processing of crystal materials and glasses

This page introduces the precision processing of crystal materials and glass materials performed at TDC.

For more information on TDC’s precision polishing services, please also see the “Precision lapping service / ultra precision lapping service” page.

Contents

- Precision processing of crystal materials and glasses at TDC

- Crystal materials and glasses that can be processed with precision

- Examples of precision processing of TDC crystal materials and glass

- Precision processing example 1 : mirror surface processing of various glass substrates and test piece production

- Precision processing example 2 : Ceramics + glass coated substrate mirror surface processing 21x11xt5.55

- Precision processing example 3 : Quartz glass roll mold mirror surface processing

- Precision processing example 4 : Sapphire cylindrical roll inner and outer diameter mirror surface processing

- Precision processing example 5 : Mirror surface processing of SOI wafer

Precision processing of crystal materials and glasses at TDC

At TDC, we also accept precision processing of crystal materials such as silicon and SiC and glass materials.

Precise processing of crystal materials and glass requires accumulated know-how and technology because the conditions and processes are different from those of metal processing.

With the processing technology that TDC has cultivated so far, we will solve the problems of crystal materials and glass processing of all kinds of precision and shape.

Precision glass polishing method at TDC

Processing method: lapping polishing

We perform precision processing of glass by lapping and polishing.

- We can finish the desired surface condition such as frosted glass finish, transparent finish, etc.

- High-precision surface roughness and flatness can be achieved by ultra-precision lapping.

- It is possible to polish not only flat surfaces but also all shapes such as inner and outer diameters of rolls and shafts.

Processing equipment used in glass precision processing

- Single-sided mirror lapping machine

- CMP lapping machine

- Precise Mirror Polish Surface on Roll and Shaft

- Inner diameter specular machine

Features of TDC’s precision processing of crystal materials and glasses

TDC’s precision processing of crystal materials and glass has the following strengths and characteristics.

- High-precision polishing technology

By controlling the removal amount with TDC’s precision polishing technology, we have achieved ultra-precision precision processing at the micron level and nano level even in the processing of crystal materials and glass.Compared to processing methods such as cutting and grinding, it is possible to handle any shape without applying a load to the object. - Short delivery time and express service available

By owning more than 100 polishing machines, we can achieve short delivery times even for large lots and complex processing. If you are in a hurry, we will also respond to consultation with “express response”. - Small lot items

Please feel free to contact us for small lot orders starting from 1 unit and prototype production. - Owns over 100 abundant processing machines

TDC owns more than 100 polishing machines such as lapping machines and surface grinders. We also have various processing machines such as machining centers and milling machines, so we can handle all kinds of processing. - Half of the polishing equipment is manufactured in-house

About half of the more than 100 polishing machines are made in-house, realizing “low-cost” and “high-quality” manufacturing.

with nano-level precision polishing.

and production from single units to mass production.

Crystal materials and glasses that can be processed with precision

We perform precision processing of crystal materials and glass using all processing technologies such as polishing and grinding, which are our strengths.

The representative crystal materials that can be handled are as follows.

- glass in general

- silicon

- SiC(silicon carbide)

- sapphire

- GaN

and others

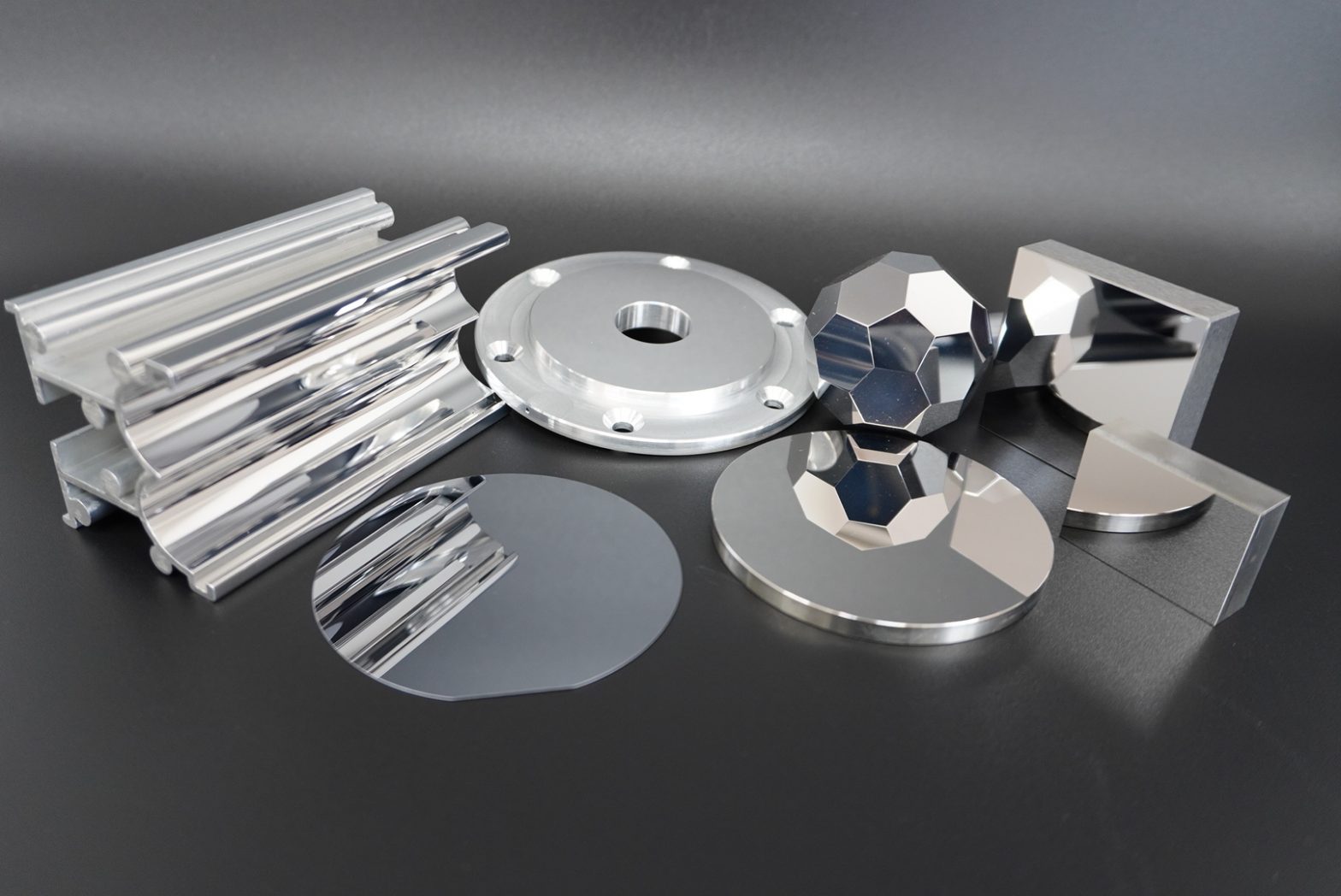

Examples of precision processing of TDC crystal materials and glass

We will introduce examples of typical crystal materials and glass that can be processed and manufactured at TDC.

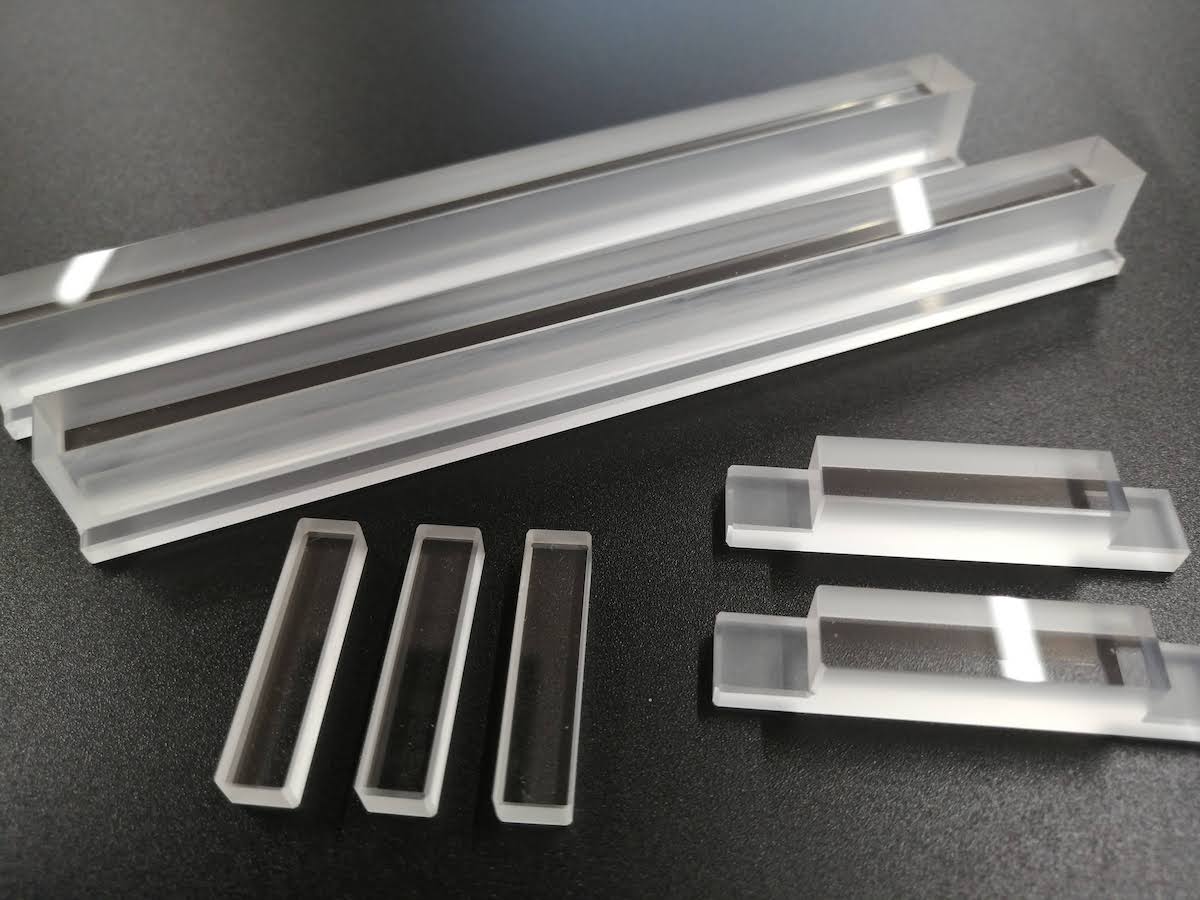

Precision processing example 1 : mirror surface processing of various glass substrates and test piece production

- Material: Various glass materials such as quartz glass, BK7, and borosilicate glass

- Processing details: Surface roughness of Ra5nm or less can be achieved with most glass materials

Mirror finishing of various glass materials such as quartz glass, BK7, and borosilicate glass is possible.

In general, the finished surface roughness of glass materials varies greatly depending on the material, but it is possible to achieve a surface roughness of Ra5nm or less with most materials.

For details, please refer to the “What is Surface Roughness” page.

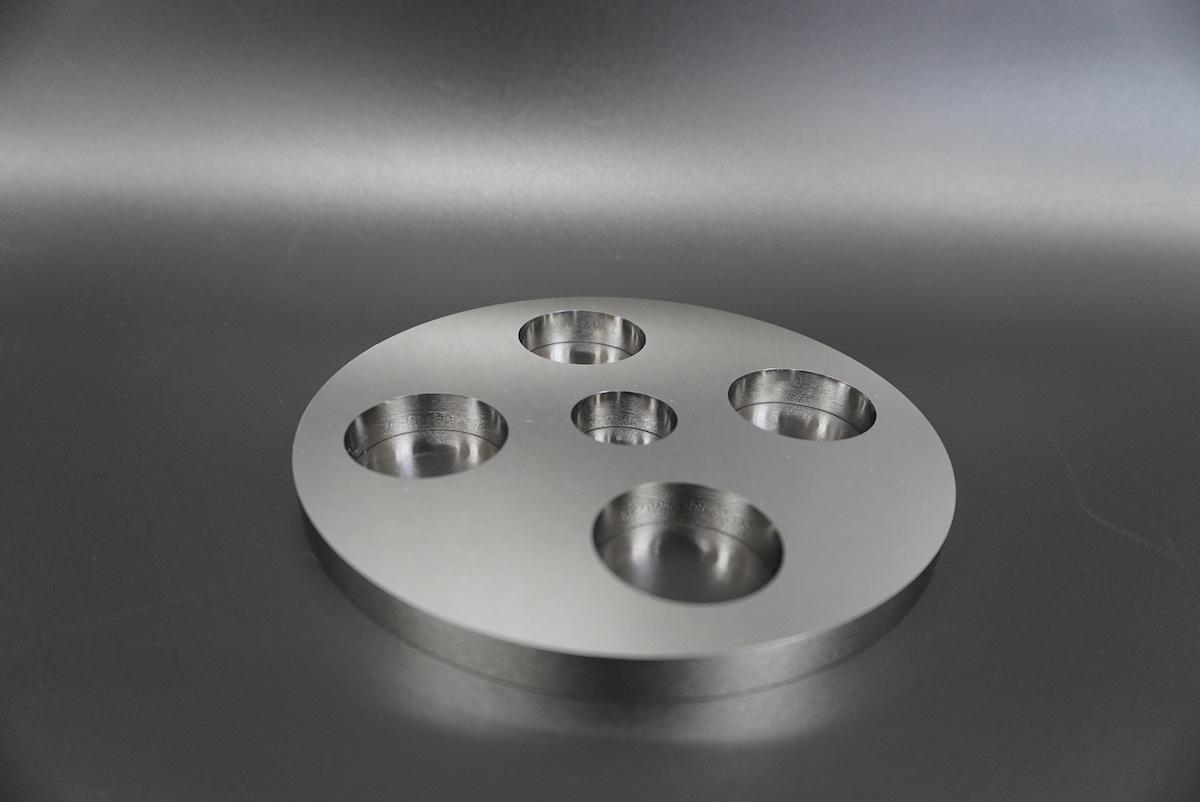

Precision processing example 2 : Ceramics + glass coated substrate mirror surface processing 21x11xt5.55

- Size: 21x11x5.55t

- Specifications: Glass-coated surface is mirror-finished to a surface roughness of Ra1nm or less

The ceramic surface can also be polished and finished with a parallelism of 1um or less.

In addition to mirror finishing, our lapping technology can also achieve strict tolerances such as parallelism and flatness.

Precision processing example 3 : Quartz glass roll mold mirror surface processing

- Size : dia. 100x150mm

- Specifications: Surface roughness Ra1nm or less, roundness 0.003, straightness 0.003

In this processing example, the surface roughness was finished to Ra1nm or less while maintaining the geometrical tolerances such as roundness and straightness.

At T.D.C., we are good at not only polishing, but also polishing more precisely without sagging.

Please use TDC’s finishing technology for mold processing where scratches and cloudiness are absolutely NG.

Precision processing example 4 : Sapphire cylindrical roll inner and outer diameter mirror surface processing

- size : outer dia. 100, innner dia 50, length 70mm

- Specifications: Outer diameter tolerance (+0/-0.05), inner diameter tolerance (+0.05/-0), surface roughness Ra1nm or less, fog free

The inner and outer diameters have been polished to a surface roughness of Ra1nm or less while managing strict dimensional tolerances of the inner and outer diameters.

Precision processing example 5 : Mirror surface processing of SOI wafer

- Size: 20 x 20 to φ6 inch board (Other sizes are also available)

- Specifications: Surface roughness Ra1nm or less, polishing amount is adjusted according to the desired thickness

Thinning and mirror finishing of various wafers and bonded substrates are TDC’s areas of expertise, so please feel free to contact us.

Related page