Friction Test results

Hi this is Alisa from Tokyo sales office writing this article.

TDC has a lot of orders of Test Pieces and Friction Piece.

However we didn’t clearly understand what the benefits were for polishing the test pieces.

Therefore we conducted a friction test on the mirror polished test piece to see if the friction force and coefficient of friction changes!

●Test Conditions

We prepared 3 different surface items, “Grinded”, “Roughly Lapped”, and “Mirror Polished”.

Condition:2 newton ×45 minutes

●Material and Roughness

| Grinded | Roughly Lapped | Mirror Polished | |

| SCM420(carbonized) | Ra 221 nm | Ra 6.83 nm | Ra 0.55 nm |

| Stainless 440C(quenched) | Ra 323 nm | Ra 4.98 nm | Ra 0.62 nm |

| Aluminum 5052 | Ra 135 nm | Ra 20.0 nm | Ra 0.71 nm |

…Unfortunately we had to stop the test for the material Aluminum 5052.

It seems like the scraped powder sticks to the rotating surface, causing problems such as an abnormal increase in frictional force when the base piece material is too soft.

Usually we get hard material orders for the use of test pieces, and I guess this is one of the reasons! This kind of failure experience is also a good lesson for us.

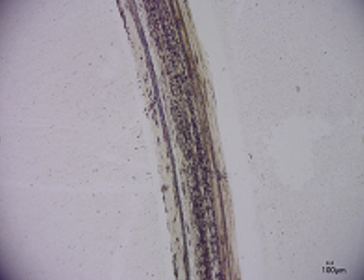

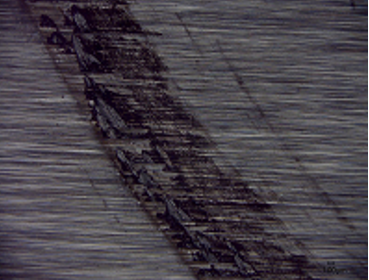

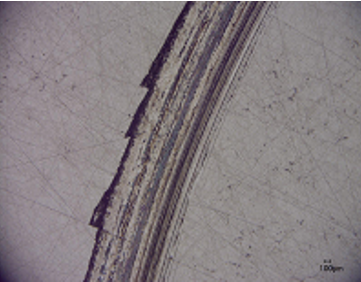

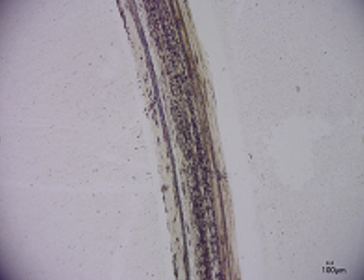

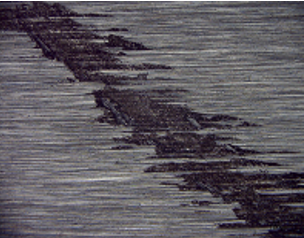

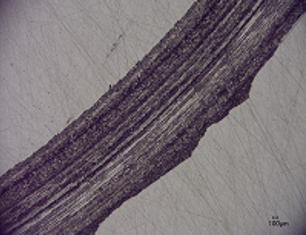

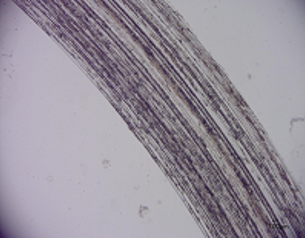

●Picture of the plate

These are some pictures of the plate surface after the friction test.

The Grinded surface of both SCM420 and SUS440C is rough, so it can be seen that the ball hits locally = the contact area is small.

The Roughly Lapped product has a better contact surface, but the contact area is still smaller than that of the Mirror Polished product.

The Mirror Polished product has the most clean scraped mark.

About the Aluminum item, it was observed that the scraped powder adhered to another place such as the ball and friction plate.

●Result

By the maximum coefficient of friction, it was a slight difference but Grinded < Roughly Lapped < Mirror Polished was seen.

In other words, we can infer that “the larger area the ball hits, the greater the frictional force is.”

It was my very first time to have an experiment like this, and the result was not as I expected. (I wanted a date with Mirror Polished item having a enormously better result).

But I think this is also a meaning full experiment.

We will continue having tests like this, so don’t forget to bookmark and check this blog frequently!

- Announcement of Summer Holiday 2024

- New release: TDC’s corporate movie

- Notice of Office Closure

- Happy Holidays from TDC

- Yuko Akabane started a series of articles on Forbes!!

- Notice of Office Closure

- Winter Holidays 2022-2023

- What is the market price for precision machining costs? How to think about processing costs and how to reduce costs

- TDC will be attending at MicroFab Summit 2022

- Yuko Akabane, our president and CEO, was commissioned as a “Reiwa 3rd Year Small and Medium Enterprise Supporter”

- Yuko Akabane, President and CEO of our company, received the 2021 “Certificate of Appreciation for Persons of Merit” from the Small and Medium Enterprise Organization

- Announcement of Summer Holidays 2022

- Thank you for stopping by TDC Booth at MEF2022

- Spring Holiday 2022

- Friction Test results

- MEMS Manufacturing 2022

- Latest info about the earthquake happened March 16th midnight

- Announcement of processing equipment expansion

- Announcement of winter holiday

- Announcement of summer holidays

- ZYGO Laser Interferometers Large Aperture Systems

- annoucement of moving and temporarily close of TDC’s Tokyo branch sales office.