Polishing of plastic/acrylic resin

This page introduces the plastic/acrylic resin polishing process performed at TDC.

For mirror finishing of plastic/acrylic resin and polishing of TDC, please refer to the following pages.

Contents

What is plastic/acrylic resin?

Plastic/acrylic resin is a material with excellent transparency and light transmission that surpasses glass and sapphire.

Although its hardness is inferior to that of other materials such as metal, one of its major characteristics is that it is durable, flexible, hard to crack, and easy to process.

Taking advantage of these properties, plastics/acrylic resins are used in large aquarium tanks, building materials such as window materials and lighting fixtures, windshields for clocks, etc., and have become one of the most familiar materials in our daily lives.

Plastics with enhanced heat resistance and strength that can be used under harsh industrial conditions are called “engineering plastics”.

Please refer to the following pages for detailed explanations of engineering plastics.

Polishing of plastic/acrylic resin

As mentioned above, plastic/acrylic resin has the disadvantage of being easily scratched due to its low hardness.

Since even the slightest scratches are noticeable, it is common to apply a polishing process to smooth the surface when scratches occur.

Polishing method for plastic/acrylic resin

In general, plastics and acrylic resins are materials that are easy to process, so there are various methods for polishing, as shown below.

- Buffing using power tools that rotate at high speed such as grinders

- Polishing using abrasives containing fine abrasive grains such as compounds

- Polishing that dissolves the surface of the acrylic material using an organic solvent

- Grinding the surface with a gas burner to give it a glossy finish

- Polishing with fine adjustment using polishing film

These are only examples, and appropriate polishing methods are used depending on the type of polishing application and material.

Polishing of TDC’s plastic/acrylic resin

While plastic/acrylic resin is easy to process, it is a material that is difficult to achieve precision because it is soft and prone to sagging.

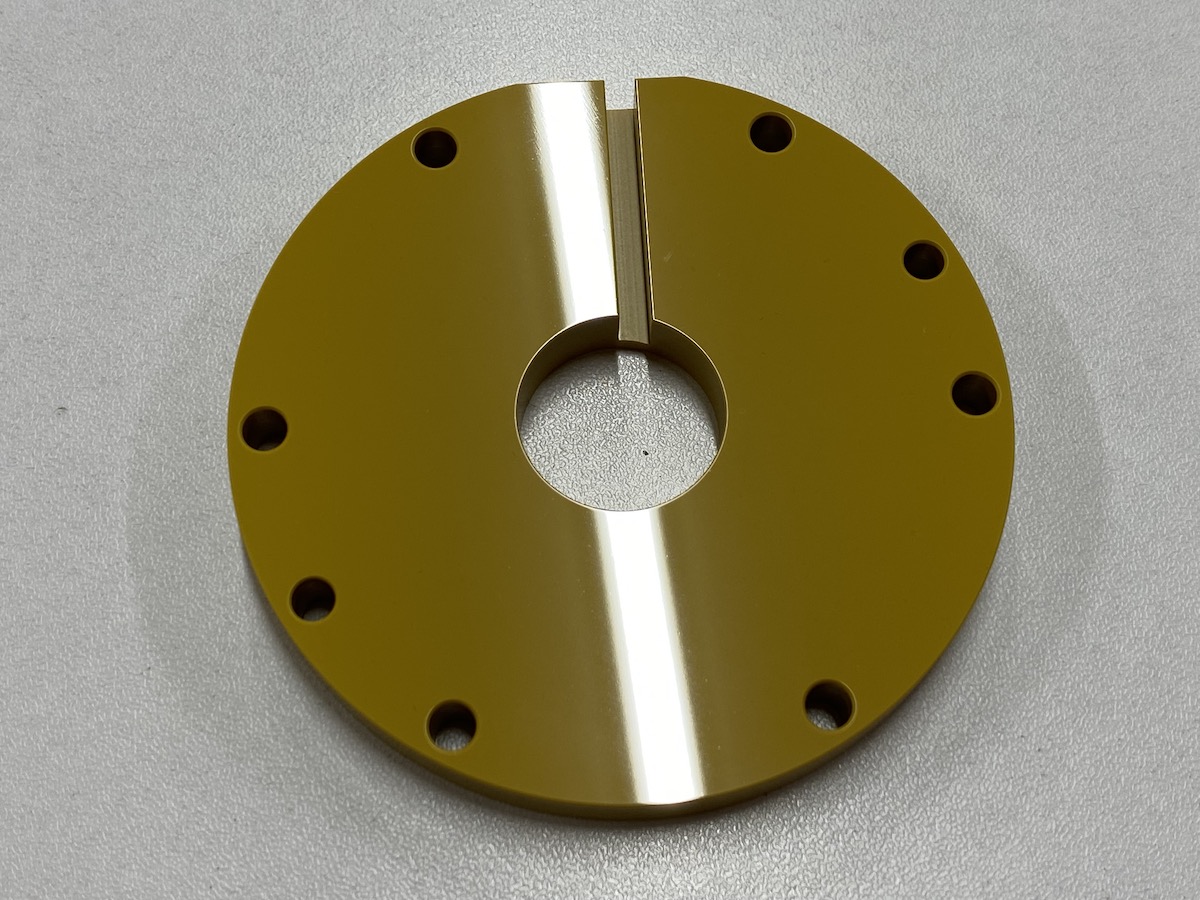

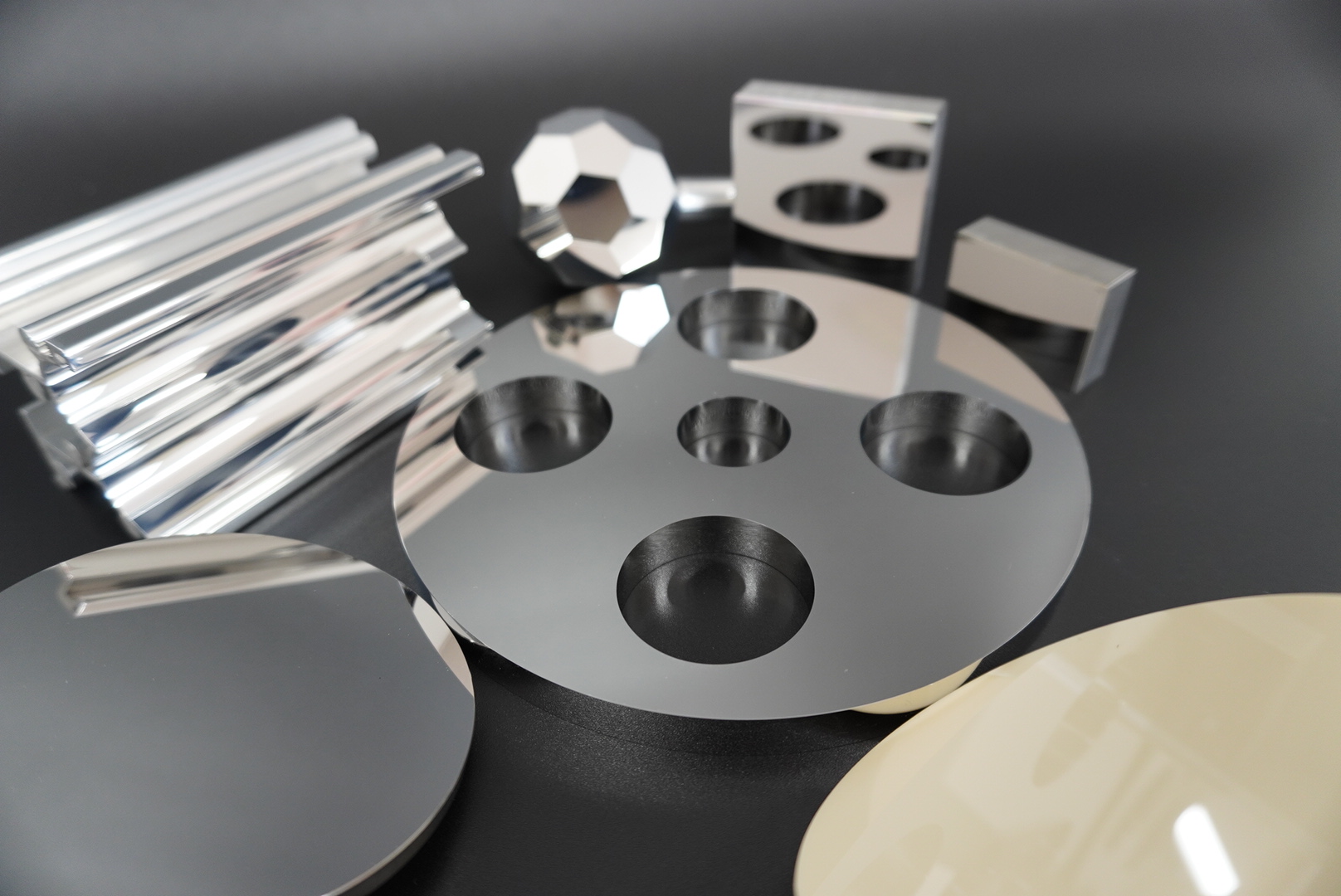

At TDC, we are able to perform high-precision polishing on acrylic resin and various plastics with our unique processing methods and know-how.

In addition to sheet material, we can handle various shapes such as inner and outer diameters of rolls and shafts, unevenness, etc. We also accept orders for thickness control and thinning processing in microns.

Examples of TDC’s plastic/acrylic resin polishing processing

Introduce examples of polishing processing of plastic/acrylic resin at TDC.

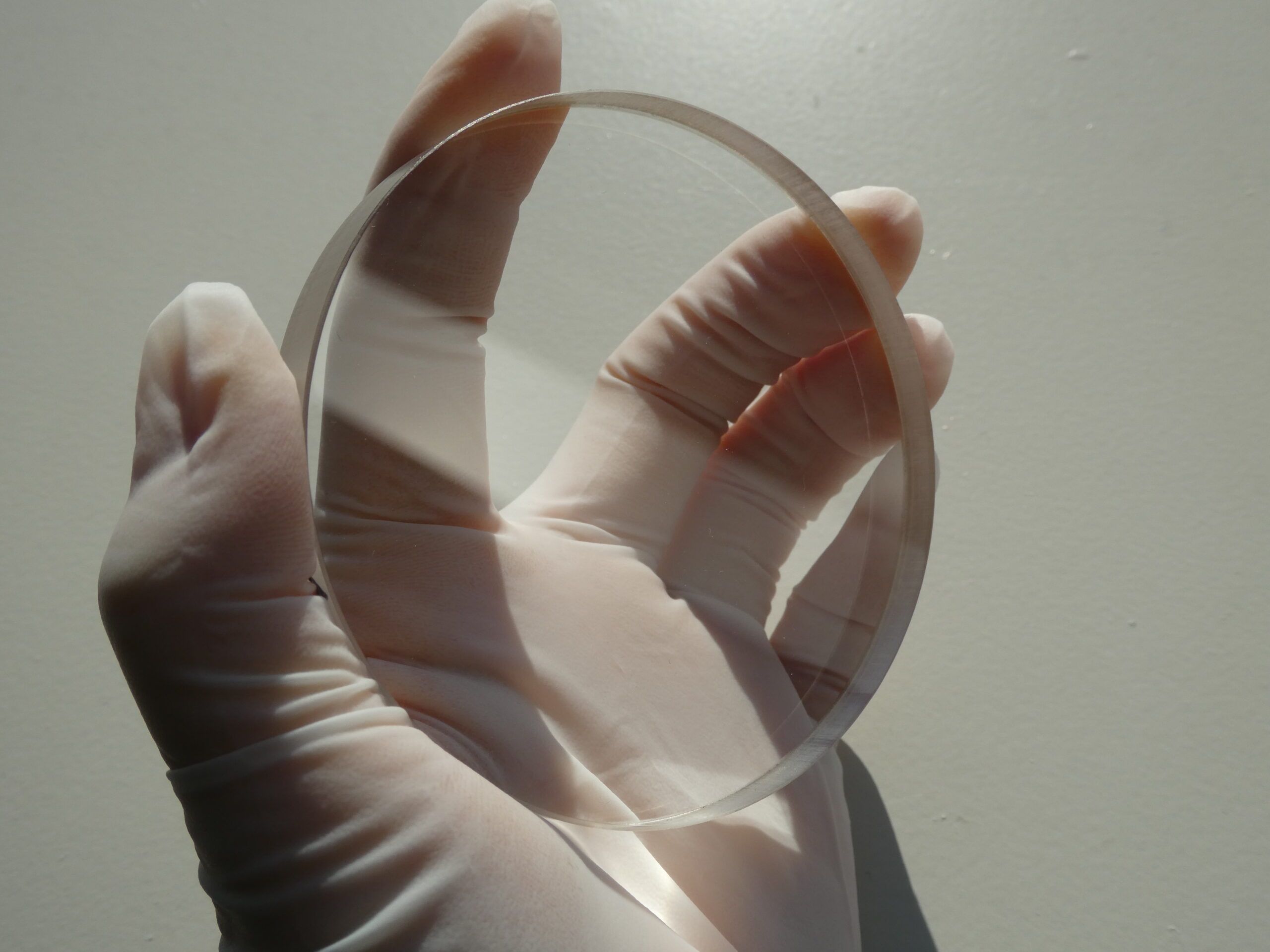

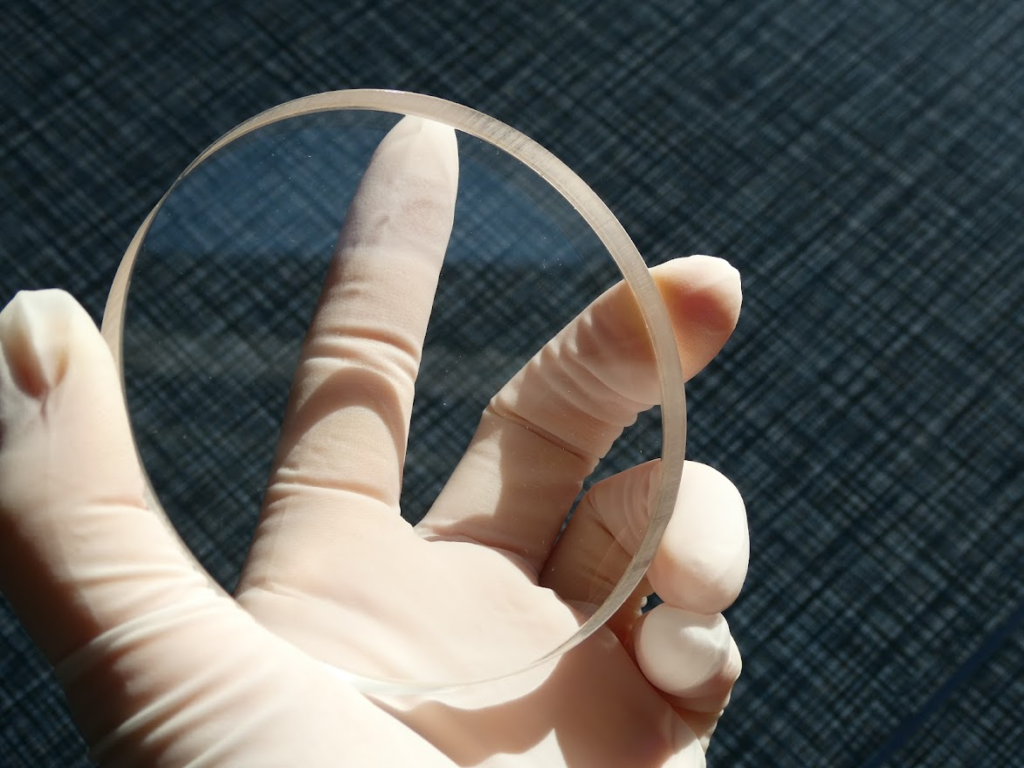

Case name/processing name ① Acrylic substrate mirror surface processing

Acrylic is a strong material that can withstand impact and water pressure, and is highly transparent, so it is often used as a substitute for glass.

At TDC, we can mirror-finish (transparent finish) various types of acrylic.

In addition, acrylic is said to be difficult to control accuracy because it is softer than metals and ceramics, but TDC is good at managing flatness, parallelism, and board thickness with its own know-how.

We can handle everything from material arrangements to shape processing.

| Material | acrylic resin |

| Accuracy | Ra<5nm(cleare surface), Flatness/parallelism/plate thickness management (guaranteed values depend on specifications) |

| Size | Available in various sizes |

Please contact TDC for polishing of plastic/acrylic resin.

At TDC, we are able to handle the polishing of all kinds of plastics and acrylic resins, based on our processing know-how for each material and our accumulated polishing technology.

- I want an acrylic material with higher transparency

- I am looking for an acrylic polisher who can process with higher precision.

- I want to reduce the number of days and man-hours until delivery

- Rejected by another company

If you have any of the above problems in polishing plastic/acrylic resin, please feel free to contact TDC.

We will listen to your problems and propose the best solutions.

Related page