Engineering Plastic

On this page, we will explain the characteristics and properties of Engineering Plastic, which is one of the processing materials, its applications, and the processing of Engineering Plasctic in TDC.

Contents

What is Engineering Plastic?

Engineering plastics are a taxonomic name that refers to a group of plastics that have particularly excellent strength and have enhanced specific functions such as “heat resistance” among synthetic resin materials (plastics).

Generally, even in an environment of 100 ° C or higher, those with a tensile strength of 49 MPa or higher and a flexural modulus of 2.5 GPa or higher are applicable.

Difference from general plastic

Engineering Plastic is positioned between metal parts and general-purpose plastic parts.

Generally, it is a general-purpose plastic that has the image of being “fragile and fragile”, but various research and development have dramatically improved its performance, and it has also realized weight reduction and cost reduction.

Nowadays, not only is this engineering plastic widely used under the harsh conditions of industrial use, but also many types have been developed and used properly according to the application.

Types of Engineering Plastics

Engineering plastics are classified into “general-purpose engineering plastics” and “special engineering plastics (super engineering plastics)”.

General Engineering Plastic

Among engineering plastics, it refers to engineering plastics (engineering plastics) used in automobiles, electric appliances, and electronic devices.

Among general-purpose engineering plastics, the general engineering plastics are as follows.

| Name | Element symbol | Feature | Main Application |

| Polymide | PA | It has excellent impact resistance, chemical resistance, abrasion resistance, wear resistance, and gas barrier resistance. | exteriors, chassis, mechanical parts, drive parts, automobile parts (gear) of various electric products such as synthetic fibers (nylon), |

| Polycarbonate | PC | It has a wide usable temperature range of -40 to + 120 ° C, and has excellent transparency, dimensional stability, and impact resistance. | headlamps, CD / DVD / BL, carports, dialyzer, etc. |

| Polyacetal | POM | It has excellent mechanical properties, especially excellent fatigue resistance. | automobiles (engine parts, ducts), electric tool Seat belts, etc.) |

| Modified polyphenylene ether | m-PPE | It has excellent hydrolysis resistance and electrical characteristics, and has the lowest specific gravity and water absorption rate among general-purpose engineering plastics. | copies chassis, power adapters, automobiles (exterior parts, electrical parts), pump parts |

| Polybutylene terephthalate | PBT | Sliding characteristics (friction, wear), impact resistance. Has excellent properties and electrical insulation | electronic parts (connectors, switches, etc.), automobiles (electrical parts, etc.), synthetic fibers (polyester) |

Special engineering plastic

Special engineering plastics (super engineering plastics) refer to those with particularly high performance among engineering plastics, and have excellent heat resistance and solvent resistance.

The main super engineering plastics are as follows.

| Name | Element symbol | Feature | Main Application |

| Polyphenylene sulfide | PPS | It has excellent mechanical strength, rigidity, flame retardancy, chemical resistance, electrical characteristics, and dimensional stability. | Mechanical parts such as automobiles, medical hollow fiber membranes such as valves and pump parts, etc. |

| Polysulfone | PSU | It has oxidation resistance and thermal stability, and can withstand use in a high temperature range for a long period of time. | medical equipment parts (endoscopes, dialysers), food machinery parts, etc. |

| Polysulfone | PES | It has amber transparency and has excellent steam resistance and hydrolysis resistance. Since it does not have a hydrolyzable bond, it has excellent heat resistance and steam resistance. | medical hollow fiber membranes such as food machinery parts, medical equipment parts (endoscopes, dialysers, etc.) |

| Polyamide-imide | PAI | It is tan transparent and has better heat resistance than PSU. It has a wide usable temperature range of -200 to + 260 ° C and is resistant to high-pressure steam and gamma rays. | Industrial equipment mechanical parts (bearings / gears), automobiles (reflectors, fog lamps, etc.) |

| Polyetherimide | PEI | It has dimensional stability, self-lubricating property at high temperature, and chemical resistance.It is a super engineering plastic that can perform various melt molding processes. It is transparent and has excellent resistance to high-pressure steam and gamma rays, steam resistance, and solvent resistance. | Automobiles (reflectors, fog lamps, etc.), aircraft parts, eyeglass frames, food heat-resistant containers, etc. |

| Polyetheretherketone | PEEK | It has excellent heat deterioration resistance, mechanical properties, heat resistance, water resistance, radiation resistance, chemical resistance, and flame retardancy.Processing methods such as injection and extrusion molding are possible. | Implants, mechanical parts (bearings / gears), aluminum substitute parts, etc. |

| Liquid crystal polymer | LCP | A general term for thermoplastic resins that exhibit liquid crystallinity when melted. It has excellent heat resistance, fluidity, dimensional stability, damping characteristics, and chemical resistance. | Electrical and electronic parts (SMT connectors, bobbins, relays), motor parts, etc. |

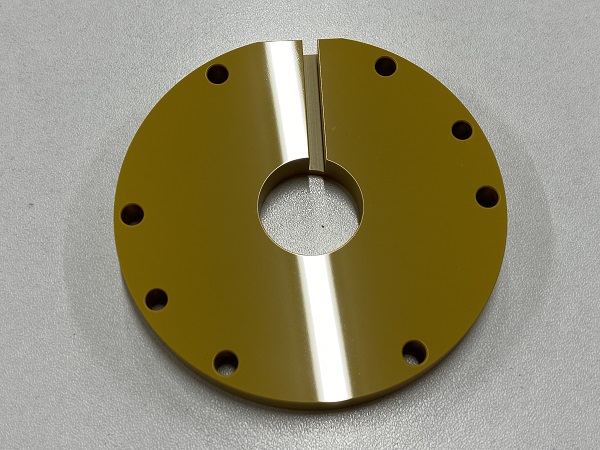

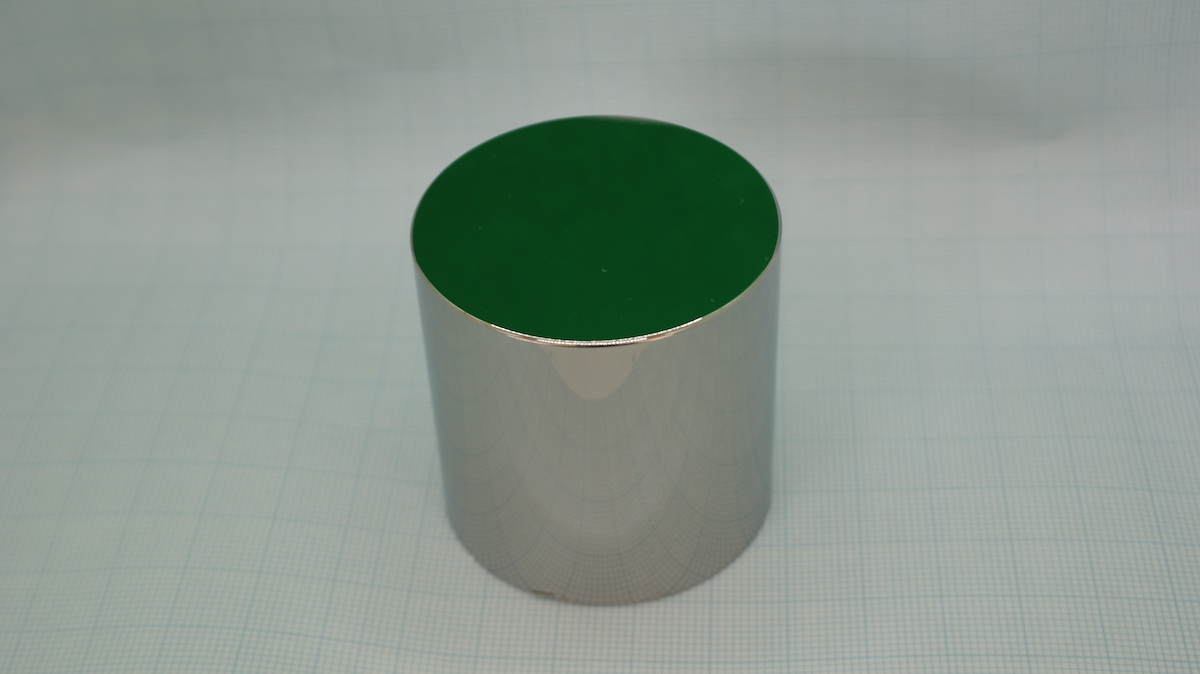

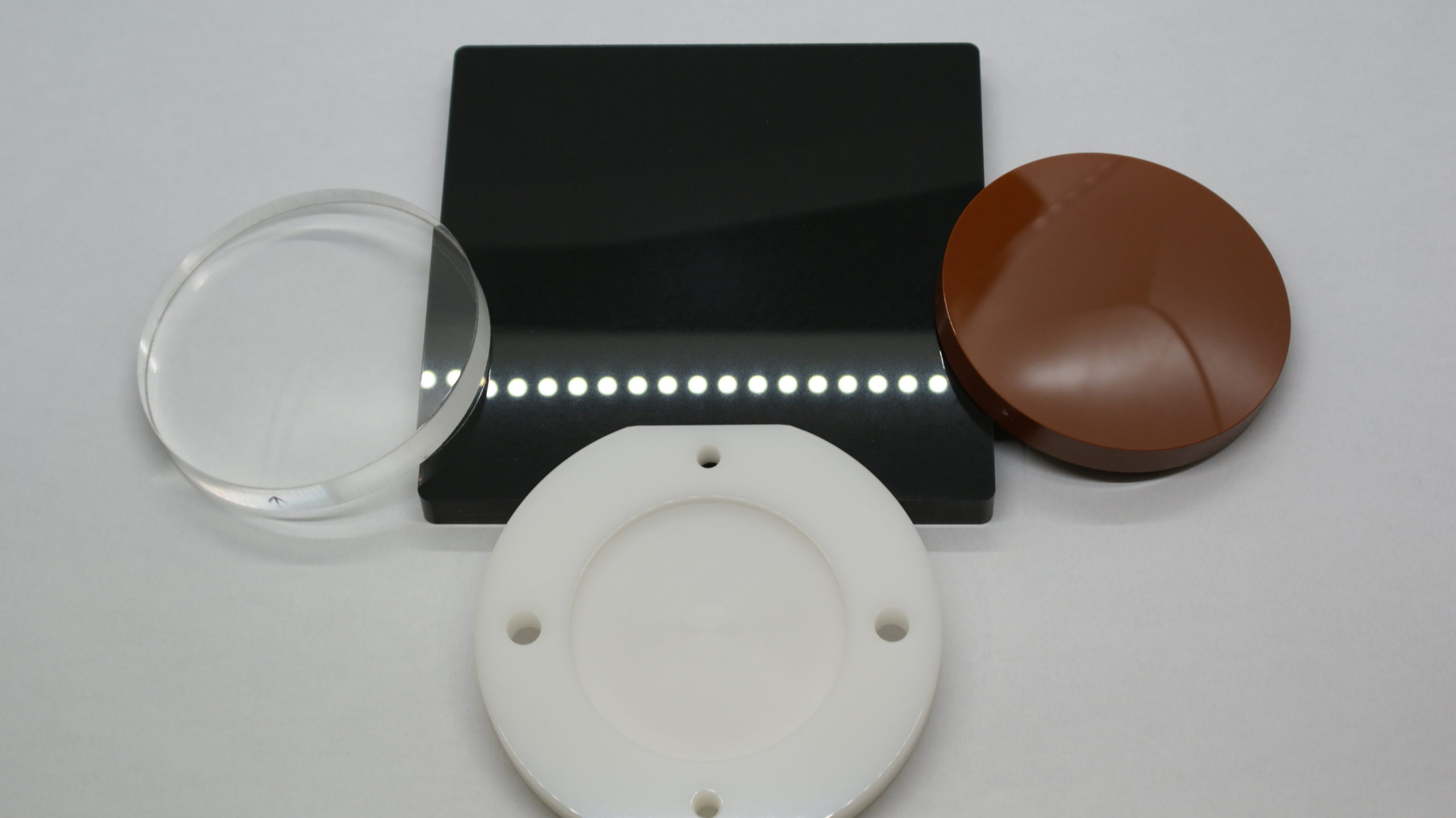

Engineering Plastic processing examples

As mentioned above, engineering plastics are used in various applications due to their excellent characteristics, but their hardness is lower than that of metals, making high-precision processing difficult.

However, TDC is good at achieving metal-equivalent accuracy for all engineering plastic materials, and not only mirror surfaces, but also geometric tolerances such as flatness, parallelism, and thickness dimensions can be achieved with the desired accuracy. It is possible to finish it.

We have many achievements such as test pieces and high-precision parts.

Please contact TDC for Engineering Plastics

At TDC, we are able to handle mirror polishing of all materials and accuracy by using the processing know-how according to the material and the polishing processing technology accumulated so far.

If you have a Engineering Plastic processing project that was rejected by another company, please feel free to contact TDC.

with nano-level precision polishing.

and production from single units to mass production.

Related page

- What is gallium nitride (GaN)? | Basic information/explanation of features and processing examples

- What is Vespel? | Vespel features and processing examples

- What is Tungsten? | Tungsten characteristics and processing examples

- Nickel

- Tantalum

- Glassy carbon (glassy carbon)

- Plate thickness and material of stainless steel plate (SUS)

- Coefficient of linear expansion

- Invar/Super Invar

- Niobium

- Hastelloy

- Engineering Plastic