Polishing of SiC

This page introduces the SiC polishing process performed at TDC.

Please also refer to the “Polishing service” page for the polishing process performed at TDC.

Contents

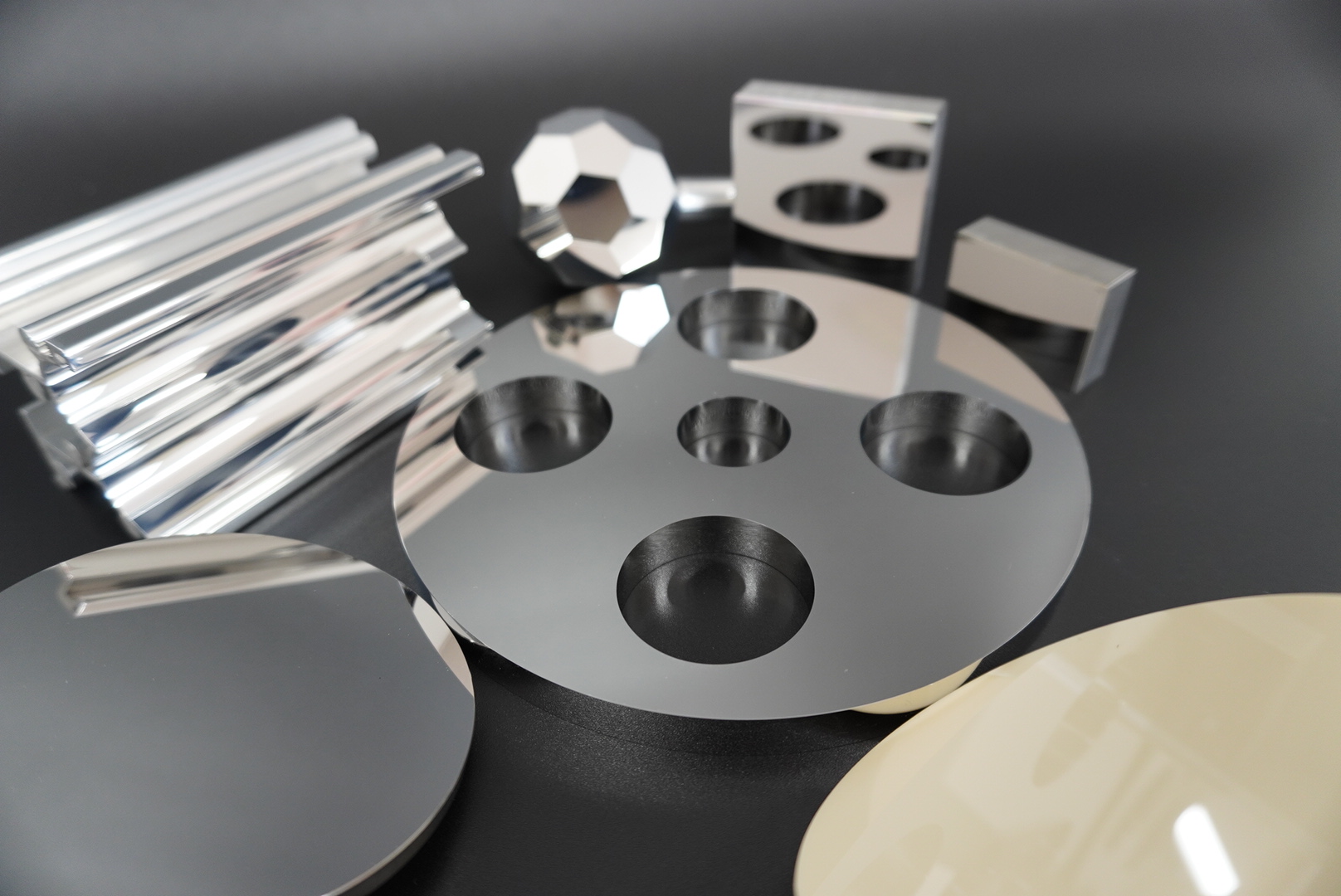

TDC’s SiC polishing process

TDC excels at polishing all kinds of metals, including SiC, through our unique technology development and the polishing technology we have cultivated over the years.

We can handle a wide range of titanium polishing processes, from precision parts that require high precision to mirror polishing of SiC surfaces.

For a detailed explanation of TDC’s polishing process, please check the “Polishing service” page.

Features of TDC’s SiC steel polishing

TDC’s stainless steel polishing has the following strengths and characteristics.

- High-precision polishing technology

TDC’s precision polishing technology enables ultra-high-precision metal precision processing at the micron and nano level by controlling the removal amount. Compared to processing methods such as cutting and grinding, it is possible to handle any shape without applying a load to the object. - Short delivery time and express service available

By owning more than 100 polishing machines, we can achieve short delivery times even for large lots and complex processing. If you are in a hurry, we will also respond to consultation with “express response”. - Small Lot

Please feel free to contact us for small lot orders starting from 1 unit and prototype production. - Owns over 100 abundant processing machines

TDC owns more than 100 polishing machines such as lapping machines and surface grinders. We also have various processing machines such as machining centers and milling machines, so we can handle all kinds of processing. - About half of the polishing equipment is manufactured in-house

About half of the more than 100 polishing machines are made in-house, realizing “low-cost” and “high-quality” manufacturing.

with nano-level precision polishing.

and production from single units to mass production.

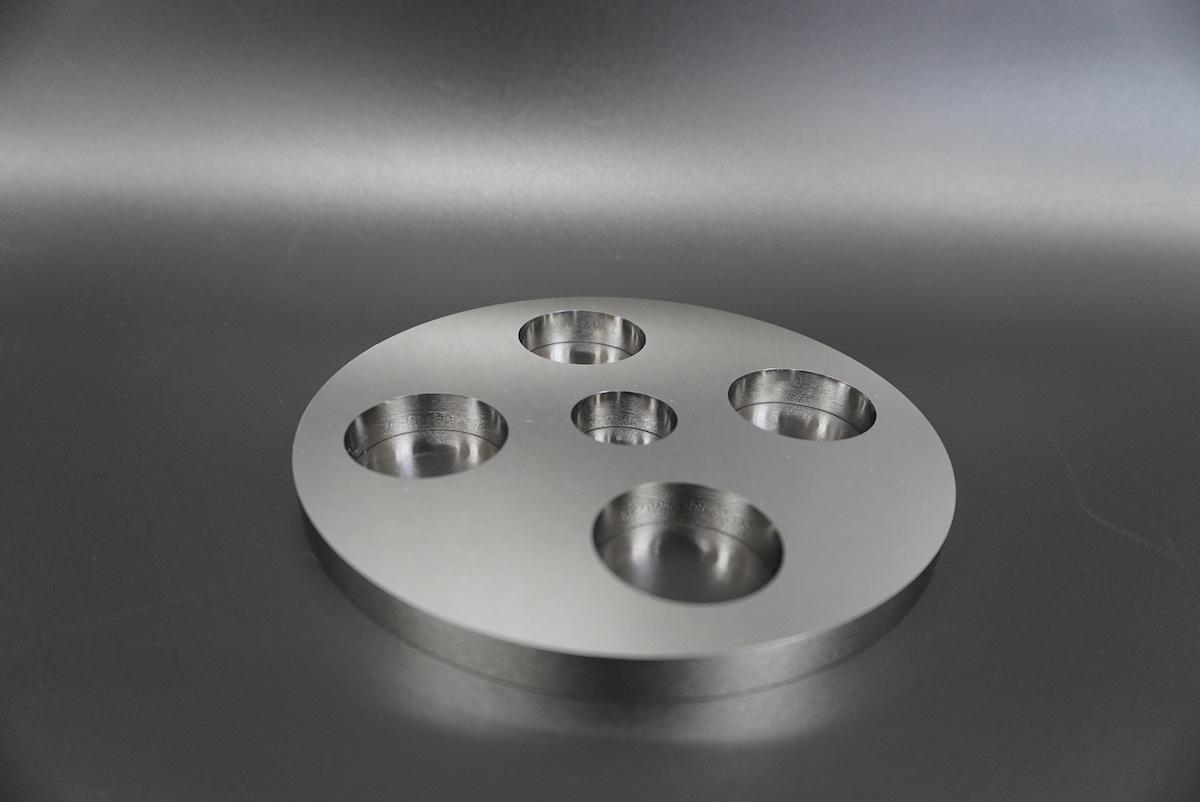

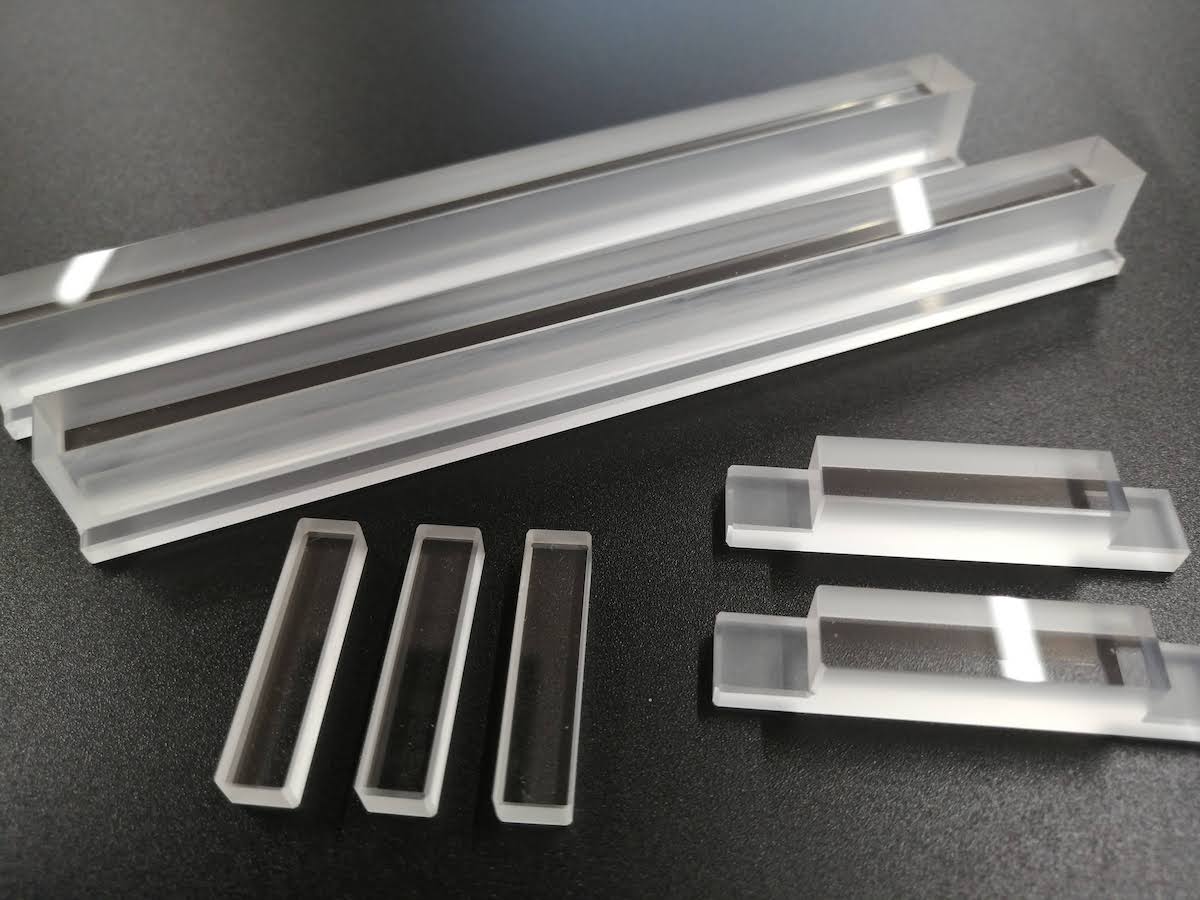

Example of TDC SiC polishing

Here are two typical SiC polishing examples in TDC.

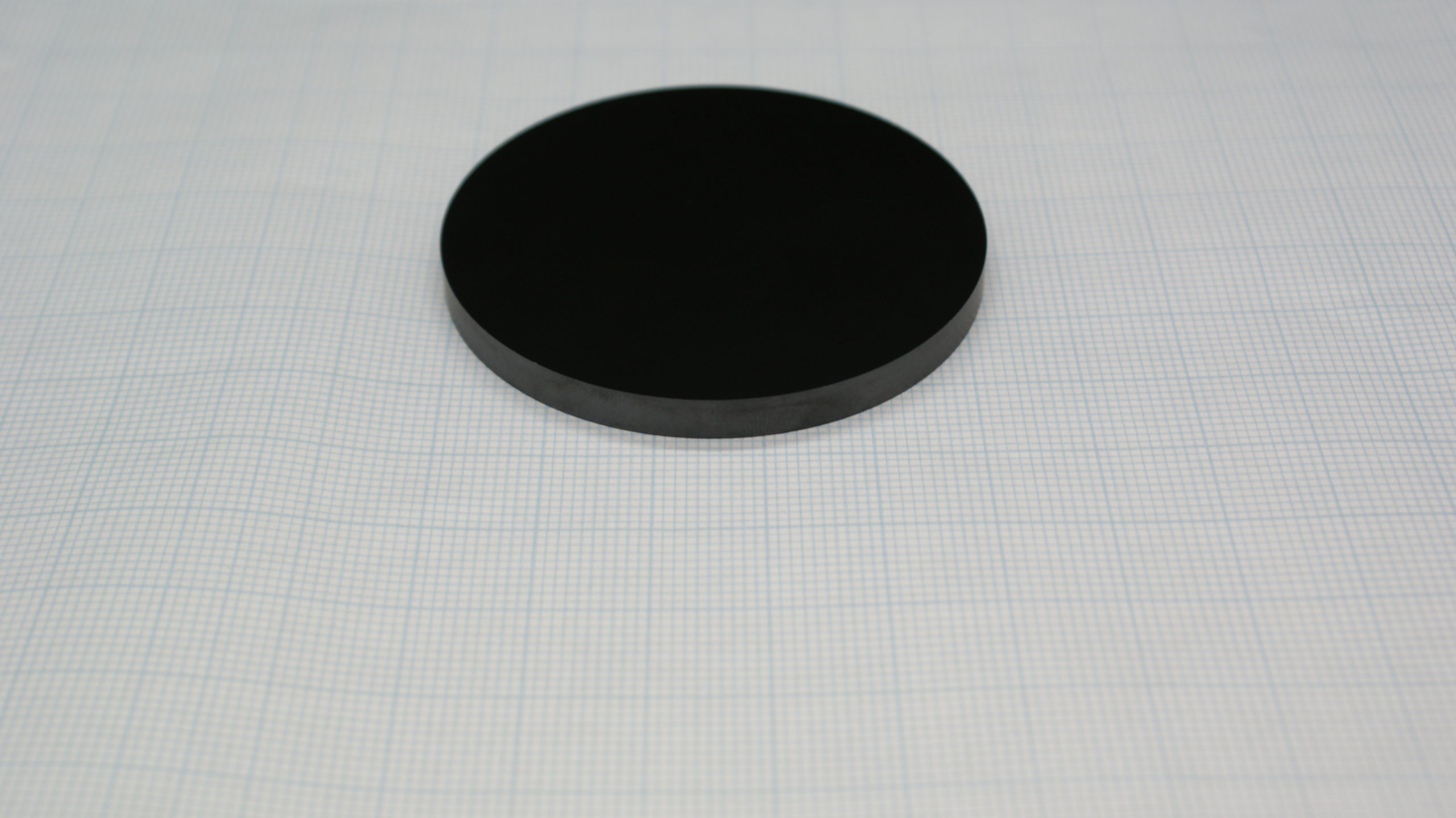

SiC polishing processing example 1: 4 inch single crystal SiC substrate mirror surface processing

- Material: Single crystal SiC

- Size: 4 inch

- Processing details: A combination of lapping and CMP polishing to achieve a mirror finish.

- Accuracy: surface roughness Ra0.07nm

SiC polishing processing example 2: 3 inch single crystal SiC thinning processing

- Material: Single crystal SiC

- Size: 3 inch

- Processing details: A wafer with a thickness of 0.35mm was reduced to a size of 0.18mm, and the surface roughness was finished to Ra1nm or less.

- Accuracy: surface roughness Ra1nm

What is SiC?

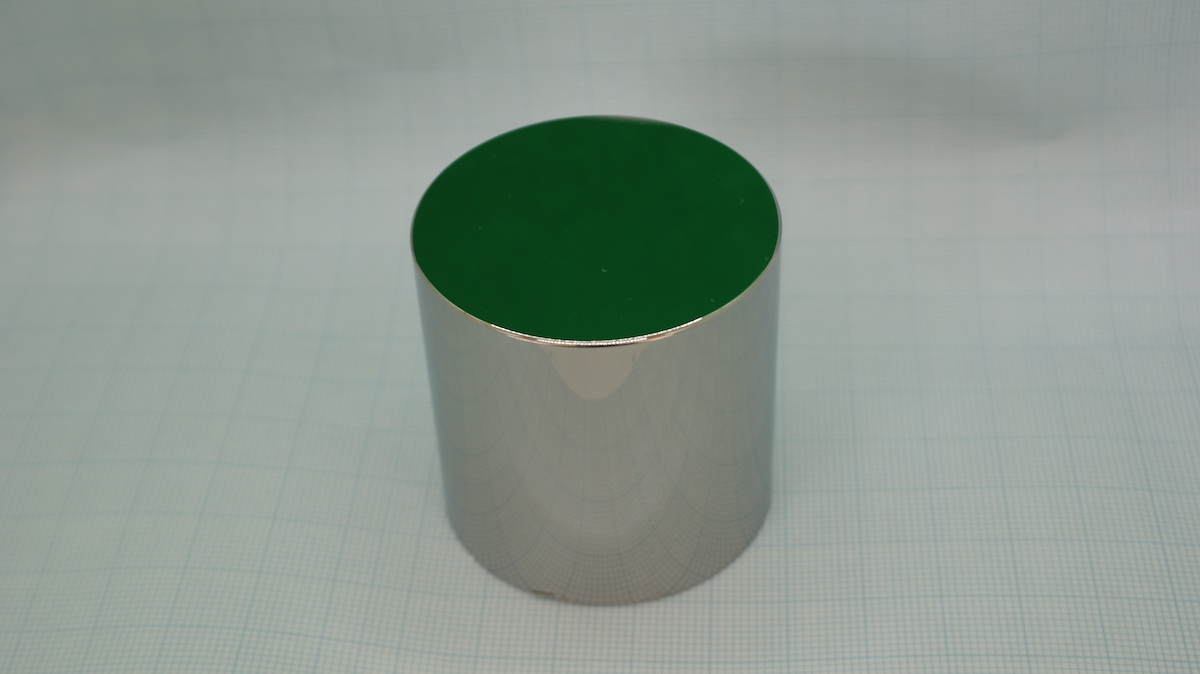

SiC is an abbreviation for a compound semiconductor consisting of carbon (C) and silicon (Si).

When applied as a power semiconductor element (semiconductor element/power device for power control), compared to a device made of silicon (Si) with the same device structure, it has a withstand voltage one order of magnitude higher and can operate at high temperatures. , are expected to be the next-generation power semiconductors.

SiC power semiconductor device

SiC power semiconductor devices are power semiconductor devices that use SiC as a material, which can greatly reduce power loss.

Implementation has begun in industries and companies that handle large amounts of power, such as railways, electric vehicles, photovoltaic power conditioners and power transmission systems, information communication such as data centers, and industrial robots.

SiC has many characteristics suitable for power semiconductors, but compared to Si, the difficulty, high cost, and reliability in manufacturing wafers that serve as substrates for power devices pose major challenges. For full-scale popularization, it is necessary to solve these problems and realize mass production.

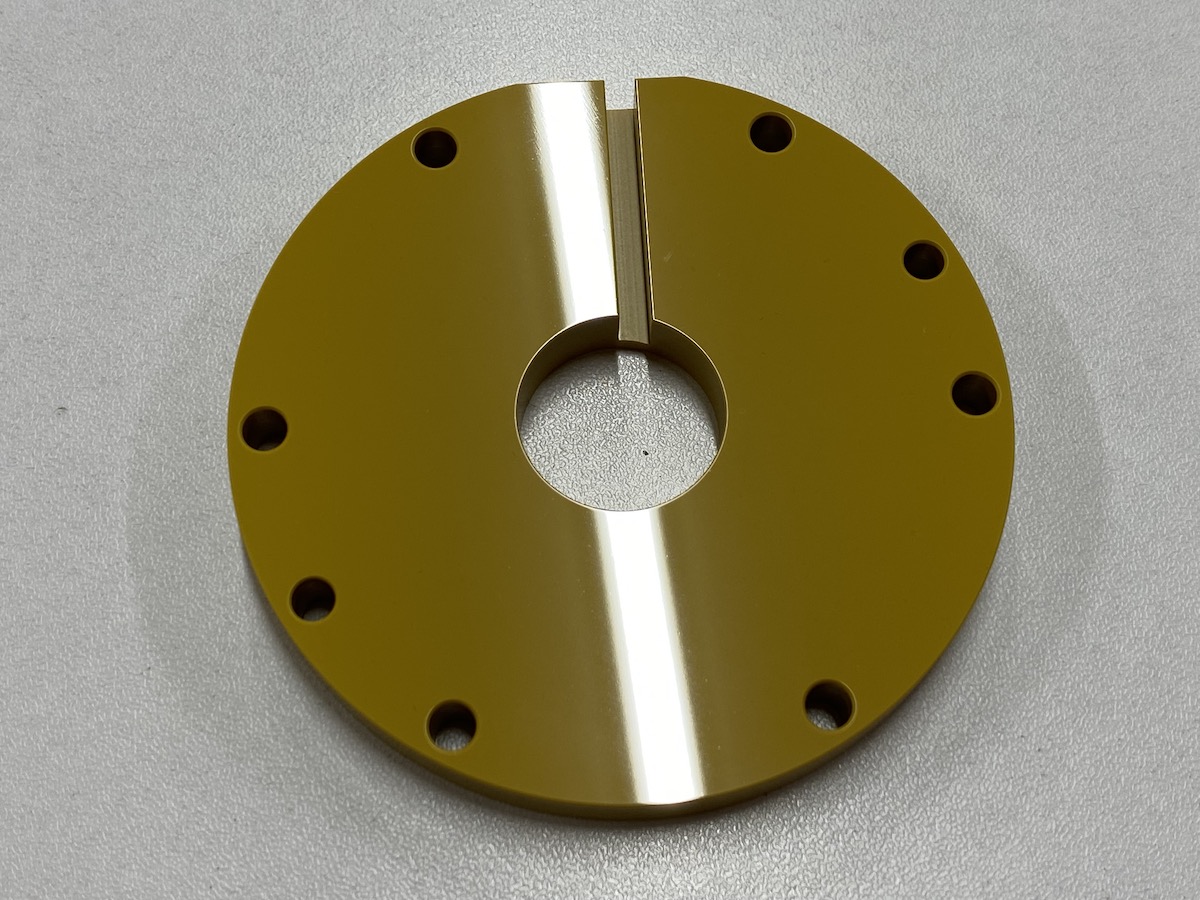

SiC wafer

SiC wafers with high hardness and high brittleness are extremely difficult materials to process.

SiC wafers are increasing in diameter from 6 inches to 8 inches each year, and processing technology for grinding and polishing is required for thinning and flattening.

Importance of Polishing Process for SiC Wafers

Polishing techniques such as lapping and polishing are commonly used as “batch-type processing techniques” suitable for flattening and mass-producing wafers.

In polishing, increasing the number of rotations of the polishing surface plate and processing pressure leads to an increase in the polishing speed, so the empirical rules and technical skills that determine the polishing conditions are extremely important.

Feel free to contact TDC for SiC polishing

At TDC, we are able to handle SiC polishing, which is difficult to process, and precision CMP and thinning polishing of SiC wafers, based on the polishing processing technology we have accumulated so far.

We can handle everything from one piece to small lots for experimental research to mass production, so please feel free to contact TDC if you have any concerns about SiC polishing.

with nano-level precision polishing.

and production from single units to mass production.

Related page