Polishing of Aluminum

This page introduces the aluminum polishing process performed at TDC.

Please also refer to the “Polishing service” page for the polishing process performed at TDC.

Contents

TDC’s Aluminum polishing process

TDC excels at polishing all kinds of metals, including aluminum, through our unique technology development and the polishing technology we have cultivated over the years.

We can handle a wide range of titanium polishing processes, from precision parts that require high precision to mirror polishing of SiC surfaces.

For a detailed explanation of TDC’s polishing process, please check the “Polishing service” page.

Features of TDC’s Aluminum steel polishing

TDC’s stainless steel polishing has the following strengths and characteristics.

- High-precision polishing technology

TDC’s precision polishing technology enables ultra-high-precision metal precision processing at the micron and nano level by controlling the removal amount. Compared to processing methods such as cutting and grinding, it is possible to handle any shape without applying a load to the object. - Short delivery time and express service available

By owning more than 100 polishing machines, we can achieve short delivery times even for large lots and complex processing. If you are in a hurry, we will also respond to consultation with “express response”. - Small Lot

Please feel free to contact us for small lot orders starting from 1 unit and prototype production. - Owns over 100 abundant processing machines

TDC owns more than 100 polishing machines such as lapping machines and surface grinders. We also have various processing machines such as machining centers and milling machines, so we can handle all kinds of processing. - About half of the polishing equipment is manufactured in-house

About half of the more than 100 polishing machines are made in-house, realizing “low-cost” and “high-quality” manufacturing.

Main aluminum materials that can be processed with TDC

A5052 (AlMg2.5)

A5052 has excellent corrosion resistance, moldability, and workability, and is the most popular material for cutting aluminum.

A5056

Aluminum material with added strength and ductility by adding magnesium to A5052.

The surface finish by cutting is also excellent, and the anodized film (alumite treatment) is also excellent.

Purealuminum

Aluminum with a purity of 99.00% or higher is called pure aluminum, and includes A1050, A1070, and A1100.

Due to its high purity, it has excellent workability, heat dissipation, and electrical conductivity, but it is said to be unsuitable for structural materials because it is extremely soft.

A2017

It is stronger than A5052 and is also known as duralumin.

It is characterized by being an alloy containing copper and magnesium, and is a heat-treated aluminum alloy with excellent machinability and strength.

A6061(AlMg1SiCu)

A6061 is an aluminum alloy 6000 series with added magnesium and silicon.

It has excellent corrosion resistance and is used as structural parts such as bolts.

A7075(AlZn5.5MgCu)

It is called extra super duralumin, and is an aluminum alloy to which zinc and magnesium are added.

Although it is one of the materials with the highest class of strength among aluminum alloys, it has the disadvantage of being inferior in corrosion resistance.

It is lightweight and strong, so it is used for aircraft, mechanical parts that require strength, and sporting goods.

Others

A2219, A6061(AlMg1SiCu), A6063(AlMg0.7Si), etc.

Materials other than the above are also available. Please feel free to contact us.

Please contact TDC for aluminum precision processing

TDC has a track record of processing all kinds of materials, from pure aluminum to aluminum alloys in the 2000s to 7000s.

If you do not know where to consult, please feel free to contact TDC first.

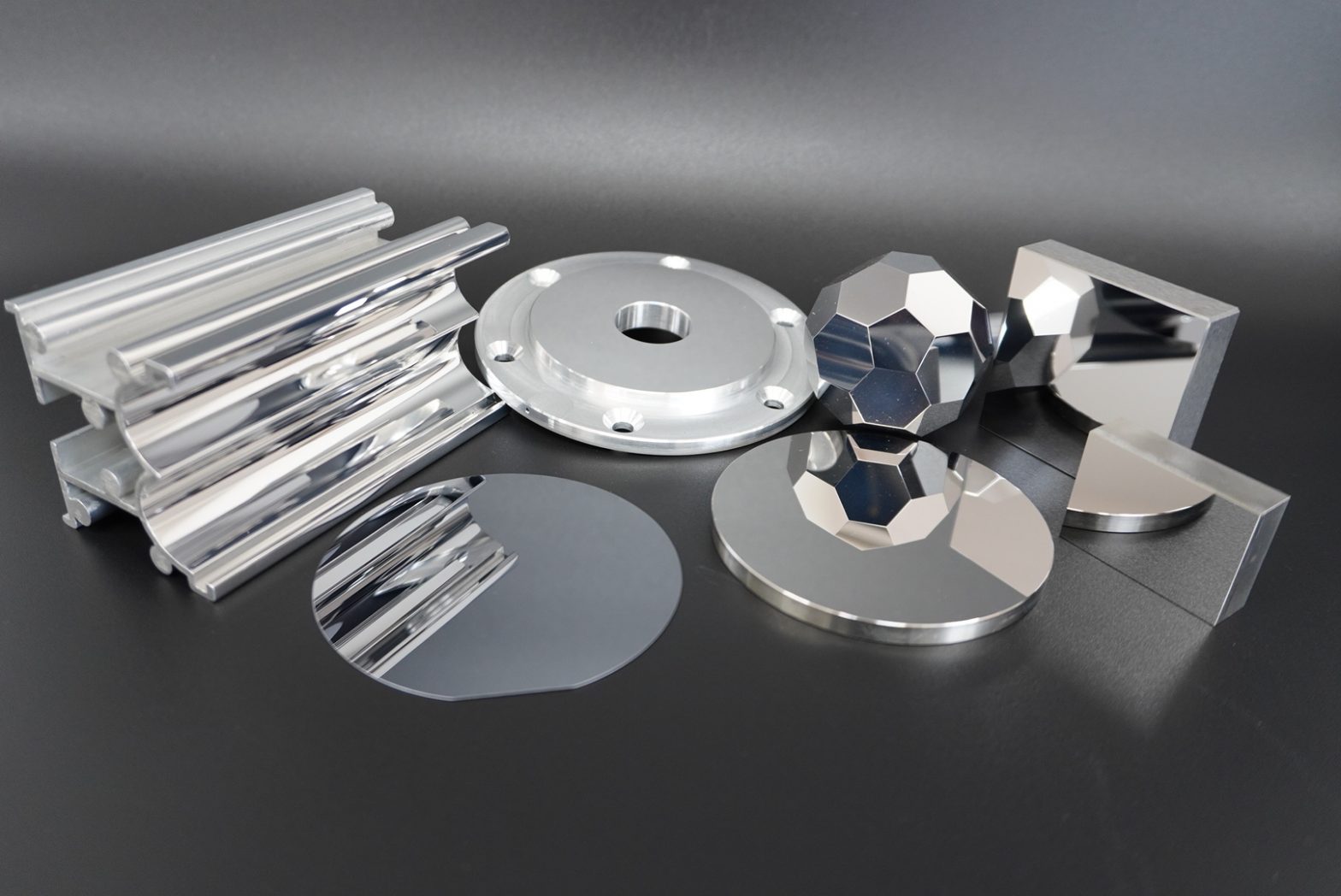

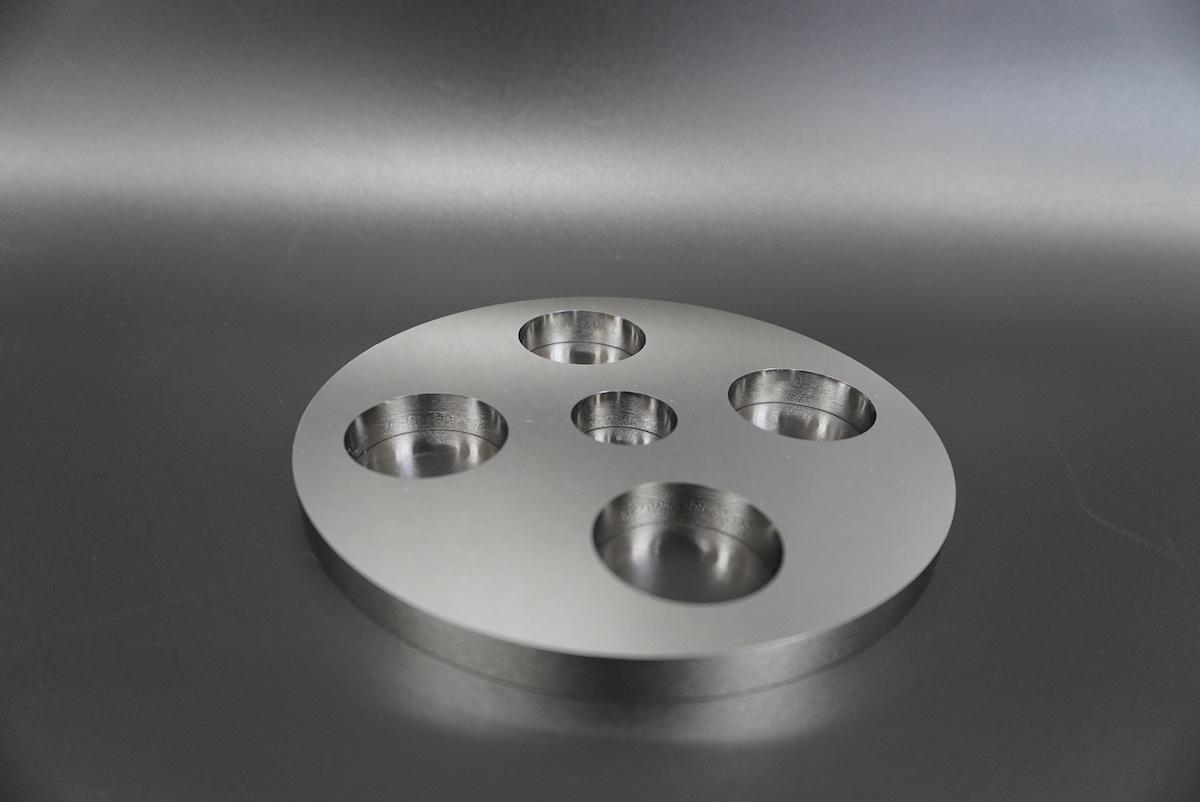

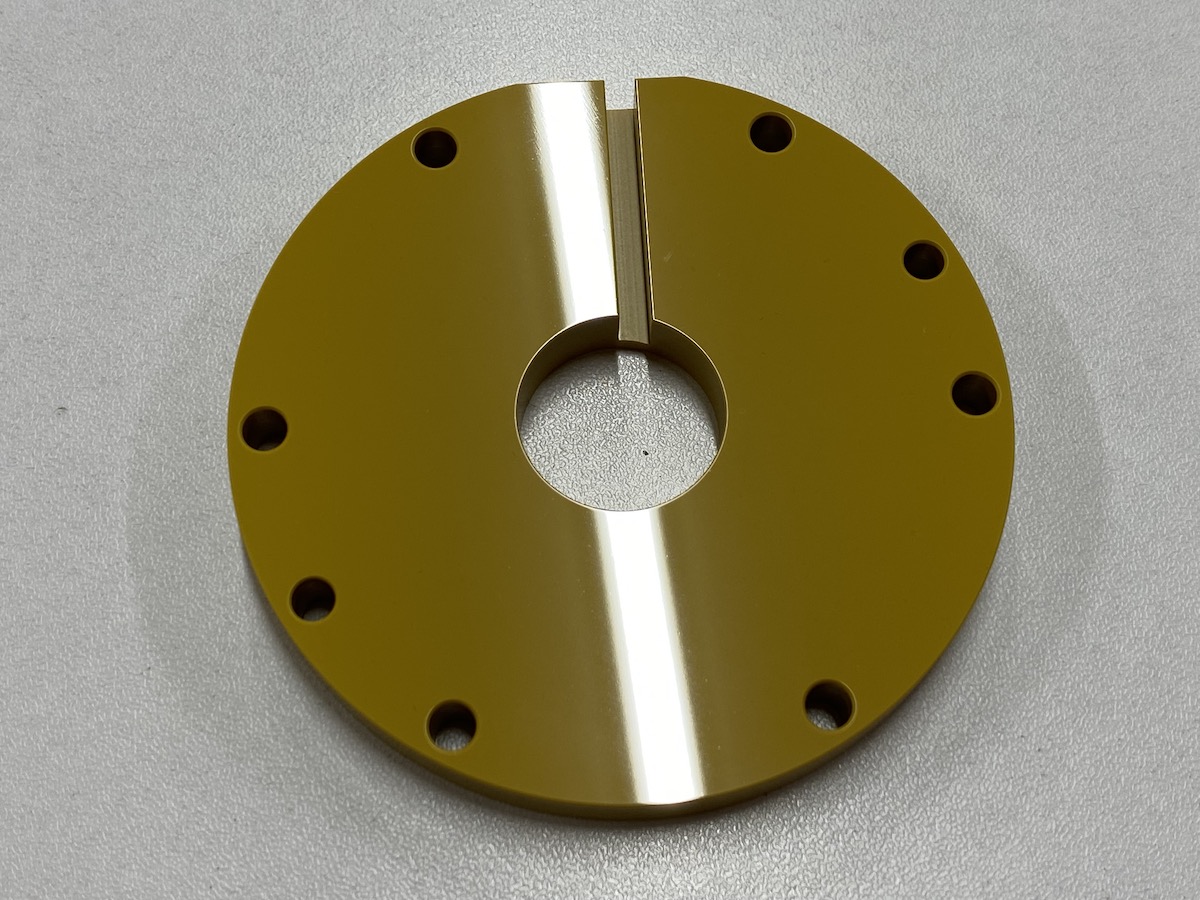

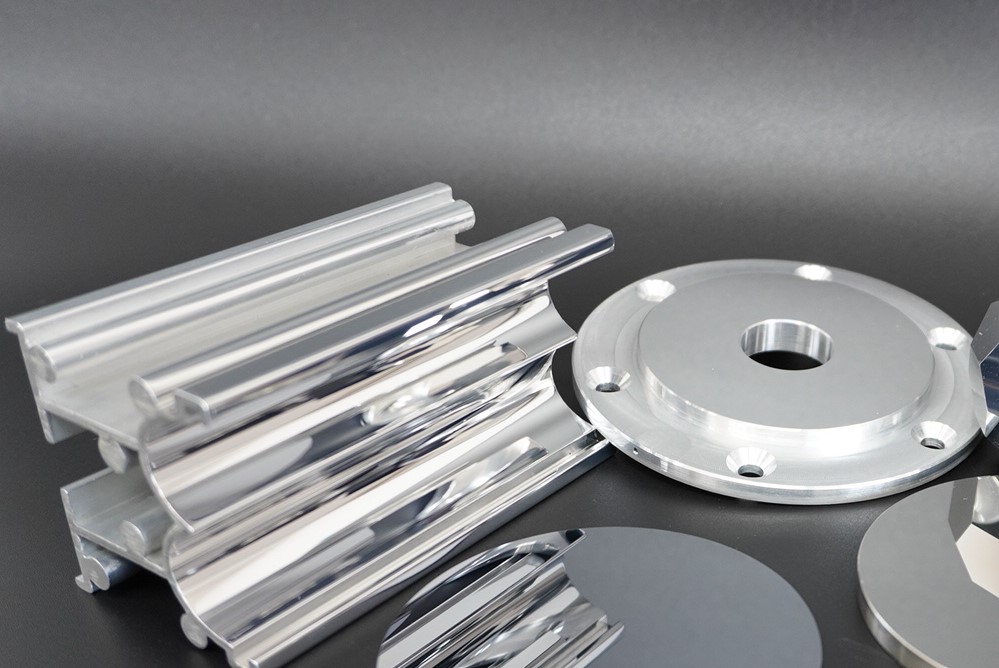

Examples of aluminum precision machining at TDC

Here are 5 examples of typical aluminum precision processing that can be processed and manufactured at TDC.

Machining example 1: A5052 reflection mirror

We made a reflector (reflective mirror) of A5052 material and dia.360mm.

- Features: Surface roughness Ra1nm or less is achieved for the entire surface of a large substrate of dia.360mm.

- Processing accuracy: Ra 1nm or less

Since it is a reflector, it is useful for improving reflectance.

Regardless of the shape, if you have a problem that you want to improve the reflectance than the current situation, feel free to contact us.

Processing example 2: Mirror surface test pieces for various aluminum materials

We manufacture specular test pieces of various aluminum materials from pure aluminum to extra super duralumin (A7075).

- Features: We manufacture ultra-precision mirror surface substrates regardless of the material.

- Processing accuracy: Ra1nm or less ~ Ra3nm (depending on material)

We manufacture various test pieces and specimens.

In addition to the mirror surface, rough polishing and satin finishing are also possible.

Processing example 3: Ultra-precision aluminum mirror surface roll

The higher the purity, the more likely it is to be scratched, so precision machining of aluminum is said to be difficult, but TDC can also mirror-finish it with rolls and shafts.

- Features: While managing cylindricity, roundness, dimensional tolerance, etc., it finishes to a scratch-free mirror surface.

- Processing accuracy: Ra1nm to Ra5nm or less (depending on material)

It can be used for molds for high-performance films.

What is aluminum material?

Good workability Aluminum is easy to plastic work and can be formed into various shapes.

For example, it is used in an extremely wide range of applications because it can easily produce foils as thin as paper and extrusions with complex shapes.

Properties and features of aluminum

- very light Aluminum is a very light metal with a specific gravity of 2.7, and is only about 1/3 the weight of iron. Taking advantage of its lightness, it brings various effects such as increasing the operating efficiency of sliding and rotating parts and reducing the weight of products. It is also used in familiar places such as the body of smartphones.

- Good corrosion resistance Aluminum forms a dense and stable oxide film on its own in the air, and this film naturally prevents corrosion and rust.

- Excellent electrical conductivity Aluminum has very high electrical conductivity and is used in high-voltage transmission lines and capacitors. Compared to copper, which has the same high electrical conductivity, the electrical conductivity is 60% that of copper. However, since it has a specific gravity of about one-third, it conducts twice as much current as copper of the same weight.

- Not affected by magnetic fields (non-magnetic) Since aluminum is non-magnetic, it is not affected by magnetic fields. It is used in various fields such as electronic medical equipment, mechatronics equipment, and linear motor cars.

- Excellent thermal conductivity The thermal conductivity of aluminum is about three times that of iron, and it has the property of conducting heat well. Therefore, it is used in a wide range of applications such as engine parts, air conditioners, and heat dissipation parts such as heat sinks.

- High castability Aluminum has a low melting point, and its surface is covered with an oxide film even when it is melted, making it a material that does not easily absorb gas. In addition, aluminum is often used in castings that can create complex shapes because it has the characteristic of good fluidity.

- reflect light and heat Aluminum with a polished surface reflects light and heat such as infrared rays, ultraviolet rays, and electromagnetic waves. By applying a mirror finish to further enhance its characteristics, it is often used in electronic products such as reflective mirrors.

Feel free to contact TDC for difficult aluminum polishing and grinding

Aluminum is a material that is often used for equipment parts that require high precision, but depending on the material, it is a soft material that makes it difficult to achieve precision.

At TDC, we are able to handle polishing of any material and precision with our know-how of processing according to the material and our accumulated polishing processing technology.

If you have an aluminum polishing project that has been rejected by other companies, please do not hesitate to contact TDC.

Related page

- What is a chuck table? | Basic information and description of types, Processing accuracy at TDC

- Copper polishing

- Precision processing of crystal materials and glasses

- Polishing after thermal spraying

- Mirror Finishing/Mirror Polishing

- Sapphire polishing

- Polishing of plastic/acrylic resin

- Polishing after surface treatment/coating

- Precision parts processing

- KEYENCE measuring instruments used at TDC

- Precision Cleaning Service

- Symbol used for polishing

- SUS (stainless steel) material test piece/specimen

- Polishing of SiC

- Polishing of titanium

- Cylindrical grinding/cylindrical polishing

- Mold Processing

- Precision machining of ceramics

- ガラスエポキシ(ガラエポ)の精密加工

- Type of polishing process

- 真鍮の精密加工・研磨加工

- What is the accuracy that can be achieved by polishing?

- Principle of polishing process

- Semiconductor Wafer Cleaning

- Ultrapure Water Cleaning

- Bruker “Dimension Icon”

- Talysurf

- Talyrond

- Dial gauge

- Precision processing of resin and plastic

- Polishing process for Resin

- Precision Measurement

- Mirror-finishing for aluminum

- Mirror-finishing for plastic/acrylic resin

- Wafer Cleaning Equipment

- Mirror Polishing for Stainless Steel/SUS304

- Metal polishing process

- Mitutoyo measuring instrument used in TDC

- Polishing of Aluminum

- Optical Nano Gauge

- ステンレスの研磨加工

- TDC’s precision machining

- 微細加工とは? | 基礎知識と加工方法の解説

- Precision polishing technology of Diamond wafers

- What is CMP

- What is polishing?

- About Lapping and Polishing