Precision machining of metal

This page introduces the precision processing of metals performed at TDC.

For more information on TDC’s precision polishing services, please also see the “Precision lapping service / ultra precision lapping service” page.

Contents

TDC’s Metal Precision Machining

At TDC, we can handle a wide range of precision metal processing, from precision parts that require the highest level of precision to metal processing for molds, and processing to create a mirror-like gloss on the surface of products. is.

We will solve the problems of metal processing of all kinds of precision and shape with the metal precision processing technology in micron units that we have cultivated so far.

Features of TDC’s precision metal processing

TDC’s precision metal processing has the following strengths and characteristics.

- High-precision polishing technology

TDC’s precision polishing technology enables ultra-high-precision metal precision processing at the micron and nano level by controlling the removal amount.

Compared to processing methods such as cutting and grinding, it is possible to handle any shape without applying a load to the object.

- Short delivery time and express service available

By owning more than 100 polishing machines, we can achieve short delivery times even for large lots and complex processing.

If you are in a hurry, we will also respond to consultation with “express response”.

- Please feel free to contact us even from a small lot.

Please feel free to contact us for small lot orders starting from 1 unit and prototype production. - Owns over 100 abundant processing machines

TDC owns more than 100 polishing machines such as lapping machines and surface grinders.

We also have various processing machines such as machining centers and milling machines, so we can handle all kinds of processing.

- About half of the polishing equipment is manufactured in-house

About half of the more than 100 polishing machines are made in-house, realizing “low-cost” and “high-quality” manufacturing.

Metal that can be precision machined

We perform precision processing of metals using various processing technologies such as polishing and grinding, which are our strengths.

The representative metals that can be handled are as follows.

- General steel

- cemented carbide

- stainless

- copper

- Titanium

- Aluminum

- molybdenum

- tungsten

- nickel

- tantalum

- Various other metals

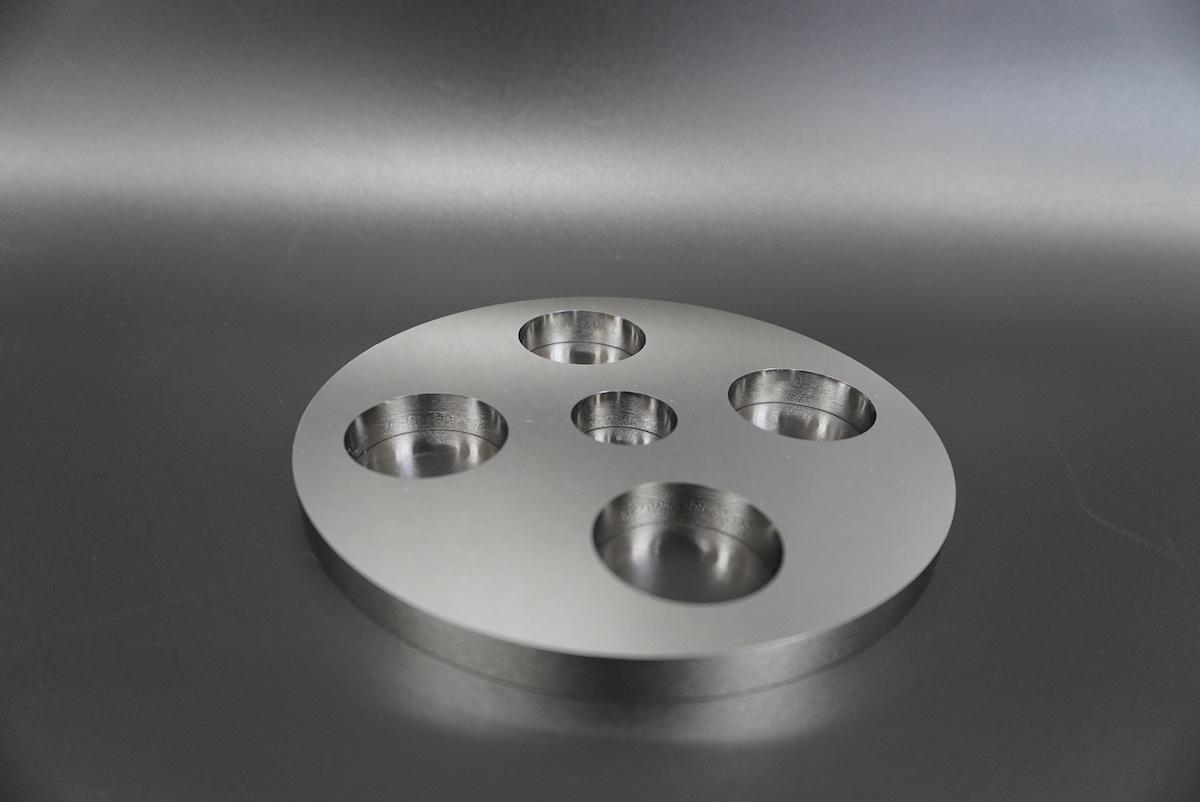

Examples of TDC metal precision processing

Here are three examples of typical metal precision processing that can be processed and manufactured with TDC.

Example of metal precision processing 1 : Accurate grinding of precision table

It is possible to achieve the ultimate precision in terms of flatness, parallelism, and plate thickness tolerance for precision stages and tables used in semiconductor manufacturing equipment that requires ultimate precision or in precision measuring machines.

- Material: SUS304

- Size: φ300xt30

- Processing details: flatness 0.0005mm, parallelism 0.001mm, plate thickness tolerance ±0.001mm

Metal precision processing example 2 : Internal mirror surface processing of pipe mold

Depending on the specifications, fine scratches and cloudiness, which were conventionally allowed, are often not acceptable in “mold” processing. Please experience the high-precision finishing of TDC once.

For example, when polishing a mold for “roller manufacturing” that is built into a printing machine, if it is a mold with a length of 300mm and an inner diameter of φ20mm, the inner diameter and coaxiality are controlled in a micro order, and the surface is polished. It can be finished to a roughness of Ra1nm or less.

Metal precision processing example 3 : Production of test pieces and test pieces with various materials

Please leave the production of specimens and test pieces that play an important role in the production of products.

It is possible to handle from the cutting process, and it is possible to make different products from a mirror surface with a surface roughness of Ra1nm to a satin finish (frosted glass state).

Please feel free to contact us not only for metals, but also for resins, ceramics, crystal materials, etc.

- 【レポート】ナノテラス計測までの道のり(前編)/ 利用の手順や予約について

- MEMS Engineer Forum (MEF) 2024にティ・ディ・シーも出展します(2024年4月17日~18日)

- 2024年度の入社式を行いました

- 【ナノテラス Vol.2】

宮城に生まれる産学官の出会いの場 - 新工場竣工のお知らせ

- 代表の赤羽による連載第三弾がForbesに掲載されました

- 【ナノテラス Vol.1】

次世代放射光施設「ナノテラス」とは? ――ナノの世界から広がる可能性 - 代表の赤羽による連載第二弾がForbesに掲載されました

- 第30回東北ニュービジネス大賞を受賞しました

- nano tech 2024にティ・ディ・シーも出展します

- 謹賀新年

- インコネルとは?| 基礎情報・特徴の解説と加工事例

- インコネルとは?| 基礎情報・特徴の解説と加工事例

- Happy Holidays from TDC

- 年末年始休暇のお知らせ

- ボストンMRS Exhibition 出展のご報告

- 難削材とは? | 基礎知識と種類についての解説

- 難削材とは? | 基礎知識と種類についての解説

- What is gallium nitride (GaN)? | Basic information/explanation of features and processing examples

- 窒化ガリウム(GaN)とは? | 基本情報・機能の説明と加工例

- ドイツ COMPAMED出展のご報告

- ネプコン ジャパンにティ・ディ・シーも出展します

- SEMICON Japanにティ・ディ・シーも出展します

- 女子会

- 第40回「センサ・マイクロマシンと応用システム」シンポジウムにティ・ディ・シーも出展します

- Yuko Akabane started a series of articles on Forbes!!

- Forbesにて代表の赤羽による連載が始まりました!

- Visit TDC at 2023 MRS Fall Meeting & Exhibit in Boston!!

- 2023 MRS Fall Meeting & Exhibit(米国/ボストン)にティ・ディ・シーも出展します

- Visit TDC at COMPAMED 2023 in Düsseldorf, Germany!!

- COMPAMED2023(ドイツ/デュッセルドルフ)にティ・ディ・シーも出展します

- What is Vespel? | Vespel features and processing examples

- 代表赤羽がものづくり中小企業における放射光活用について説明させて頂きます。

- 精密工学会 JSPE2023年度秋季大会@福岡にティ・ディ・シーも出展します

- 応用物理学会 JSAP EXPO Autumn 2023@熊本にティ・ディ・シーも出展します

- ベスペルとは?| ベスペルの特徴・加工事例

- 事業方針説明会を開催しました

- 2023年 夏季休暇のお知らせ

- SPECIAL STORY | Ultra-precision polishing of nano-order with “visualization” and onsite communication

- 〈TDCのものづくりストーリー〉

“可視化”と現場でのコミュニケーションが支える、ナノオーダーの超精密研磨 - What is a chuck table? | Basic information and description of types, Processing accuracy at TDC

- What is Tungsten? | Tungsten characteristics and processing examples

- SPECIAL STORY |Unique Technology originated from Trial and Error

- 〈TDCのものづくりストーリー〉

トライ&エラーから生まれた独自技術 - チャックテーブルとは?| 基礎情報と種類の解説・TDCでの加工精度

- Notice of Office Closure

- 【ご連絡】6/2は創立記念日のため休業となります

- 【ブルカー x ティ・ディ・シー共催】超精密研磨・評価ウェビナーのご案内

- タングステンとは?| タングステンの特徴・加工事例

- G7科学技術大臣会合にてティ・ディ・シーの技術紹介を行いました