Precision processing of resin and plastic

This page introduces the precision processing of resin and plastic performed at TDC

For more information on TDC’s precision polishing services, please also see the ”Precision lapping service / ultra precision lapping service”.

Contents

TDC’s precision processing for resin and plastic

TDC offers precision processing service for resin and plastic.

Features of TDC’s precision machining for resin and plastic

Although many have voiced concerns such as the inability to achieve precision when compared to metal processing, resin and plastic are now becoming an indispensable material in the semiconductor, automotive, and machine tool industries. TDC’s resin and plastic processing technology, which we have cultivated over the years, can solve any precision or shape resin processing problems.

TDC’s resin precision processing has the following strengths and features.

- High-precision polishing

Our precision polishing technology enables ultra-high-precision metal precision machining at the micron and nano-level by controlling the amount of removal. Compared to machining methods such as cutting and grinding, TDC can handle any shape without placing a load on the object. - Quick delivery and express delivery are possible.

With more than 100 polishing machines, we can provide quick delivery even for large lots and complex processing.

For urgent cases, we can also provide “express response” services. - Please feel free to contact us for

TDC takes small lot orders from one piece, or for prototype production. - Owns a wide variety of over 100 processing

TDC owns over 100 processing machines such as lapping and polishing machines, surface grinders, and other polishing equipment.

We also have a variety of CNN, milling machines, and other machining equipment to handle all types of processing.

About half of the more than 100 polishing machines are manufactured in-house, enabling “low cost” and “high quality” manufacturing.

TDC’s surface roughness results for mirror-finished resin and plastic

| Materials | Ra (nm) | Rz (nm) |

| Acrylic | 0.99 | 7.04 |

| ABS | 4.972 | 29.637 |

| COP | 2.317 | 19.9 |

| PTFE | 1,918 | 12.663 |

| PES4100G | 1.698 | 11.247 |

| PC | 3.7 | 28.72 |

| PEEK | 2.39 | 17.4 |

| PEEK450G | 1.785 | 10.807 |

| Vespel | 1.96 | 14.1 |

| Polyimide | 1.42 | 11.9 |

| Polyester | 3.693 | 33.963 |

| PPS | 1.41 | 9.96 |

| PDMS | 1.191 | 9.177 |

| PP | 1.615 | 10.13 |

| ORGA | 1.937 | 12.487 |

| SUMI-EPOXY | 5.256 | 82.863 |

| Iupilon® | 3.852 | 57.597 |

| Polymer Monolith | 0.054 | 500 |

| Glass Epoxy | 1.736 | 17.81 |

| Epoxy | 2.137 | 12.59 |

| POM | 48.0 | 489.0 |

Materials

We perform precision processing of resins using all the processing technologies in which we excel, such as polishing, cutting, and grinding. Typical resins that can be handled are as follows

- Engineering plastics PEEK, PES, PBN, PEI, PPS, PI, PAI, PSF, PTFE, POM, PC ,PVDF ,PA, PBT ,PET ,UHMWPE and others

- Acrylic PMMA, PVC, HT-PVC, PP, PET, ABS, and others

- Teflon and other coatings

Compatible sizes for resin/plastic precision processing

At TDC, we can handle the following sizes for precision processing of resins and plastics.

- Plate material: ~500 mm square (mirror finish)

- Roll: Outer diameter dia. 500 mm, length L=3,000 mm

Available processing types for resin/plastic precision processing

At TDC, the following processing is available for precision processing of resins and plastics.

- Precision mirror processing

- precision lapping

Processing equipment for precision processing of resins and plastics owned by TDC

TDC has the following equipment for precision processing of resins and plastics.

- Single-sided mirror lapping machine

- Long mirror finishing machine

- Roll inner and outer diameter mirror surface machine

For TDC’s processing equipment, please refer to the “Processing Equipment” page.

Importance of Resin and Plastic Precision Machining

Resin materials are attracting a great deal of attention as alternative materials to metal to reduce body weight in electric and electric vehicles, which are now becoming the mainstream. In addition to the actual adoption of resin-based parts, precision processing technology for resins is becoming increasingly important, coupled with advances in engineering plastics and resin-to-metal bonding technology. With the development of recycling technologies and biodegradable plastics, the demand for resins is expected to grow even more in the future. If you are considering precision processing of resin, please feel free to contact us.

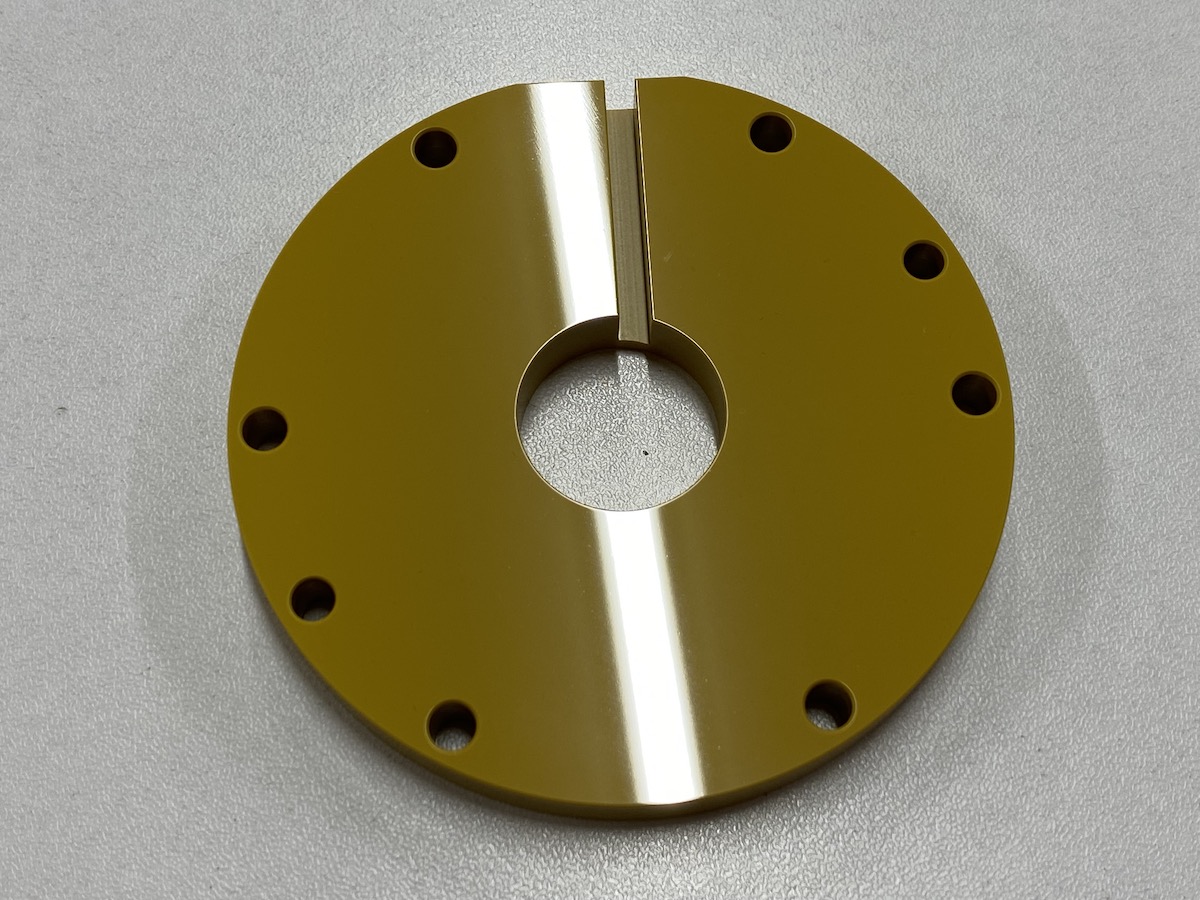

Example of TDC’s Resin and Plastic precision machining

Here are some examples of typical precision machining of resins at TDC.

Mirror processing and test piece fabrication of various resin substrates

- Materials: Engineering plastics, Acrylic, Polycarbonate, Teflon coating, etc

- Processing details: Surface roughness of less than 5 nm can be achieved for most resin materials.

Mirror finishing can be applied to various resin materials, including polishing of all engineering plastics, acrylic, polycarbonate, and Teflon coated films. In addition, the finished surface roughness of resin materials generally varies greatly depending on the material, but it is possible to achieve a surface roughness of less than 5 nm for most materials. For details, please refer to the “What is the surface roughness“.

High precision shim and gauge of polyimide resin

Compared to metals and ceramics, resin is an extremely soft material that is generally considered difficult to process with precision. However, TDC’s polishing technology, which we have cultivated over the years, makes it possible to produce high-precision shims and gauges with minimal sagging and warping, even with resin materials.

Please feel free to consult with us for suggestions on appropriate materials, not limited to polyimide, depending on the environment and specifications of your application.

Key points for precision processing of resins and plastics

Even if we say precision processing of resins and plastics, there are various processing methods and requests for processing.

In order to realize them, it is a major premise that high technology and know-how are required, but facilities and environmental maintenance are also important points.

Specifically, the following facilities are required.

- Dedicated machine for fine hole processing

- surface polisher

- Seismic isolation equipment

- material processing equipment

- Environment such as temperature control is in place

- measuring machine

- Multitasking machine

Another important point is the selection of materials.

For example, resin materials such as Teflon and ultra-high-molecular-weight polyethylene are said to be soft and difficult to achieve precision. On the other hand, super engineering plastics such as PPS and PEEK are suitable for high-precision processing.

Understanding the characteristics of these materials and being able to make all sorts of proposals is an important point in precision processing of resins and plastics.

At TDC, we not only have these facilities, but also provide proposals that can realize customer requests.

We can provide a one-stop service from proposal to processing, cleaning, and measurement for any request.

Please contact TDC for precision processing of resins and plastics.