What is a chuck table? | Basic information and description of types, Processing accuracy at TDC

This page provides an overview of chuck tables used to hold wafers, etc.

Contents

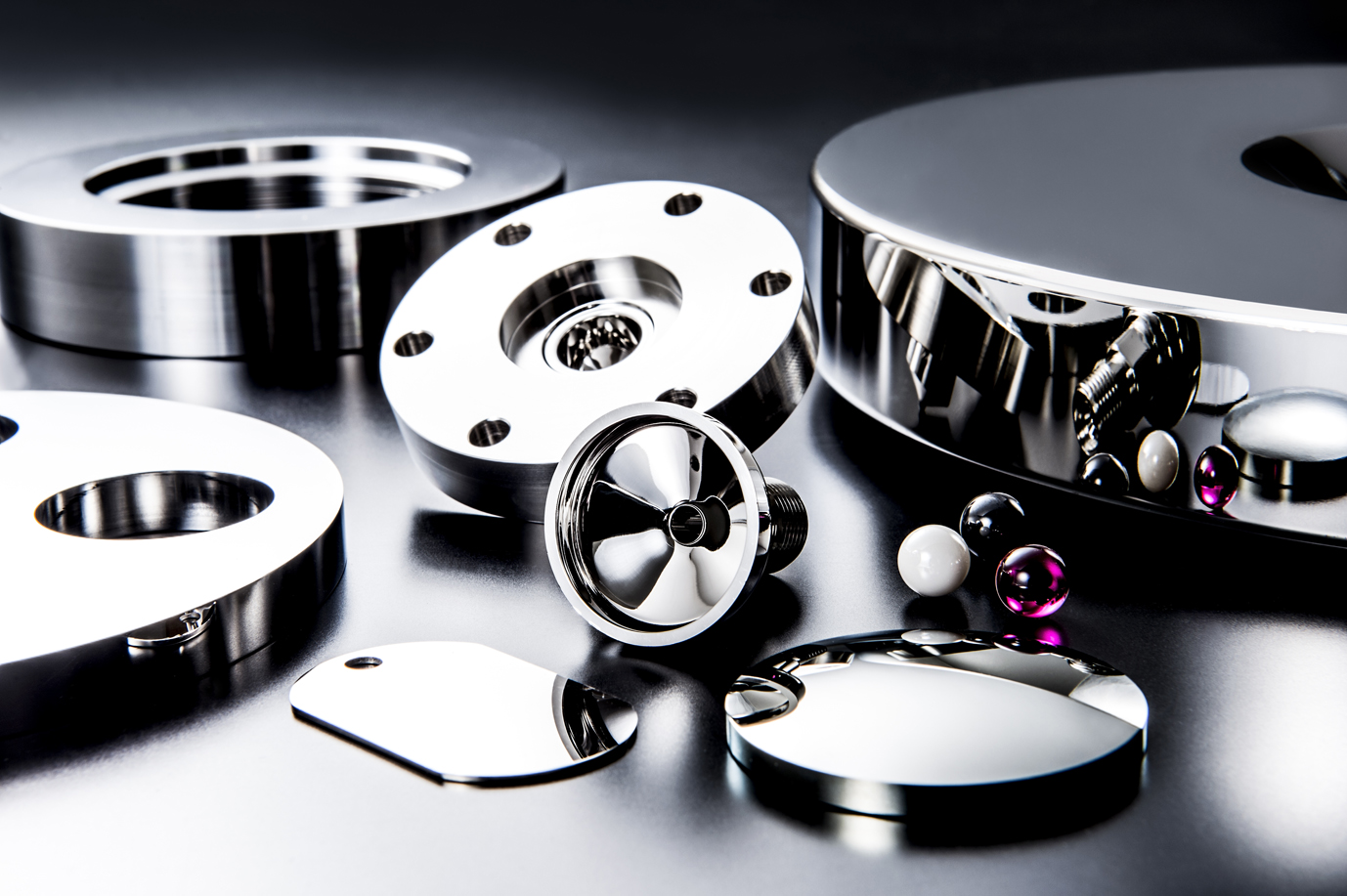

What is a chuck table

A chuck table is a pedestal that mainly fixes thin workpieces such as wafers and films.

It is used in applications such as machining and inspection because it can firmly absorb and fix the workpiece.

Workpieces can be fixed in various ways, such as by applying a negative pressure between the work and the table, or by using electricity.

The main material of the chuck table is metal, but there are some that combine other materials such as resin to reduce damage to the workpiece.

Type of chuck table

There are various types of chuck tables, depending on the fixing method. Here, we will introduce the following three typical chuck tables.

- Vacuum chuck (vacuum chuck)

- electrostatic chuck

- magnet chuck

Vacuum chuck

A vacuum chuck is a type that sucks a workpiece by creating a negative pressure between the workpiece and the table through grooves and holes on the table’s suction surface.

By narrowing the area of the open hole, even thin workpieces such as film can be adsorbed without deformation.

In addition to vacuum chucks that combine metal, there is also a type called “porous chuck” that combines other materials.

A porous chuck consists of a material with countless holes called “porous material” and a pedestal that holds the porous material.

There are various porous materials such as resin, stainless steel, and silicon carbide, and they are used according to the application.

Elecrtostatic chuck

An electrostatic chuck is a type that fixes a workpiece with the power of electricity generated on the table.

Since it is a mechanism that applies voltage to the table to manipulate and attract the electric charge in the work, it can be used safely without affecting people.

The electrostatic chuck uses electrical force instead of physical force to evenly attract the entire object. Since the force is not concentrated on one point, it is suitable for avoiding damage to the workpiece. It is also characterized by being able to adsorb workpieces with holes such as mesh.

Magent chuck

A magnetic chuck is a type that fixes a workpiece with the force of a magnet.

Magnetic chucks include “electromagnetic chucks” that can attach and detach workpieces with switch operations, and “permanent magnetic chucks” that can be fixed without switch operations.

The strength of the electromagnetic chuck is that it is easy to attach and detach the workpiece by turning on and off the magnetic force, and that the strength of the attraction force can be controlled.

On the other hand, permanent magnetic chucks can be fixed without using electricity because the adsorption force works with a certain force when detaching the workpiece.

Accuracy is essential for manufacturing chuck tables

Nano-level precision is required for manufacturing and processing wafers, which are the basic materials of semiconductors. The precision of the chuck table itself, which serves as the base for the wafer, is essential to achieving that precision.

If the chuck table that holds the wafer is slightly undulated or distorted, the wafer cannot be finished with high quality. Therefore, it is important that the flatness and parallelism of the chuck table are extremely accurate.

At TDC, which has been involved in ultra-precision polishing for many years, we support the polishing and processing of all types of chuck tables, including vacuum chucks. We also have various high-performance measuring instruments, so we can provide measurement data after processing and guarantee quality.

Please refer to the following page for the measuring equipment owned by TDC.

Chuck table accuracy provided by TDC

| Material | Size | Thickness | Flatness(guaranteed) |

| Alumina | Φ400㎜ | 15mm | <1 um |

| Φ200㎜ | 10mm | <0.5um | |

| SiC Ceramics | Φ400㎜ | 15mm | <1 um |

| Φ200㎜ | 10mm | <0.5 um | |

| SUS304 | Φ400㎜ | 15mm | <1 um |

| Φ200㎜ | 10mm | <0.5 um | |

| A5052Anodized | Φ400㎜ | 15mm | <1 um |

| Φ200㎜ | 10mm | <0.5 um | |

| ceramic porous chuck | Φ400㎜ | 15mm | negotiable |

| Φ200㎜ | 10mm | negotiable | |

| metal porous chuck | Φ400㎜ | 15mm | negotiable |

| Φ200㎜ | 10mm | negotiable |

Please contact TDC for chuck table polishing.

A chuck table mainly refers to a base for fixing workpieces such as wafers. Semiconductor production sites require high precision in nano-level units, so precision processing is also required in the manufacture of chuck tables.

If you have a chuck table processing project that has been rejected by other companies, please do not hesitate to contact TDC.

with nano-level precision polishing.

and production from single units to mass production.

- Precision lapping service / ultra precision lapping service

- Polishing service

- What is Grinding

- What is cutting

- What is a chuck table? | Basic information and description of types, Processing accuracy at TDC

- Copper polishing

- Polishing after thermal spraying

- Sapphire polishing

- Polishing of plastic/acrylic resin

- Polishing after surface treatment/coating

- Symbol used for polishing

- Polishing of SiC

- Polishing of titanium

- Cylindrical grinding/cylindrical polishing

- Type of polishing process

- What is the accuracy that can be achieved by polishing?

- Principle of polishing process

- Polishing process for Resin

- Metal polishing process

- What is CMP

- What is polishing?

- About Lapping and Polishing