What is gallium nitride (GaN)? | Basic information/explanation of features and processing examples

This page explains the characteristics, applications, and processing examples of gallium nitride (GaN), a material for next-generation power semiconductors.

Contents

What is gallium nitride (GaN)?

Gallium nitride (GaN) is a compound of gallium (Ga) and nitrogen (N), and is a semiconductor material also known as “gallium nitride.”

Semiconductors are components necessary for controlling electrical equipment such as automobiles and home appliances, and silicon (Si) is currently often used.

Carbon neutrality, which is an initiative to eliminate greenhouse gas emissions, has been gaining importance in recent years, but achieving carbon neutrality requires reducing the power consumption of electrical equipment and electrifying automobiles.

Therefore, compound semiconductors such as gallium nitride and silicon carbide (SiC), which have properties superior to conventional silicon, are being put into practical use as semiconductors that will play an active role in the next generation. It is expected that the scale will increase.

Characteristics and properties of gallium nitride

Gallium nitride has a band gap (*) of 3.39eV, which is approximately three times as large as silicon’s 1.12eV. In addition, the material is hard and has a stable bonding structure, and is characterized by high heat capacity and excellent thermal conductivity.

*Band gap in semiconductors refers to the energy difference (forbidden band) between the valence band and the conductor. Semiconductors with a large bandgap have a high dielectric breakdown field strength, can handle high voltage and high power, and are expected to have high energy efficiency.

Uses of gallium nitride

Gallium nitride is in practical use as a material for power semiconductors used in smartphone and computer chargers, train motor controls, solar power generation, etc.

Furthermore, demand is expected to increase for voltage converters in servers around 2025, and for power supplies for data centers around 2030.

Gallium nitride attracts attention as a material for power semiconductors

Power semiconductors are semiconductors that convert and supply electric power, and are characterized by their ability to handle large currents and voltages.

Typical products that use power semiconductors include diodes, transistors, and ICs. These products are used for purposes such as converting alternating current to direct current, converting direct current to alternating current, and amplifying current, and convert and supply power to the electrical appliances around us.

Gallium nitride is a material that is attracting attention as a next-generation power semiconductor, and is expected to have improved energy-saving performance compared to conventionally used silicon, so the market size is expected to expand in the future.

In addition to gallium nitride, silicon carbide (SiC) is a typical next-generation power semiconductor. Next-generation power semiconductors are sometimes called “wide bandgap semiconductors” because they have a wider bandgap than silicon, which is widely used as conventional semiconductors.

Comparison of power semiconductors GaN/SiC and Si

Here, we will explain the differences in the characteristics of power semiconductors gallium nitride (GaN), silicon carbide (SiC), and silicon (Si). A comparison table of performance characteristics is shown below.

Comparison table of performance characteristics of GaN/4H-SiC/Si

| material | Gallium nitride (GaN) | Silicon carbide (4H-SiC) | Silicon (Si) |

| Bandgap (eV) | 3.39 | 3.26 | 1.12 |

| Electron mobility (cm2/Vs) | 2000 | 1000 | 1350 |

| Breakdown electric field (MV/cm) | 3.3 | 2.8 | 0.3 |

| Electron saturation velocity (cm/s) | 2.7×107 | 2.2×107 | 1.0×107 |

| Thermal conductivity (W/cmK) | 2 | 4.9 | 1.5 |

Reference source: Tokyo Electron Device Co., Ltd. https://www.inrevium.com/pickup/gan-power-semiconductor/

Gallium nitride has three times the band gap and 11 times the dielectric breakdown electric field compared to silicon, a conventional semiconductor material, so it can operate under high temperatures and has high voltage resistance. It is also characterized by its excellent energy-saving performance.

Silicon carbide (SiC) is a type of next-generation power semiconductor material, similar to gallium nitride. Depending on the combination of the positions of Si and C atoms, there are names such as 6H-SiC and 4H-SiC, and 4H-SiC is used in power semiconductors such as white goods.

Comparing gallium nitride and silicon carbide, gallium nitride has higher electron transfer speed and electron saturation speed, so it has better switching characteristics and is suitable for small parts and high frequency applications such as switching power supplies.

On the other hand, although silicon carbide has a high dielectric breakdown field similar to gallium nitride, its thermal conductivity is higher than that of gallium nitride, so it is used in high voltage and large current applications such as motor drives. I am.

If you would like to know the basics of silicon carbide, please see the article “Polishing of SiC”.

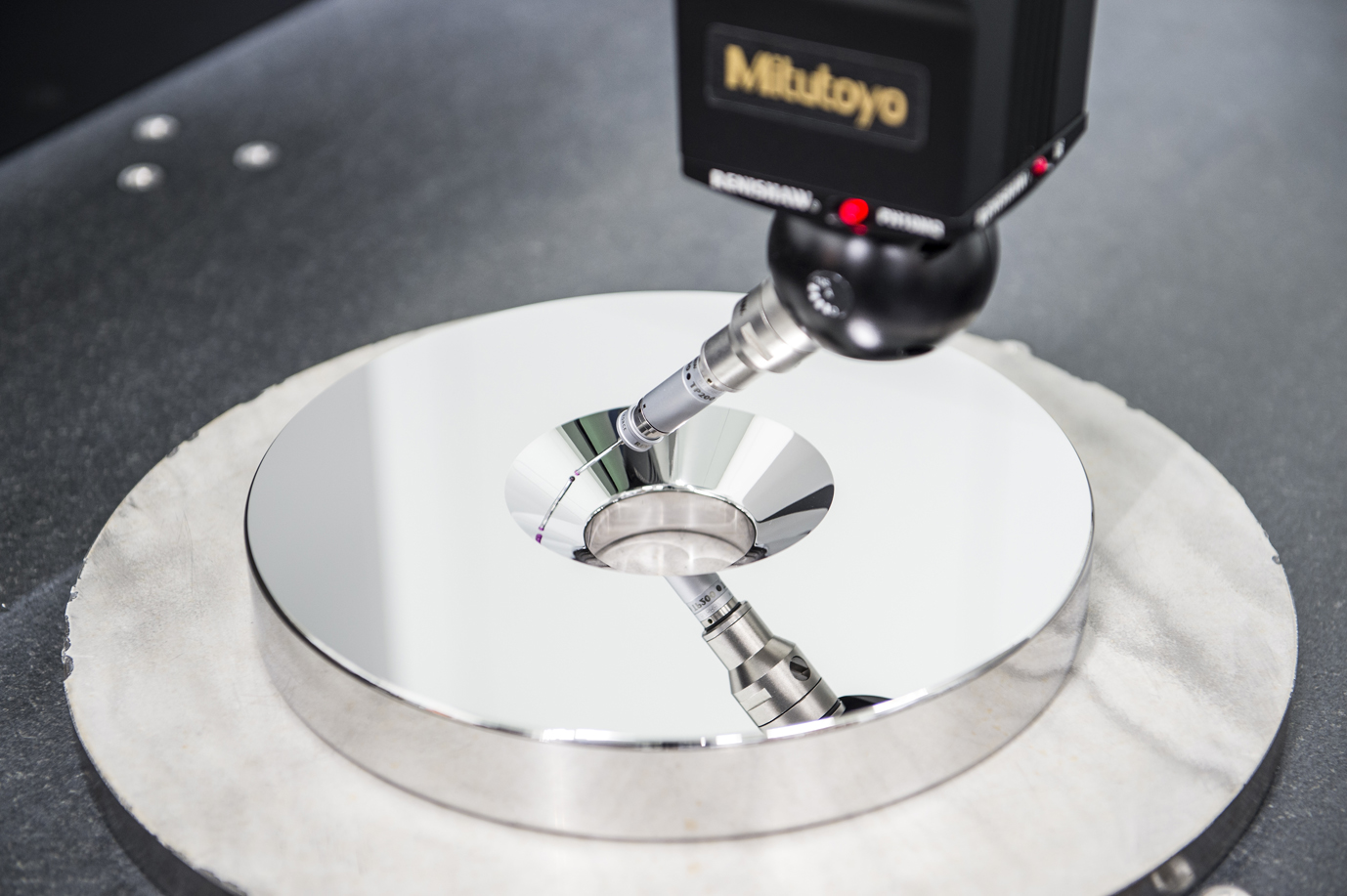

Example of processing gallium nitride at TDC

We have a track record of polishing gallium nitride wafers and epitaxial films in sizes up to 6 inches.

It is also possible to polish GaN on Si and GaN on GaN wafers used as power semiconductors.

We can accommodate orders starting from 1 piece, so please feel free to contact us.

Please contact TDC for processing of gallium nitride.

Gallium nitride is a material used in next-generation power semiconductors, and is more energy efficient than silicon, which has traditionally been used. However, because it is a hard and mechanically stable material, it tends to be difficult to process.

At TDC, we process gallium nitride with high precision using processing know-how tailored to the material and processing technology we have accumulated over the years.

If you have a gallium nitride processing project that has been rejected by another company, please contact TDC.

with nano-level precision polishing.

and production from single units to mass production.

Related page

- What is gallium nitride (GaN)? | Basic information/explanation of features and processing examples

- What is Vespel? | Vespel features and processing examples

- What is Tungsten? | Tungsten characteristics and processing examples

- Nickel

- Tantalum

- Glassy carbon (glassy carbon)

- Plate thickness and material of stainless steel plate (SUS)

- Coefficient of linear expansion

- Invar/Super Invar

- Niobium

- Hastelloy

- Engineering Plastic