What is Vespel? | Vespel features and processing examples

This page explains the characteristics, uses, types, etc. of Vespel, a type of super engineering plastic.

Contents

What is Vespel?

Vespel is a super engineering plastic molded from fully aromatic polyimide resin powder developed by DuPont.

Typical materials include “Vespel® SP-1” and “Vespel® SCP-5000.”

Vespel can withstand environments from extremely low temperatures to high temperatures, and is characterized by superior wear resistance than general engineering plastics.

Due to its excellent properties, it is used in a wide range of applications including aircraft, automobiles, electronic equipment, electrical equipment, and industrial machinery.

If you would like to know the basics of engineering plastics and super engineering plastics, please check our “Engineering plastic” article.

Characteristics, characteristics, and properties of Vespel

The main features of Vespel are as follows.

- Can withstand conditions ranging from extremely low temperatures to exposed to fire

- Excellent wear resistance, sliding properties, heat resistance, chemical resistance, and electrical properties

- Good gas release resistance in vacuum

- Good machinability and easy machining with small tolerances

Detailed characteristics of each type, such as Spell® SP-1, are introduced below.

Types and uses of Vespel

Here, we will introduce some of the typical types of “Vespel®SP series” and “Vespel®SCP series” regarding their characteristics and applications.

Vespel®SP-1

Vespel® SP-1 is a Vespel material made of 100% polyimide resin, and has the characteristics of heat resistance, insulation, and high mechanical strength.

Applications: Used in many industrial fields such as insulation, insulation parts and valves.

Vespel®SP-21

Vespel® SP-21 is a Vespel material containing 15% graphite by weight. Materials for use under a wide range of friction and wear conditions and function with or without lubrication.

Applications: Typical parts include thrust washers, seal rings, gears, and bearings.

Vespel®SP-22

Vespel® SP-22 is a Vespel material containing 40% graphite by weight. It has excellent wear resistance due to improved lubricity due to graphite.

It also has good dimensional stability, low thermal expansion, and excellent creep resistance.

Application: Used in sliding parts such as radial bearings.

Vespel®SCP-5000

Vespel® SCP-5000 is a high-grade Vespel wood. In addition to having superior strength compared to Vespel® SP-1, it also has improved thermal stability, chemical resistance, and plasma resistance.

Another feature is that there is little weight loss when exposed to high temperatures and dimensional changes due to water absorption.

Applications: Used in plasma-resistant parts and parts that require dimensional stability, such as liquid crystals and semiconductors.

Reference source

DuPont: https://www.dupont.co.jp/vespel.html

Mitsuboshi Belting Co., Ltd.: List of VESPEL® (mitsuboshi.com)

Ishihara Chemical Co., Ltd.: Polyimide resin Vespel® | Super engineering plastic products | Product information | Ishihara Chemical Co., Ltd. (unicon.co.jp)

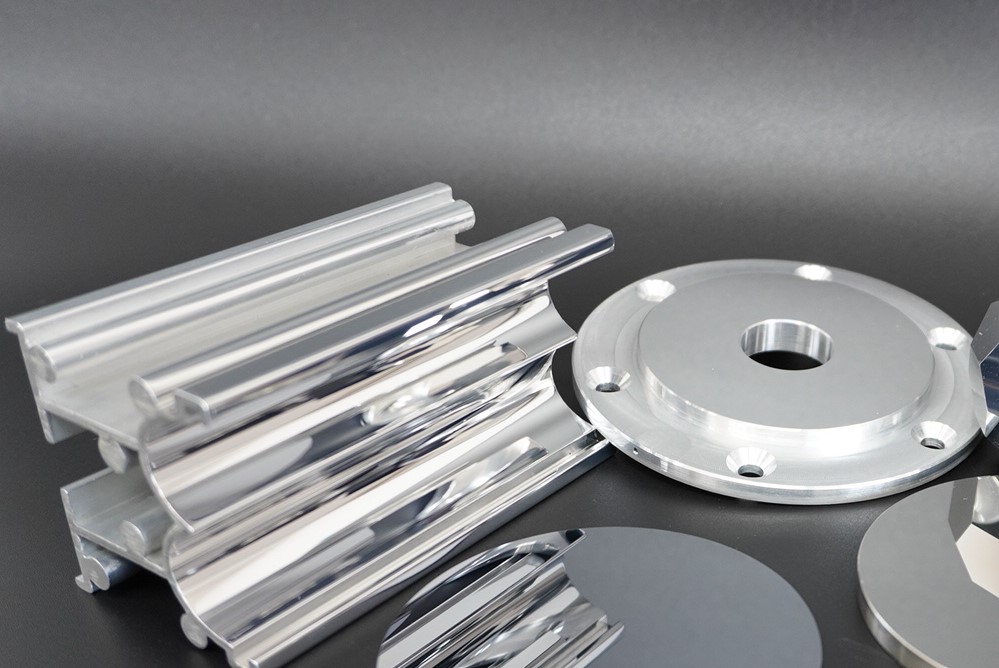

Vespel processing example at TDC

We will introduce typical Vespel polishing process examples at TDC.

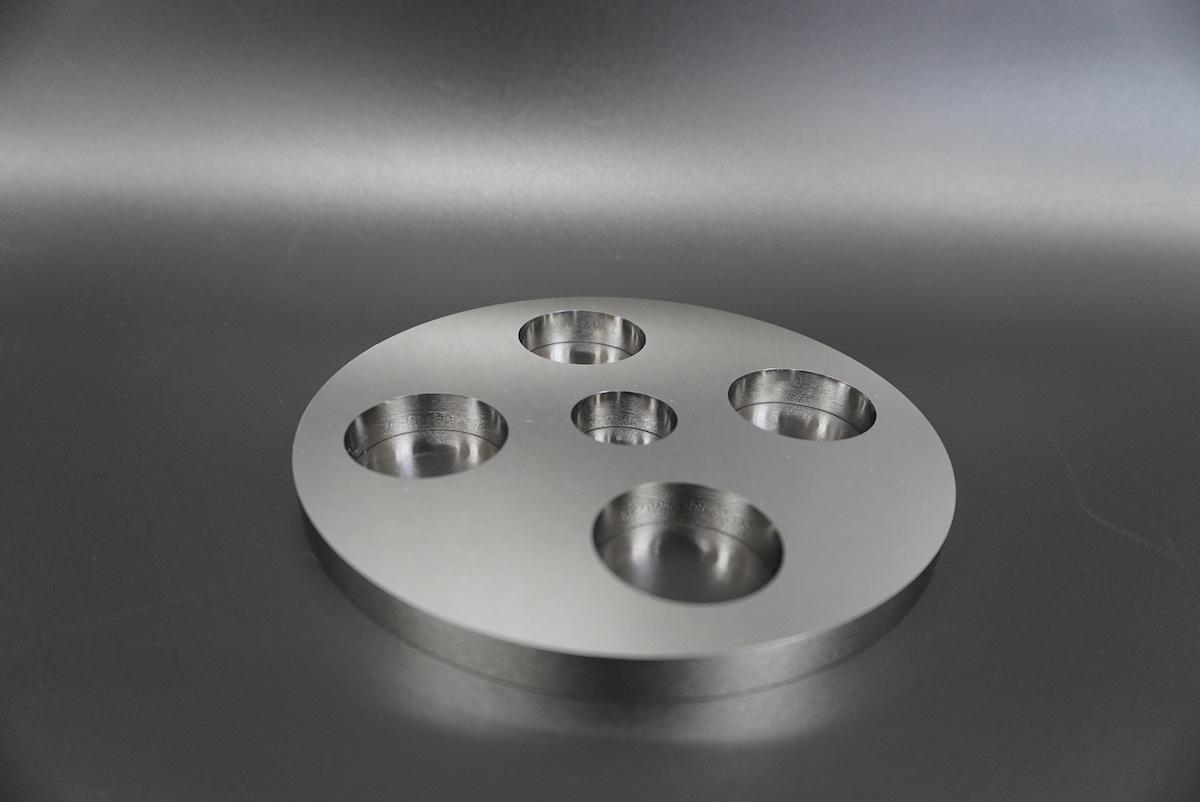

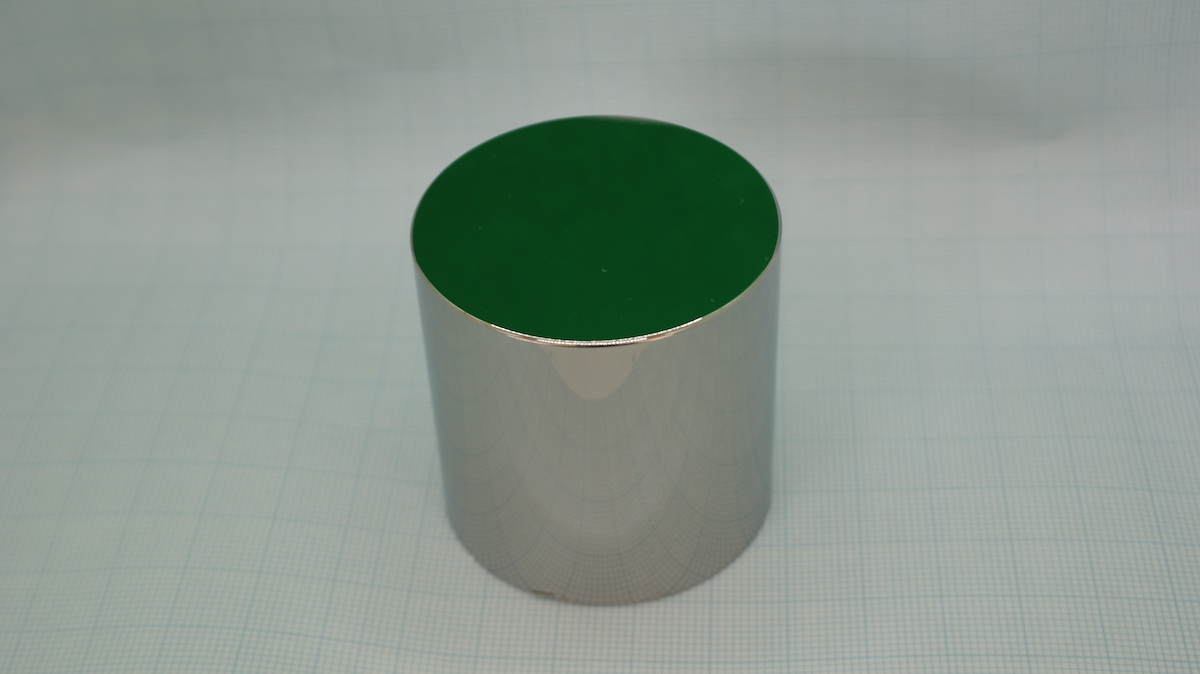

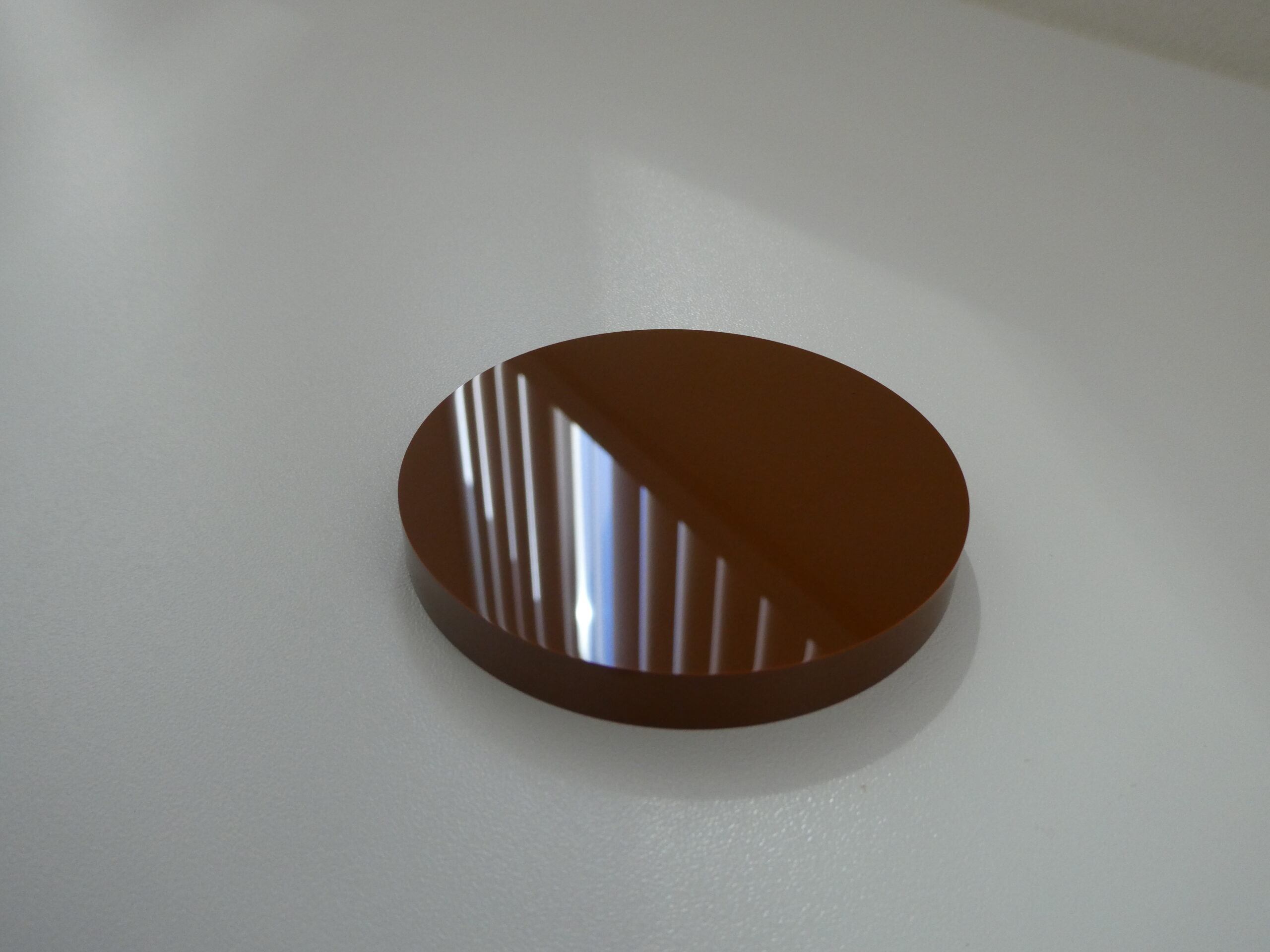

Vespel polishing example ①: “Mirror surface test piece”

- Size: according to your request

- Specifications/Accuracy: Ra2nm or less

- Processing details: We will produce mirror-finished pieces using Vespel according to your desired size.

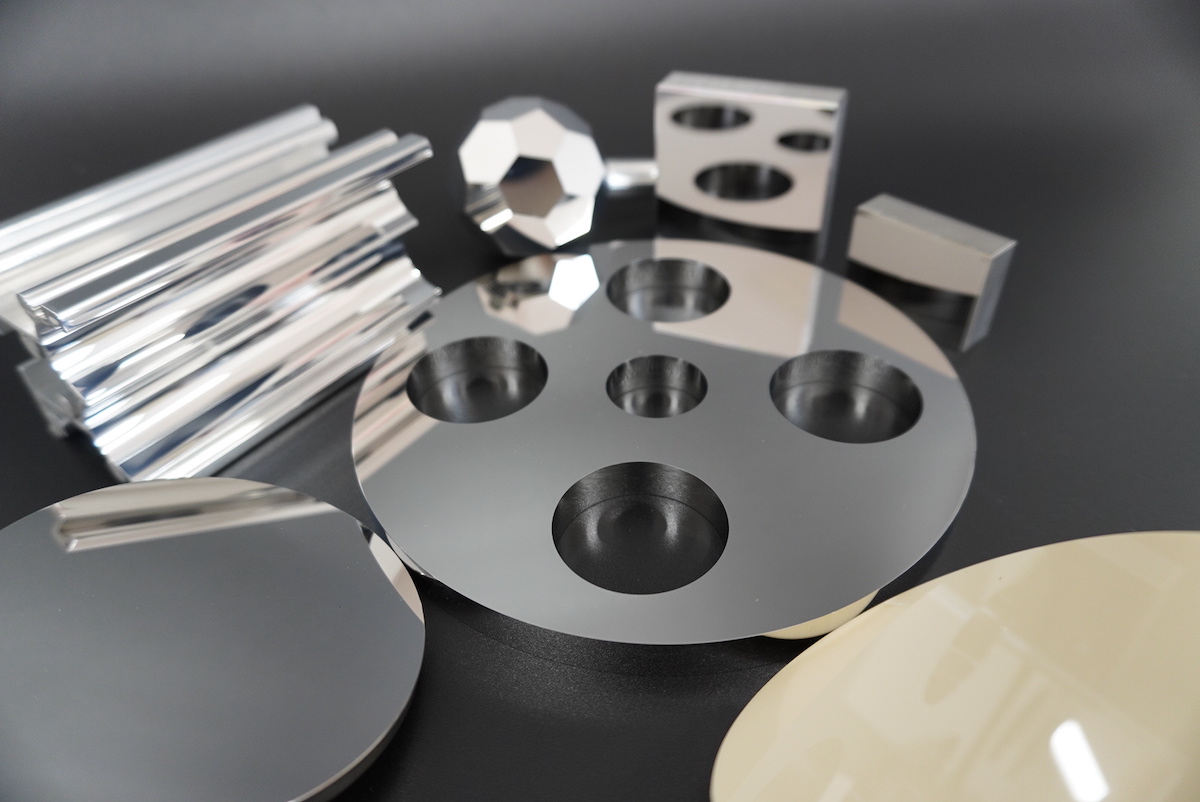

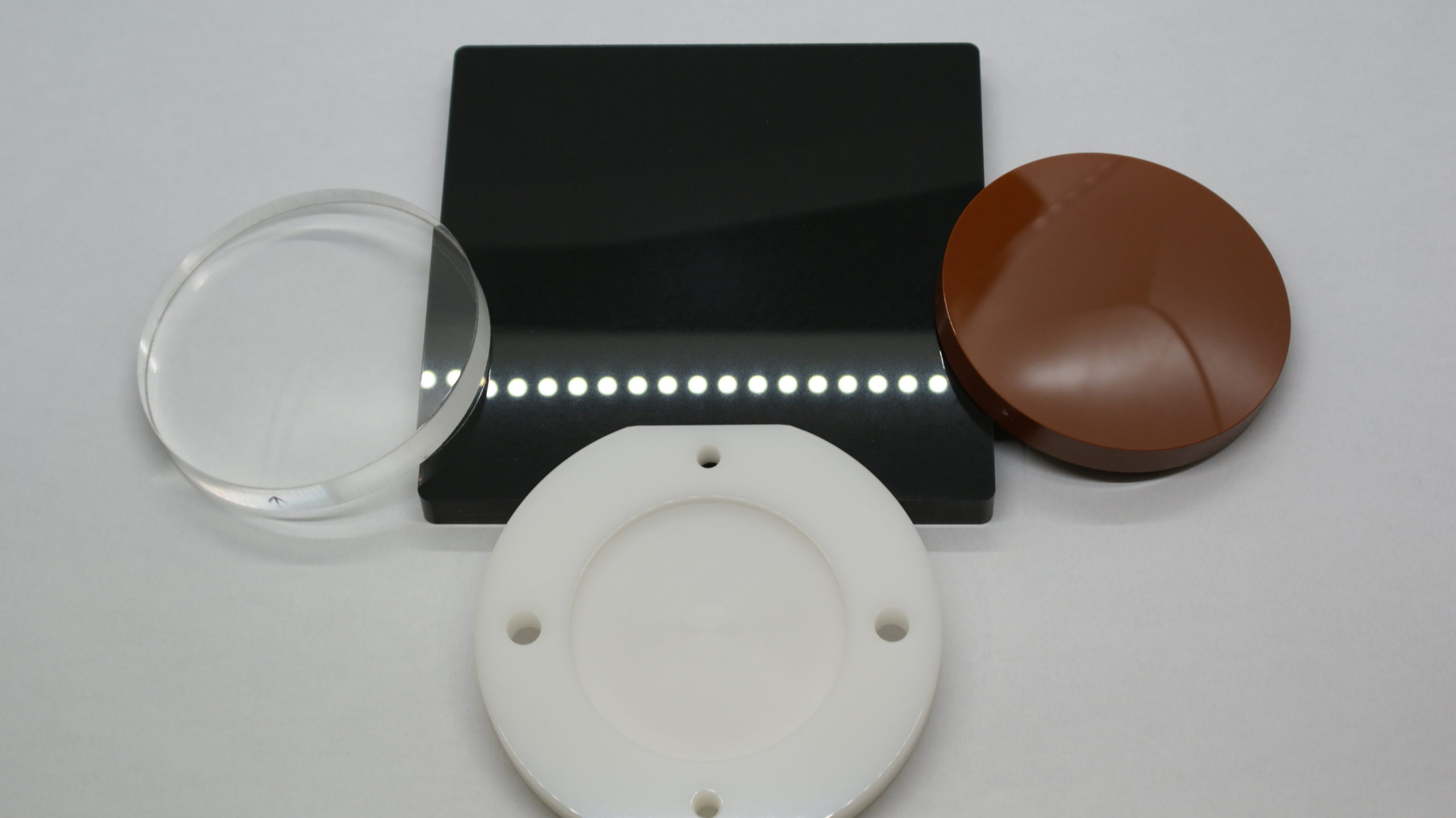

Vespel polishing example ②: “Mirror finishing of various jigs and tools”

- Size: according to your request

- Specifications/Accuracy: Surface roughness Ra nano level, flatness/parallelism, etc. can be accommodated according to specifications.

- Processing details: We manufacture various jigs and tools such as retainer rings used in semiconductor devices. If you provide us with a drawing, we will manufacture it to your desired specifications.

Please contact TDC for processing of Vespel

Vespel is a super engineering plastic developed by DuPont, and is characterized by its ability to withstand environments from extremely low to high temperatures, and has excellent wear resistance and sliding properties.

At TDC, we process Vespel with high precision using processing know-how depending on the material and processing technology accumulated over many years.

If you have a Vespel processing project that has been rejected by another company, please feel free to contact TDC.

Related page

- インコネルとは?| 基礎情報・特徴の解説と加工事例

- 難削材とは? | 基礎知識と種類についての解説

- What is gallium nitride (GaN)? | Basic information/explanation of features and processing examples

- What is Vespel? | Vespel features and processing examples

- What is Tungsten? | Tungsten characteristics and processing examples

- Nickel

- Tantalum

- Glassy carbon (glassy carbon)

- Plate thickness and material of stainless steel plate (SUS)

- Coefficient of linear expansion

- Invar/Super Invar

- Niobium

- Hastelloy

- Engineering Plastic