Tantalum

On this page, we will explain the characteristics and properties of Tantalum, which is one of the processing materials, its applications, and the processing of Tantulm in TDC.

Contents

What is Tantalum?

Tantalum is a group 5 element in the 6th period of atomic number 73, and is a regular metal that represents the element symbol.

Discovered by Andesh Gustav Ekeberg in 1802. The name Tantalum comes from the Greek mythology Tantalus.

In addition to being used as a trace component of alloys as one of the rare metals, it is also known to be a refractory metal due to its high melting point.

Tantalums Features, Characteristics, and Properties

Tantalum has high density and ductility, and although it is a very hard substance, it is easy to process and has high heat and electrical conductivity.

It is silvery white and glossy, and has high corrosion resistance to acid corrosion.

Tantalum has a high melting point of 3,017 degrees Celsius (boiling point is 5,458 degrees Celsius), and the only elements above this are tungsten, rhenium, osmium, and carbon.

| General characteristics | |

| Chemical formula | Ta |

| Classification | Transition Metals |

| Atomic weight | 180.94788 |

| Physical characteristics | |

| density | 16.654(293 K、solid)g/cm3 |

| Liquid density at melting point | 15.000(melting point、liquid)g/cm3 |

| Melting point | 3258K, 2985°C |

| Melting point | 5783K, 5510°C |

Tantalum applications

Tantalum is widely used in the fields of aerospace equipment, medical equipment, military, and energy because of its corrosion resistance, as well as electrical and electronic equipment.

The following are just a few examples of how tantalum can be used.

- Capacitor

About half of the annual consumption of tantalum is mainly used as powder for capacitors and wires. - Semiconductor

By using tantalum for the semiconductor circuit board, a thin film diffusion barrier layer can be formed to protect the copper interconnection. - Engine turbine blade

Due to the characteristics of tantalum, which has high melting point and corrosion resistance, it is used as a nickel-based superalloy for turbine blades of aircraft engines and gas turbines. - Laminated modeling (3D printer)

Tantalum’s high corrosion resistance, high strength and high purity enable 3D printers for parts for the aerospace, automotive, medical, defense, energy and chemical industries. - Chemical processing equipment

Due to the corrosion resistance and heat resistance of tantalum, it is used as a liner for containers, pipes, valves, and heat exchangers used in the chemical and pharmaceutical industries.

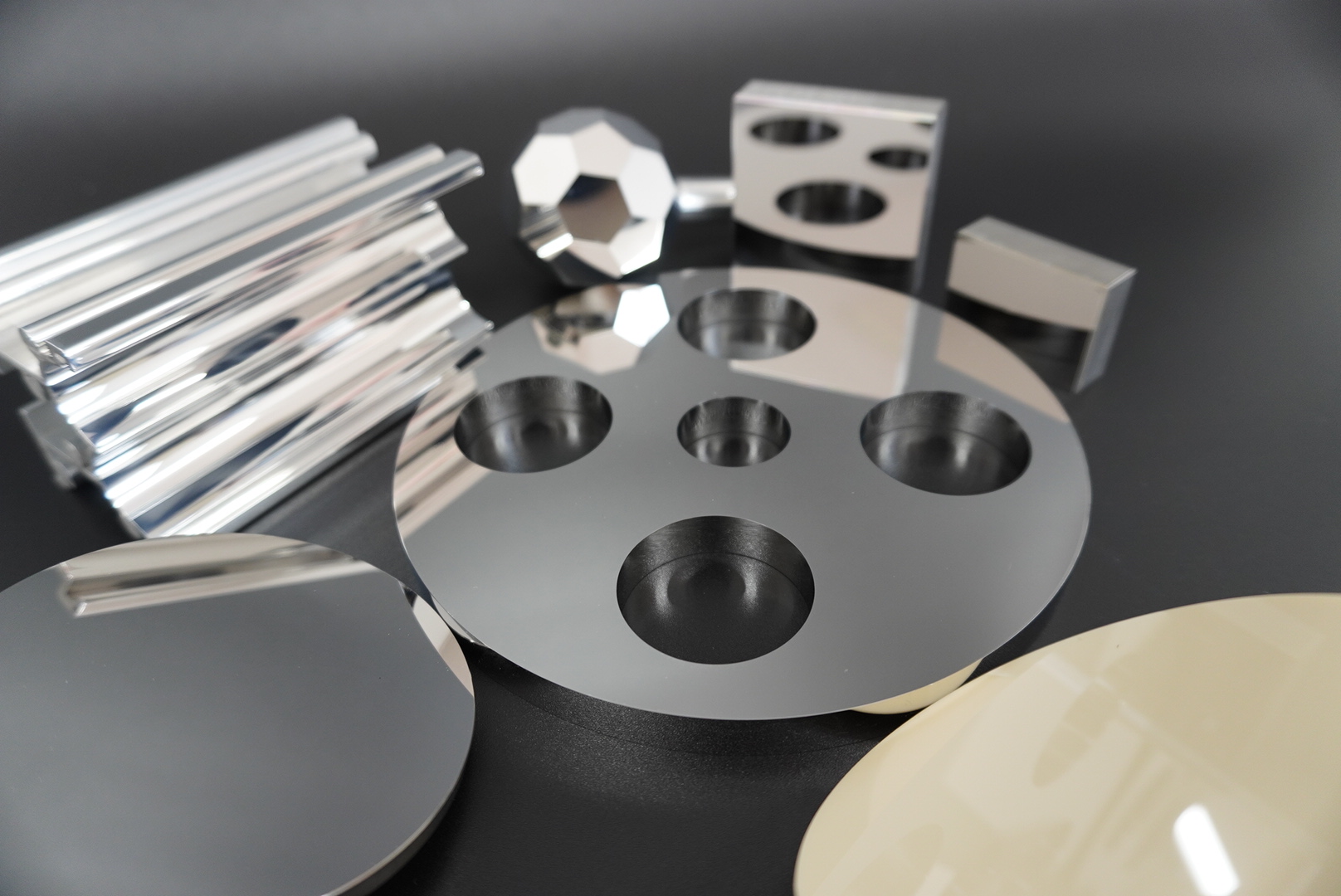

Tantalum processing in TDC

| Roughness | <Ra1nm |

| Flatness | <0.001mm |

| Parallelism | <0.001mm |

Tantalum processing examples

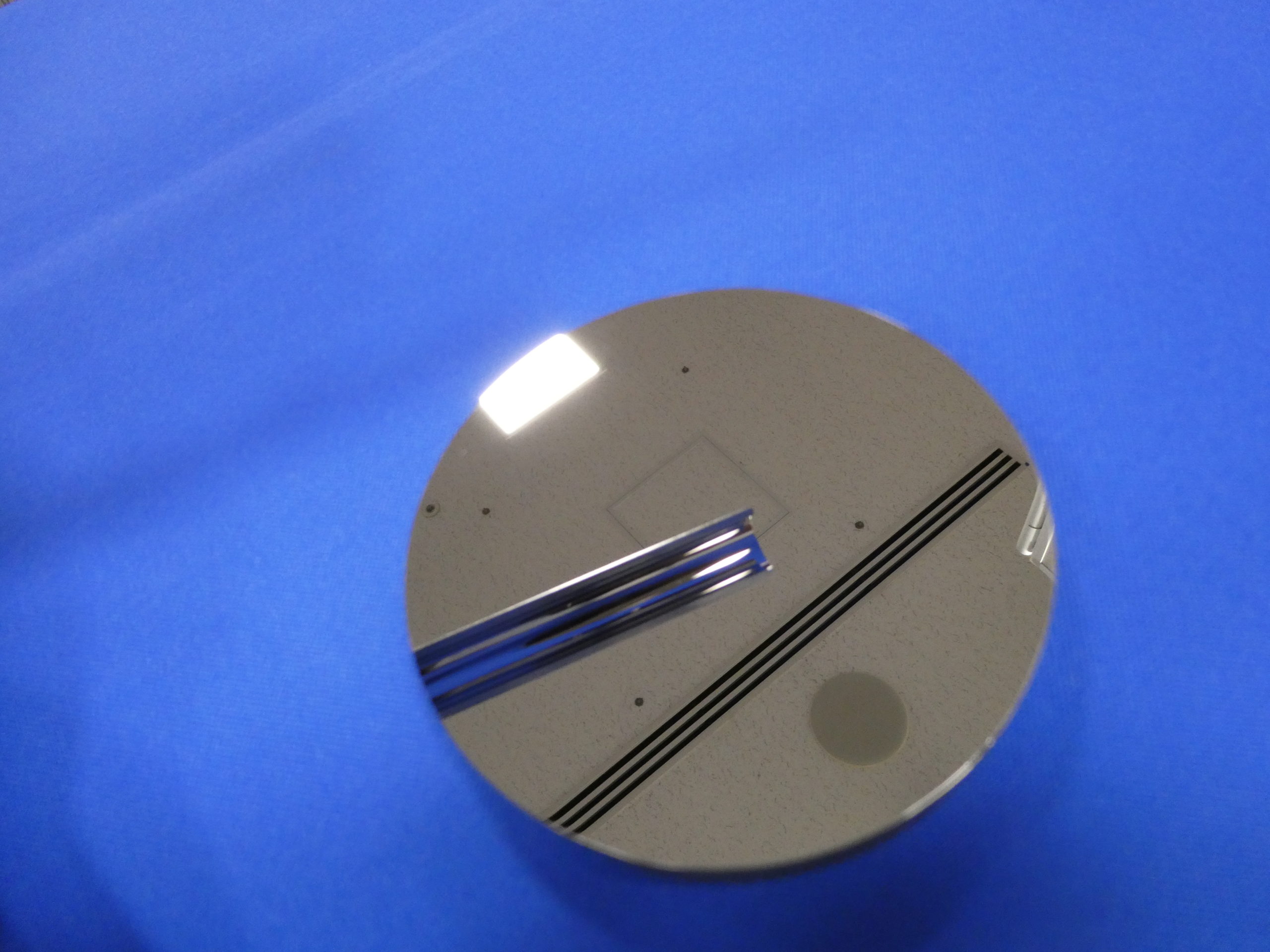

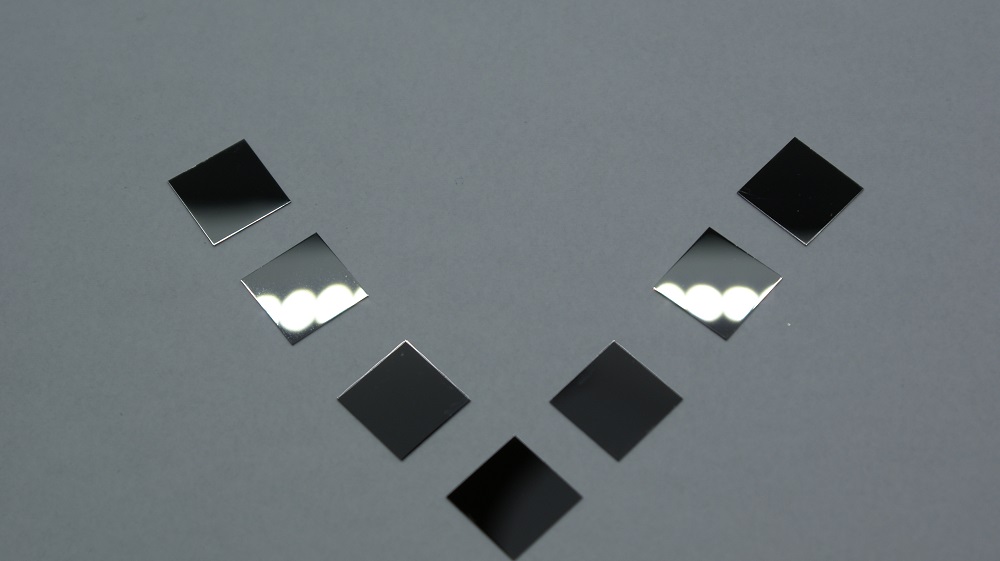

Tantalum is a material that has high thermal and electrical conductivity and is resistant to corrosion, so it is sometimes used as a slit knife to block synchrotron radiation.

We manufacture this slit knife, and we have received many requests from each research institute.

そのIn addition, we have you use our polishing technology for various purposes.

Please contact TDC for Tantalum processing

At TDC, we are able to handle mirror polishing of all materials and accuracy by using the processing know-how according to the material and the polishing processing technology accumulated so far.

If you have a Tantalum processing project that was rejected by another company, please feel free to contact TDC.

with nano-level precision polishing.

and production from single units to mass production.

Related page

- What is gallium nitride (GaN)? | Basic information/explanation of features and processing examples

- What is Vespel? | Vespel features and processing examples

- What is Tungsten? | Tungsten characteristics and processing examples

- Nickel

- Tantalum

- Glassy carbon (glassy carbon)

- Plate thickness and material of stainless steel plate (SUS)

- Coefficient of linear expansion

- Invar/Super Invar

- Niobium

- Hastelloy

- Engineering Plastic