Nickel

On this page, we will explain the characteristics and uses of nickel, the difference between pure nickel and nickel alloys, and examples of TDC processing.

Contents

What is Nickel

Nickel (element symbol: Ni) is a kind of rare metal and is a shiny silvery-white metal. It has stable corrosion resistance in a wide range of environments, from air to seawater, and is used for items and places where corrosion should be avoided, such as cooking utensils and chemical factories.

Nickel gets its name from the German word “Kupfernickel” which means “devil’s copper”.

It is said that around the 15th century, nickel ore was called by miners working in mines because, despite its similarity to copper ore, it was thought that copper could not be liberated and that it caused poisoning symptoms.

Nickel is often used as an alloy in combination with metals such as chromium rather than used alone, and is also used in the production of stainless steel and heat-resistant steel. In familiar places, it is also included in cooking utensils such as frying pans.

In addition to being used as an alloy, it is also used as a material for plating to protect metal surfaces and prevent rust.

Characteristics and properties of nickel

The advantages of nickel over other metals include corrosion resistance, strength, and ductility. In terms of corrosion resistance in particular, it exhibits stable characteristics even in neutral or seawater environments.

It also has a high melting point of 1455°C and is a ferromagnetic material.

Physical properties of nickel (element symbol Ni)

| Melting point(℃) | 1455 |

| Boiling point(℃) | 2913 |

| Density(g/cm3) | 8.91 |

| Specific gravity(g/cm3) | 20℃:8.90 |

Use of Nickel

Nickel-containing metals have excellent corrosion resistance and durability, as well as high strength at high or low temperatures, so they are mainly used for the following applications.

- kitchenware

- Building

- Medical equipment

- chemical factory

- automobile, aircraft parts

- coin

- batteries, etc.

Difference between Pure Nickel and Nickel Alloy

In addition to pure nickel, nickel is often used as an alloy with iron or copper.

Here, we introduce pure nickel and typical nickel alloys.

Pure Nickel

Pure nickel is a metal containing more than 99% nickel. Due to its strong corrosion resistance against caustic soda and chlorine gas, it is used as a material for equipment that handles caustic soda and chemicals.

In addition to being magnetic, it also has low thermal conductivity and excellent workability.

Nickel Iron Alloy

Nickel-iron alloys are alloys composed of nickel and iron. A typical example is “Invar/Super Invar” which contains 36% nickel in iron.

Invar has a low coefficient of thermal expansion, less than one-tenth that of iron and nickel, and has high toughness in low-temperature environments as low as -200°C, and has excellent workability in normal-temperature environments.

Nickel Copper Alloy

A nickel-copper alloy is an alloy containing copper in nickel. By combining nickel and copper, it exhibits excellent strength and hardness in addition to nickel’s unique corrosion resistance and heat resistance.

Due to these characteristics, it is used for applications such as seawater immersion parts and oil refining equipment.

Typical examples include Monel 400, which has excellent workability, and 7:3 Cupro, which is resistant to rust in seawater.

Nickel Chromium Alloy

Nickel-chromium alloy is an alloy in which chromium is added to nickel. It has good strength and corrosion resistance even in high-temperature environments, and is used in applications such as industrial furnace components and aircraft jet engines.

A representative example is “Hastelloy” which is made by adding a large amount of molybdenum and chromium to nickel.

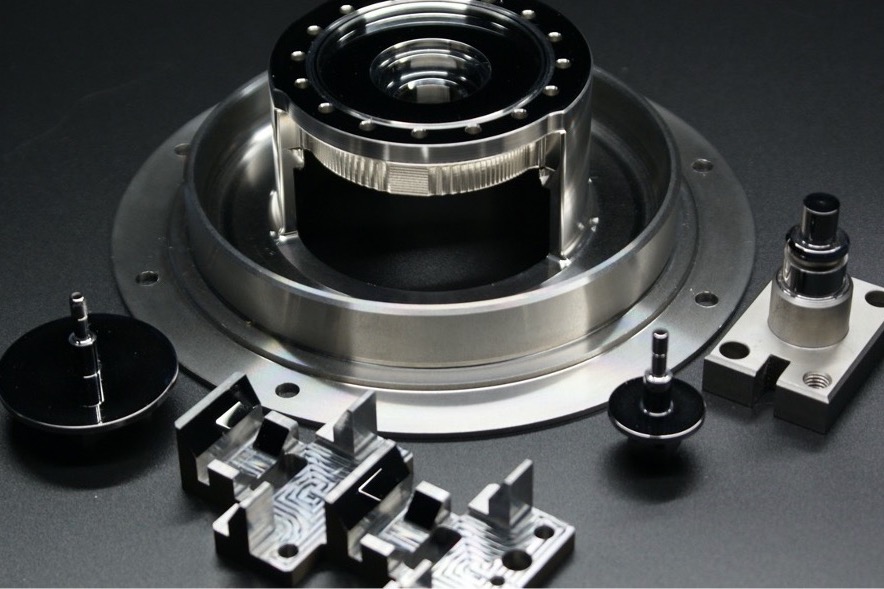

Example of nickel processing at TDC

Introduces typical examples of nickel polishing at TDC.

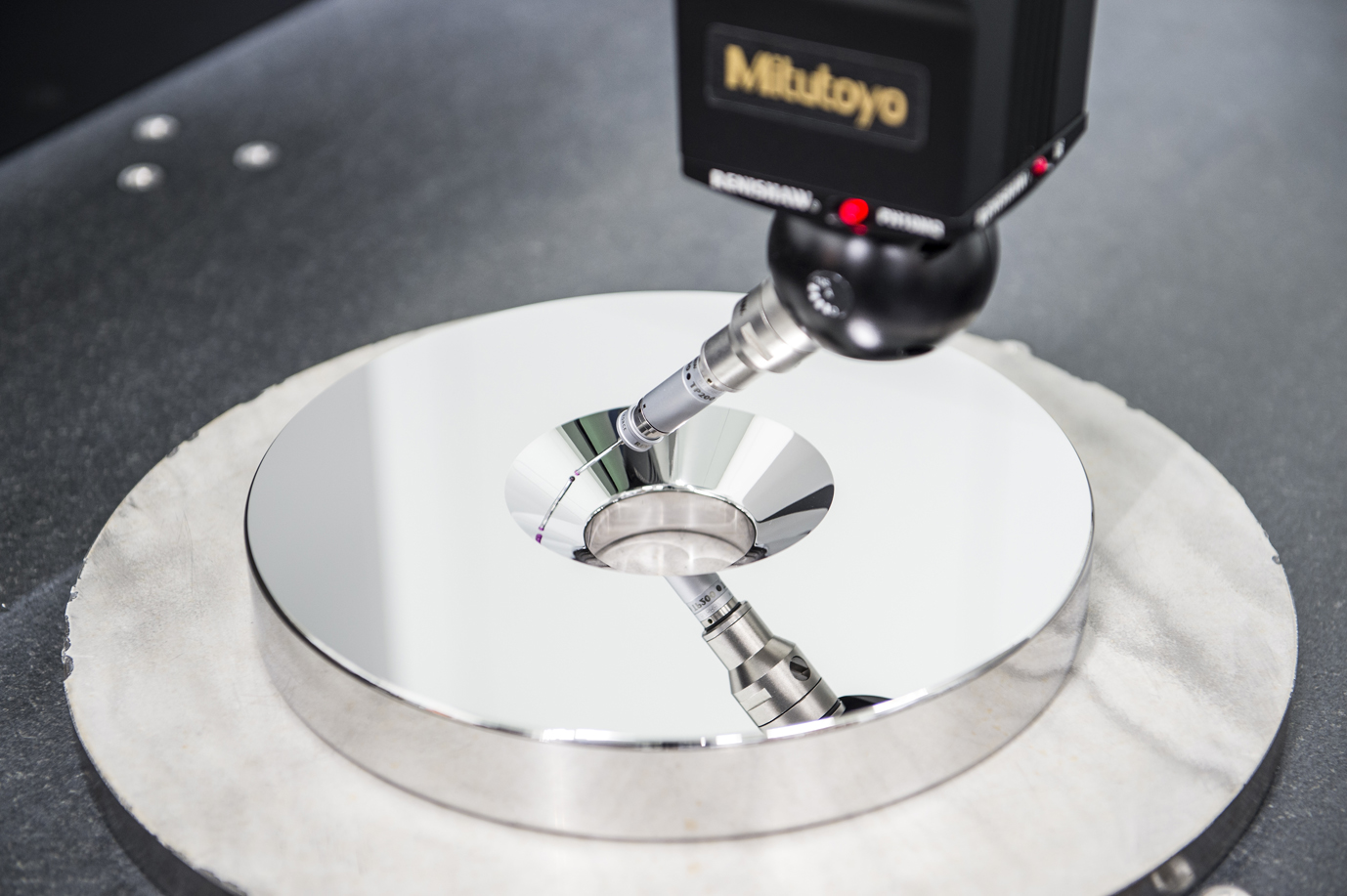

Nickel polishing example (1)

- Size: 150 x 200 aspheric lens

- Specifications/accuracy: surface roughness Ra ≤ 1 nm

- Material: Nickel plating and film formation on aluminum base material

- Processing details: After diamond turning, the nickel plated surface is further polished at our company to finish it to Ra ≤ 1 nm. It is possible to mirror-finish even the surface after normal cutting.

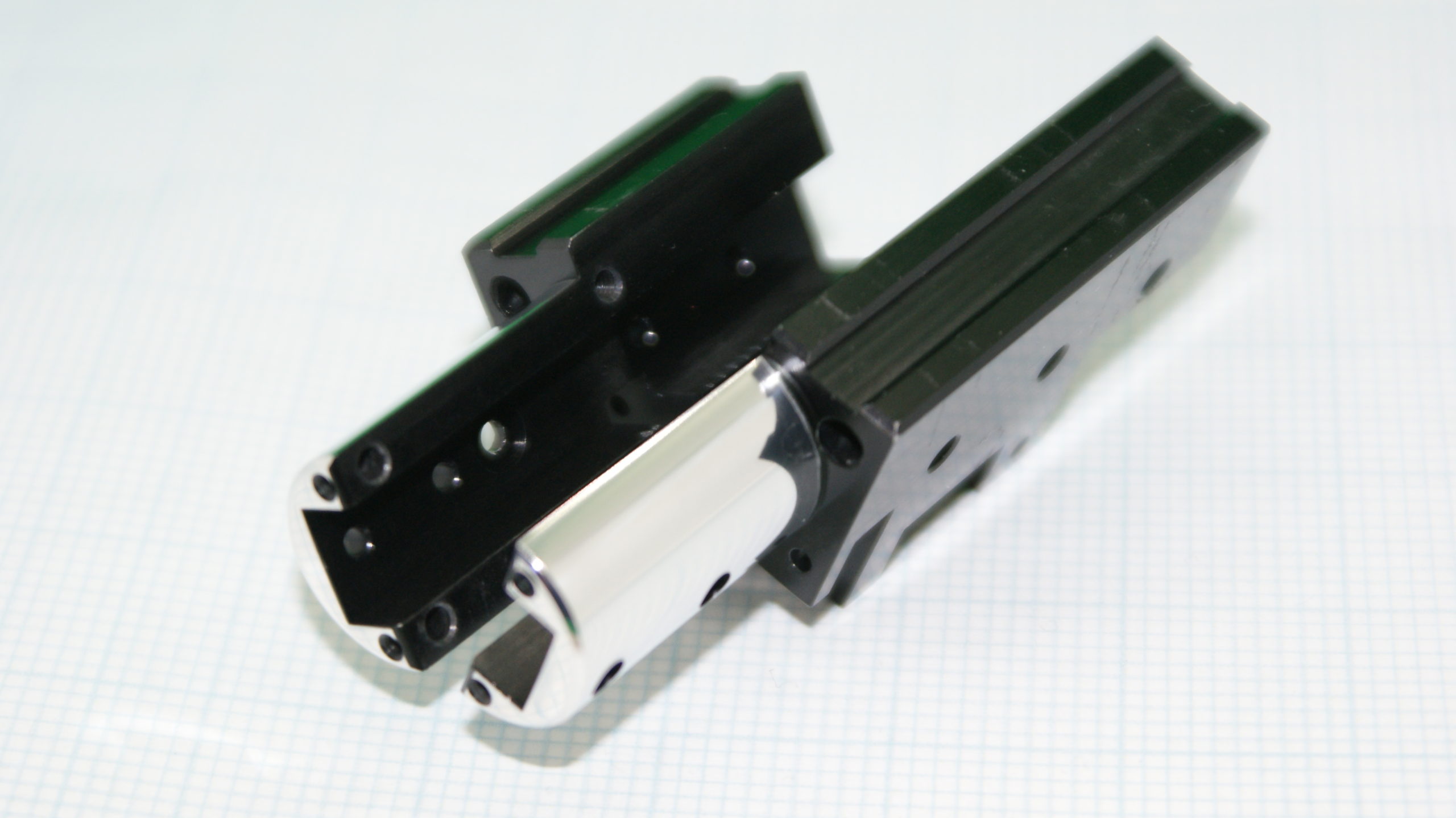

Nickel polishing example (2)

- Size: W210 x L1500 x T0.02 (long foil)

- Specifications: Mirror finish on both sides Ra ≤ 2nm

- Processing details: Both sides of a long nickel foil are polished. The thickness is from about 0.02, and the length can be mirror-finished. In addition, it is possible to polish not only long pieces but also small pieces.

Nickel polishing example (3)

- Size: Small pieces up to 500mm square

- Specifications/accuracy: surface roughness Ra ≤ 1 nm, flatness ≤ 0.001, parallelism ≤ 0.001, etc.

- Processing details: We can manufacture various test pieces and parts with the desired accuracy. It is possible to manufacture high-precision parts by combining multiple factors such as flatness, parallelism, and angular tolerance, as well as surface roughness.

contact TDC for nickel processing

At TDC, we are able to handle mirror polishing of any material and precision with our know-how for processing materials and our accumulated polishing technology.

Please feel free to contact TDC for nickel processing projects that have been rejected by other companies.

with nano-level precision polishing.

and production from single units to mass production.

Related page

- What is gallium nitride (GaN)? | Basic information/explanation of features and processing examples

- What is Vespel? | Vespel features and processing examples

- What is Tungsten? | Tungsten characteristics and processing examples

- Nickel

- Tantalum

- Glassy carbon (glassy carbon)

- Plate thickness and material of stainless steel plate (SUS)

- Coefficient of linear expansion

- Invar/Super Invar

- Niobium

- Hastelloy

- Engineering Plastic