Glassy carbon (glassy carbon)

This page introduces precision processing of glassy carbon (glass-like carbon) performed at TDC.

Contents

- What is glassy carbon?

- Features of glassy carbon

- Advantages and disadvantages of glassy carbon

- Difference from quartz glass

- Applications and industries of glassy carbon

- For precision processing of glassy carbon (glass-like carbon), please contact TDC

- Example of precision processing of TDC’s glassy carbon (glass-like carbon)

What is glassy carbon?

Glassy carbon (glass-like carbon) is a black glass-like carbon material, and refers to a material that is carbonized by applying heat to resin.

It is widely used mainly in the semiconductor field due to its excellent stability even in vacuum at 3000°C and in air at 500°C, as well as excellent electrical conductivity.

Features of glassy carbon

Glassy carbon has the following characteristics.

- lightweight

- Has electrical and thermal conductivity

- Low coefficient of thermal expansion, excellent heat resistance, and high strength

- Excellent chemical resistance and corrosion resistance

- Highly airtight and impermeable to gases and liquids. gas impermeable

- high purity

- Does not generate dust such as carbon powder

- Degassing free

- Molten glass and molten metal do not adhere easily

- Dense isotropic structure without pores

- Smooth surface like glass

Advantages and disadvantages of glassy carbon

Glassy carbon has the following advantages and disadvantages.

| Characteristics | Advantages | Diasdvantages(notes) |

| Corrosion resistance | It has high corrosion resistance against many chemicals. | In the atmosphere above 500°C, oxidation may occur. |

| Heat-resistant | It can withstand temperatures up to about 3,000°C in a vacuum. | If the material is stressed, plastic deformation begins in the region above 2,500°C. If heat is applied locally, it may lead to material damage. |

| Contamination prevention | Contamination by metal elements is almost non-existent. |

Precision cleaning is essential as the material surface may become contaminated during processing and handling. |

| Prevention of dust generation | Because it is highly airtight and hard, it is possible to suppress dust generation compared to general carbon materials. | Not suitable for mechanical sliding parts as it is not self-lubricating. |

Difference from quartz glass

Glassy carbon is often compared to silica glass because of its use in the semiconductor field and its properties.

When comparing quartz glass and glassy carbon in terms of physical properties, the following differences can be seen.

| Characteristics | Glassy Carbon (glass-like carbon) | Quartz glass |

| Bulk density(kg/m3) | 1,530 | 2,200 |

| Flexural strength(MPa) | 150 | 50 |

| Young’s modulus(GPa) | 23 | 73 |

| Coefficient of thermal expansion(×10-6/℃) | 3.7 | 0.5 |

| Specific heat(J/gK) | 0.75 | 0.8 |

| Thermal conductivity(W/mK) | 7 | 1.3 |

| Heat resistance | great | ok |

| Electrical conductivity | high | none |

| Dust generation | none | none |

| gas permeability | none | none |

Applications and industries of glassy carbon

Glassy carbon has excellent chemical resistance, electrical conductivity, and low gas permeability, so it is commonly used in the semiconductor field.

In addition, it is mainly used in the following industries and fields.

- Materials for semiconductor devices

- Liquid crystal parts

- Heat treatment jig

- Glass molding parts/parts

- substrate holder

- Heat shield plate

- Susceptor

- guide ring

- Etcher electrode

- cleaning material

- Dummy wafer (~400mm)

- glass molding member

- Crucible

- fuel cell electrode

- protective tube

For precision processing of glassy carbon (glass-like carbon), please contact TDC

TDC can handle precision processing of all types of glassy carbon using the polishing technology we have cultivated so far.

We also accept processing with precision that other companies refused. If you have any questions about glassy carbon processing, please feel free to contact TDC.

with nano-level precision polishing.

and production from single units to mass production.

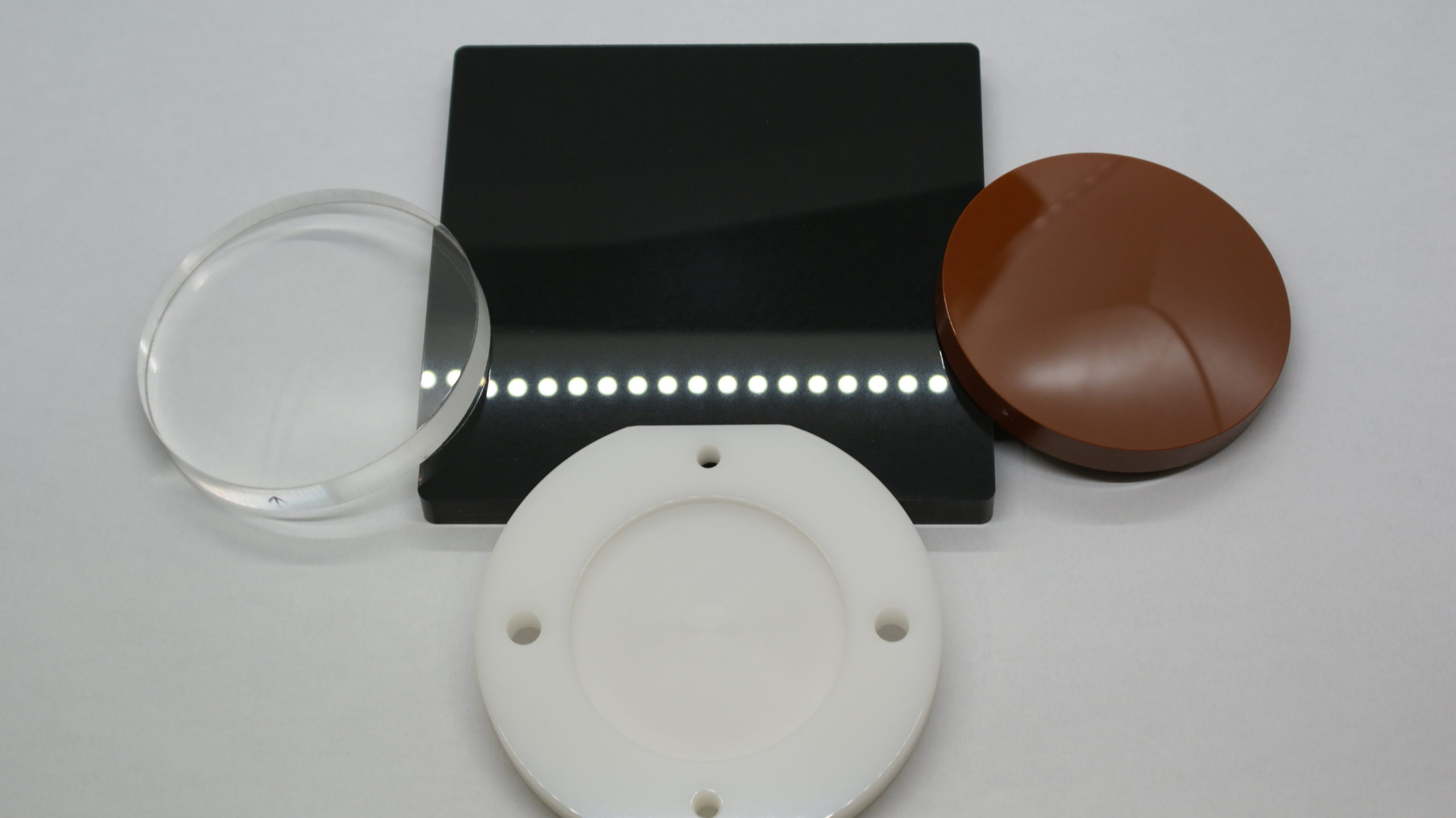

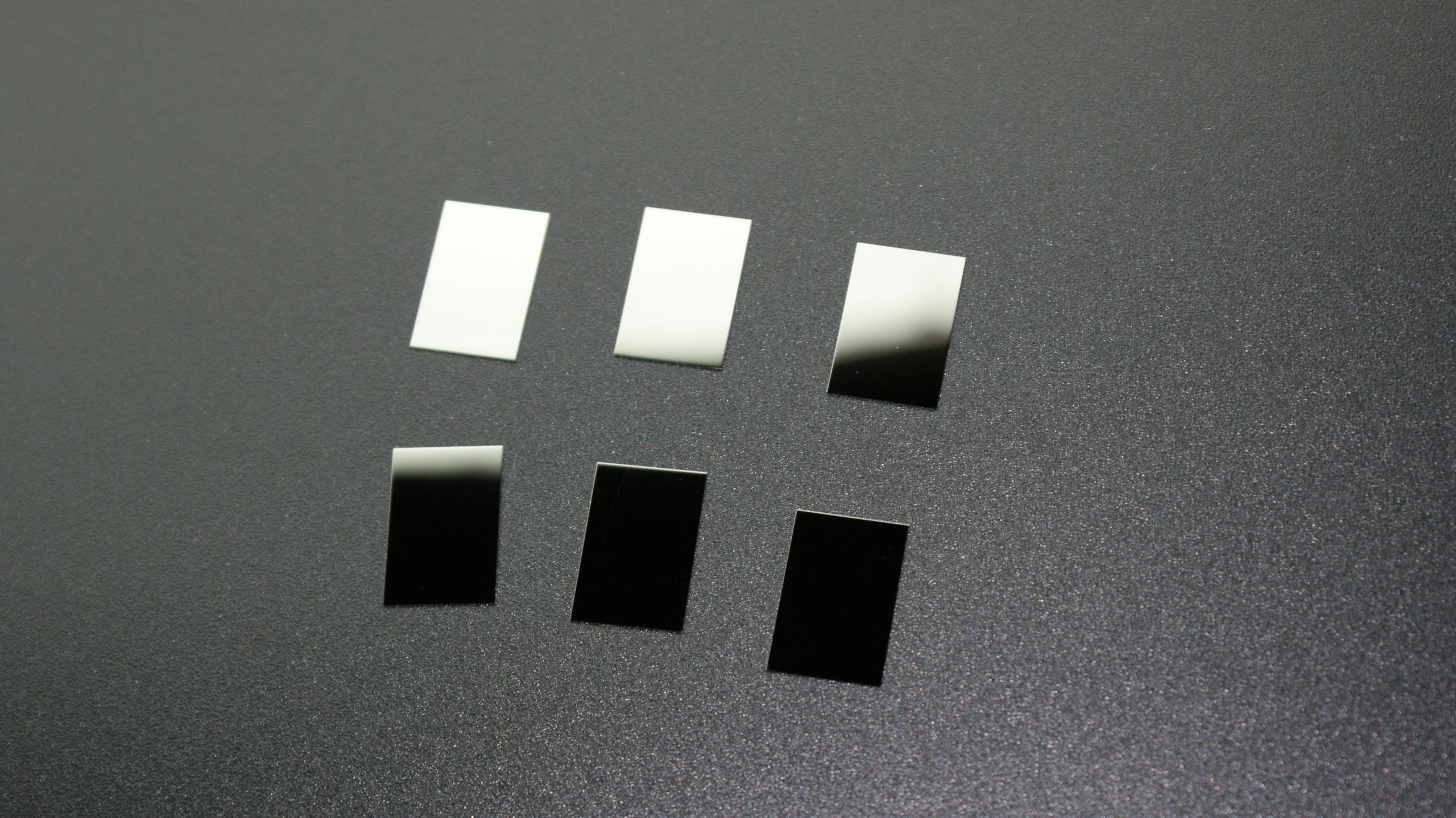

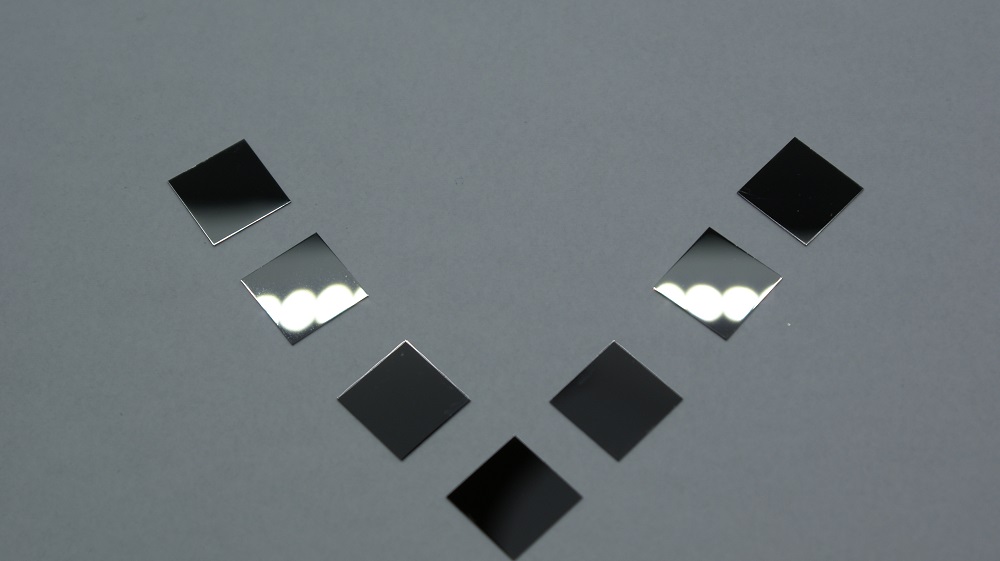

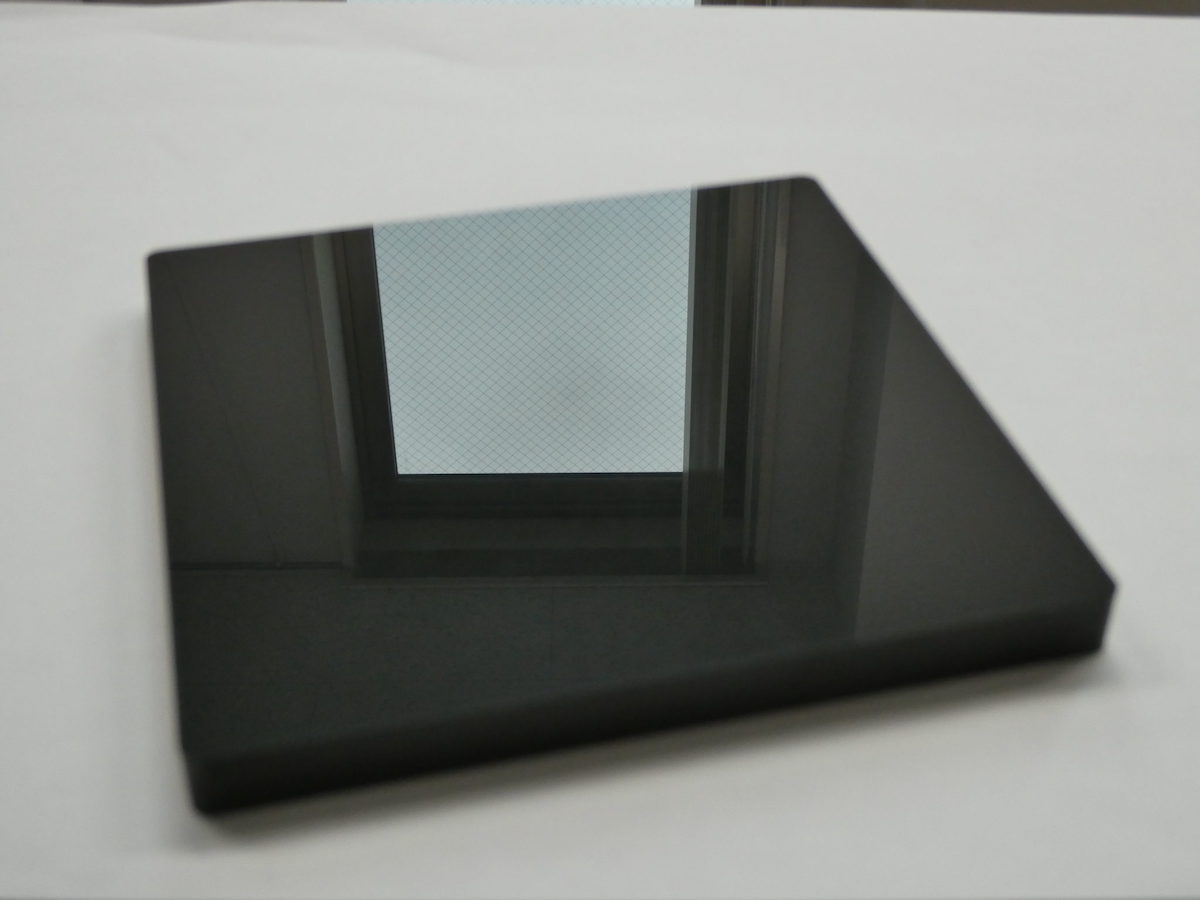

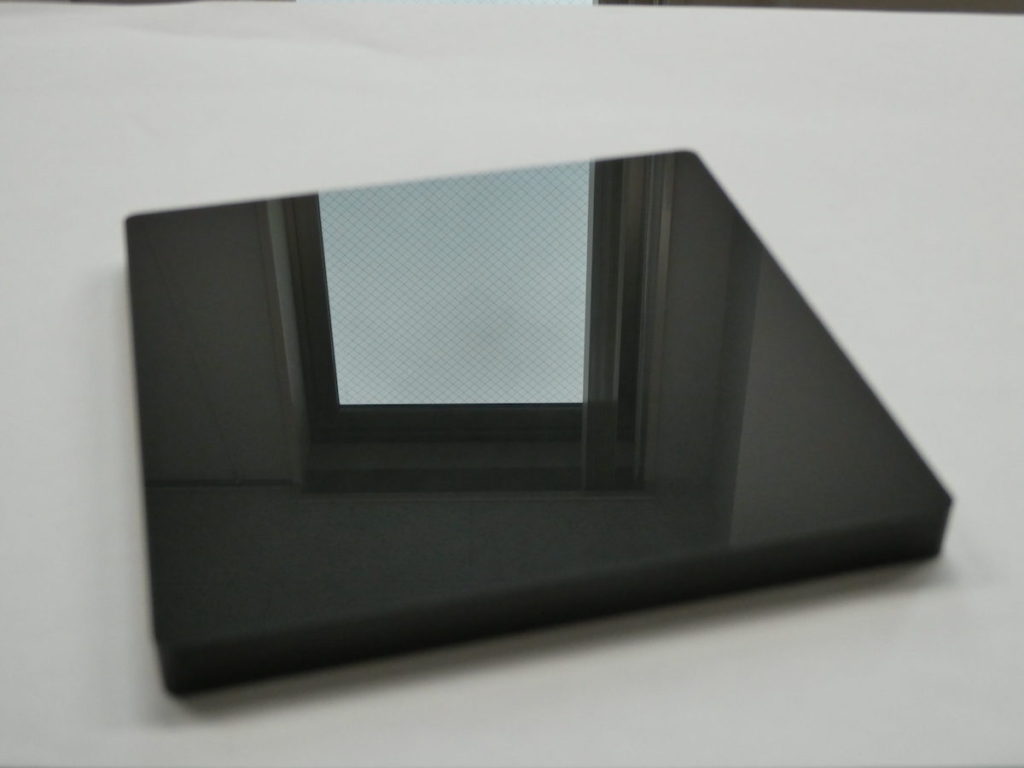

Example of precision processing of TDC’s glassy carbon (glass-like carbon)

Examples of precision processing of glassy carbon (glass-like carbon) at TDC are as follows. With our processing know-how according to the material and our accumulated polishing processing technology, we can handle any precision. Please feel free to consult with TDC for glassy carbon processing projects that have been rejected by other companies.

Precision machining example

- Size: Any size you want

- Specifications: Ra1nm or less

- Material: Glassy Carbon

- Processing details: We will manufacture glassy carbon mirror surface substrates in your desired size. In addition, we can also manufacture high-precision substrates with added geometric tolerances such as flatness and parallelism according to specifications.

Related page

- What is gallium nitride (GaN)? | Basic information/explanation of features and processing examples

- What is Vespel? | Vespel features and processing examples

- What is Tungsten? | Tungsten characteristics and processing examples

- Nickel

- Tantalum

- Glassy carbon (glassy carbon)

- Plate thickness and material of stainless steel plate (SUS)

- Coefficient of linear expansion

- Invar/Super Invar

- Niobium

- Hastelloy

- Engineering Plastic